Outer shear wall suspension board stereotyping aluminum template supporting system and construction method

A formwork support and support system technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of cantilever plate fracture, many support steps, and difficult to control the quality of operation and other issues, to achieve the effect of safe and convenient construction and high construction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the scaffolding erection process, concrete pouring process, formwork hoisting construction, etc. will not be repeated in this embodiment, and the embodiments of the present invention related to structures will be focused on.

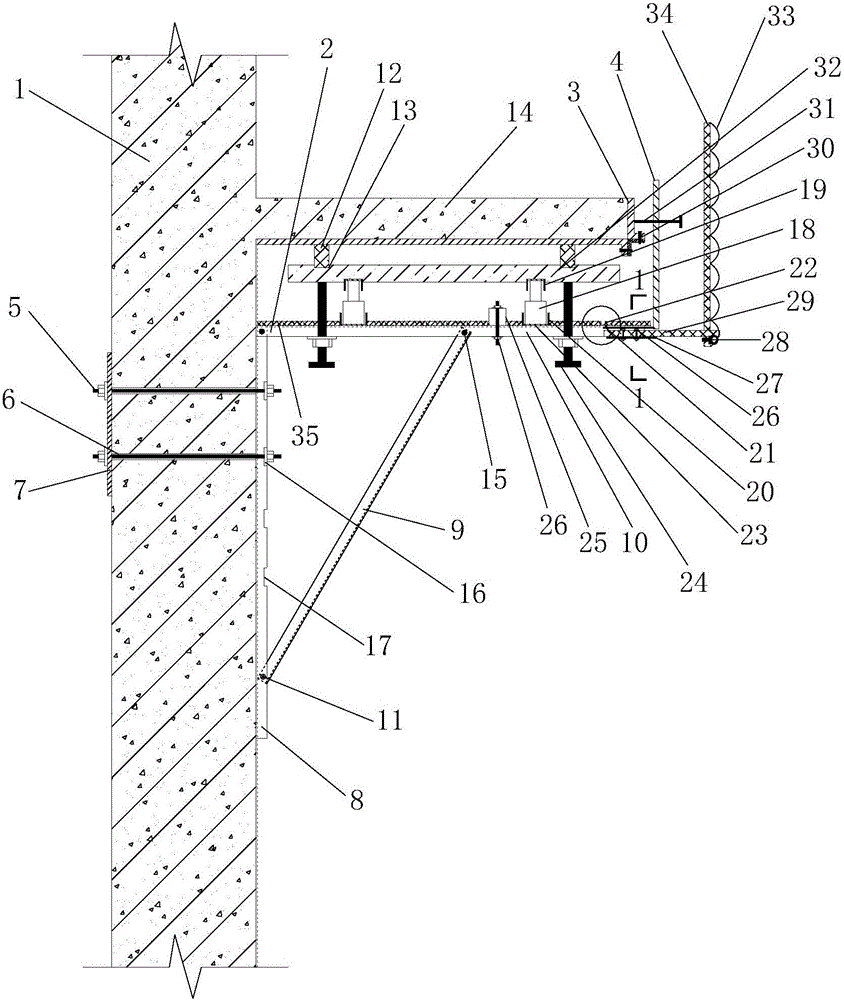

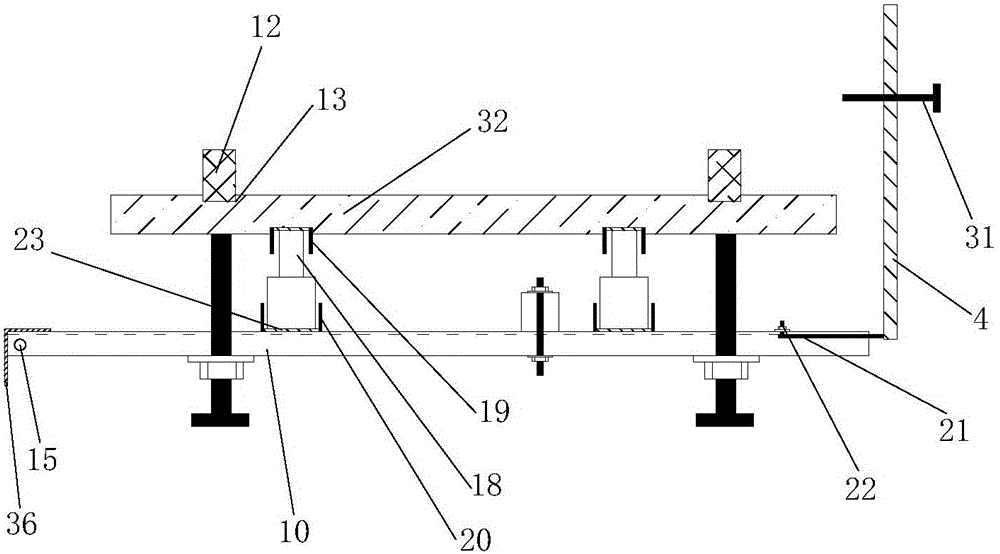

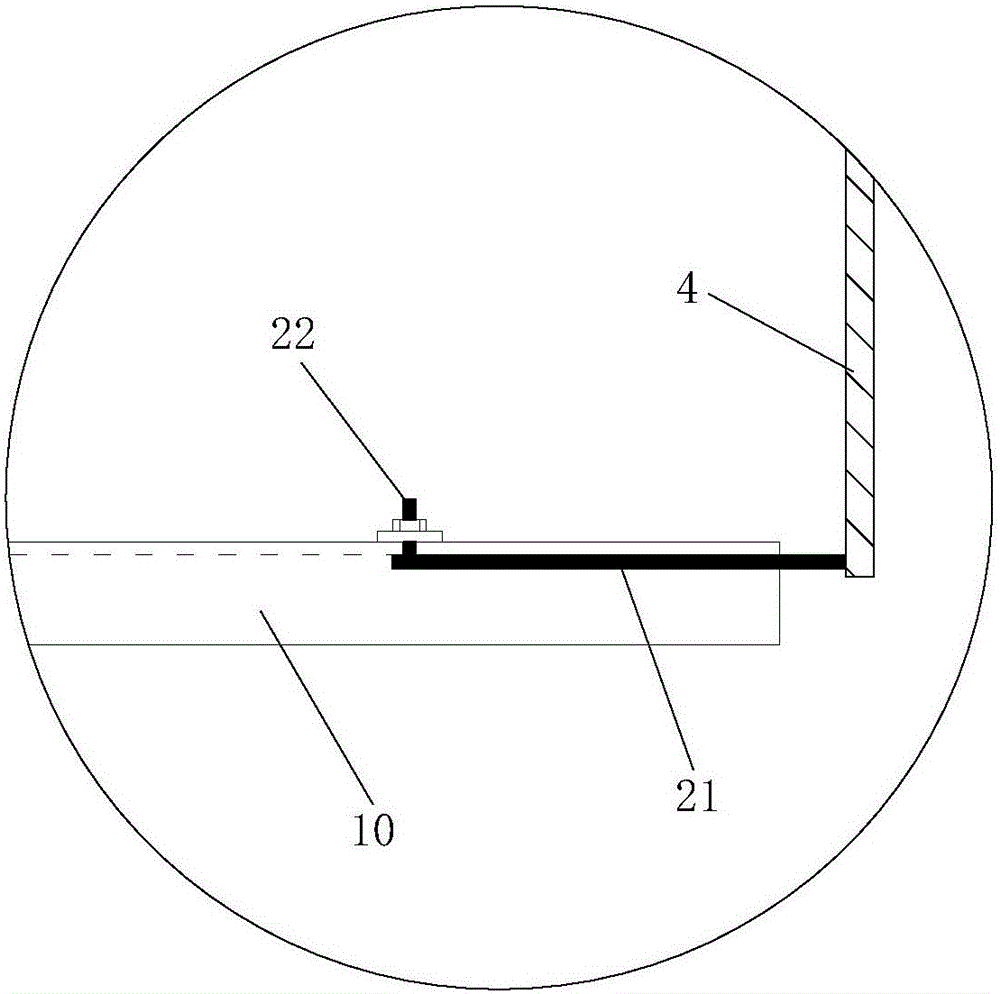

[0037] figure 1 It is a schematic diagram of the stereotyped aluminum formwork support system for the cantilever plate of the outer wall of the high shear wall of the present invention, refer to figure 1 The support system shown is composed of a support frame and an upper adjustment structure. The support frame mainly includes a cross bar 10, a vertical bar 8, and an oblique bar 9. Plate 36, the width of the horizontal bar 10 is slightly larger than that of the vertical bar 8, the width of the oblique bar 9 is smaller than that of the vertical bar 8, the horizontal bar is made of No. Rod 9 adopts No. 5 channel steel with a horizontal length of 2100mm. The upper adjustment structure is composed of small jack 18, end plate 4, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com