High-strength non-combustible decoration plate and preparation method thereof

A high-strength, decorative board technology, applied in chemical instruments and methods, paper/cardboard layered products, synthetic resin layered products, etc., can solve problems such as low strength of decorative boards and failure to meet special process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

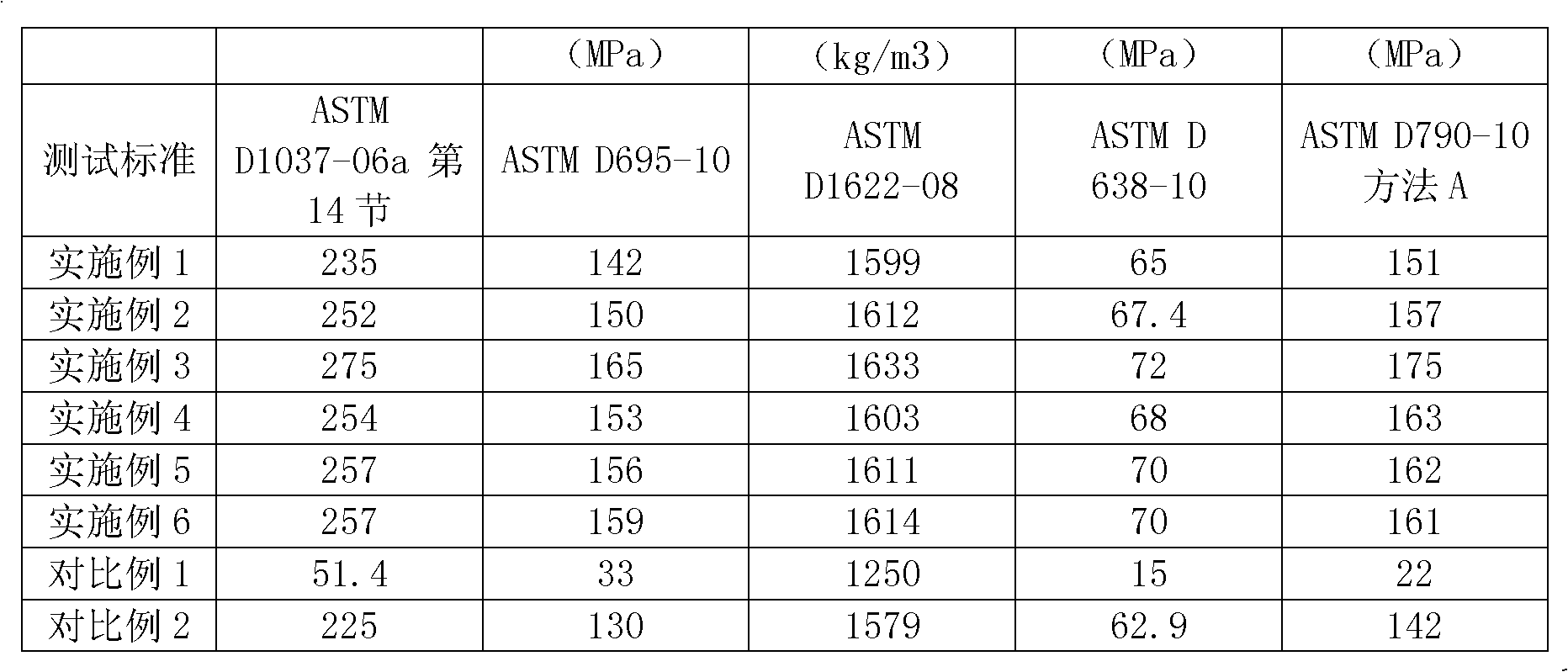

Examples

Embodiment 1

[0047] A. Under normal temperature and pressure, 10kg of magnesium oxide powder and 11.25kg of 80 mesh cotton stalk powder and 3.75kg of expanded perlite powder are mixed evenly and poured into a sealed kettle, and the pressure in the kettle is evacuated until the pressure is 0.5atm. Add 17.5 L of magnesium chloride solution with a concentration of 6 mol / L and a pH value of 7.0, and stir for 15 minutes to prepare a slurry. A layer of non-woven fabric is laid on the bottom layer of the plate making machine (Shandong Innovation Building Materials Complete Equipment Co., Ltd.), and 5 layers of glass fiber cloth are laid on the top of the non-woven fabric, and the resulting slurry is transported to the bottom of the plate making machine through a sealed delivery pipe. The feed port is coated on the surface of 5 layers of glass fiber cloth, and the inside of the sealed conveying pipe is also vacuumed at a pressure of 0.5 atm. After the slurry is coated on the surface of 5 layers of...

Embodiment 2

[0053] A. Under normal temperature and pressure, 4 kg of magnesium oxide powder and 20 kg of 80 mesh cotton straw powder and 1 kg of expanded perlite powder are mixed evenly and then poured into a sealed kettle, and the pressure in the kettle is evacuated until the pressure is 0.1 atm. Add 52.6 L of magnesium chloride solution with a concentration of 2 mol / L and a pH value of 6.5, and stir for 10 minutes to prepare a slurry. Lay a layer of non-woven fabric on the bottom layer of the plate making machine (Shandong Innovation Building Materials Complete Equipment Co., Ltd.), and lay 3 layers of glass fiber cloth on the top of the non-woven fabric, and the resulting slurry is transported to the bottom of the plate making machine through a sealed delivery pipe The feed port is coated on the surface of 3 layers of glass fiber cloth, and the inside of the sealed conveying pipe is also vacuumed with a pressure of 0.1 atm. After the slurry is coated on the surface of the three layers ...

Embodiment 3

[0059] A. Under normal temperature and pressure, 20 kg of magnesium oxide powder and 4 kg of expanded perlite powder of 80 mesh cotton stalk powder are mixed evenly and then poured into a sealed kettle, and the pressure in the kettle is evacuated until the pressure is 0.3 atm. Add 10.5 L of magnesium chloride solution with a concentration of 10 mol / L and a pH value of 9.5, and stir for 15 minutes to prepare a slurry. A layer of non-woven fabric is laid on the bottom layer of the plate making machine (Shandong Innovation Building Materials Complete Equipment Co., Ltd.), and a layer of glass fiber cloth is laid on the top of the non-woven fabric, and the resulting slurry is transported to the bottom of the plate making machine through a sealed delivery pipe The feed port is coated on the surface of a layer of glass fiber cloth, and the inside of the sealed conveying pipe is also vacuumed with a pressure of 0.3 atm. After the slurry is coated on the surface of one layer of glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com