Fireproof marine-grade plywood

A marine plywood and baseboard technology, which is applied to other plywood/plywood appliances, wooden veneer joints, lamination devices, etc. Strength, architectural decoration and transportation manufacturing products cannot be guaranteed, and composite plywood innovation and research and development capabilities are insufficient to achieve product load and nail holding power, long service life, and excellent insect-proof effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described.

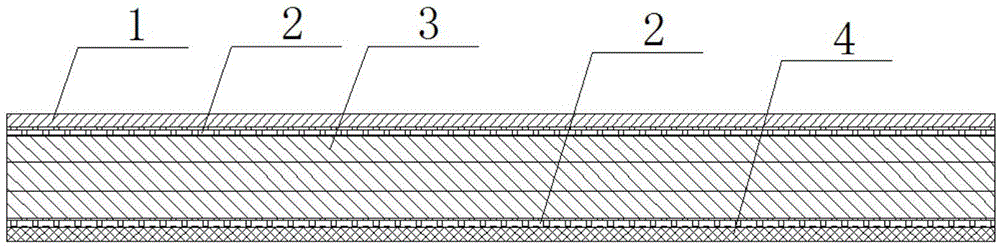

[0031] see as figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes a flame-retardant decorative panel 1, a high-strength glass fiber mesh 2, a flame-retardant solid wood core board 3, and a flame-retardant bottom plate 4; the flame-retardant decorative panel 1 is arranged on the uppermost layer, The flame-retardant bottom plate 4 is set on the bottom layer, and a layer of high-strength glass fiber mesh 2, three layers of flame-retardant solid wood core board 3 and a layer of high-strength glass are sequentially arranged between the flame-retardant decorative panel 1 and the flame-retardant bottom plate 4 from top to bottom. Fiber web 2; each board layer is bonded by improved polymer WBP flame-retardant and waterproof glue.

[0032] Its production process is:

[0033] 1. Soak the flame-retardant veneer 1 with a high-efficiency halo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com