Underground excavation construction deformation control method for three-hole small clear distance tunnel underpass trunk railway

A deformation control, small clear distance technology, applied in tunnels, earth-moving drilling, mining equipment, etc., to achieve the effect of ensuring operation safety, construction safety, and construction process safety and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

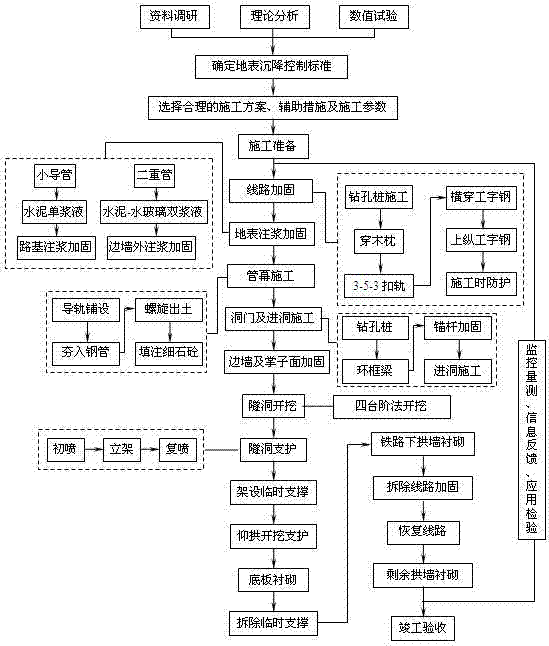

Method used

Image

Examples

example 1

[0050] The railway mileage at the intersection of the center line of the tunnel and the upward line of a certain railway is: K88+056.20, and the angle between the tunnel axis and the railway axis is 87°. This project includes the main works of open and concealed excavation tunnels. The height from the tunnel vault to the ground is 2m, and the height from the railway shoulder is 4.33m. The length of the single-bore tunnel is 42m, of which the length of the underground excavation section is 32m, and the length of the open excavation section is 10m. The underground section of the 3-hole tunnel is 96m in total, and the open excavation section is 30m in total.

[0051] The distance between the upper and lower lines of the railway is 4.27m, the track surface elevation of the up line is 12.14m, and the longitudinal slope of the line is 3‰; the track surface elevation of the down line is 12.14m, and the longitudinal slope of the line is 3‰; The slope ratio is 1:1.5. The railway is ...

example 2

[0057] The railway mileage at the intersection of the center line of the tunnel and the upward line of a certain railway is: K66+833, and the angle between the tunnel axis and the railway axis is 46.8°. This project includes the main works of open and concealed excavation tunnels. The height from the tunnel vault to the ground is 2m, and the height from the railway shoulder is 5.92m. The entrance pile number of the tunnel body is XW93+753, and the exit pile number is XW93+823. The length of the single-hole tunnel body is 70m, of which the length of the underground excavation section is 45m, and the length of the open excavation section is 25m. The underground section of the 3-hole tunnel is 135m in total, and the open excavation section is 75m in total.

[0058] The distance between the upper and lower lines of the railway is 4.6m, the elevation of the uplink track surface is 12.32m, and the longitudinal slope of the line is -0.8‰; the track surface elevation of the downlink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com