Recyclable environment-friendly mulberry fiber board

A mulberry fiber and environmental protection technology, applied in the field of mulberry fiber recyclable environmental protection board, can solve the problems of poor nail holding power of density board, high cost of solid wood board, large deformation of density board, etc., to achieve improved nail holding power, moisture resistance and moisture resistance The effect of improvement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

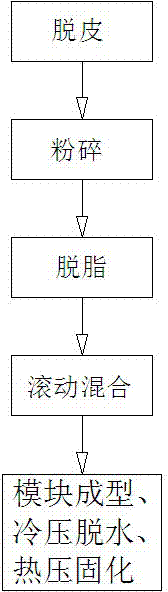

[0021] Embodiment 1: by figure 1 As shown, a mulberry fiber recyclable environmental protection board is formed by hot pressing of mulberry fiber and sheet-shaped mulberry trunk through adhesive. Its production method comprises the following steps:

[0022] (1) Peeling. It is difficult to peel off the mulberry bark from the fresh mulberry branches and dry preserved mulberry branches. After soaking it in water for a week, the mulberry bark can easily separate the two due to the swelling of the mulberry bark.

[0023] (2) Grinding, dehydrating the separated mulberry bark to a moisture content of 6-8% and then pulverizing to obtain mulberry fibers with a length of 15-25 mm and a fineness of 2.57 dtex; dehydrating the dry mulberry bark to a moisture content of 6-8% After crushing, the sheet-shaped mulberry trunks are obtained. The length of a single piece is 15-25 mm, the width is 5-10 mm, and the thickness is 100-300 microns. The mulberry fibers of the above specification...

Embodiment 2

[0038] Example 2: A recyclable and environmentally friendly mulberry fiber board, formed by hot pressing of mulberry fibers and sheet-shaped mulberry trunks through an adhesive, the adhesive is grassland environmental protection glue, and the amount of glue is 12%. Its production method comprises the following steps:

[0039] (1) Peeling. It is difficult to peel off the mulberry bark from the fresh mulberry branches and dry preserved mulberry branches. After soaking it in water for a week, the mulberry bark can easily separate the two due to the swelling of the mulberry bark.

[0040] (2) Grinding, dehydrating the separated mulberry bark to a moisture content of 6-8% and then pulverizing to obtain mulberry fibers with a length of 15-25 mm and a fineness of 2.57 dtex; dehydrating the dry mulberry bark to a moisture content of 6-8% After crushing, the sheet-shaped mulberry trunks are obtained. The length of a single piece is 15-25 mm, the width is 5-10 mm, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com