Patents

Literature

37results about How to "Solve compound problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strong-alkalinity composite ion exchange resin material and preparation method thereof

ActiveCN104558360AImprove heat resistanceGood anti-swelling performanceAnion exchangersState of artAlkalinity

The invention relates to a strong-alkalinity composite ion exchange resin material and a preparation method thereof and is mainly used for solving the problems of low heat resistance and swelling resistance of the strong-alkalinity ion exchange resin in the prior art. The strong-alkalinity composite ion exchange resin material comprises the following components in percentage by weight: a) 75-90% of polymer monomer; b) 5-15% of copolymer monomer; c) 0.1-5% of graphene; and d) 0.1-10% of initiator. The technical can be used for solving the problem relatively well and can be applied to the industrial production of strong-alkalinity composite ion exchange resin material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

ActiveCN102372812ASolve compound problemsIn situ functionalizationAnion exchangersHydration reactionCarbon nanotube

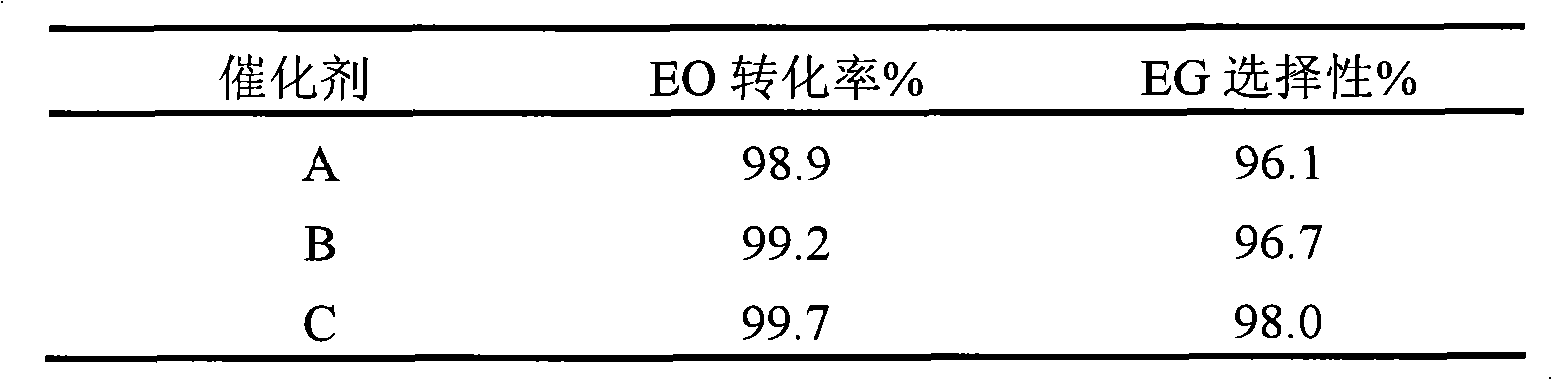

The invention relates to a macroporous strong alkaline carbon nanotube composite ion exchange resin and a preparation method thereof, and aims to solve problems of weak heat resistance and weak swelling resistance of an ion exchange resin in a prior art. The macroporous strong alkaline carbon nanotube composite ion exchange resin comprises the following components: (1) 40-65% of monomer; (2) 3-10% of copolymerization monomer; (3) 0.1-10% of nano material; and (4) 0.1-2% of initiator. The monomer is at least one selected from p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloroamyl) styrene and 4-(5-bromoamyl) styrene; the copolymerization monomer is at least one selected from EGDMA, dipropenyl benzene, divinyl phenyl methane and divinyl benzene; the nano material is at least one selected from multi-wall carbon nanotube, single arm carbon nanotube and fullerene of C60 or C70; the initiator is at least one selected from benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide and cumyl hydroperoxide. The invention also provides a preparation method of the macroporous strong alkaline carbon nanotube composite ion exchange resin. The above technical scheme well solves the problems and can be applied to industrial production of ethylene oxide catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Strong-basicity ternary composite metal-graphene-ion exchange resin material and preparing method thereof

The invention relates to a strong-basicity ternary composite metal-graphene-ion exchange resin material and a preparing method thereof to mainly solve the problems that in the prior art, strong-basicity ion exchange resin is poor in heat resistance and swelling resistance and likely to be decomposed and deactivated when heated in the application process. The strong-basicity ternary composite metal-graphene-ion exchange resin material is prepared from, by weight, 75-90% of polymerized monomers, 5-15% of copolymer monomers, 0.1-10% of graphene, 0.1-1% of metal particle components and 0.1-10% of an initiator. According to the technical scheme, the problems are well solved, and the strong-basicity ternary composite metal-graphene-ion exchange resin material can be used for industrial production of strong-basicity composite ion exchange resin materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

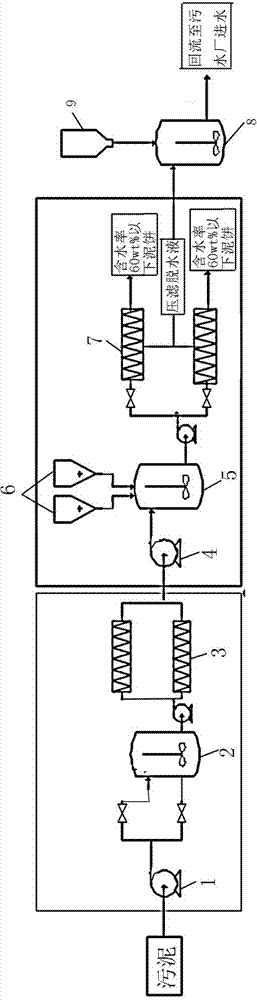

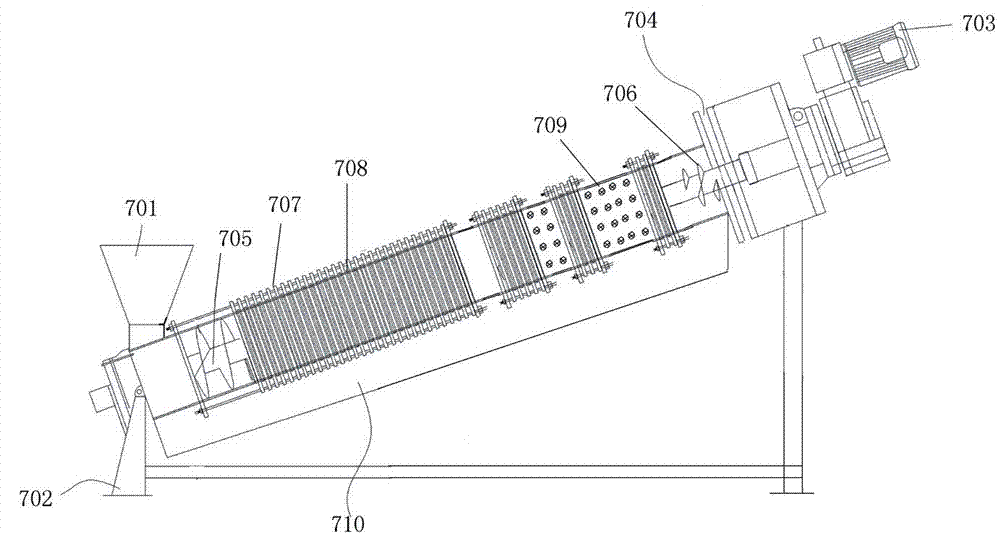

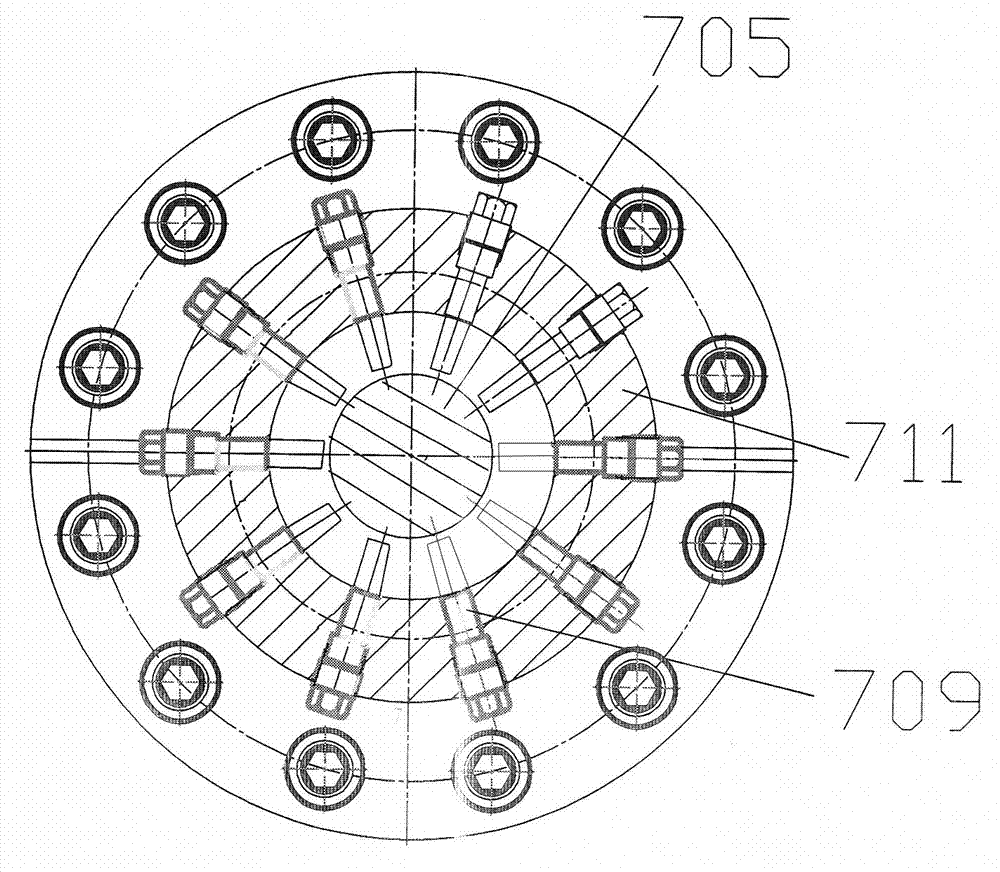

Inorganic conditioning based integrated sludge deep dehydration treatment process

InactiveCN103482844AReduce the ratioReach the smellSludge treatment by de-watering/drying/thickeningThermal energySocial benefits

The invention relates to an inorganic conditioning and pin screw machine based integrated sludge deep dehydration treatment process. The process comprises the steps such as primary dehydration, deep dehydration, dehydrated sludge delivery and the like; the moisture content in the sludge is reduced from 99.7% to less than 60% once in two stages by only adopting medication modifying and pin screw machine filter pressing ways instead of depending on any external conditions such as thermal energy and the like. In the whole operation process, no smoke, odor and noise are generated, no external thermal sources are needed, no secondary pollution is caused, the clean production can be realized, and more importantly, an operable approach is provided for waste sludge recycling, so that the process has very important significance in handling a large-area and large-quantity sludge treatment situation on both economic and social benefits.

