Pipeline dredging device

A technology for dredging equipment and pipelines, applied in water supply equipment, cleaning sewer pipes, waterway systems, etc., can solve problems such as long time-consuming dredging, low work efficiency, and hidden dangers of operation safety, so as to achieve no personnel safety hazards and construction reliability High and simple construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

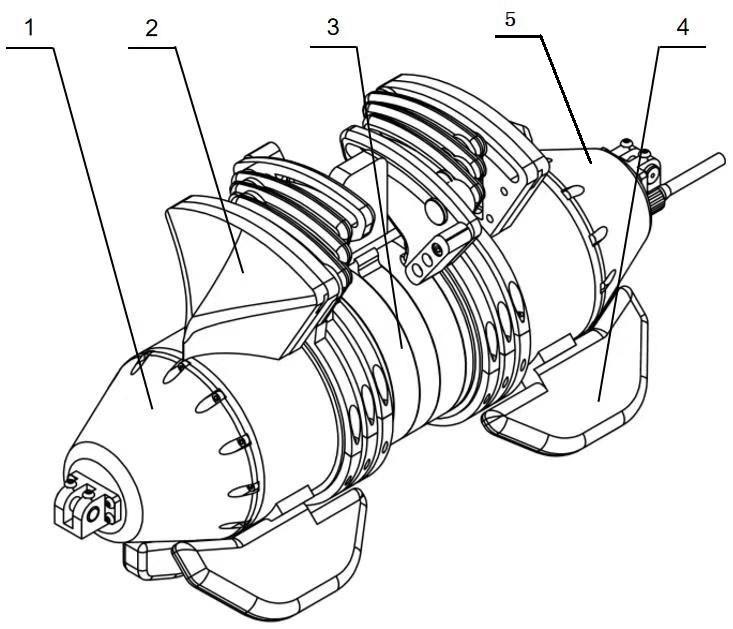

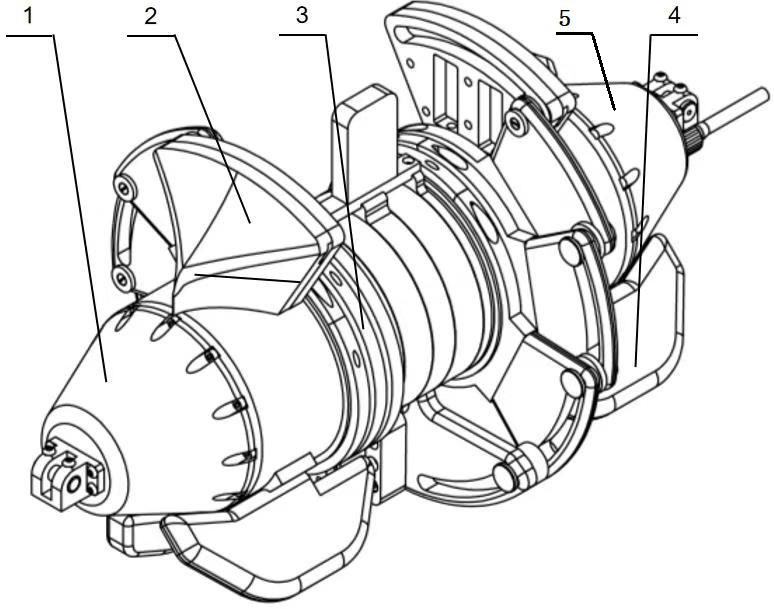

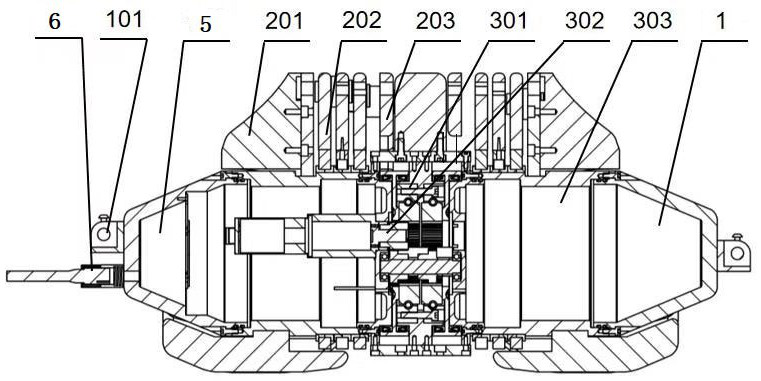

[0019] Such as figure 1 It is a schematic diagram of tightening the pipeline dredging device of the present invention, the pipeline dredging device includes: front end structure 1, rear dredging scraper mechanism 2, front dredging scraper mechanism, body 3, guide shoe 4, rear end structure 5. The traction and fixing device 101 and the cable system 6; one end of the body 3 and the rear end structure 5 are fixedly connected by screws, the cable system 6 is arranged on the rear end structure 5, and the other end of the body 3 is connected to the front end structure 1 The outer side of the rear end structure 5 and the outer side of the front end structure 1 are respectively fixedly connected with a traction device 101 through screw fixed connection, and the traction device 101 is connected with an external dragging mechanism to drive the pipeline dredging device to move in the pipeline . The rear dredging scraper mechanism 2 and the front dredging scraper mechanism are symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com