Mulberry fiber composite board

A technology of mulberry fiber and composite board, which is applied in the field of boards, can solve the problems of high construction technology requirements, poor nail-holding force, and large amount of consumables, and achieve the effects of improved moisture-proof and moisture-proof performance, low cost, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

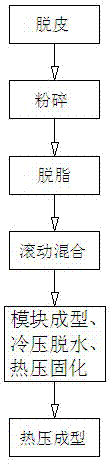

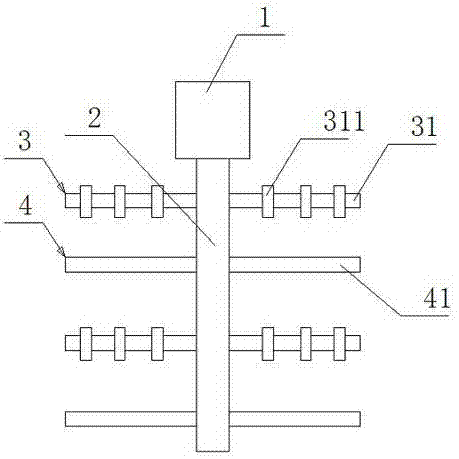

[0020] Embodiment 1: by figure 1 As shown, a mulberry fiber composite board includes a mulberry fiber substrate and a panel fixed on the mulberry fiber substrate, and the panel is a solid wood board or a particle board. The mulberry fiber substrate includes mulberry fibers and sheet-like mulberry trunks, and the mulberry fibers and sheet-like mulberry trunks are hot-pressed with an adhesive. Its production method comprises the following steps:

[0021] (1) Peeling. It is difficult to peel off the mulberry bark from the fresh mulberry branches and dry preserved mulberry branches. After soaking it in water for a week, the mulberry bark can easily separate the two due to the swelling of the mulberry bark.

[0022] (2) Grinding, dehydrating the separated mulberry bark to a moisture content of 6-8% and then pulverizing to obtain mulberry fibers with a length of 15-25 mm and a fineness of 2.57 dtex; dehydrating the dry mulberry bark to a moisture content of 6-8% After crushing, th...

Embodiment 2

[0038] Embodiment 2: A mulberry fiber composite board, comprising a mulberry fiber substrate and a panel fixed on the mulberry fiber substrate, and the panel is a solid wood board or a particle board. The mulberry fiber substrate includes mulberry fibers and sheet-like mulberry trunks. The mulberry fibers and sheet-like mulberry trunks are hot-pressed with an adhesive. The adhesive is environmentally friendly glue with a sizing amount of 12%. Its production method comprises the following steps:

[0039] (1) Peeling. It is difficult to peel off the mulberry bark from the fresh mulberry branches and dry preserved mulberry branches. After soaking it in water for a week, the mulberry bark can easily separate the two due to the swelling of the mulberry bark.

[0040] (2) Grinding, dehydrating the separated mulberry bark to a moisture content of 6-8% and then pulverizing to obtain mulberry fibers with a length of 15-25 mm and a fineness of 2.57 dtex; dehydrating the dry mulberry bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com