Owner:孙阳 +1

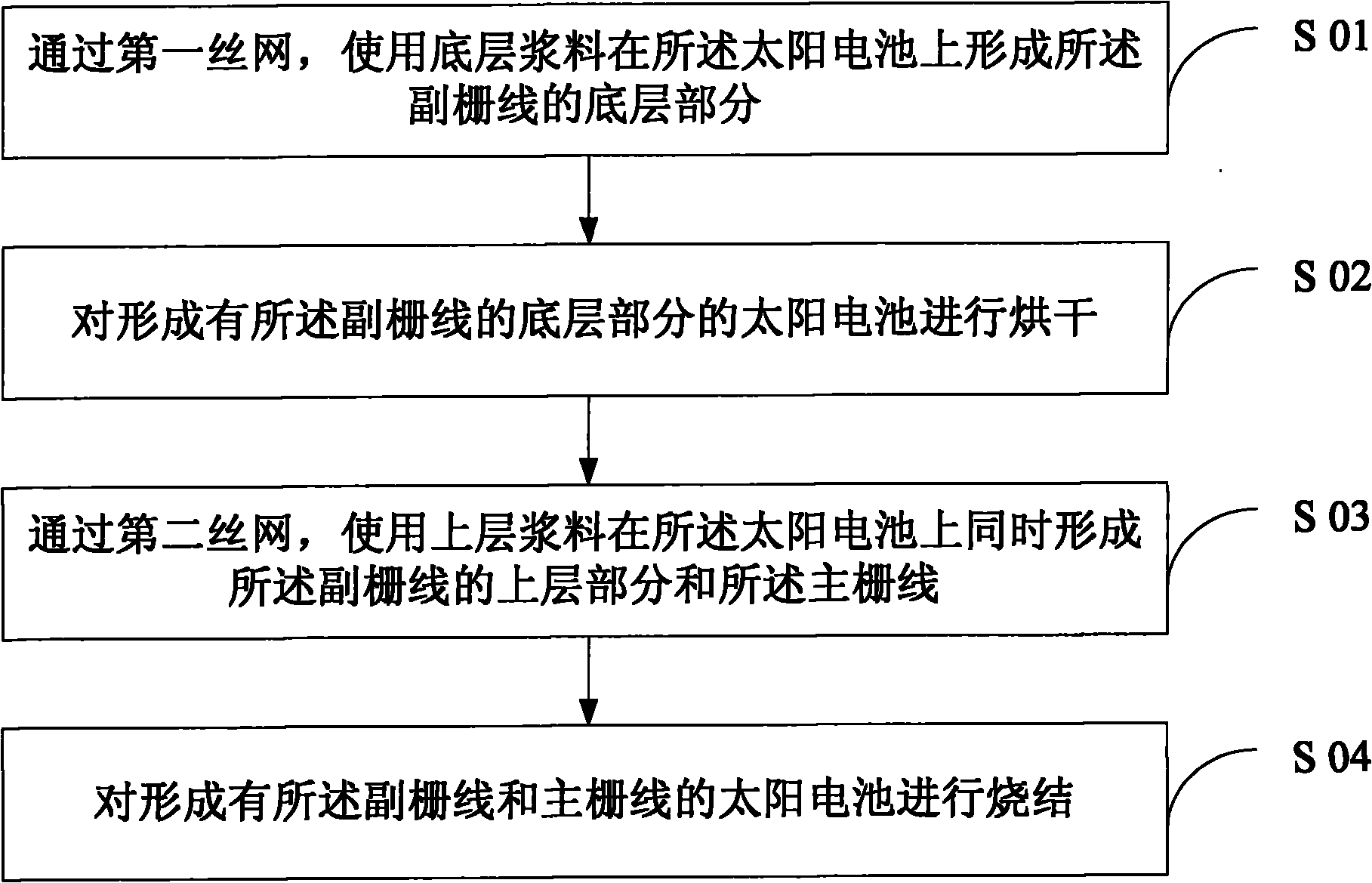

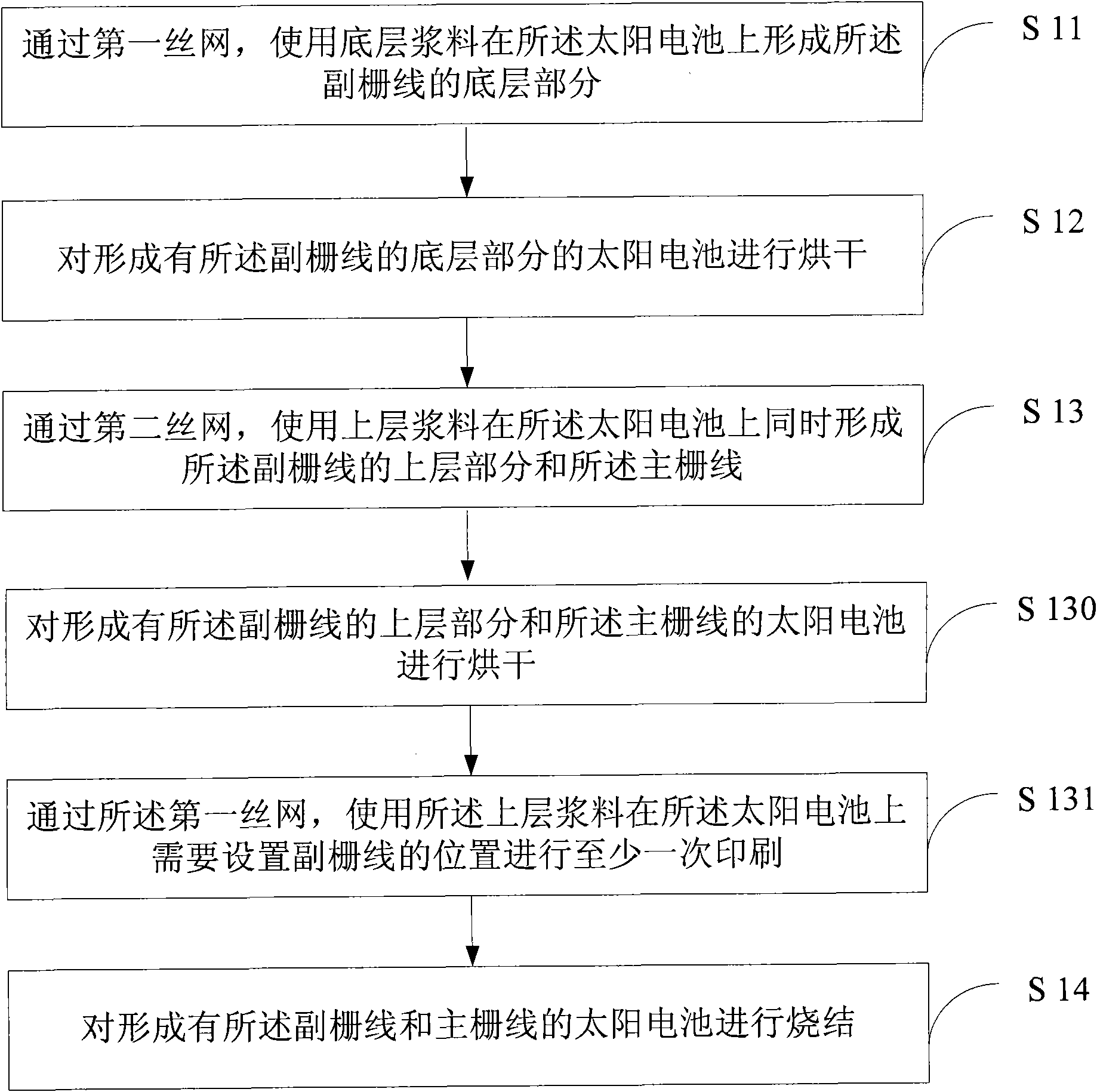

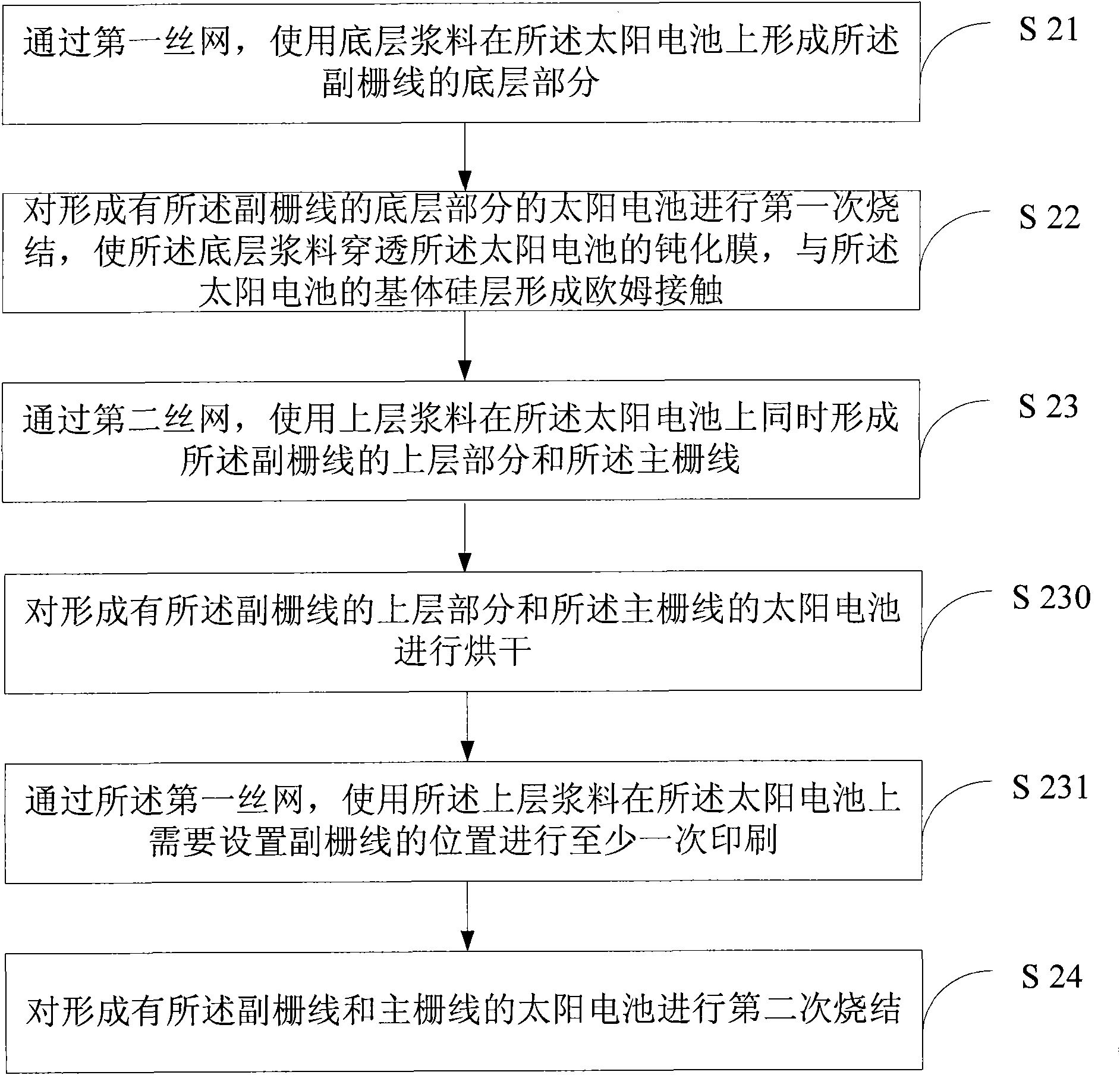

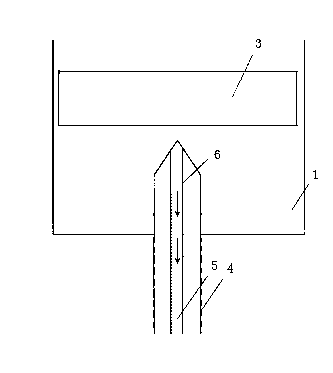

Method for forming positive electrode of solar cell

InactiveCN102479883AHigh aspect ratioImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesEngineeringSlurry

The invention discloses a method for forming a positive electrode of a solar cell, which comprises the step of forming a secondary grid line and a main grid line on the solar cell. The method comprises the following steps of: forming a bottom-layer part of the secondary grid line on the solar cell by using bottom-layer slurry through a first silk net; oven-drying the solar cell formed with the bottom-layer part of the secondary grid line; forming an upper-layer part of the secondary grid line and the main grid line at the same time on the solar cell by using upper-layer slurry through a second silk net; and sintering the solar cell formed with the secondary grid line and the main grid line. By means of the method disclosed by the invention, the height-to-width ratio of the secondary grid line can be increased, the redundant composition will not be produced at the position of the main grid line, the cost of the slurry is effectively reduced, the internal stress produced at an electrode part during assembly production and welding is reduced, and the positive electrode of the solar cell, particularly the electrode at the position of the secondary grid line is enabled to realize functional differentiation. The invention also provides a method for producing the solar cell by using the above method and the solar cell produced by the above method.

Owner:WUXI SUNTECH POWER CO LTD

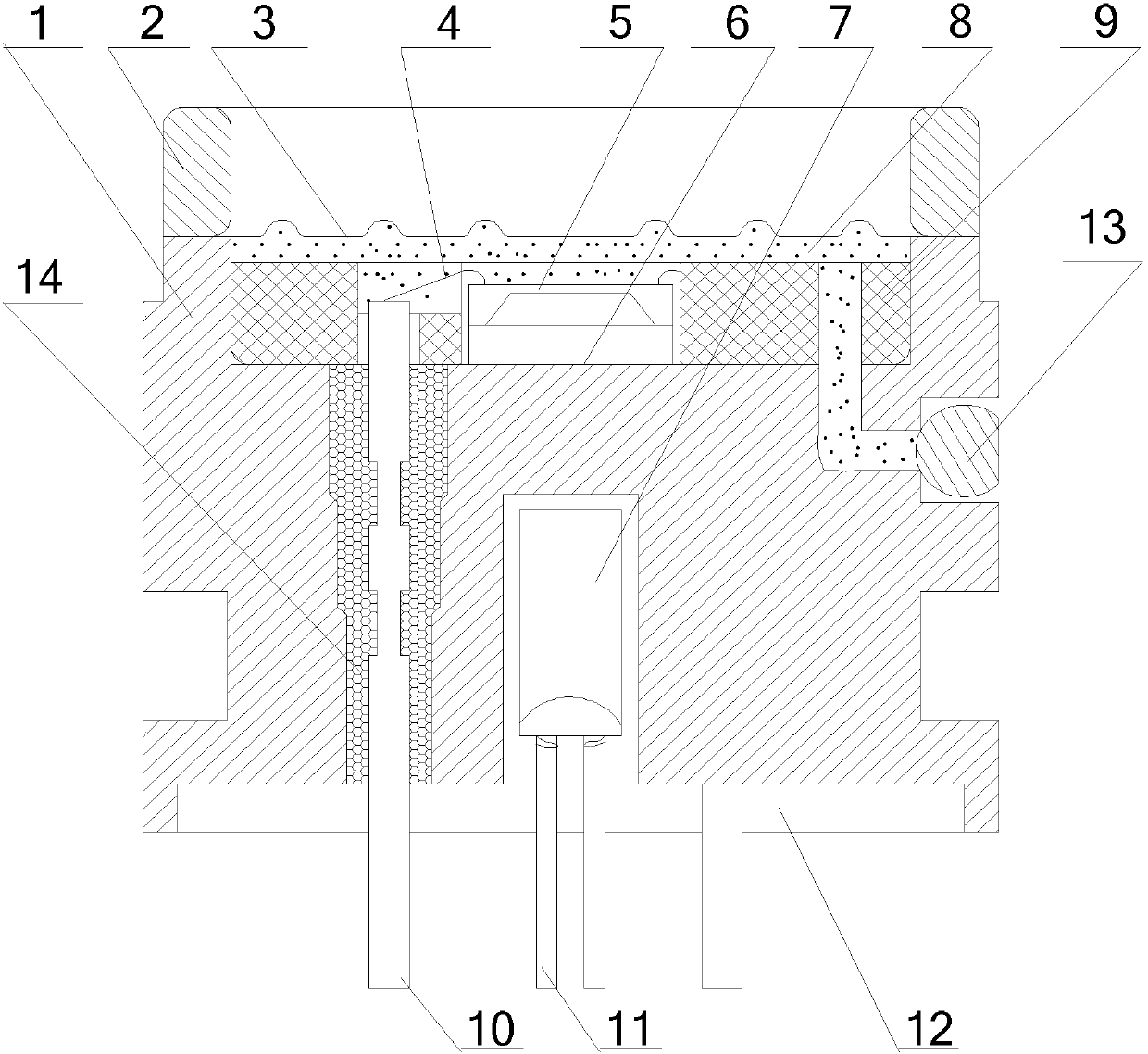

High-temperature pressure and temperature integrated composite sensor

InactiveCN107806947AReduce volumeImprove stabilityThermometers using electric/magnetic elementsForce measurement using piezo-electric devicesSteel ballSilicone oil

A high-temperature pressure and temperature integrated composite sensor relates to the field of pressure and temperature composite sensors. The invention aims to solve the problem that the existing pressure and temperature composite sensor is large, has poor compatibility and cannot measure pressure in a large range at high temperature. A ceramic ring is disposed in a large circular groove. A pressure sensitive chip is disposed in the ring of the ceramic ring. A corrugated diaphragm covers the open end of the large circular groove. The gap between the corrugated diaphragm and the large circular groove is filled with high-temperature silicon oil. An oil injection hole is plugged by a plugging steel ball. A pressure ring is fixed to the opening of the large circular groove. A pressure lead-out wire column is disposed in an end column lead-out through hole. The inner wall of the end column lead-out through hole is of a double-step structure. The pressure lead-out wire column is provided with two annular slots along the circumference thereof. A temperature sensitive chip is disposed in a small circular groove. The open end of the small circular groove and the tail end of the end columnlead-out through hole are plugged by high-temperature sealing glue. The high-temperature pressure and temperature integrated composite sensor of the invention is suitable for measuring temperature and large-range pressure at a high temperature of 200 DEG C.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

ZnO-mixed cathode buffer layer-based organic solar battery and preparation method thereof

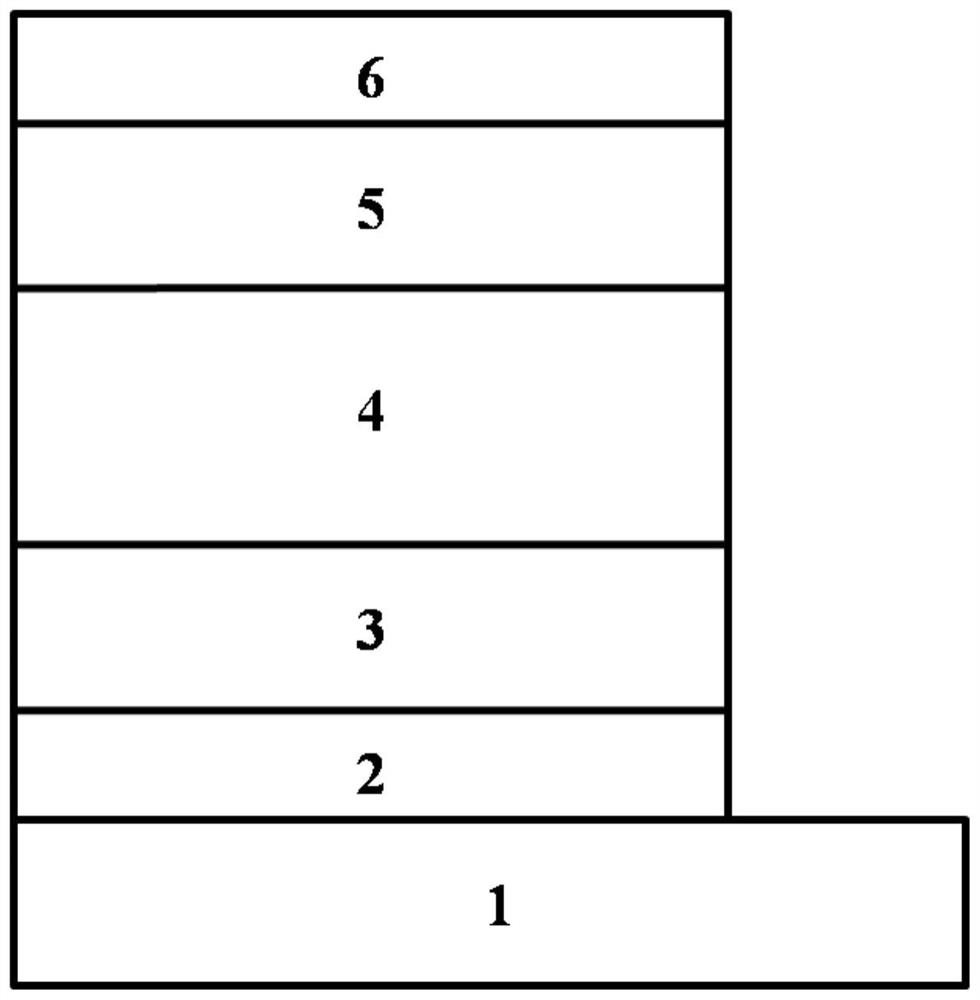

InactiveCN107565029AReduce defectsEnhanced electron transport capabilitiesSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolar battery

The invention relates to a ZnO-mixed cathode buffer layer-based organic solar battery. An inversion structure is adopted by the organic solar battery; the organic solar battery comprises a substrate layer, a transparent conductive cathode layer, a cathode buffer layer, a photoactive layer, an anode buffer layer and a metal anode layer which are sequentially arranged from bottom to top; and the cathode buffer layer is a solid thin film which is formed by mixing a ZnO nano-particle dispersion liquid and a ZnO precursor solution prepared through a sol-gel method at a ratio and carrying out thermal annealing. The invention further discloses a preparation method of the battery. The cathode buffer layer is prepared through mixing a certain amount of ZnO precursor solution prepared through the sol-gel method into the large-particle size ZnO nano-particle dispersion liquid, and gaps among ZnO nano-particles can be filled while relatively large contact area of the cathode buffer layer and the photoactive layer is ensured, so that the defect of the cathode buffer layer is reduced and the photoelectric conversion efficiency of a device is effectively improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

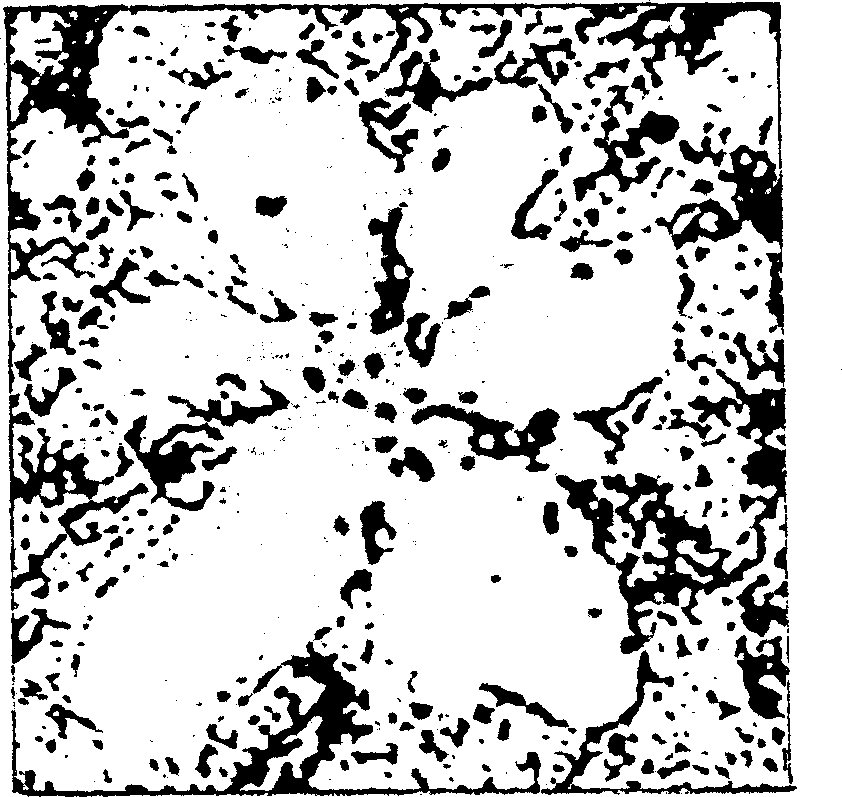

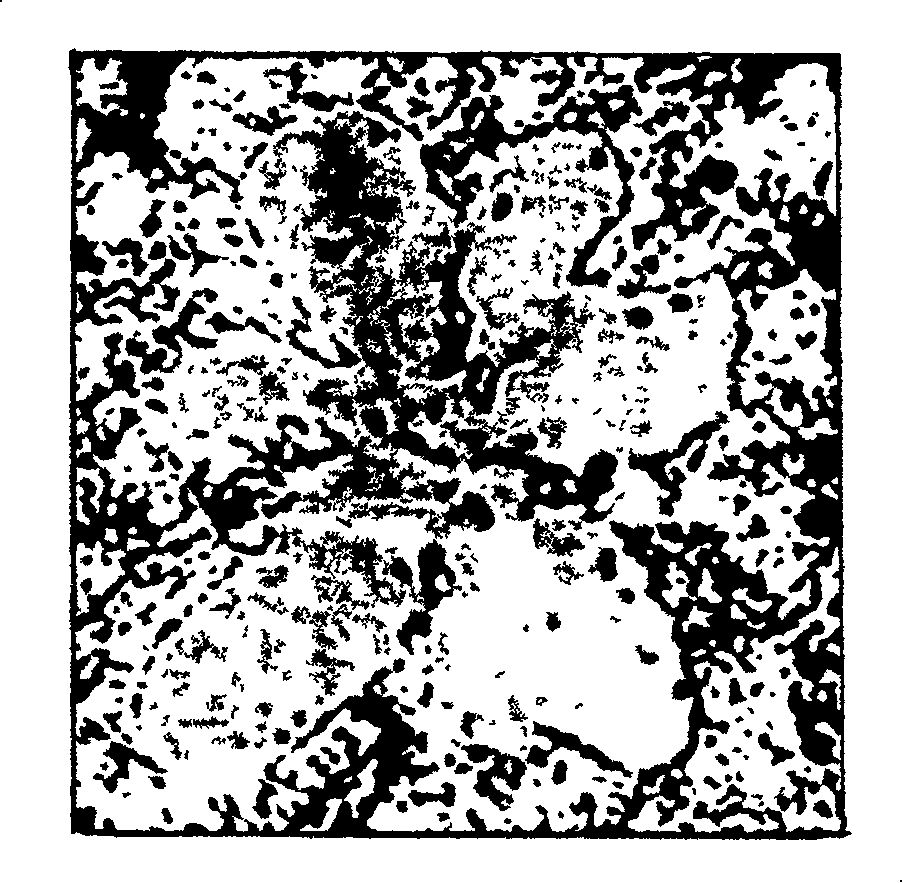

Zinc-alluminium-based wear-resistant alloy and production thereof

InactiveCN1818115AImprove wear resistanceImprove room temperature strengthChemical compositionWear resistant

