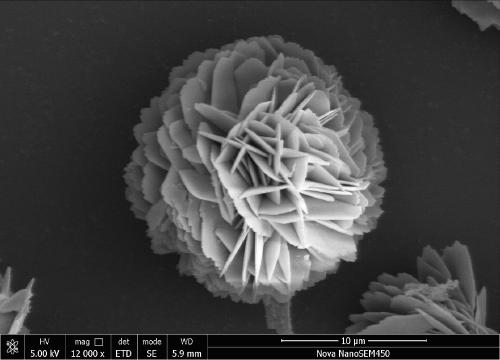

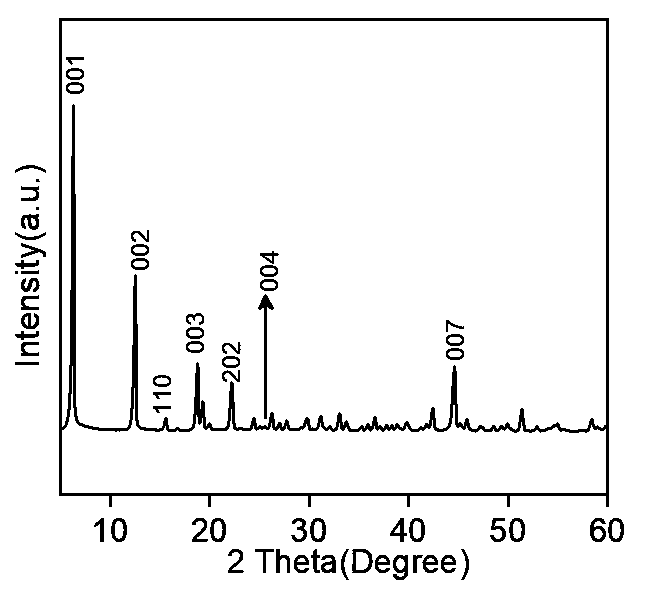

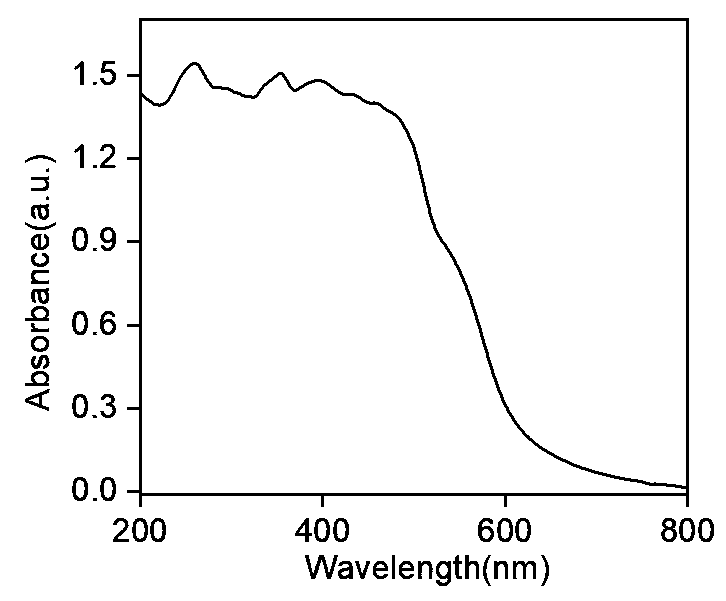

Petal-shaped perylenetetracarboxylic acid zinc supramolecular assembly photocatalytic material and preparation method thereof

A technology of supramolecular assemblies and photocatalytic materials, applied in the field of photocatalysis, can solve the problems of high cost, unfavorable production, and high recombination rate of photogenerated charges, and achieve the effects of solving environmental degradation, improving photocatalytic activity, and inhibiting aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 1.4500g perylene-3,4,9,10-potassium perylene-3,4,9,10-tetracarboxylate in 250 ml of deionized water, 3.660g of zinc acetate in 500 ml of deionized water; transfer the zinc acetate solution into the reaction kettle, turn on the stirring , the rotation speed is 200r / min, and the perylene-3,4,9,10-potassium tetracarboxylate solution is dripped with a precision metering pump under the condition of nitrogen atmosphere and 60°C, and the dropping rate is 5ml / min. After the addition is completed, Turn off the agitation, age at 60°C for 1 day, then centrifuge the mixture at a speed of 5000r / min for 5min, wash with deionized water for 3 times, and finally put it under the condition of a temperature of 60°C and a vacuum of 20pa. Drying for 48 hours under the hood to obtain a petal-shaped zinc perylenetetracarboxylate supramolecular assembly photocatalytic material.

Embodiment 2

[0024] Dissolve 0.1130g lithium perylene-3,4,9,10-tetracarboxylate in 250 ml mixed solvent of deionized water and ethanol, the volume ratio of deionized water and ethanol is 9:1, dissolve 0.322g zinc sulfate in In the same solvent; transfer the zinc sulfate solution into the reaction kettle, turn on the stirring at a speed of 400r / min, and add perylene-3,4,9,10 dropwise with a precision metering pump under the condition of argon atmosphere and 30°C -Lithium tetracarboxylate solution, the dropping speed is 15ml / min, after the dropwise addition is completed, turn off the stirring, age at 30°C for 10 days, then centrifuge the mixed solution for 5min at a speed of 10000r / min, and use The mixed solvent of ionized water and ethanol was washed 4 times, and finally dried for 48 hours at a temperature of 30°C and a vacuum of 10 Pa to obtain a petal-shaped zinc perylenetetracarboxylate supramolecular assembly photocatalytic material.

Embodiment 3

[0026] Dissolve 0.0129g of sodium perylene-3,4,9,10-tetracarboxylate in 250 ml of a mixed solvent of deionized water and methanol, the volume ratio of deionized water and methanol is 8:2, and dissolve 0.0148g of zinc nitrate in In the same solvent; transfer the zinc nitrate solution into the reaction kettle, turn on the stirring, the rotation speed is 600r / min, and add perylene-3,4,9,10 dropwise with a precision metering pump under the condition of argon atmosphere and 5°C -Sodium tetracarboxylate solution, the dropping rate is 30ml / min, after the dropwise addition is completed, turn off the stirring, age at 5°C for 20 days, then centrifuge the mixed solution for 10min at a speed of 15000r / min, and use The mixed solvent of ionized water and methanol was washed 5 times, and finally dried for 48 hours at a temperature of 50°C and a vacuum of 1 Pa to obtain a petal-shaped zinc perylenetetracarboxylate supramolecular assembly photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com