Wood-plastic plate and production process

A production process and technology of wood-plastic panels, applied in the field of wood-plastic panels, can solve the problems of different quality, static bending strength, hardness, bending elastic modulus of screw holding force, and impact toughness, etc., and achieve the production cycle. Longer, improve mechanical properties, reduce mechanical wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

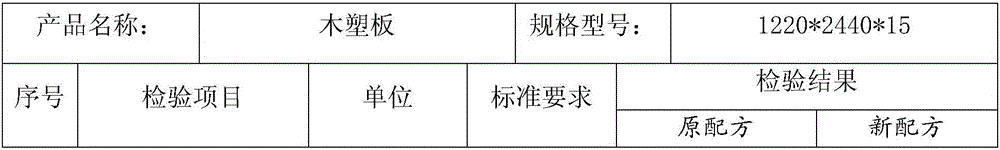

[0033] Embodiment 1: comparative test of wood-plastic board

[0034] Inspection report of Shandong Shengli Wood Plastic Service Co., Ltd.

[0035] Total 2 pages Page 2

[0036]

[0037]

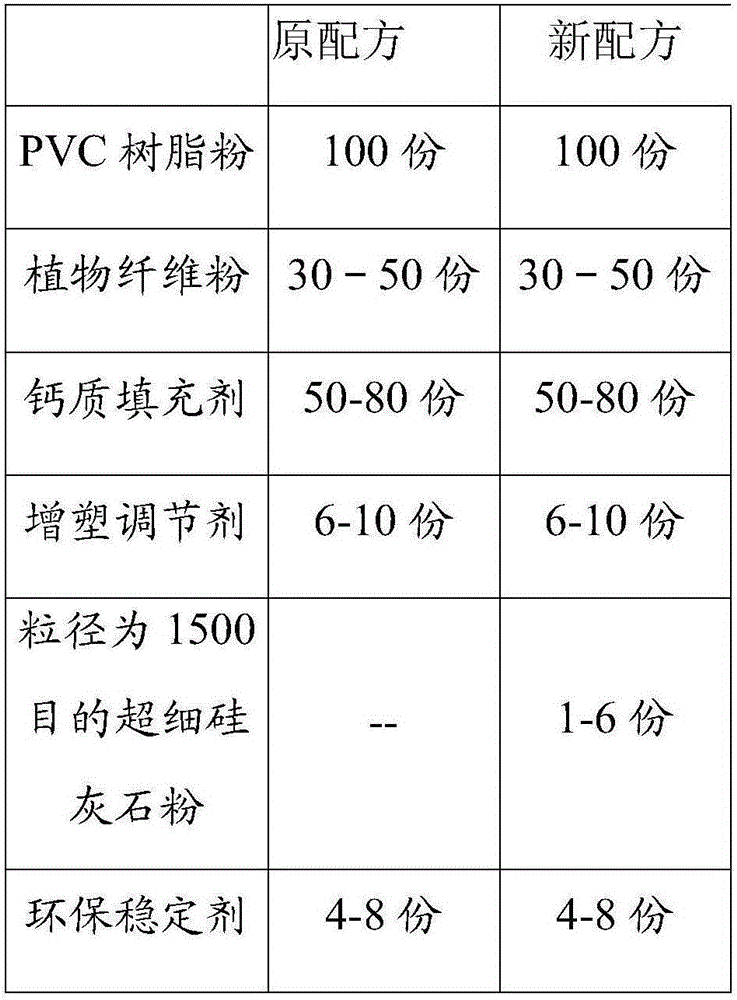

[0038] Recipe comparison

[0039]

[0040]

Embodiment 2

[0041] Embodiment 2: the production technology of wood-plastic board, the steps are:

[0042] (1) Send the processing aid into the high-speed mixer, add an activator according to the weight ratio of 100:0.25, and activate it at a temperature of 105°C for 2 hours. The activator is a hyperdispersive coupling agent, and the activator The dispersed coupling agent is aryl carboxylic acid metal soap, and the processing aid is superfine wollastonite powder with a particle size of 1500 mesh;

[0043] (2) According to the weight ratio of raw materials, waste PVC resin powder: 100 parts; straw fiber powder: 35 parts; calcium filler: 75 parts; plasticizing regulator (dimethyl ester): 3 parts; Wollastonite powder: 3 parts; Environmental stabilizer: 8 parts; ACR processing aid: 5 parts; Foaming agent: 1.1 parts; Internal and external lubricants: 1.3 parts. , and then cooled to 55 ° C into the barrel;

[0044] (3) Put the mixed raw materials into the extruder, heat to 175°C and extrude, t...

Embodiment 3

[0050] Embodiment 3: the production technology of wood-plastic panel, the steps are:

[0051] (1) Send the processing aid into the high-speed mixer, add an activator at a weight ratio of 100:0.1 to 0.3, and activate it at a temperature of 80 to 120°C for 1 to 2 hours. The activator is a hyperdisperse coupling agent, the activator dispersing coupling agent is an aryl carboxylic acid metal soap, and the processing aid is an ultrafine wollastonite powder with a particle diameter of 1500 objects;

[0052] (2) The raw materials are according to PVC resin powder: 100 parts; plant fiber powder: 30 parts; calcium filler: 70 parts; plasticizing regulator (dimethyl ester): 3 parts; processing aid superfine wollastonite powder: 4 parts; Environmental stabilizer: 6.5 parts; ACR processing aid: 5.5 parts; Foaming agent: 1.2 parts; Internal and external lubricants: 1.2 parts Put it into the barrel at 60°C;

[0053] (3) Put the mixed raw materials into the extruder, heat to 170°C and extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com