The invention is about the wearing allumen material and its preparation. The material based on the allumen with the Si, tellurium or lanthanum. Anthesis Si is distributed in the allumen uniformly. The micromorphic of the Si phase is the nodular cracked polycrystal. The weight content of the composition is Al 40-50%, tellurium or lanthanum 0.02-0.05%, Si 1.0-3.0%, the residue is Zn; the hardness of the alloy in the room temperature is HB130-150. The alloy needn't the applied ceramic intensify particle.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

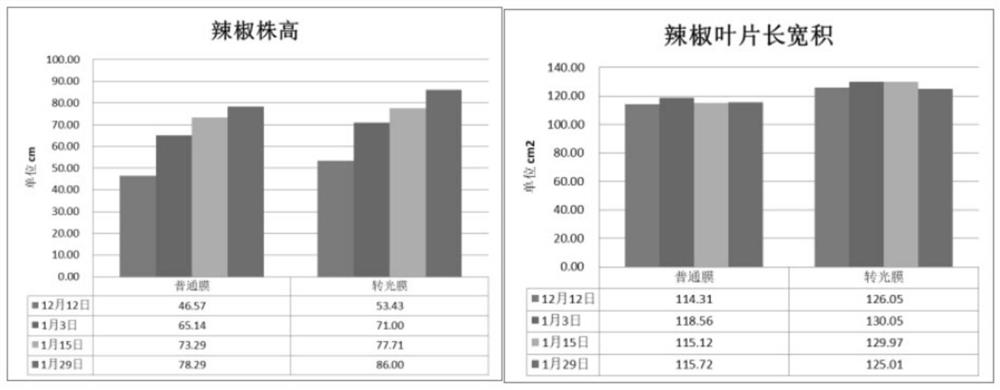

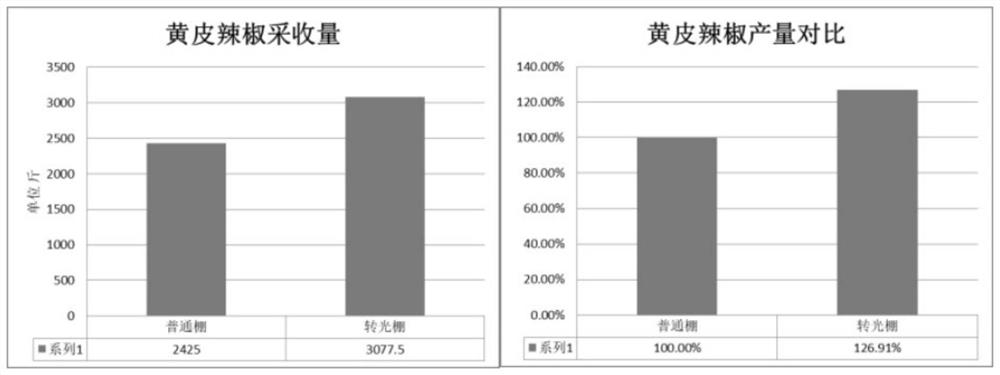

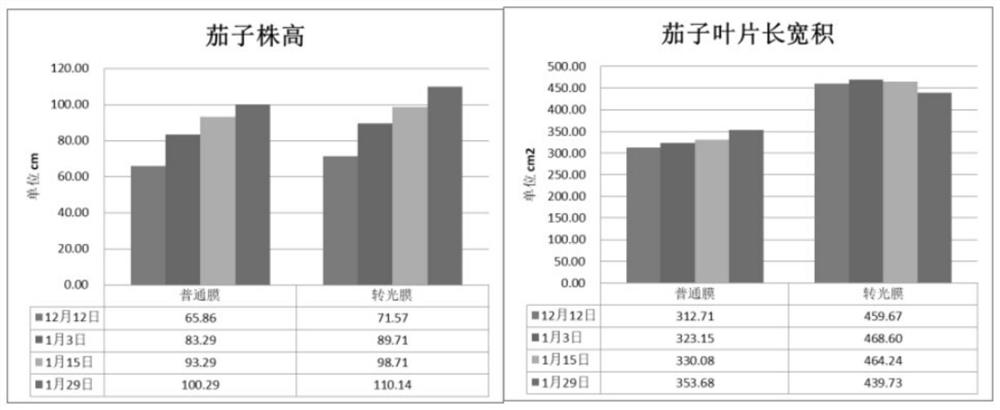

Degradable light conversion film as well as preparation method and application thereof

ActiveCN112521738ASolving Mixed Dispersion ProblemsImprove uniformityClimate change adaptationGreenhouse cultivationPolymer sciencePolyolefin

The invention belongs to the technical field of light conversion films, and discloses a degradable light conversion film and a preparation method and application thereof. The degradable light conversion film comprises the following components in parts by mass: 20-100 parts of a degradable polymer base material, 0.1-1.2 parts of a surface-modified light conversion agent, 0-80 parts of a polyolefinfilm base material and a solubilizer which accounts for 1%-10% of the mass of the polyolefin film base material. According to the invention, a specific surface modification method is adopted to solvethe problem of mixing and dispersing of the light conversion agent in the degradable polymer substrate, and the obtained light conversion film has good uniformity, light transmittance and processability, and completely meets the use requirements of agricultural greenhouse films and agricultural mulching films. It is verified that the greenhouse applying the light conversion film can effectively improve the yield and disease resistance of fruit and vegetable crops. The degradable polymer base material and the polyolefin film base material can be further compounded, so that the degradability andthe service life of the film can be both considered.

Owner:FOSHAN ONMILLION NANO MATERIALS

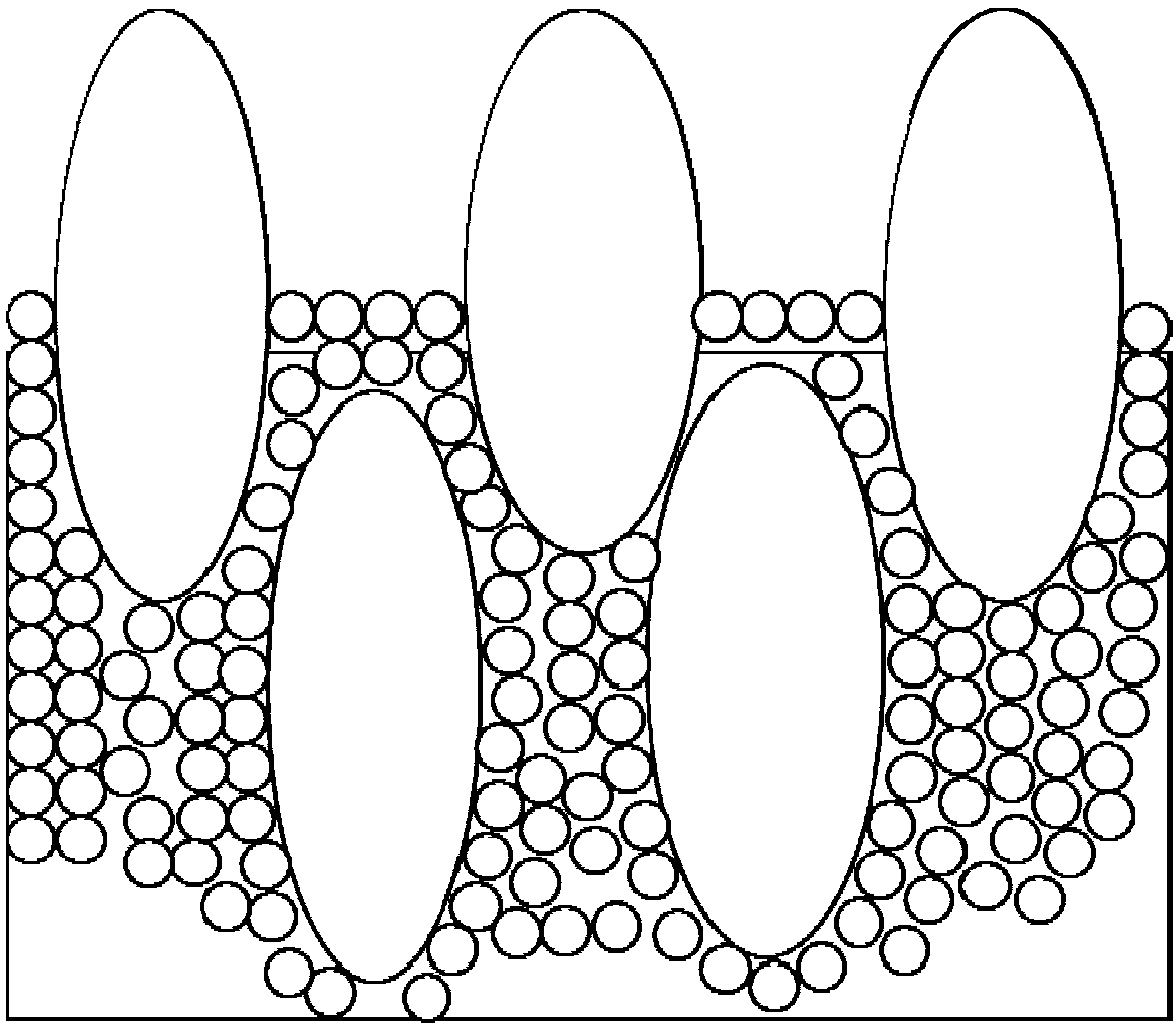

Metal-based composite reinforcement phase casting technique

InactiveCN104550857ASolve the problem of infiltrationSolve compound problemsLiquid metalMetal particle

The invention relates to a metal-based composite reinforcement phase casting technique. The casting technique comprises the steps of infiltrating and combining reinforcement phase metal in a quick-wearing part of a metal part, mixing and pressing reinforcement phase metal particles, powder and a binding agent into pellets, pre-sintering the pellets, fixing the pellets on the surface of the metal part, casting liquid metal on the pellets, infiltrating molten metal to the pellets to soak and combine with the reinforcement phase metal by virtue of static pressure and capillary force, and forming metal and a reinforcement phase composite layer when a casting is formed. The casting process provided by the invention is convenient in production process and low in cost; furthermore, the infiltration and combination between the prefabricate pellets and a casting body can be solved, therefore the pellets and a matrix are fused together without any obvious limit.

Owner:北京金煤创业科技股份有限公司

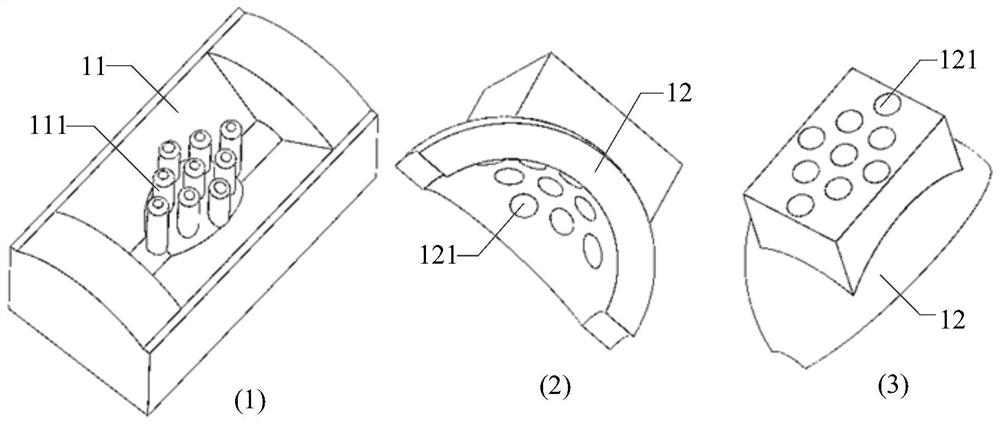

Compound medicine administration method

InactiveCN103100128AEasy to carryEasy to operateInfusion syringesMedication injectionEmergency treatment

The invention belongs to a compound medicine administration method in the field of medical equipment. According to the compound medicine administration method, various liquid medicines are enabled to be packaged inside a capsule, the capsule is put into a needle cylinder, a pushing plug is installed in the needle cylinder, a pushing plate is installed inside the pushing plug, the pushing plate is fixed by a bolt, a pull ring is connected with one end of the bolt, a spring is installed between the pushing plate and the bottom of the pushing plug; a needle head is installed on the bottom of the needle cylinder, a hollow portion of the needle is a needle passage, one end of the needle head is inserted into the needle cylinder to serve as an inner needle head, the other end of the needle head servers as an injection needle head; a needle passage of the inner needle head is in a straight-through shape, or in a cross shape, or in a T shape; when medicines are administrated, the bolt is pulled out through the pull ring; under the function of the spring, the capsule is pressed by the pushing plate, the inner needle head is enabled to penetrate all capsules in sequence, and the liquid medicines flow into subcutaneous tissues or muscle. The compound medicine administration method is capable of completing multi-medicine injection processes at one time, ration is accurate, instruments are convenient to carry, operation is simple, the problem of mixing of a plurality of emergency treatment medicines is effectively resolved, and the compound medicine administration method is especially suitable for occasions of self-saving and mutual saving of wounded people.

Owner:CHENGDU MILITARY GENERAL HOSPITAL OF PLA

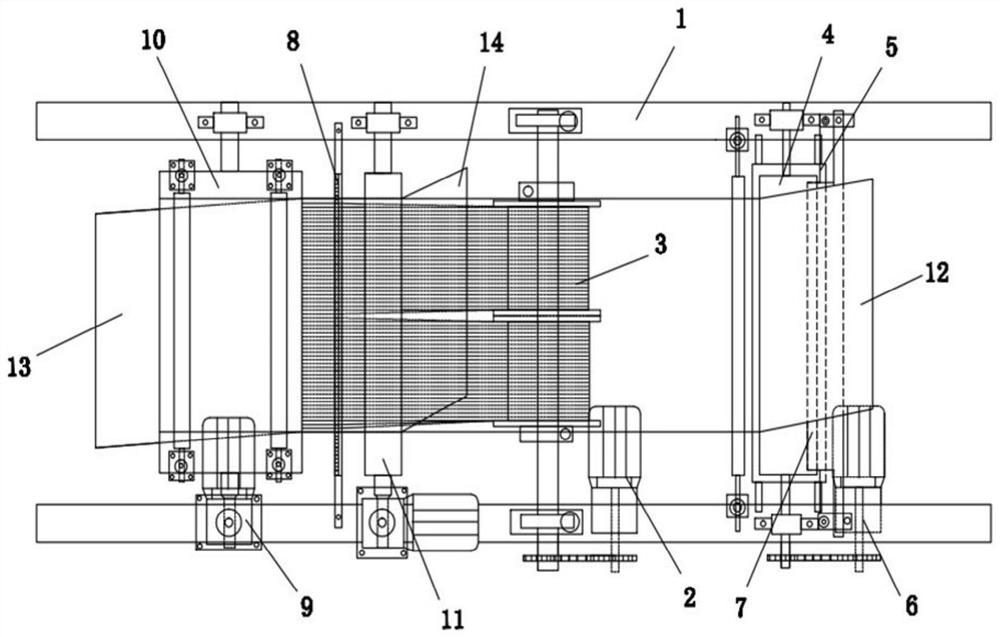

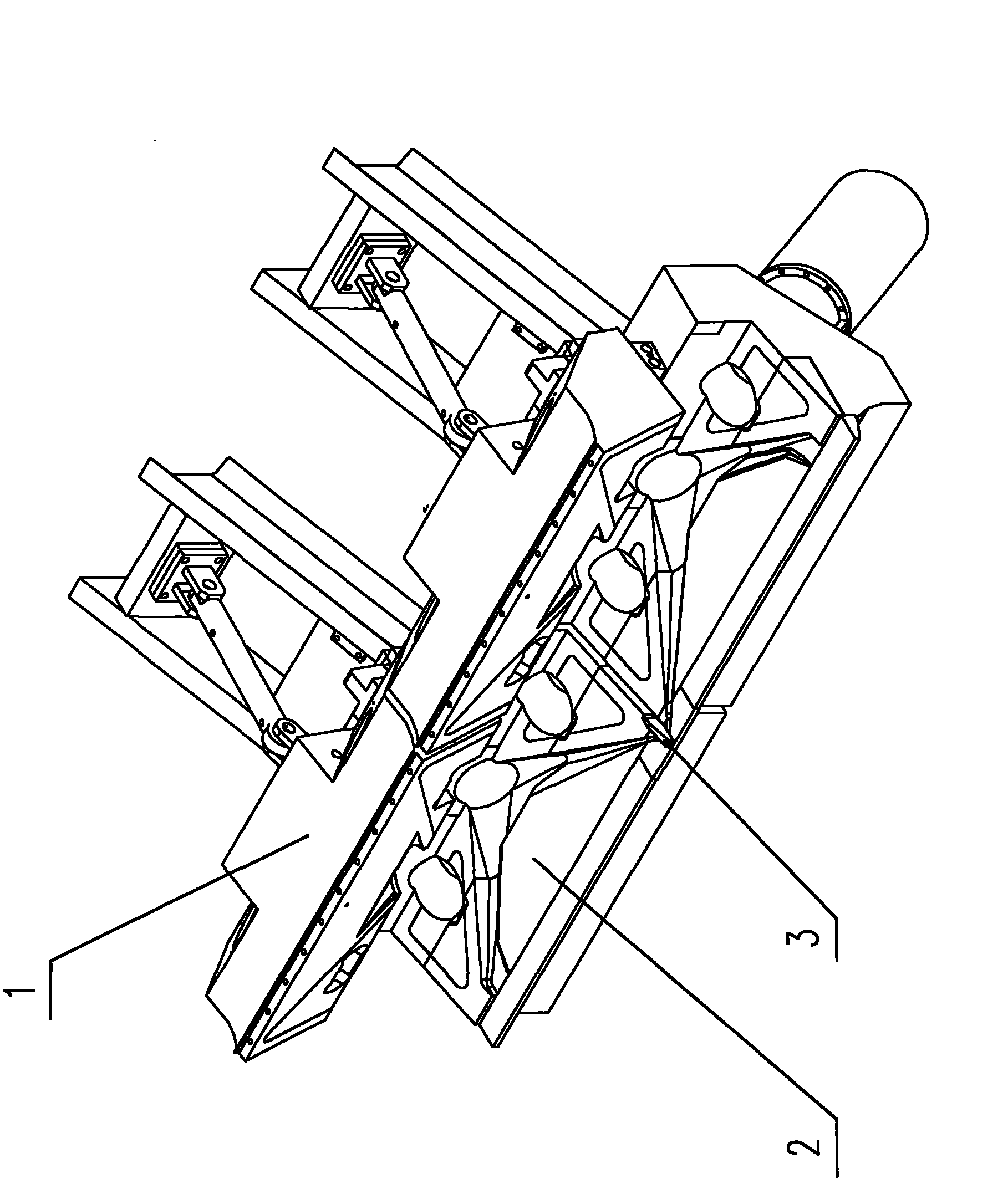

Production device of elasticity-adjustable gauze-fabric composite fabric

The invention relates to a production device of an elasticity-adjustable gauze-fabric composite fabric. The production device comprises a spandex yarn unwinding roller used for unwinding spandex yarns, a non-woven fabric unwinding roller used for unwinding non-woven fabric, a gauze unwinding roller used for unwinding gauze and a composite fabric winding roller used for winding the composite fabriccoming out of a drying drum. An anilox gluing roller is immersed into a glue tray, the non-woven fabric unwinding roller is arranged at a feeding port of the anilox gluing roller, and the anilox gluing roller uniformly transfers glue in the glue tray to coat the surface of passing non-woven fabric with the glue; a yarn dividing needle plate is arranged in the discharging conveying direction of the spandex yarn unwinding roller, and unwound spandex yarns are evenly separated and then compounded on the non-woven fabric glue surface coated with the glue; and the gauze unwinding roller is arranged at the front end of a feeding port of the drying drum, and the drying drum is used for compounding entered gauze and the non-woven fabric glue surface with spandex yarns to form the elasticity-adjustable gauze-fabric composite fabric. The composite fabric with excellent stability in elasticity and composite firmness is produced, and thus the requirements of different people are met.

