ZnO-mixed cathode buffer layer-based organic solar battery and preparation method thereof

A cathode buffer layer and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low photoelectric conversion efficiency, rough surface, and large gaps in the cathode layer, so as to improve electron transmission capacity and reduce surface roughness , the effect of increasing the photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

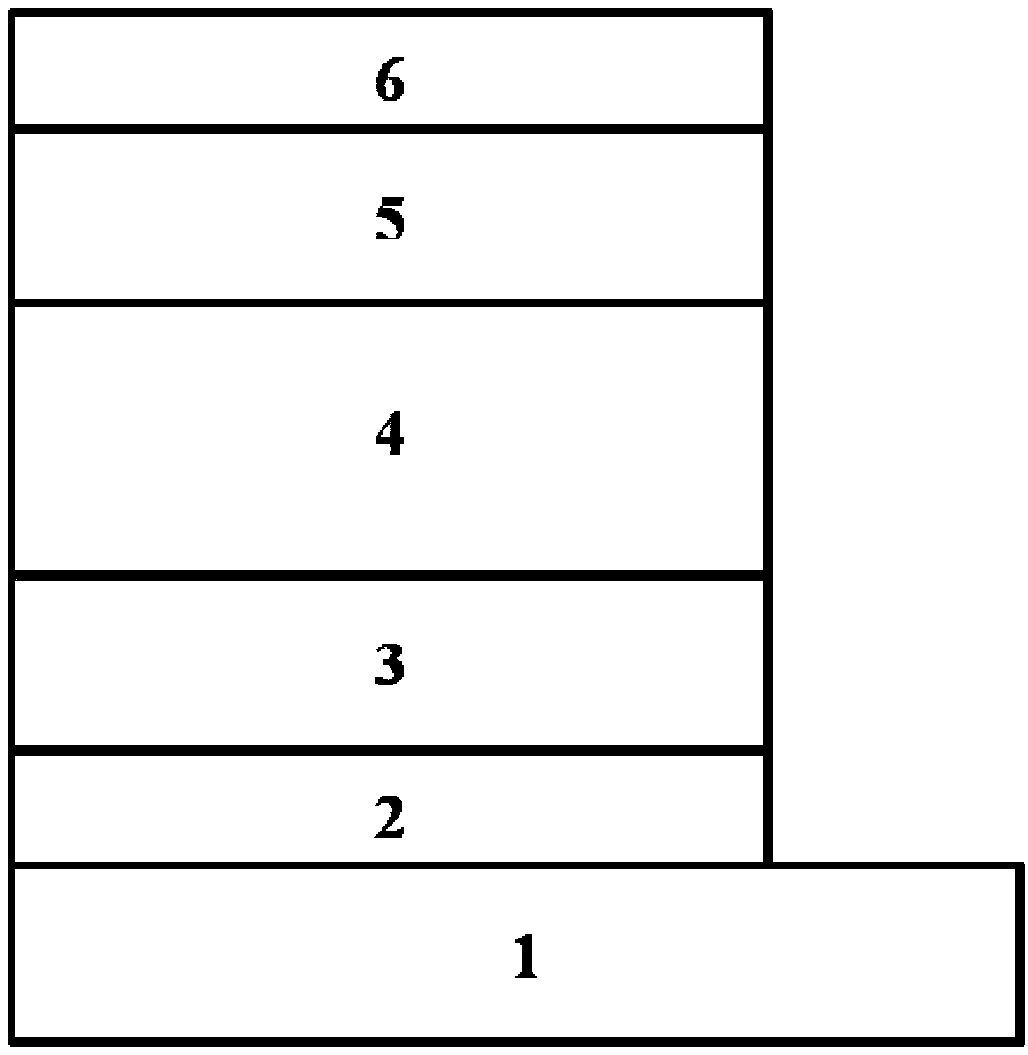

[0045] Such as figure 1 , figure 2 As shown, an organic solar cell based on a mixed ZnO cathode buffer layer adopts an inverted structure, including a substrate layer 1, a transparent conductive cathode layer 2, a cathode buffer layer 3, and a photoactive Layer 4, anode buffer layer 5 and metal anode layer 6;

