A multifunctional industrial yarn spinning machine

An industrial and spinning machine technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of single function and not suitable for processing special fiber yarns for industrial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings; the embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

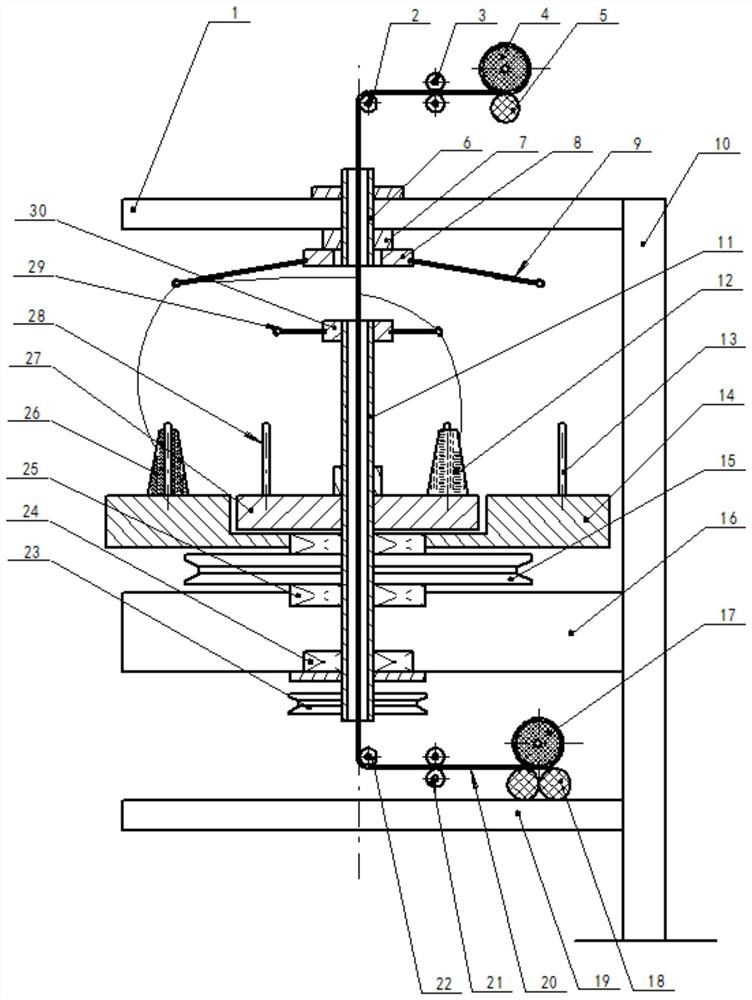

[0025] A multifunctional industrial spinning machine is composed of a frame and a yarn core feeding mechanism, a first wrapping mechanism, a second wrapping mechanism and a winding mechanism. The frame is composed of a column 10, a lower beam 19, a middle The beam 16 and the upper beam 1 are constituted. The horizontal lower beam, the middle beam and the upper beam are fixedly installed on the vertical column. The yarn core feeding mechanism is installed on the lower beam, and the first wrapping mechanism is installed on the middle beam. Above the middle beam The turntable part of the second wrapping mechanism is installed, the yarn guide part of the second wrapping mechanism is hoisted under the upper beam, and the winding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com