Owner:SUZHOU MEDSPORT PROD

Organic photoelectric detector based on mixed hole transport layer and preparation method of organic photoelectric detector

ActiveCN110504368AReduce defectsIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsCharge carrier

The invention discloses an organic photoelectric detector based on a mixed hole transport layer. The organic photoelectric detector comprises a substrate, a conductive cathode, an electron transfer layer, an optical activity layer, a hole transport layer and a metal anode which are sequentially arranged from bottom to top, wherein the hole transport layer is formed by mixing MoO3 and chitosan andcarrying out vacuum evaporation; and the mass ratio of MoO3 to chitosan is 1: (0.03-0.2). The invention discloses a preparation method of the detector; the chitosan is doped in the MoO3 hole transportlayer, the migration rate of a hole can be filled while the hole transport layer and the optical activity layer are relatively large in contact area, the composite loss of the hole in the transport process is reduced, the hole can be more effectively transported, the carrier recombination rate is reduced, the dark current is reduced while the photocurrent is increased, and the overall performanceof the device is finally improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

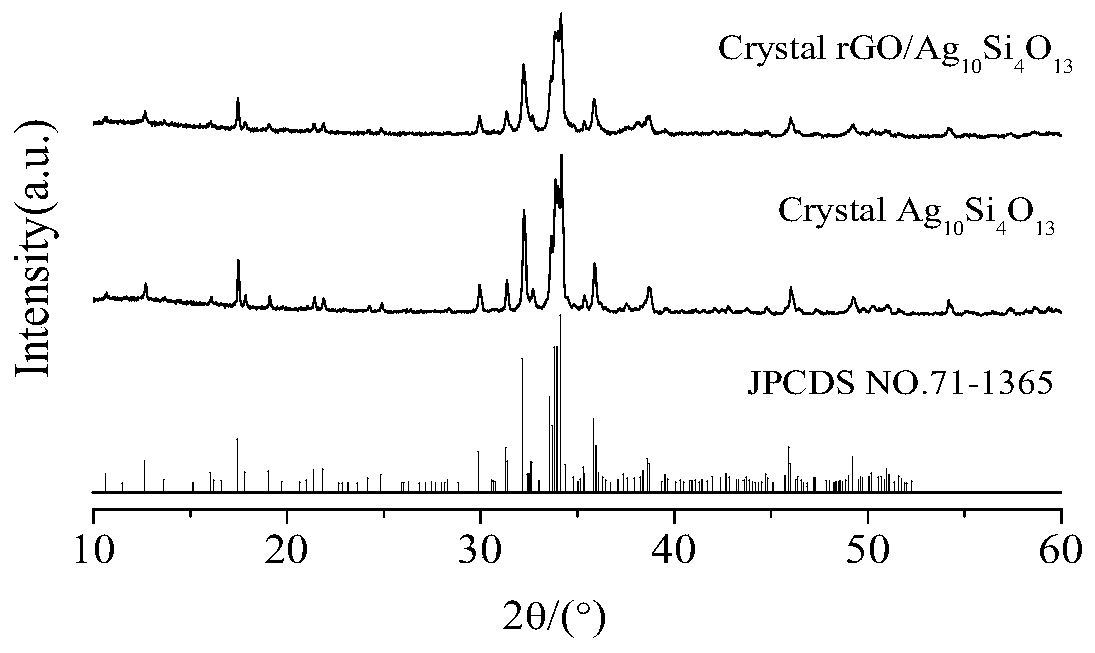

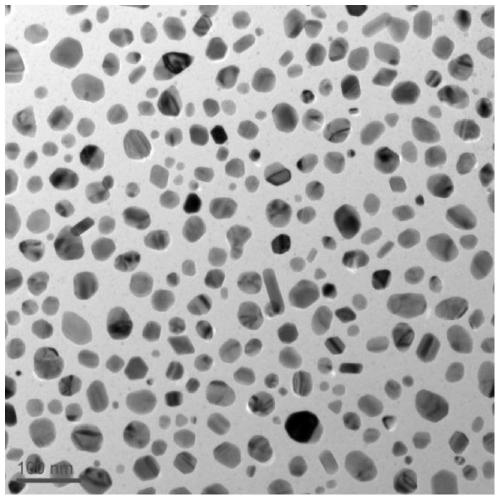

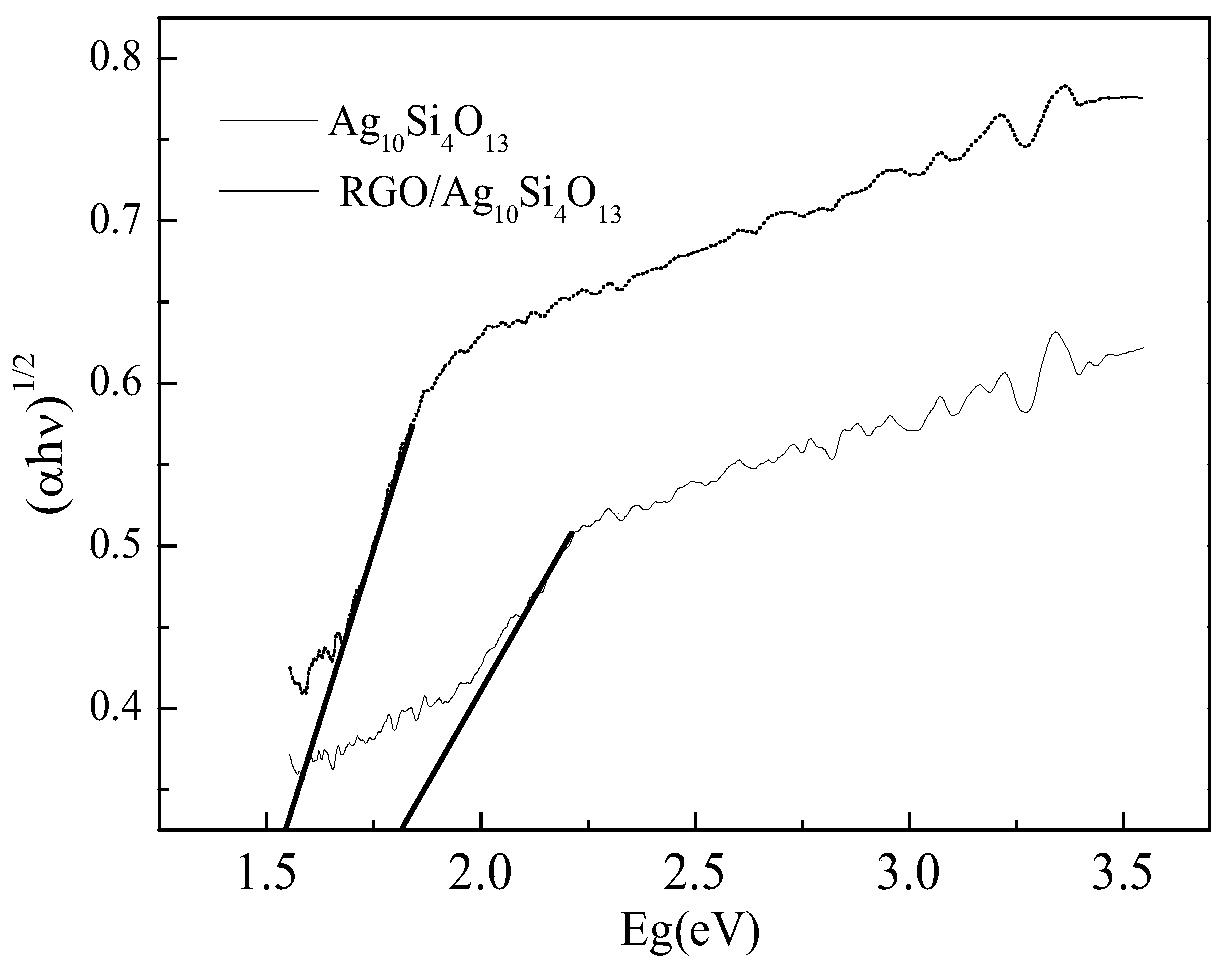

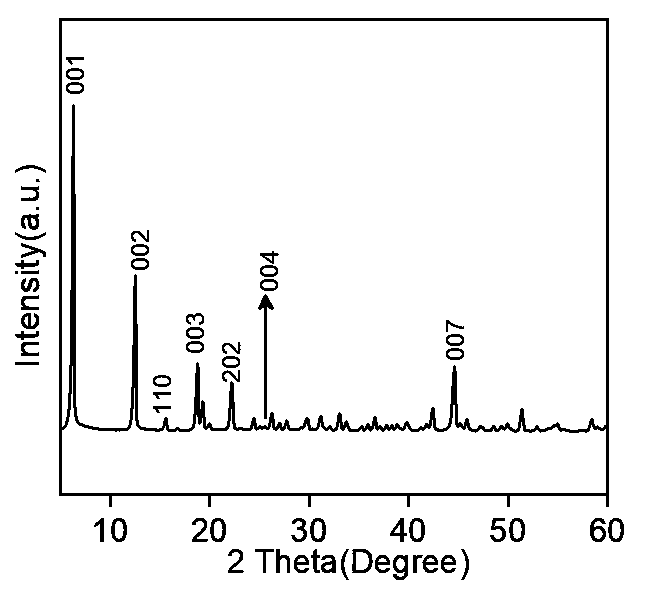

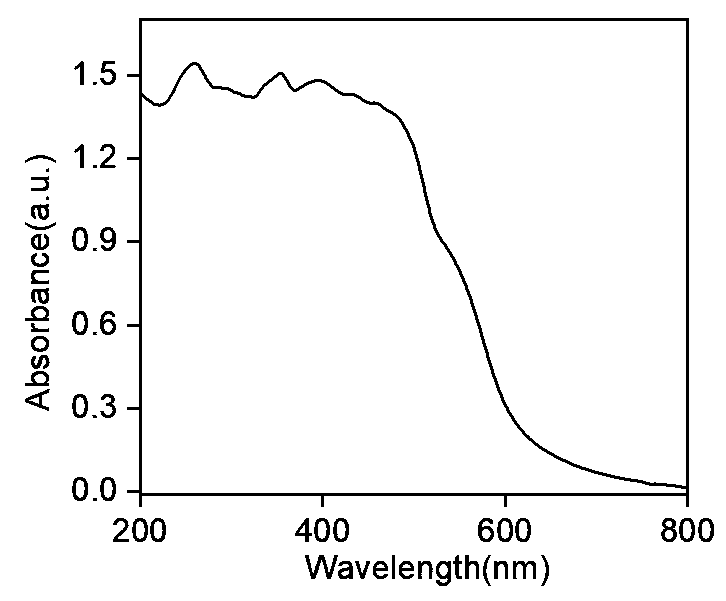

rGO/silver silicate composite and preparation method and application thereof

InactiveCN109794238AHinder mutual contactAvoid reunionMaterial nanotechnologyWater/sewage treatment by irradiationPhotocatalytic degradationGrain distribution

The invention provides an rGO / silver silicate composite and a preparation method and application thereof, and belongs to the technical field of photocatalytic materials. By the combination of rGO andAg10Si4O13, a composite photocatalyst with smaller particle size (about 25 nm) and more uniform grain distribution is successfully prepared. At the same time, because of the excellent conductivity ofrGO, rGO can rapidly transfer photo-generated carriers produced by Ag10Si4O13 to the surface after being combined with Ag10Si4O13; the combination problem of the photo-generated carriers can be overcome, the photocatalytic efficiency is improved, the photo-corrosion problem caused by the enrichment of photo-generated electrons on the surface of Ag10Si4O13 can be avoided, and the stability of the Ag10Si4O13 material is improved. The material can be well applied to photocatalytic degradation of pollutants.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

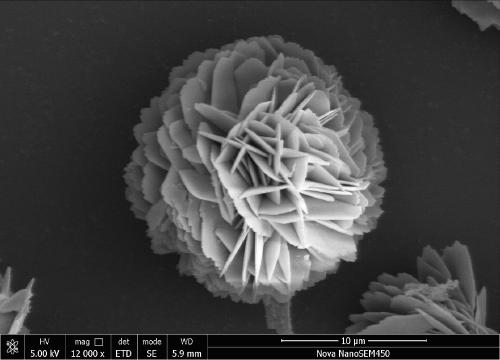

Petal-shaped perylenetetracarboxylic acid zinc supramolecular assembly photocatalytic material and preparation method thereof

ActiveCN111514934AInhibit aggregationImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsPeryleneAcrylate ester

The invention discloses a petal-shaped perylenetetracarboxylic acid zinc supramolecular assembly photocatalytic material and a preparation method thereof. According to the method, the perylene material is regularly arranged in the skeleton of the supramolecular assembly, the problem of high photogenerated charge recombination rate caused by molecular aggregation of the perylene material is solved,the method does not need to perform complex pretreatment work on the perylene material, and the method is simple and convenient to operate, mild in reaction condition, low in production cost and capable of realizing large-scale preparation. The petal-shaped perylenetetracarboxylic acid zinc supramolecular assembly photocatalytic material synthesized by the method can be used for degrading organicpollutants and catalyzing polymerization of acrylate monomers by utilizing 200-1200nm photocatalysis, and has huge potential in the aspects of environmental treatment and energy utilization.

Owner:SICHUAN UNIV

Zinc-alluminium-based wear-resistant alloy and production thereof

InactiveCN100400692CImprove wear resistanceImprove room temperature strengthChemical compositionWear resistant

The invention is about the wearing allumen material and its preparation. The material based on the allumen with the Si, tellurium or lanthanum. Anthesis Si is distributed in the allumen uniformly. The micromorphic of the Si phase is the nodular cracked polycrystal. The weight content of the composition is Al 40-50%, tellurium or lanthanum 0.02-0.05%, Si 1.0-3.0%, the residue is Zn; the hardness of the alloy in the room temperature is HB130-150. The alloy needn't the applied ceramic intensify particle.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