[0046] in,

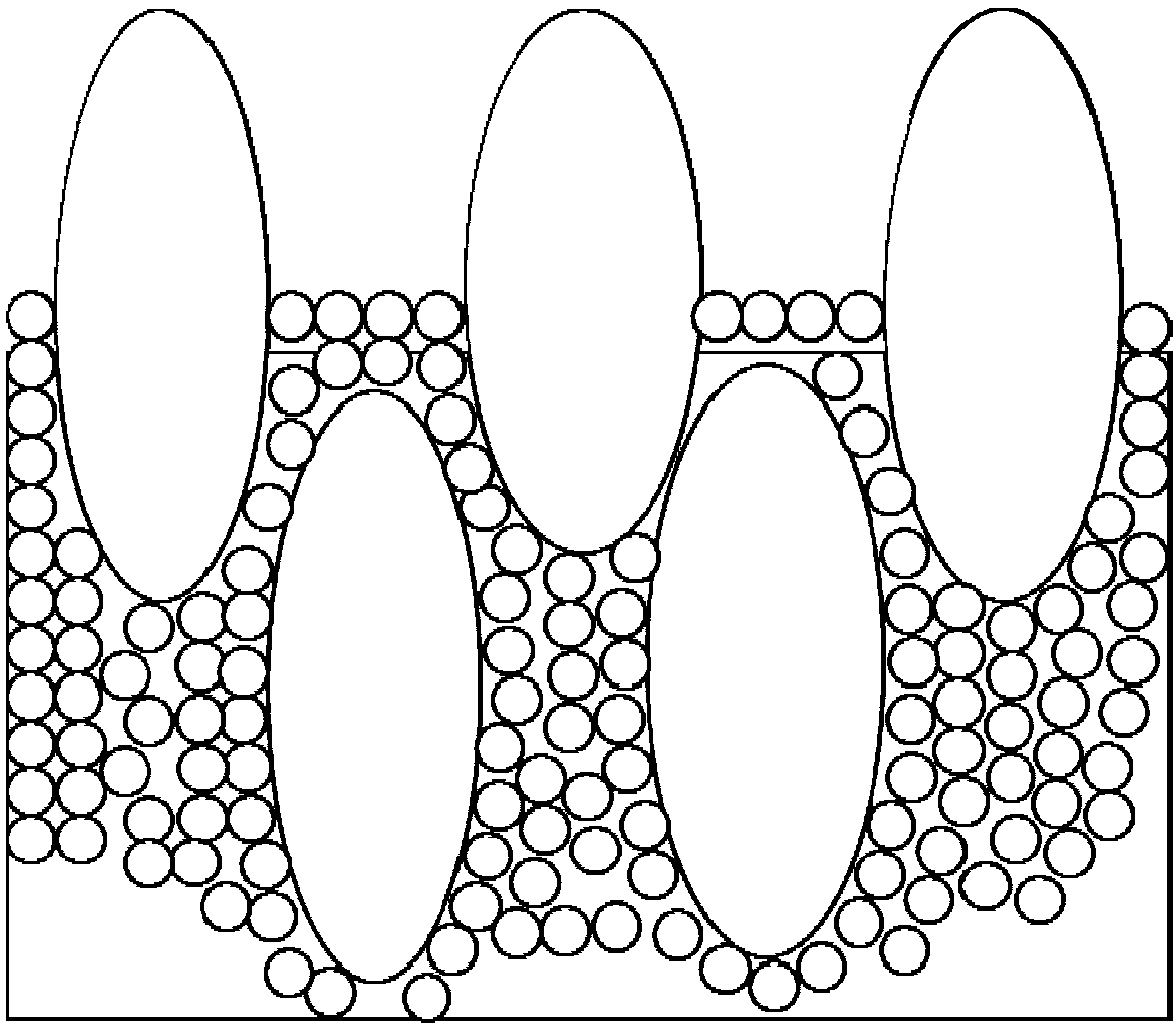

[0047] The cathode buffer layer 3 is a solid film formed by mixing a ZnO nanoparticle dispersion and a ZnO precursor solution prepared by a sol-gel method in a certain proportion, and forming after thermal annealing;

[0048] In the mixed solution, the mass percent ratios of the ZnO nanoparticle dispersion and the ZnO precursor solution are respectively:

[0049] ZnO nanoparticles 80% to 98%;

[0050] ZnO precursor 2% to 20%;

[0051] The thickness range of the cathode buffer layer 3 is 220-380nm.

[0052] Preferably, the thickness of the photoactive layer 4 is 50-300nm, mainly composed of electron donor material PTB7-TH and electron acceptor materia...

specific Embodiment

[0073] Control group 1

[0074] Clean the substrate composed of a transparent substrate layer 1 and a transparent conductive cathode layer 2 composed of ITO with a surface roughness less than 1 nm, and dry it with nitrogen after cleaning; spin-coat the ZnO nanoparticle dispersion on the surface of the transparent conductive cathode ITO (Working parameters: rotating speed 4000rpm, time 40s, thickness 300nm, the same below, no further explanation) Prepare the cathode buffer layer 3, and prepare PTB7-TH:PC on the cathode buffer layer 3 by spin coating 71 BM (mass ratio 1:1.5, concentration 25mg / ml, the same below, no longer elaborated) photoactive layer 4 (1200rpm, 90s, 120nm), vapor-deposited anode buffer layer 5MoO3 (thickness 15nm) on the photoactive layer 4 surface; Metal anode Ag (thickness: 100 nm) is vapor-deposited on the anode buffer layer 5 . Under standard test conditions: air quality AM 1.5, light intensity 100mW / cm 2 , the open circuit voltage of the device was mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com