Pipeline repairing robot

A robot and pipeline technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of complex construction, overall side shifting of roads, and road occupation by engineering vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

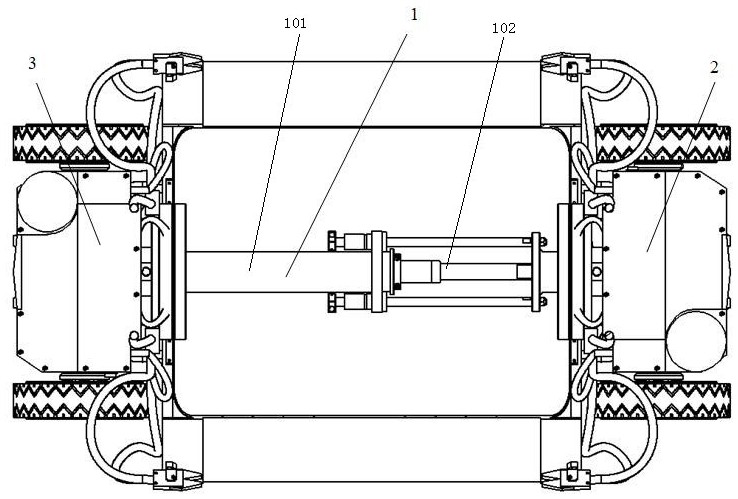

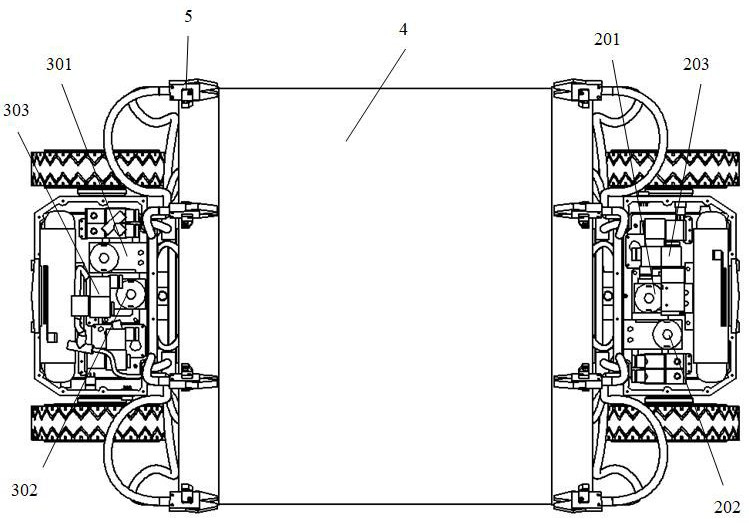

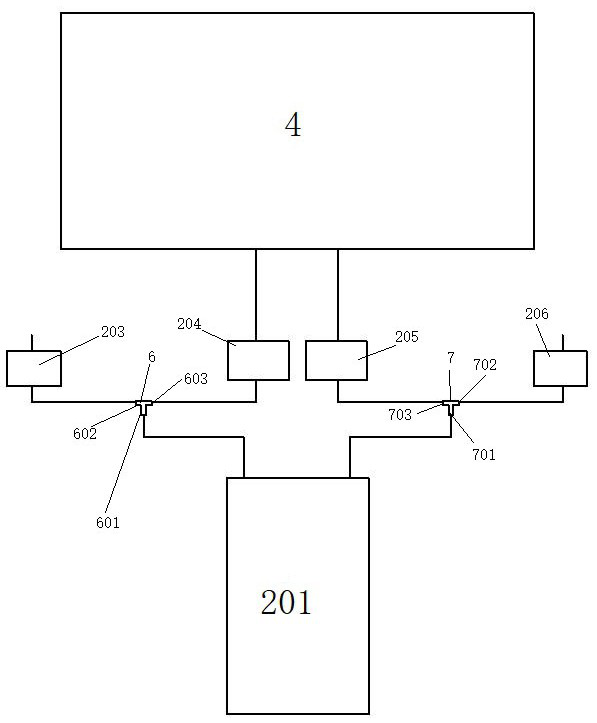

[0018] see Figure 1-2 , the pipeline repairing robot of the present invention comprises: electric push rod 1, drive rear seat module 2, drive front seat module 3, air bag 4 and air clip 5; The rear seat module 2 is connected, and the fixed rod 101 is connected with the driving front seat module 3. The present invention realizes the length change of the pipeline repair robot through the expansion and contraction of the electric push rod 1. When the electric push rod 1 is in the retracted state, the length of the pipeline repair robot Shorter, it is beneficial for the pipeline robot to enter the pipeline; when the electric push rod 1 is in the extended state, on the one hand, it is conducive to the addition of repair paint, on the other hand, it is conducive to the close fit of the repair paint and the damaged pipe during repair, and the repair is completed smoothly Work. The driving rear seat module 2 and the driving front seat module 3 are all connected with the air bag 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com