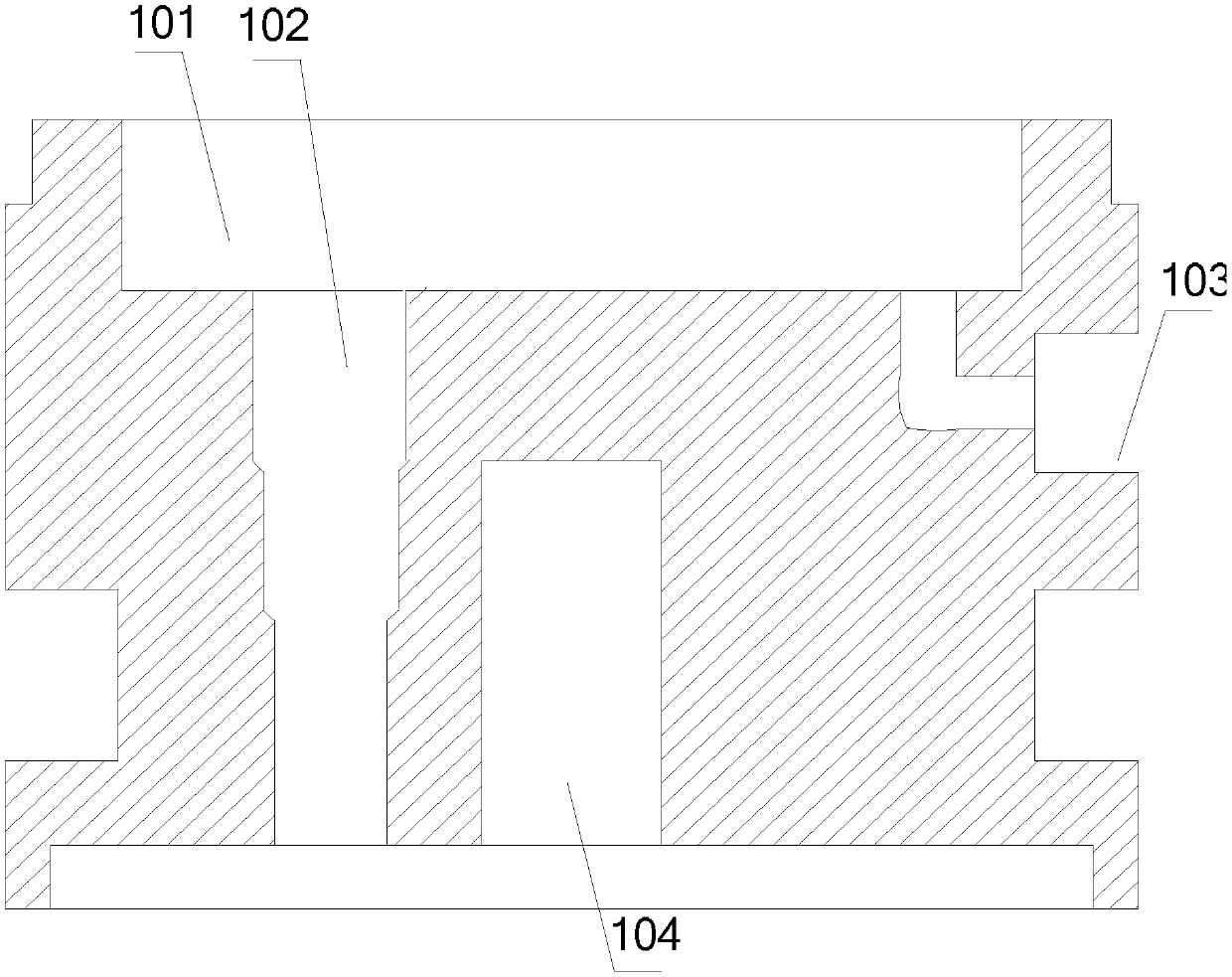

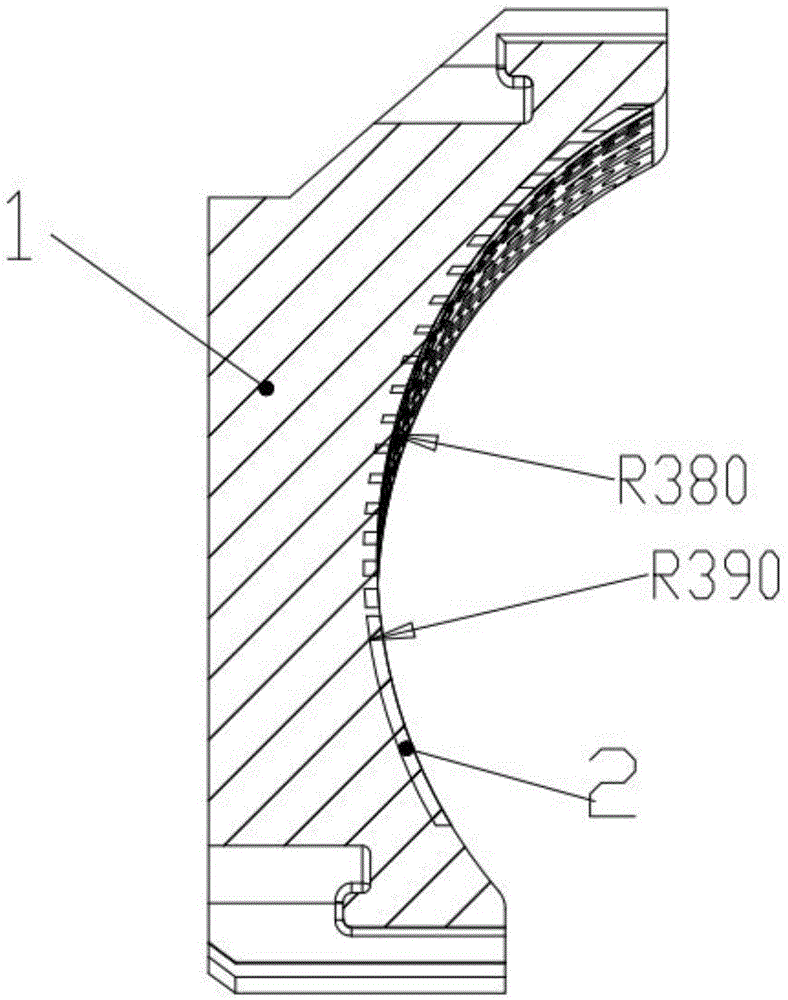

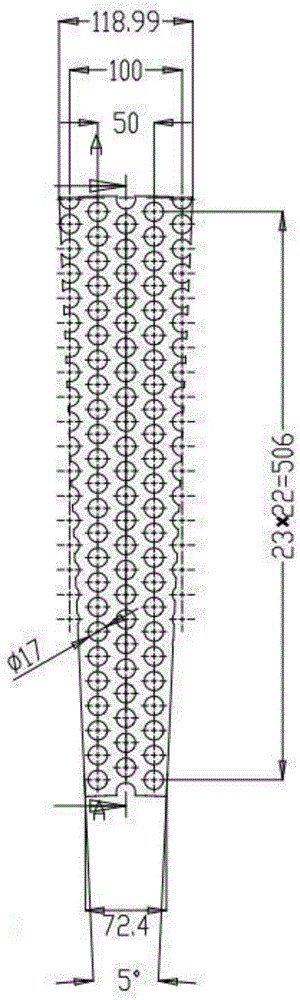

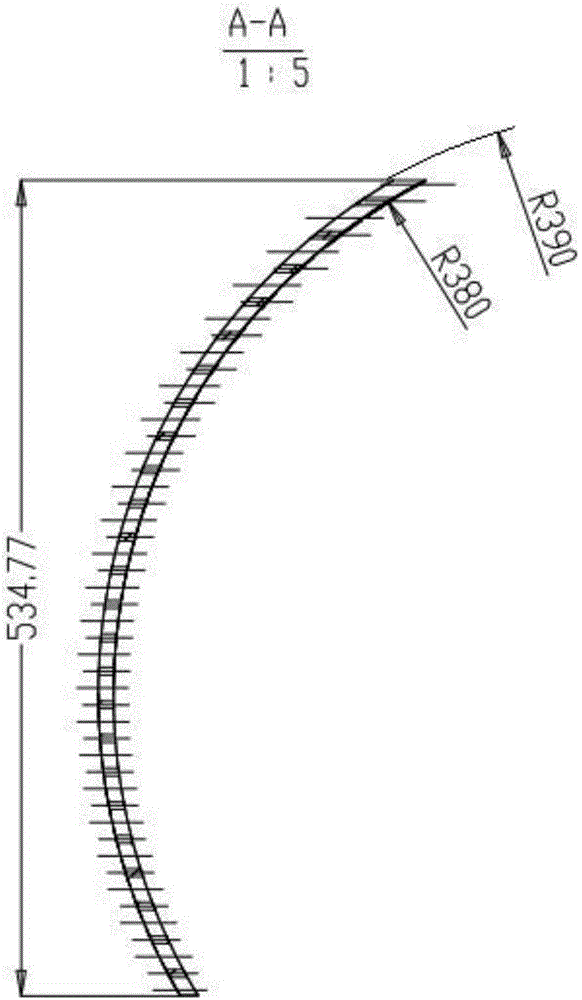

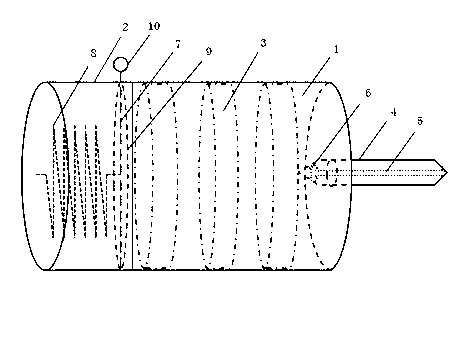

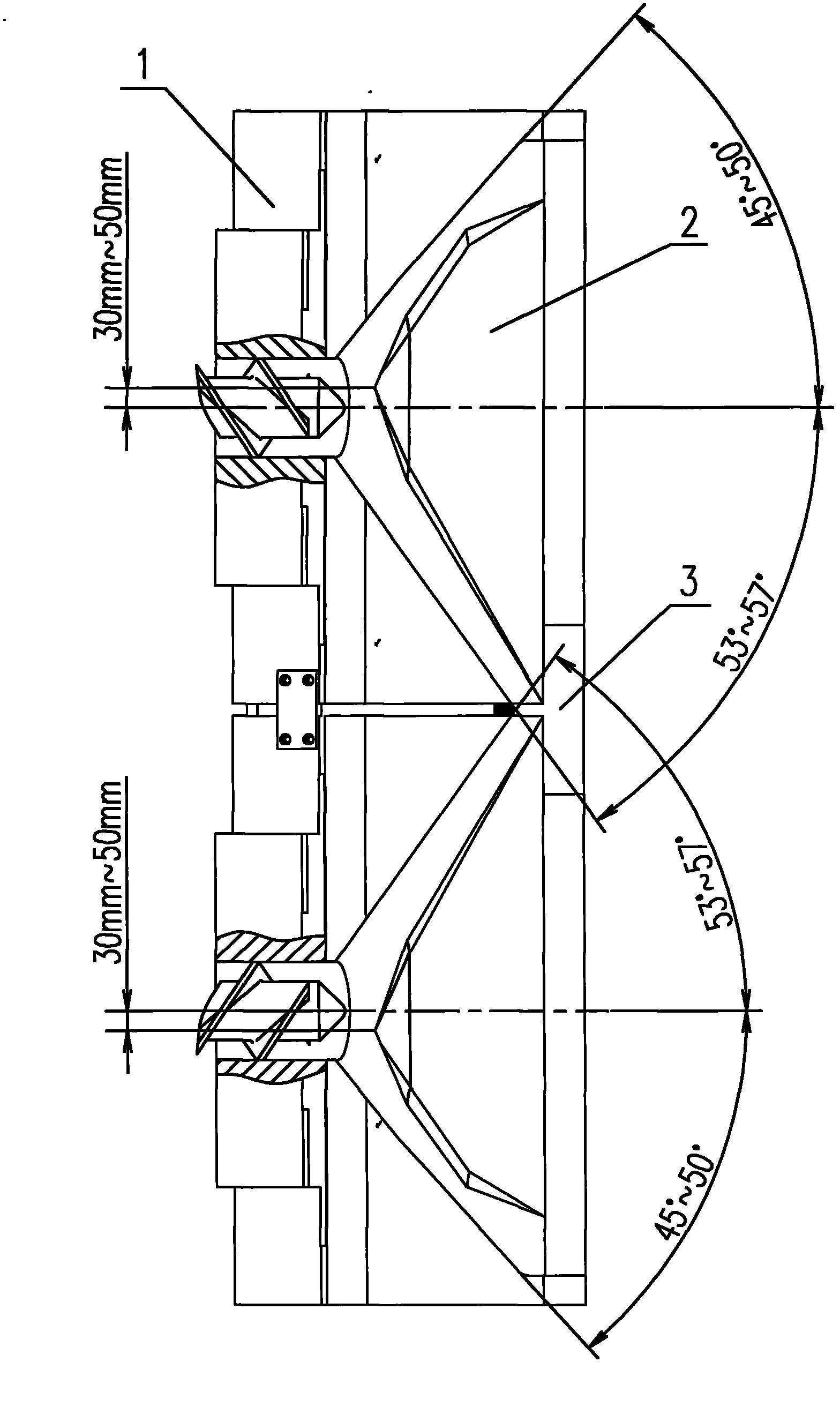

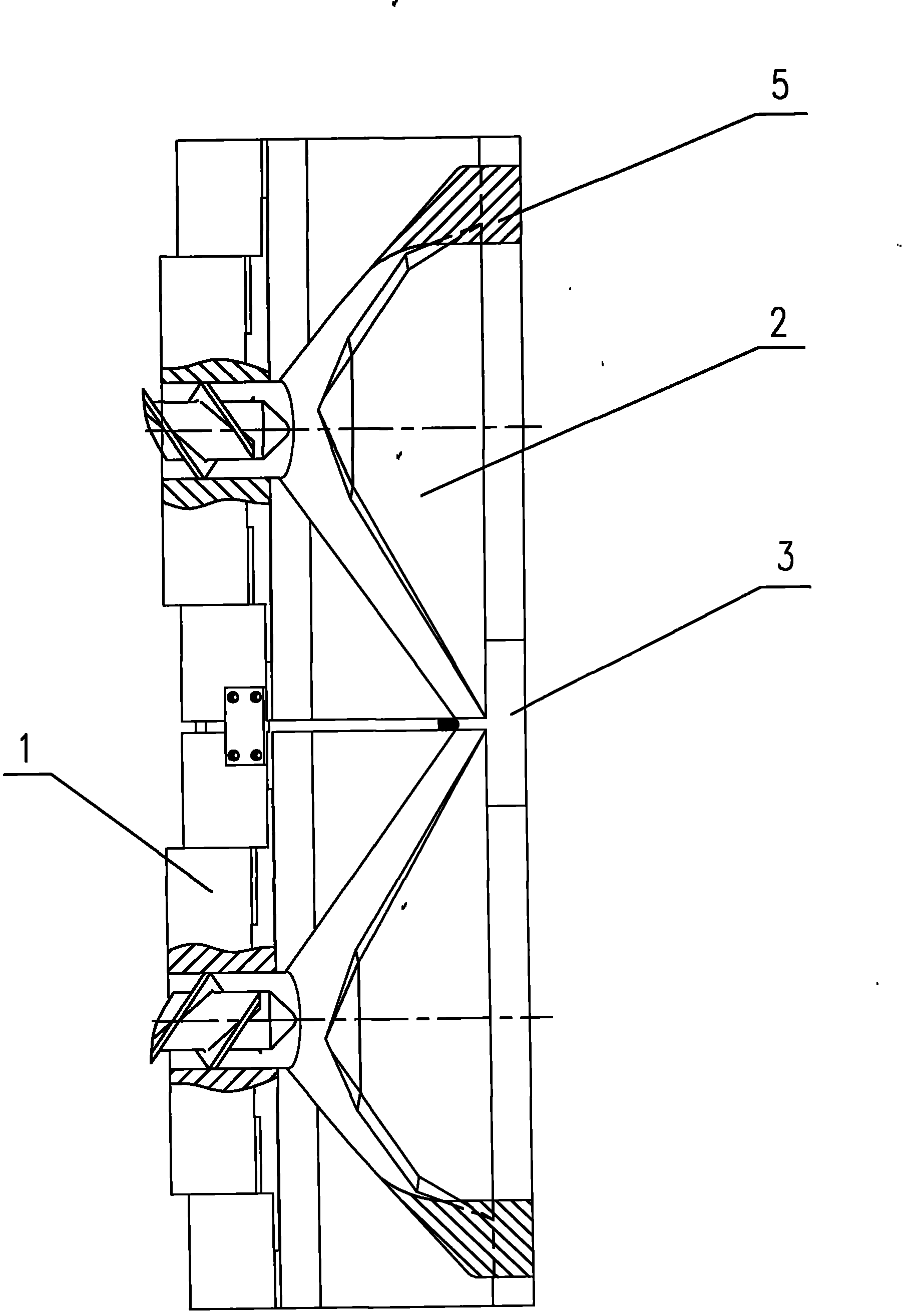

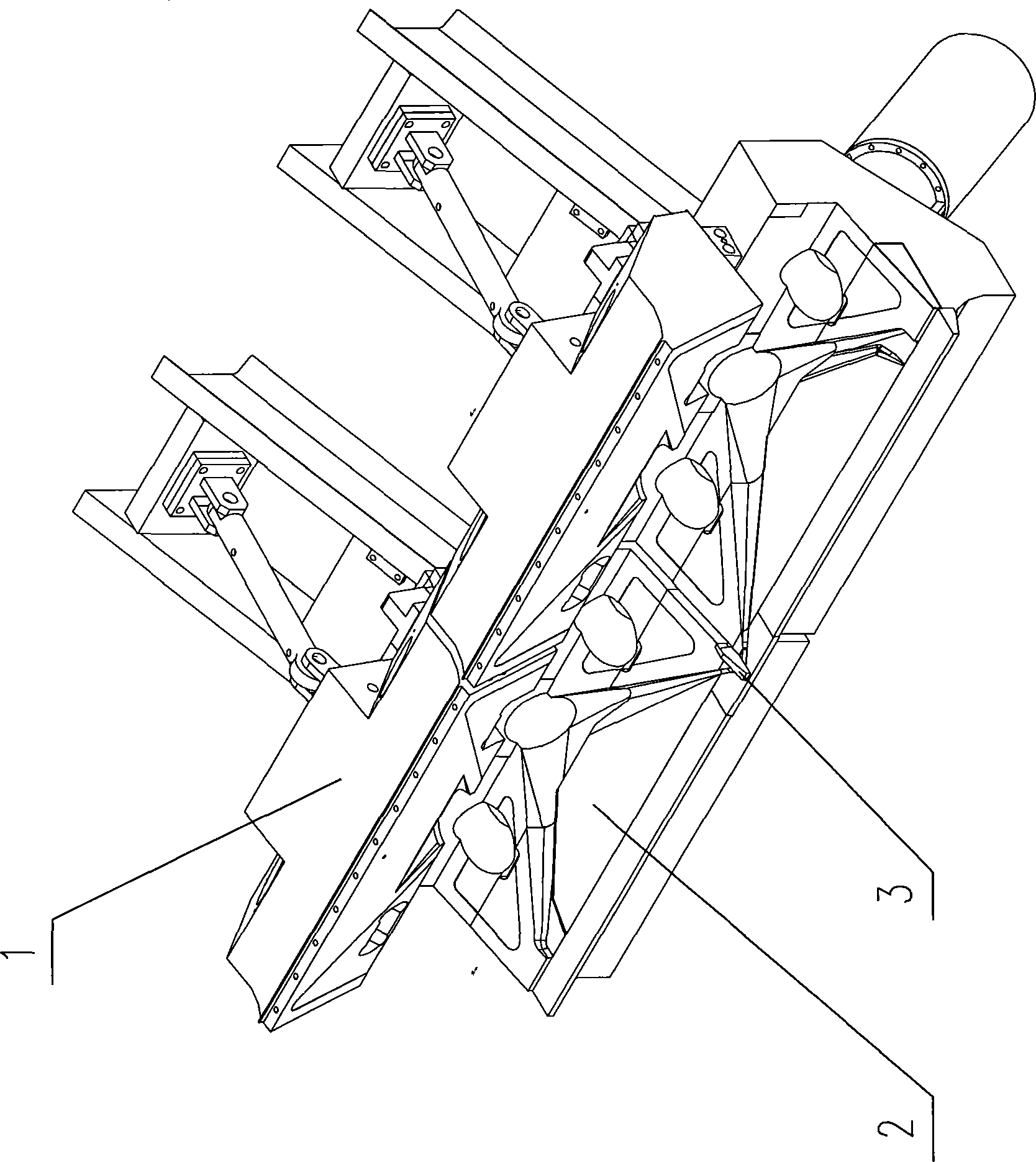

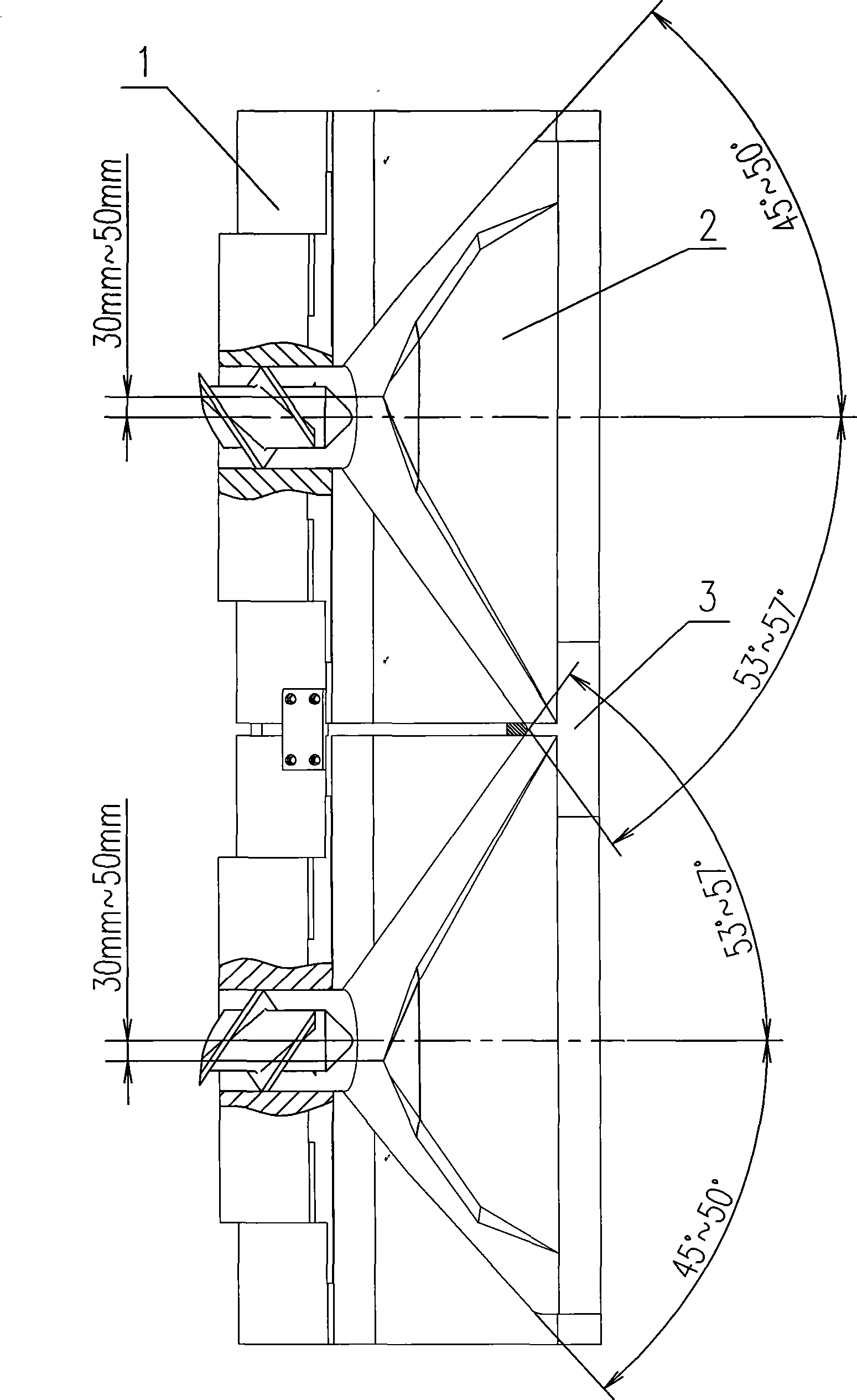

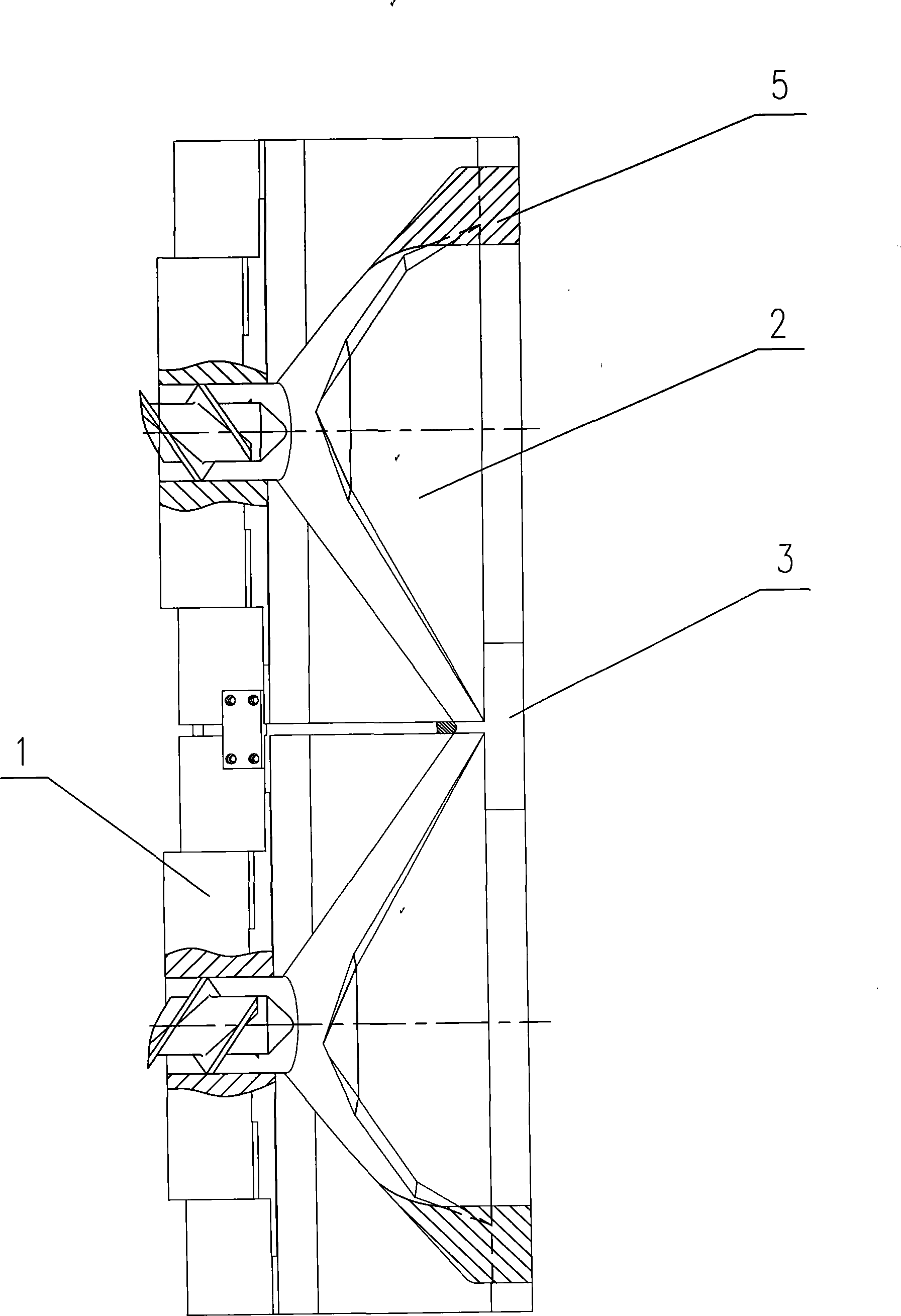

Unsymmetrical compound machine heads of passageway of wide rubber sheet extruder

The invention discloses unsymmetrical compound machine heads of a passageway of a wide rubber sheet extruder, comprising a plurality of extruding machine heads arranged in parallel, wherein a crossing part of passageway chambers between the adjacent extruding machine heads is connected by a mixer or a material stream divider; the passageway chamber of the outermost side extruding machine head uses an unsymmetrical structure; and passageway chambers of the middle extruding machine heads use a symmetrical structure. The unsymmetrical structure of the passageway chamber is that the top part of the passageway chamber deviates from an extruding central line to the outside; and the angle between an opening direction of the passageway in the passageway chamber and the extruding central line is greater than the angle between the opening direction of the outside passageway and the extruding central line. The extruding machine head in the invention uses the unsymmetrical passageway structure so that two or a plurality of passageways are extruded in parallel; the width scale of the rubber sheet is skillfully enlarged; the maximal yield is improved; the manufacturing cost and the processing difficulty are decreased; and the compound strength and the rubber sheet quality are guaranteed under enough pressure and space.

