Manufacturing process of small-sized thin buzzer piece

A manufacturing process and small size technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve waste, small size and thin buzzer Problems such as low pass rate of film production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

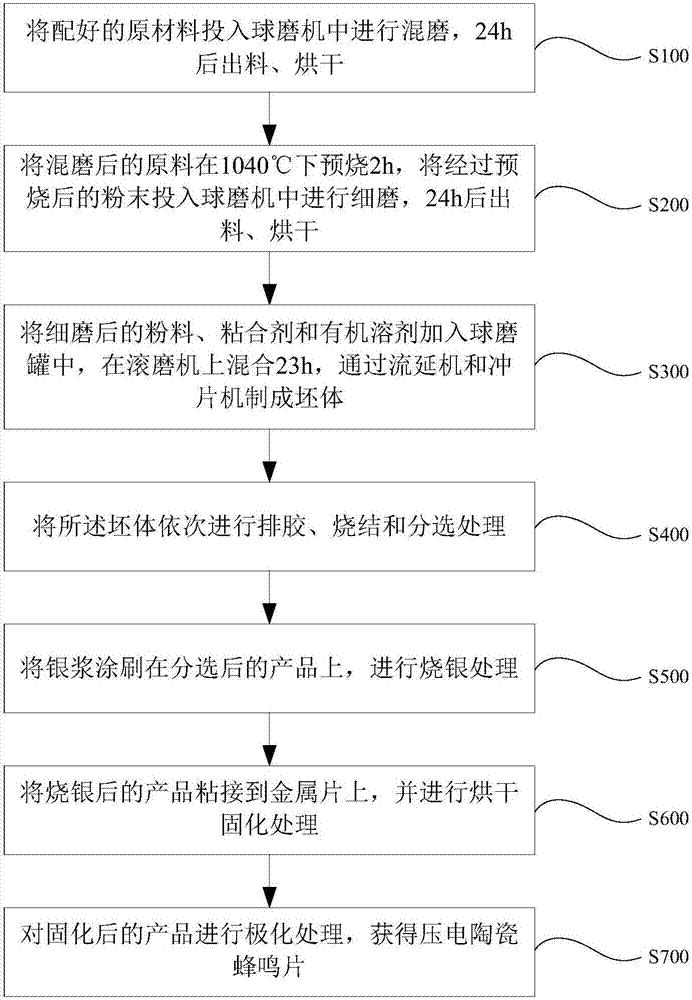

[0039] see figure 1 , is a flow chart of the manufacturing process of the small-sized thin buzzer chip provided by the embodiment of the present invention.

[0040] S100: put the raw materials for making the buzzer sheet into a ball mill for mixed grinding, discharge and dry after 24 hours.

[0041] Specifically, the main raw material for making piezoelectric ceramic buzzers is Pb 3 o 4 、TiO 2 , ZrO 2 , SrCO 3 , the excipient is Nb 2 o 5 , Sb 2 o 3 , MnO 2 、Ni 2 o 3 , When selecting raw materials, attention should be paid to purity, fineness and activity. The principle of purity is not to introduce harmful impurities. Alkaline earth metal oxides are more likely to absorb moisture, and the oxides generated by the decomposition of carbonates during pre-calcination are highly active, which is related to the entire preparation. Process and final product performance. After the raw materials are selected, pre-treatment is carried out to remove impurities and moisture, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com