Two-component polyurethane waterproof coating containing non-polar polymer modified compound and preparation method thereof

A two-component polyurethane and non-polar polymer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor bonding, and achieve the effect of improving construction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

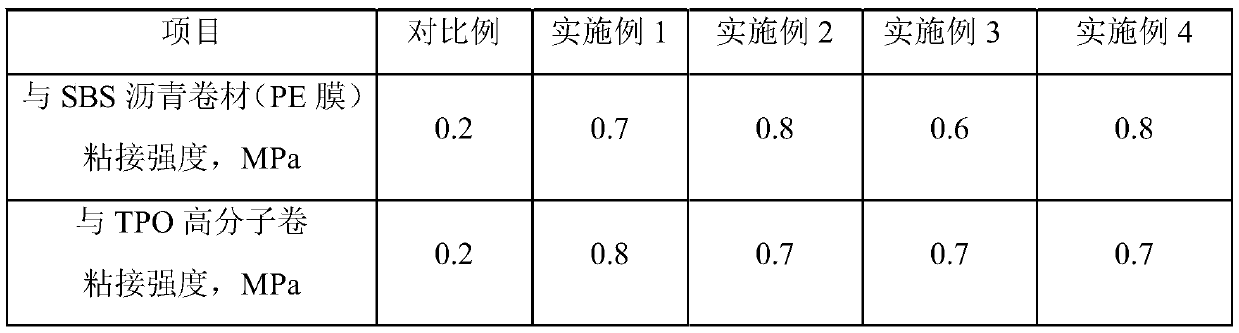

Examples

preparation example Construction

[0064] Preparation of component A:

[0065] contacting and reacting the first polyol after vacuum dehydration with isocyanate; after cooling down, discharging in the presence of inert gas to obtain component A;

[0066] Preparation of component B:

[0067] i) the main chain contains a plurality of C=C double bonds of non-polar polymers and organic peroxyacids to carry out contact reaction to obtain the epoxidation modification of the main chain containing a plurality of C=C double bonds of non-polar polymers Sexual compounds;

[0068] ii) uniformly mixing the second polyol after vacuum dehydration and the solid chain extender with the epoxidized modified compound of the non-polar polymer containing multiple C=C double bonds in the main chain to obtain the mixture; after cooling , mix the mixture with the catalyst evenly, lower the temperature again, and discharge in the presence of an inert gas to obtain component B.

[0069] Method 2:

[0070] Preparation of component A: ...

Embodiment 1

[0094] This embodiment provides a two-component polyurethane waterproof coating containing a non-polar polymer modified compound. In parts by weight, the raw material formula for preparing component A includes: 10 parts of isocyanate (TDI), polyether diol (2000D) 20 parts, polyether triol (330N) 10 parts; the raw material formula for preparing component B includes: polyether triol (330N) 10 parts, dibutyl phthalate (DBP) 10 parts, 15 parts of linear SBS polymer, 1 part of formic acid peroxide, 6 parts of chain extender MOCA, 50 parts of pigment (heavy calcium), 0.2 part of organic tin catalyst (T-12), 0.5 part of defoamer, 0.2 part of dispersant, 20 parts of xylene.

[0095] Concrete preparation steps are as follows:

[0096] Preparation of component A:

[0097] Mix 20 parts of polyether diol (2000D) and 10 parts of polyether triol (330N), heat up to 110°C, dehydrate for 5 hours under vacuum pressure of -0.095MPa; lower the temperature to below 80°C, Add 10 parts of isocyan...

Embodiment 2

[0101] This example provides a two-component polyurethane waterproof coating containing a non-polar polymer modified compound. In parts by weight, the raw material formula for preparing component A includes: 15 parts of isocyanate (MDI-50), polyether two 20 parts of polyol (2000D), 10 parts of polyether triol (330N); 10 parts of chlorinated paraffin; the raw material formula for preparing component B includes: 10 parts of polyether triol (330N), 10 parts of chlorinated paraffin , 15 parts of star-shaped SBS polymer, 1 part of formic acid peroxide, 6 parts of chain extender MOCA, 50 parts of pigment (heavy calcium), 0.2 part of organotin catalyst (T-12), 0.5 part of defoamer, 0.2 part of dispersant Parts, xylene 20 parts.

[0102] Concrete preparation steps are as follows:

[0103] Preparation of component A:

[0104] Mix 20 parts of polyether diol (2000D), 10 parts of polyether triol (330N) and 10 parts of chlorinated paraffin, heat up to 110°C, and dehydrate for 6 hours und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com