Owner:CHINA CHEM GUILIN ENG

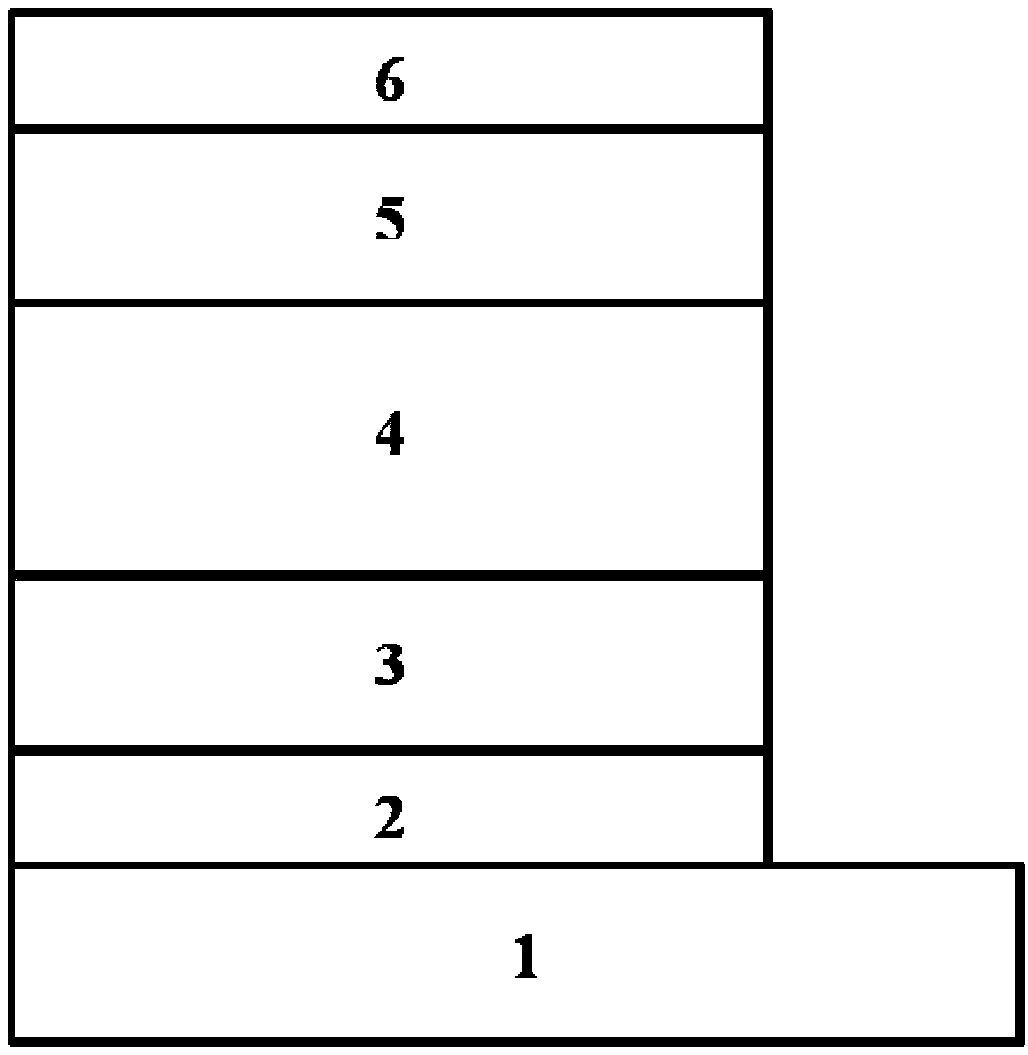

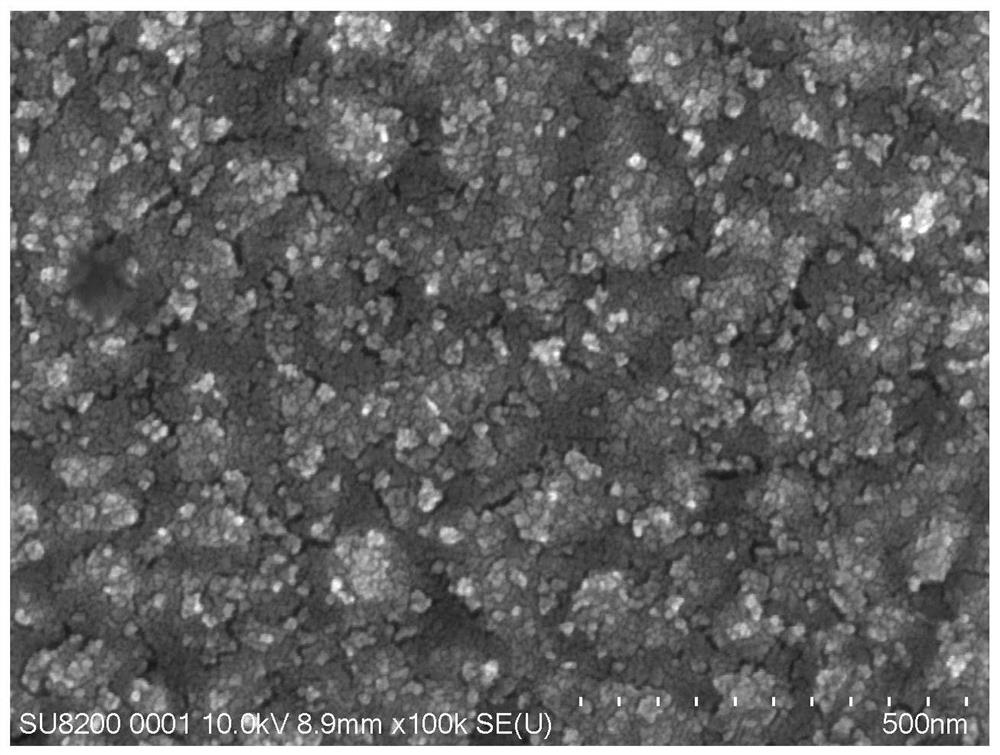

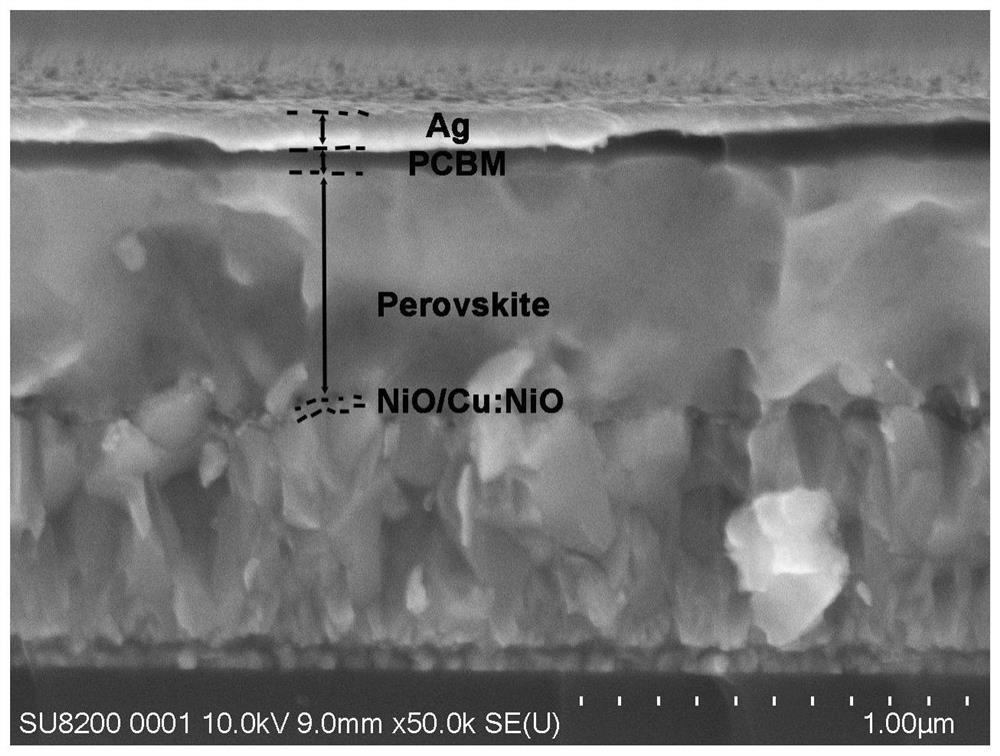

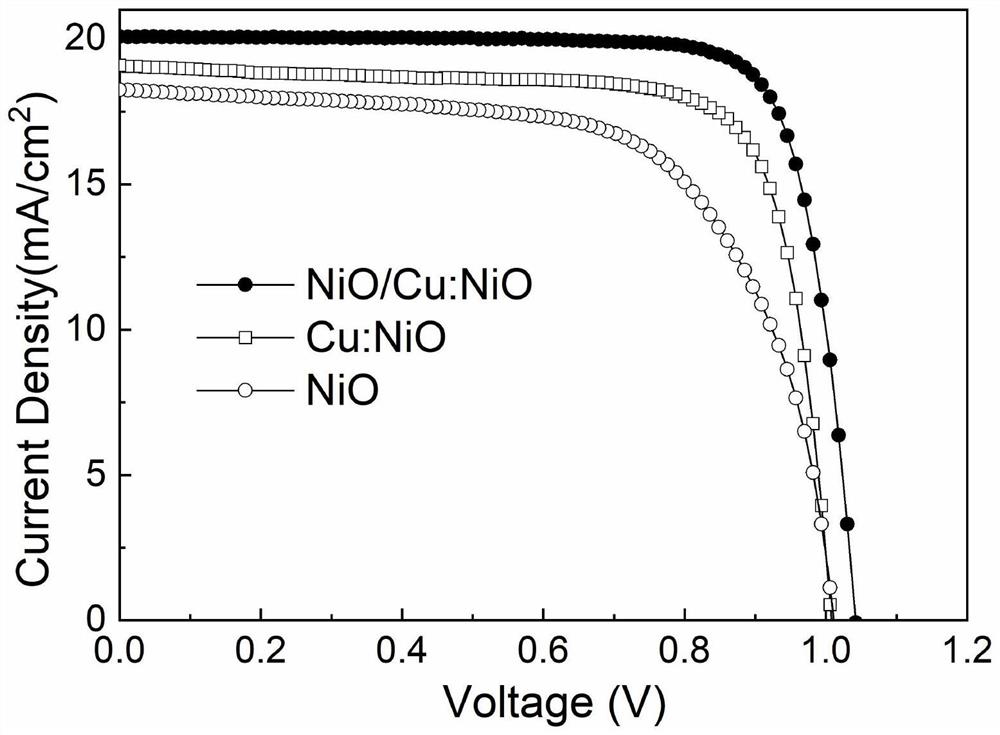

Homojunction charge transfer film for perovskite solar cell

PendingCN113161488AEasy to transportReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrical battery

The invention provides a homojunction charge transfer film for the perovskite solar cell. The film is applied to the perovskite solar cell, and the photoelectric property of a device can be remarkably improved. Charge transport materials with different impurity concentrations are deposited on a substrate layer by layer by adopting a spin coating method, a spraying method or an atomic layer deposition method and the like, and a built-in electric field beneficial to carrier transport can be generated in the charge transport film by regulating and controlling the impurity concentrations, so that separation and transport of carriers on a perovskite / charge transport film interface are accelerated, and the performance of the perovskite cell device is improved. Compared with a charge transport film with a traditional structure for a perovskite battery, the film has the advantages that a built-in electric field beneficial to carrier transport can be generated in the film, so that interface carrier recombination is reduced, and the battery performance is improved.

Owner:徐州革锐能源科技有限公司

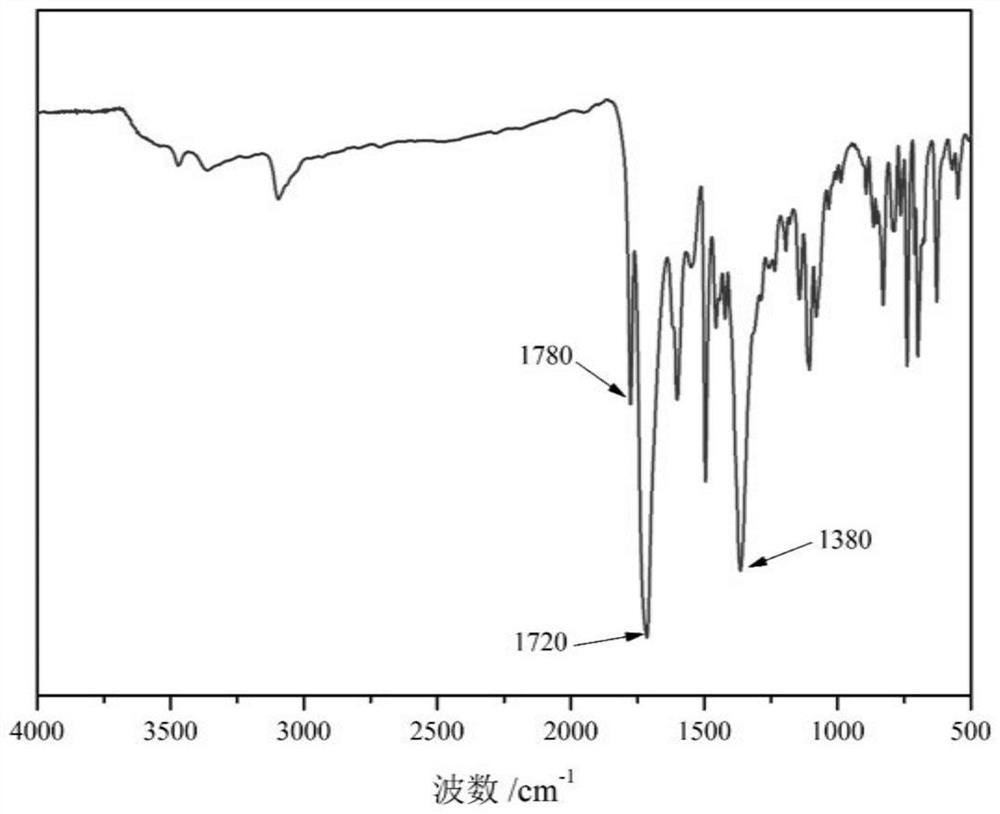

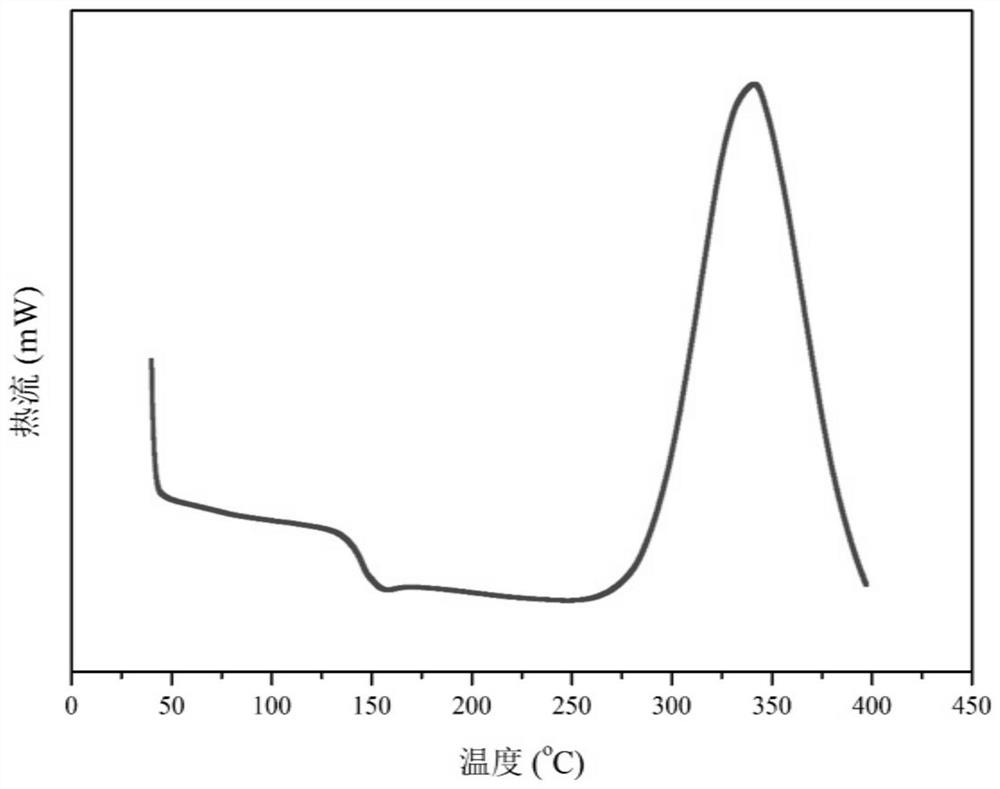

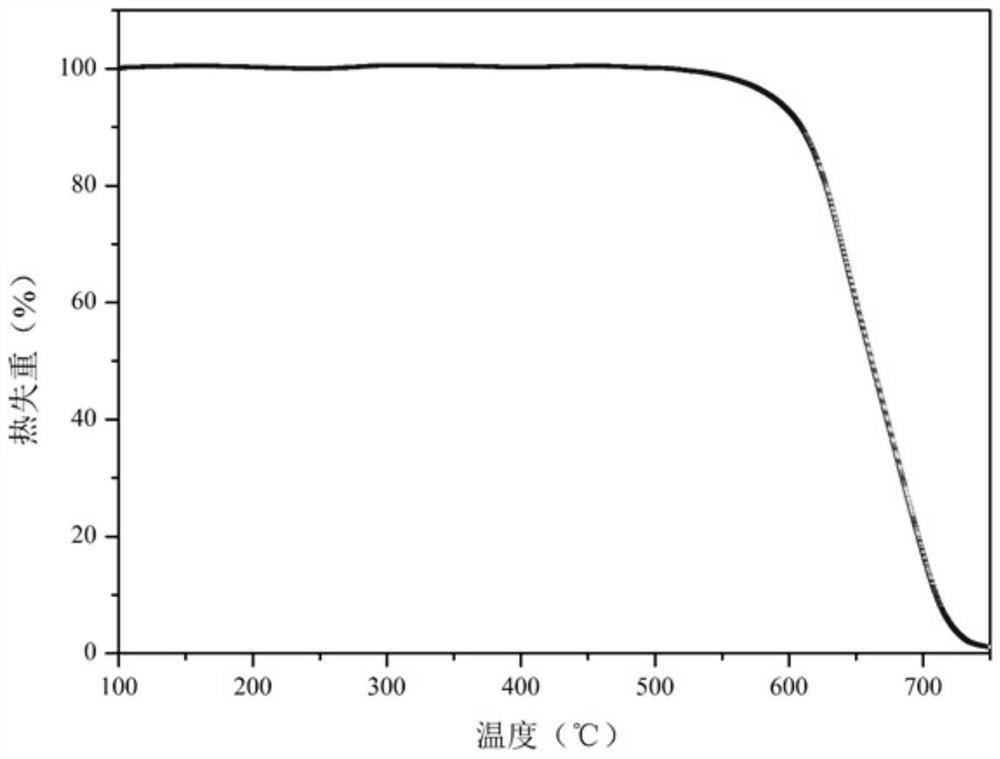

Low-viscosity thermosetting polyimide resin as well as preparation method and application thereof

The invention relates to low-viscosity thermosetting polyimide resin as well as a preparation method and application thereof, and belongs to the technical field of high polymer materials. The technical problems that in the prior art, thermosetting polyimide resin is large in viscosity, poor in manufacturability, limited in application and the like are solved. The structural formula of the low-viscosity thermosetting polyimide resin is shown as a formula I in the specification. The thermosetting polyimide resin has the advantage of low melt viscosity, and can be well combined with reinforcing fibers. Meanwhile, the thermosetting polyimide resin has good heat resistance and has a wide application prospect in the field of high-temperature-resistant fiber composite materials. The thermosetting polyimide resin disclosed by the invention is reasonable in synthetic route, simple in process and easily available in raw materials, and has important popularization and application values.

Owner:长春长光宇航复合材料有限公司

Strongly basic ternary composite metal-graphene-ion exchange resin material and preparation method thereof

The invention relates to a strong-basicity ternary composite metal-graphene-ion exchange resin material and a preparing method thereof to mainly solve the problems that in the prior art, strong-basicity ion exchange resin is poor in heat resistance and swelling resistance and likely to be decomposed and deactivated when heated in the application process. The strong-basicity ternary composite metal-graphene-ion exchange resin material is prepared from, by weight, 75-90% of polymerized monomers, 5-15% of copolymer monomers, 0.1-10% of graphene, 0.1-1% of metal particle components and 0.1-10% of an initiator. According to the technical scheme, the problems are well solved, and the strong-basicity ternary composite metal-graphene-ion exchange resin material can be used for industrial production of strong-basicity composite ion exchange resin materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Strong basic composite ion exchange resin material and preparation method thereof

ActiveCN104558360BImprove heat resistanceGood anti-swelling performanceAnion exchangersState of artIon exchange

The invention relates to a strongly basic composite ion exchange resin material and a preparation method thereof, which mainly solves the problems of poor heat resistance and poor swelling resistance of the strong basic ion exchange resin in the prior art. The present invention includes the following components by weight percentage: a) 75-90% polymerized monomer; b) 5-15% comonomer; c) 0.1-5% graphene; d) 0.1-10% The technical scheme of % initiator solves this problem well, and can be used in the industrial production of strongly basic composite ion exchange resin material.

Owner:CHINA PETROLEUM & CHEM CORP +1

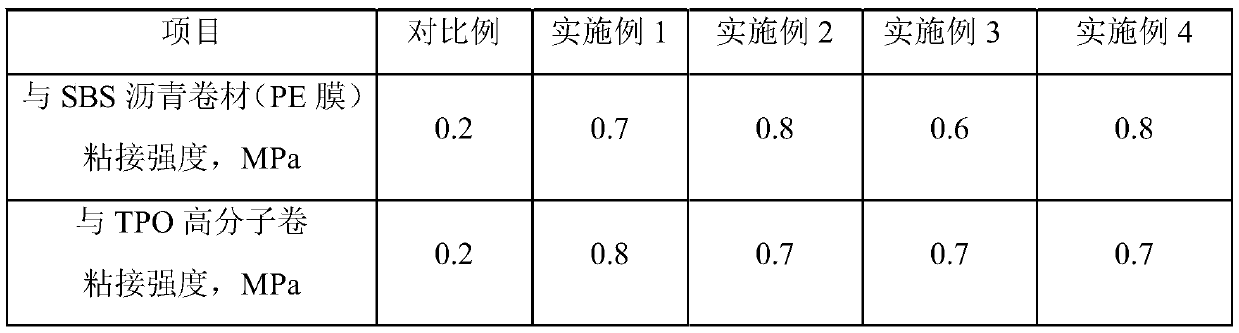

Two-component polyurethane waterproof coating containing non-polar polymer modified compound and preparation method thereof

ActiveCN107955516BImprove construction reliabilitySolve compound problemsPolyurea/polyurethane coatingsPolymer sciencePolymer modified

The invention discloses a two-component polyurethane waterproof coating containing a non-polar polymer modified compound and a preparation method of the two-component polyurethane waterproof coating.The two-component polyurethane waterproof coating is prepared from a component A and a component B, wherein the component A is a polyurethane prepolymer prepared from 3-15 parts by weight of isocyanate and 2-40 parts by weight of first polyol; the component B comprises 2-20 parts by weight of second polyol, 2-30 parts by weight of the compound subjected to epoxidation modification with a non-polarpolymer, 2-15 parts by weight of a chain extender and 0.1-2 parts by weight of a catalyst, and a main chain of the non-polar polymer contains multiple C=C double bonds. The polyurethane waterproof coating has good performance of adhesion with a bituminous waterproof coiled material and a polymer waterproof coiled material and is used for adhesion, composition or repair of the bituminous waterproof coiled material or the polymer waterproof coiled material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

ActiveCN102372812BSolve compound problemsIn situ functionalizationAnion exchangersPolymer scienceIon exchange

The invention relates to a macroporous strong alkaline carbon nanotube composite ion exchange resin and a preparation method thereof, and aims to solve problems of weak heat resistance and weak swelling resistance of an ion exchange resin in a prior art. The macroporous strong alkaline carbon nanotube composite ion exchange resin comprises the following components: (1) 40-65% of monomer; (2) 3-10% of copolymerization monomer; (3) 0.1-10% of nano material; and (4) 0.1-2% of initiator. The monomer is at least one selected from p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloroamyl) styrene and 4-(5-bromoamyl) styrene; the copolymerization monomer is at least one selected from EGDMA, dipropenyl benzene, divinyl phenyl methane and divinyl benzene; the nano material is at least one selected from multi-wall carbon nanotube, single arm carbon nanotube and fullerene of C60 or C70; the initiator is at least one selected from benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide and cumyl hydroperoxide. The invention also provides a preparation method of the macroporous strong alkaline carbon nanotube composite ion exchange resin. The above technical scheme well solves the problems and can be applied to industrial production of ethylene oxide catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

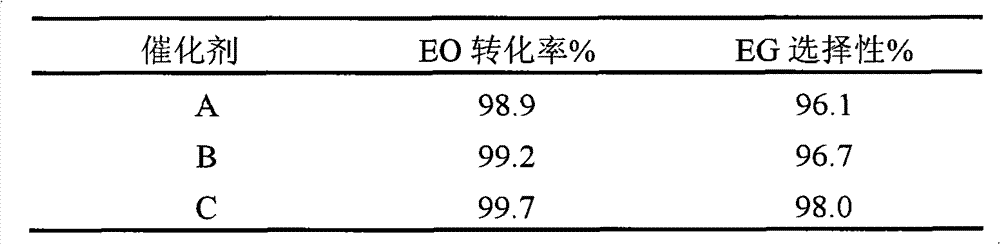

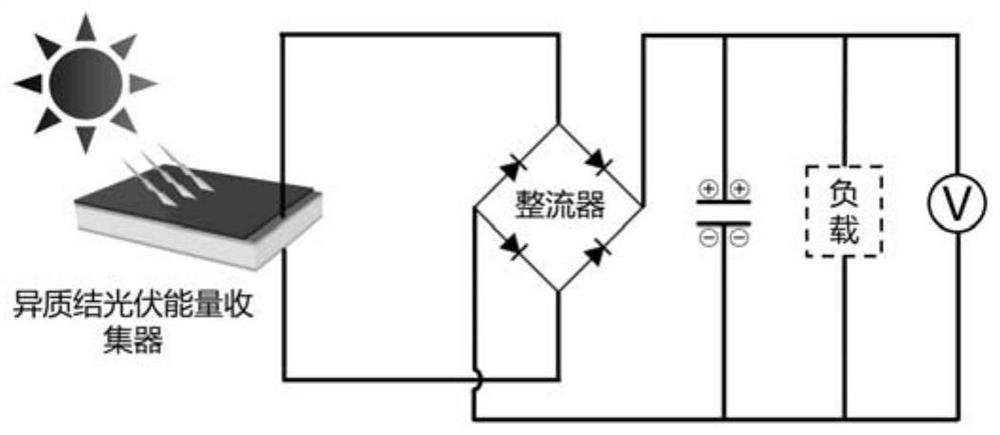

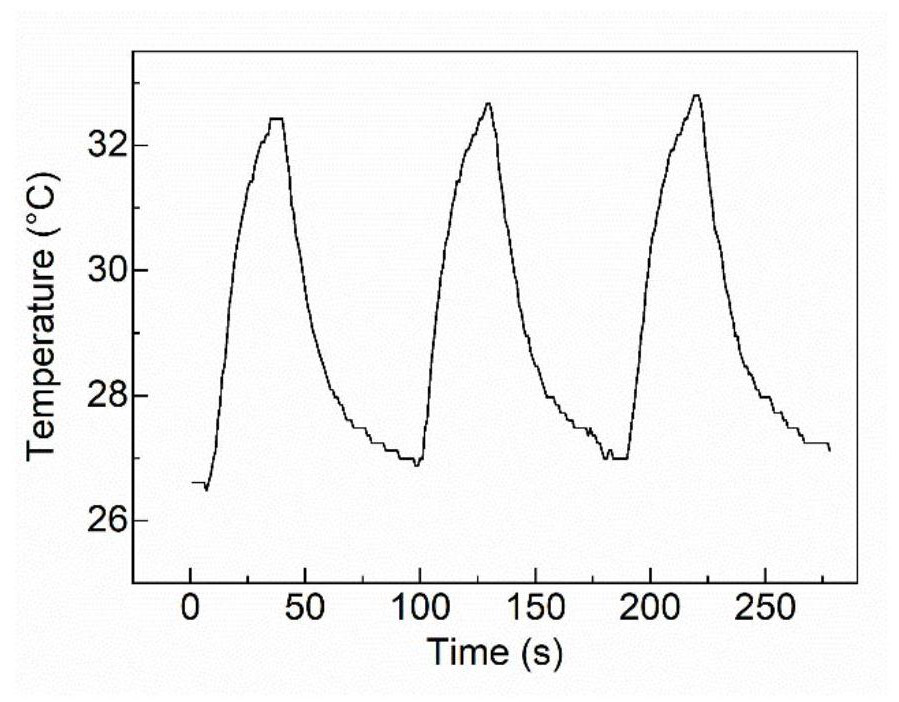

A kind of preparation method of photothermal-pyroelectric heterojunction photovoltaic energy harvester

ActiveCN112910379BSolve compound problemsEfficient use ofPrecision positioning equipmentPV power plantsEpoxyHeterojunction

The invention provides a photothermal-pyroelectric heterojunction photovoltaic energy collector and a preparation method thereof, belonging to the technical field of energy collection. The collector includes a photothermal area and a pyroelectric area; the photothermal area and the pyroelectric area are connected by epoxy resin; wherein, the pyroelectric area is composed of a pyroelectric material and an electrode layer, and the electrode The layers are coated on the upper and lower surfaces of the pyroelectric material to form a sandwich structure; the photothermal zone is a flexible film. The preparation method is as follows: adding an organic polymer to the photothermal material, mixing to obtain the photothermal material-organic polymer original slurry, using a casting method or a blade coating method to prepare a flexible film; coating an electrode on the pyroelectric material The upper and lower surfaces of the film obtain pyroelectric regions; epoxy resin is used to bond the flexible film and the pyroelectric regions to form the novel heterojunction photovoltaic energy collector based on the photothermal-pyroelectric synergistic effect. The collector has the advantages of low cost, simple process and no noise.

Owner:NANJING UNIV OF SCI & TECH

Producing and using methods of automobile body sheet metal stiffener film

InactiveCN106118568AImprove adhesionGuaranteed demandFilm/foil adhesivesSuperstructure subunitsEpoxySheet film

The invention provides a production method of a body sheet metal reinforcing film. The body sheet metal reinforcing film is added with epoxy resin at a mass percentage of 10% to 50% during production, and the body sheet metal reinforcing film is stamped Using laser die cutting device. The present invention also provides a method for using a body sheet metal reinforcement film, the body sheet metal reinforcement film is used after the body electrophoretic primer, and the body sheet metal reinforcement film is cured at 135-145°C for 15 ~25 minutes. Preferably, the vehicle body sheet metal reinforcement film is cured at 140° C. for 20 minutes during use. The present invention optimizes the proportion of epoxy resin in the base material and adjusts the dosage, thereby improving the adhesion of the sheet metal reinforcing film, being simple and convenient to operate, effectively ensuring customer needs, and reducing the operating cost of the enterprise.

Owner:江苏新长宜科技有限公司

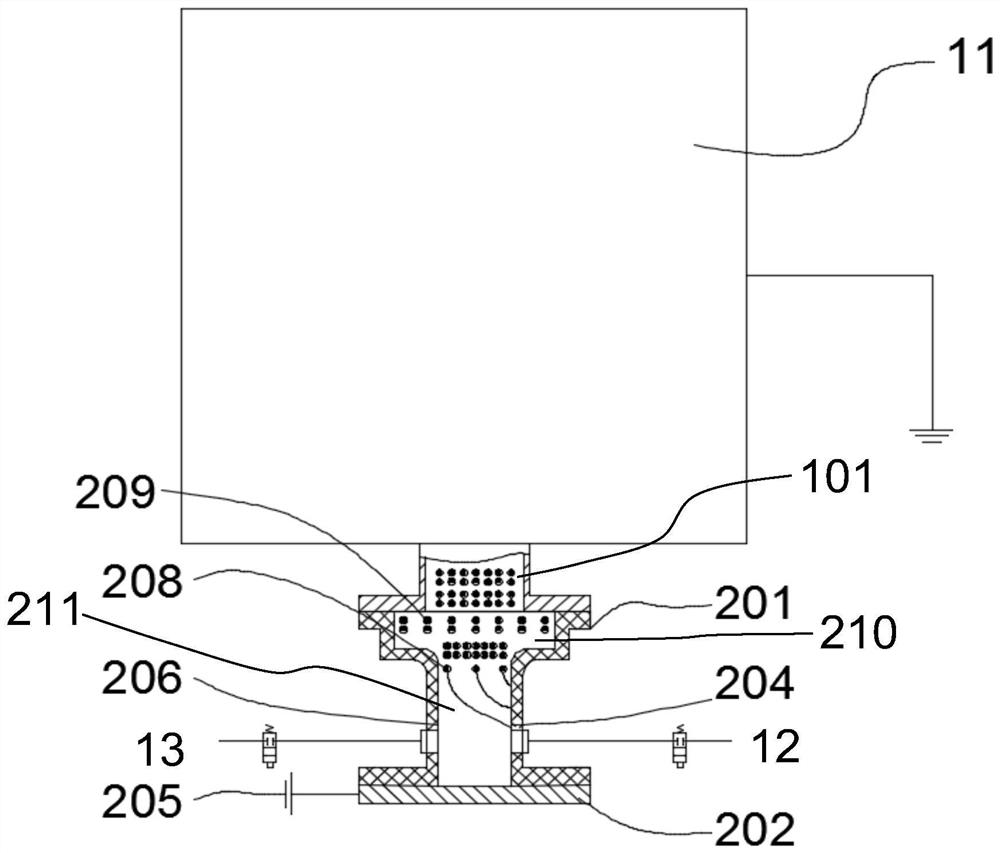

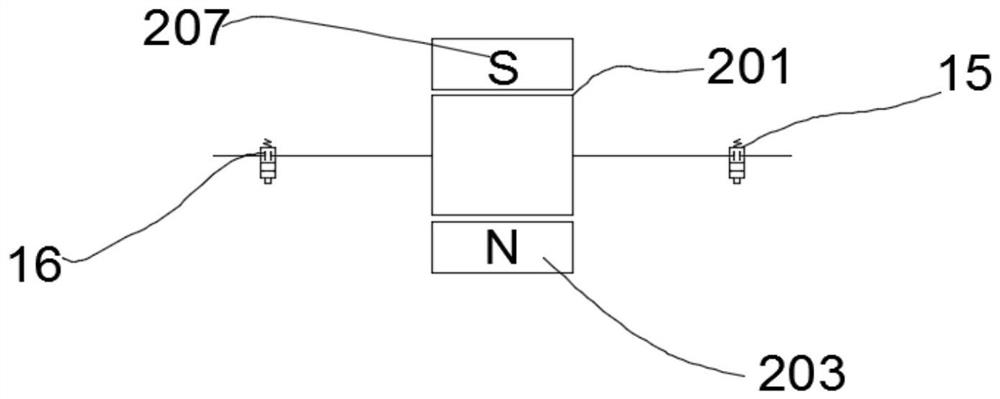

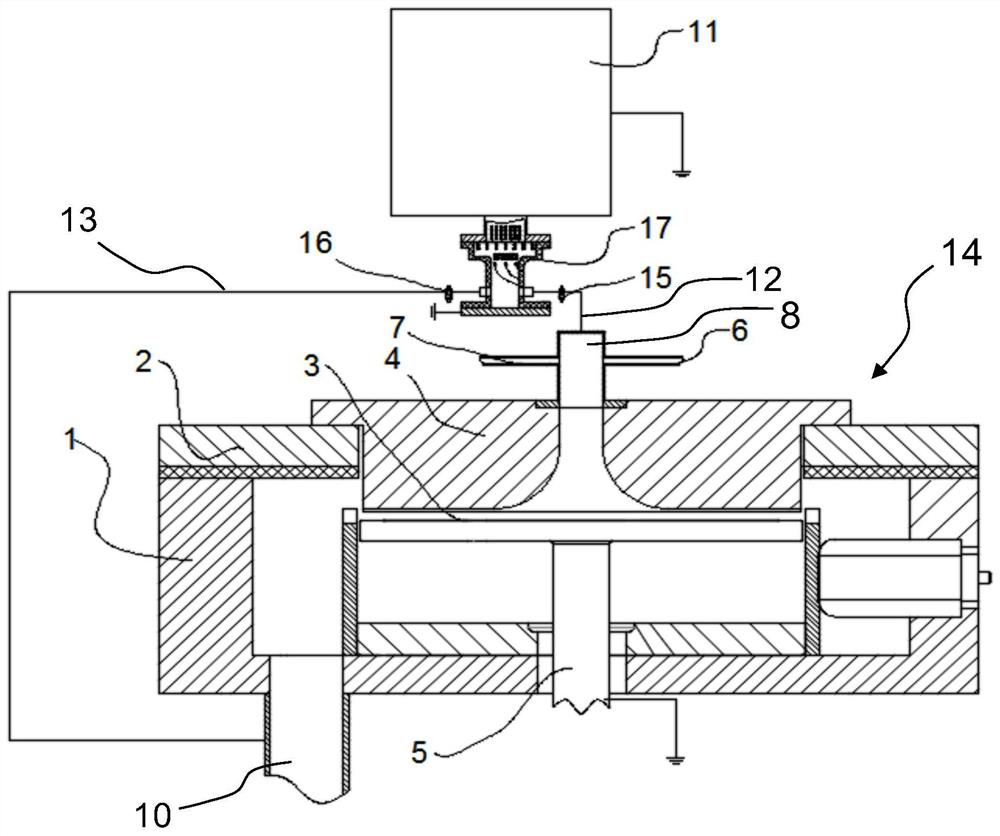

Device for separating positive and negative ions, film forming equipment and chamber cleaning method

ActiveCN109841471BSolve compound problemsIncrease profitElectric discharge tubesParticle physicsPlasma

The invention discloses a device for separating positive and negative ions, which is used to realize the separation of positive and negative ions in a plasma source. The opening and the second opening; the electric field generating component is used to generate an electric field with alternating directions, which can make the positive ions and negative ions move to the bottom of the insulating cavity alternately under the force of the electric field; the magnetic field generating component is used to make the negative ions move in the Luo The positive ions enter the first opening after being deflected under the action of the Lorentz force, or the positive ions enter the second opening after being deflected under the action of the Lorentz force. The invention can effectively avoid the recombination of positive and negative ions, and improve the cleaning effect and cleaning efficiency of film forming equipment. The invention also provides a film-forming device equipped with a device for separating positive and negative ions and a chamber cleaning method thereof.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

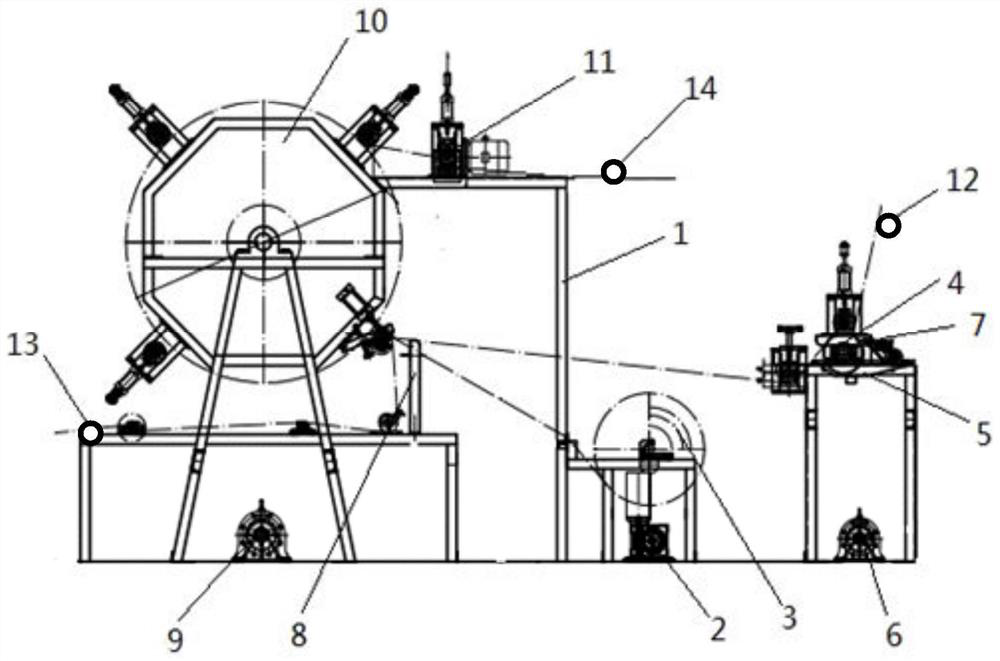

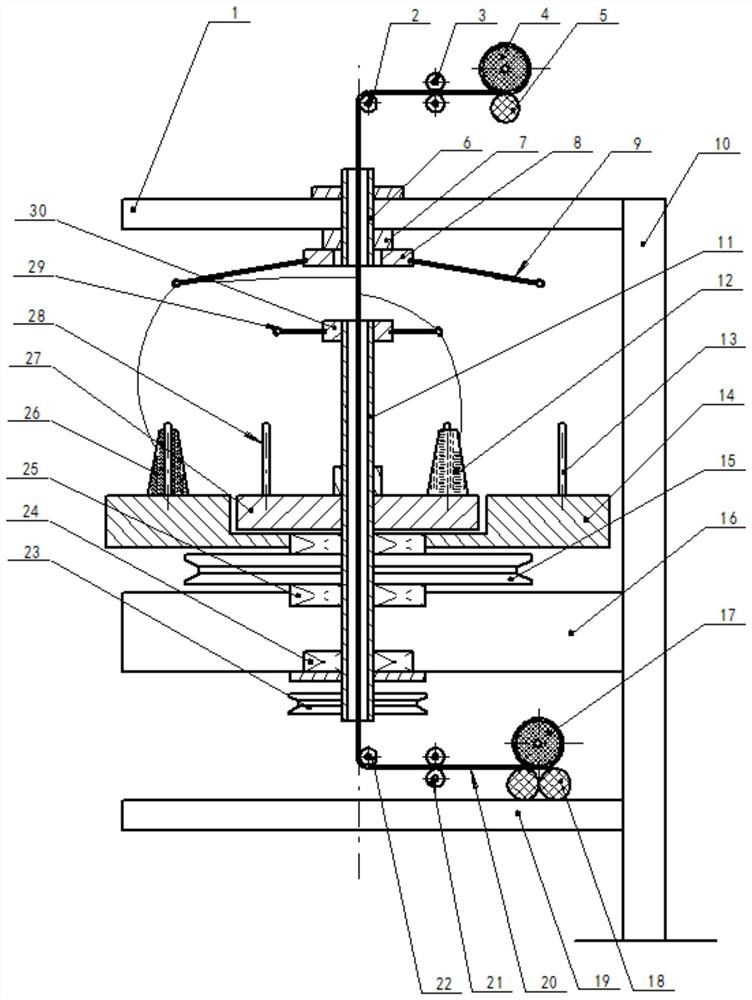

A multifunctional industrial yarn spinning machine

The invention relates to a multifunctional industrial spinning machine, which is composed of a frame, a yarn core feeding mechanism, a first wrapping mechanism, a second wrapping mechanism and a winding mechanism. The frame consists of a column, a lower beam, It consists of a middle beam and an upper beam, and the horizontal lower beam, middle beam and upper beam are fixed on the column at intervals, the yarn core feeding mechanism is installed on the lower beam, the first wrapping mechanism is installed on the middle beam, and the top of the middle beam is installed. The turntable part of the second wrapping mechanism is hoisted under the upper crossbeam, the yarn guide part of the second wrapping mechanism is installed, and the winding mechanism is installed on the upper end of the upper crossbeam. The yarn core of this spinning machine mainly uses thicker roving filaments such as basalt, metal fiber, and ceramic fiber or various multifilament materials. The weavable performance is improved by wrapping to obtain special-purpose industrial products, which are suitable for Composite yarns between various fiber filaments or between filaments and yarns.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Unsymmetrical compound machine heads of passageway of wide rubber sheet extruder

Owner:CHINA CHEM GUILIN ENG

An organic photodetector based on a hybrid hole transport layer and its preparation method

ActiveCN110504368BReduce defectsIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerPhotocurrent

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

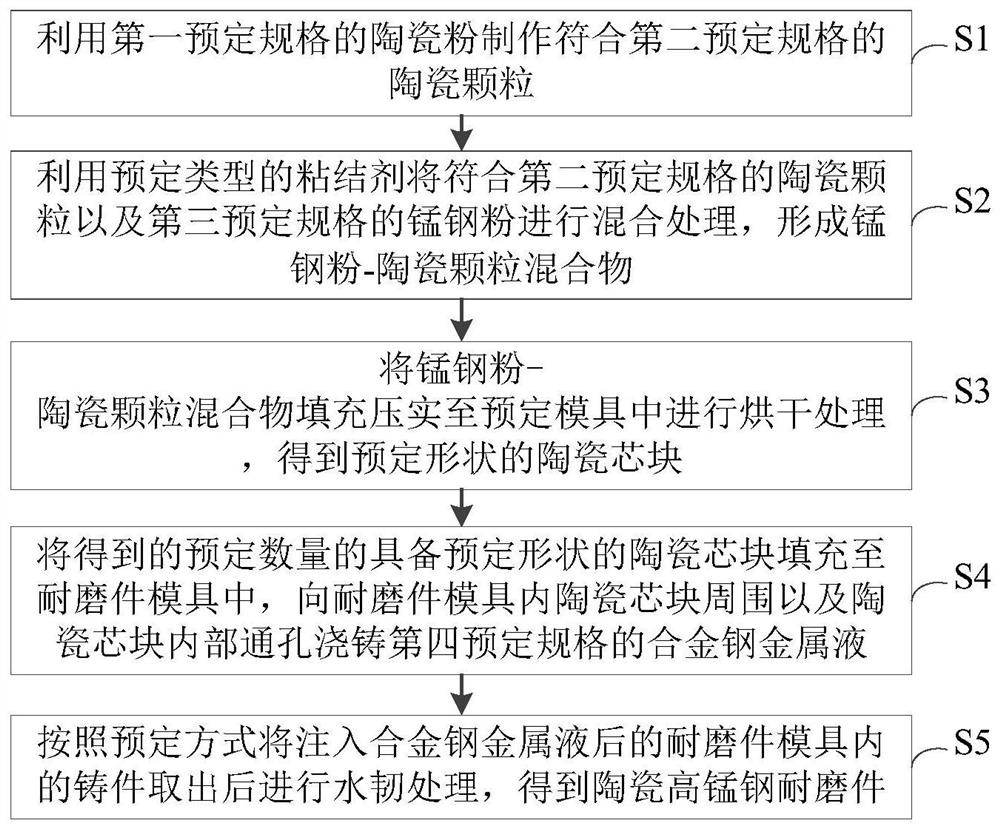

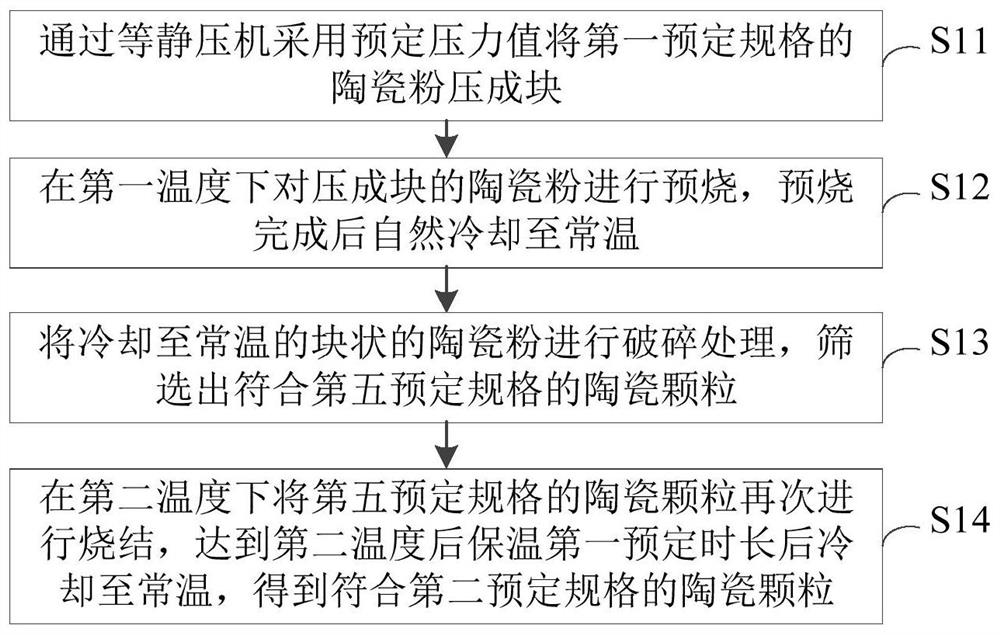

Casting Method of Ceramic High Manganese Steel Composite Wear-resistant Parts

The invention discloses a ceramic high manganese steel composite wear-resistant part casting method. The ceramic high manganese steel composite wear-resistant part casting method comprises the steps that ceramic powder is used for manufacturing ceramic particles which meet specifications; the ceramic particles and manganese steel powder are mixed by a binder to form a manganese steel powder-ceramic particle mixture; the manganese steel powder-ceramic particle mixture fills and is compacted into a predetermined mold for drying treatment, and ceramic core blocks are obtained; a wear-resistant part mold is filled with a predetermined number of ceramic core blocks, and high manganese steel metal liquid is casted into the wear-resistant part mold; and a casting in the wear-resistant part mold after the high-manganese steel metal liquid is injected is taken out for water toughening, and a ceramic high manganese steel composite wear-resistant part is obtained. The ceramic high manganese steelcomposite wear-resistant part casting method ensures the density of the ceramic core blocks in the compacted state by bonding the ceramic particles with the manganese steel powder with the same or similar specifications, and further, the high manganese steel molten metal is injected between the ceramic core blocks, the outer surfaces of the ceramic core blocks and through holes in the ceramic core blocks to ensure the wear resistance of the ceramic high manganese steel composite wear-resistant part after water toughening.

Owner:北京金煤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com