Patents

Literature

67results about How to "Wrap tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced type silicon rubber self-adhesion insulated rubber tape

InactiveCN102965048AHigh strengthImprove safe operationNon-macromolecular adhesive additivesFilm/foil adhesivesFiberPolymer science

The invention discloses a reinforced type silicon rubber self-adhesion insulated rubber tape. Cotton fiber cloth is taken as a base material and adhesive layers are respectively coated on upper and lower faces. Each adhesive layer comprises the following materials in parts by weight: 30-60 parts of silicon rubber, 10-25 parts of gas-phase white carbon black, 0-5 parts of silicone oil softening agent, 5-20 parts of silicon-boron tackifier, 0.2-0.5 part of coloring agent and 0.5-5 parts of vulcanizing agent. According to the reinforced type silicon rubber self-adhesion insulated rubber tape, the breaking strength is more than or equal to 5 MPa and the definite elongation strength is more than or equal to 3 MPa; when the reinforced type silicon rubber self-adhesion insulated rubber tape is used for an insulating, sealing and winding process of various cable connectors under 35 kV or below, the safety operation capability, the anti-cracking capability, the anti-fouling capability and the wear-resisting capability of cables are improved, the winding is more tight and the sealing waterproof effect is better; and the use is safe and reliable at a temperature rangoffing from -40 DEG C to 260 DEG C, and the anti-current-leakage capability is further improved.

Owner:吴孟怀

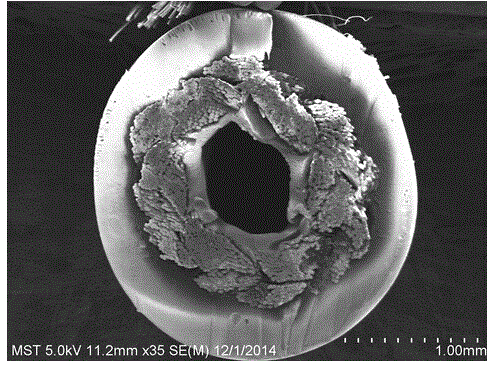

A braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film and a preparing method thereof

The invention discloses a preparing method of a braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film, and belongs to the field of polymer film product preparation. The preparing method includes firstly preparing a polyvinylidene fluoride solution A having a certain low concentration, dipping a braided tube with the solution A to allow the polyvinylidene fluoride solution to penetrate into the inside of the braided tube, coating the outside of the braided tube with a high-concentration polyvinylidene fluoride film casting solution B having a certain formula, and putting the braided tube coated with the solution A and the solution B into a coagulating bath to allow the polyvinylidene fluoride coated in the two times to be subjected to phase separation simultaneously. The polyvinylidene fluoride hollow fiber film prepared by the method is advantageous in that 1) the inner low-concentration polyvinylidene fluoride solution tightly surrounds fibers of the braided tube, is tightly connected to an outer film layer after phase transition, and is not liable to shed; 2) a high-aperture-ratio compact surface layer is formed from the outer high-concentration film casting solution and provides effects of filtration; and 3) the braided tube with high strength provides excellent film fiber longitudinal stretching strength.

Owner:安徽指南针科创园发展有限公司

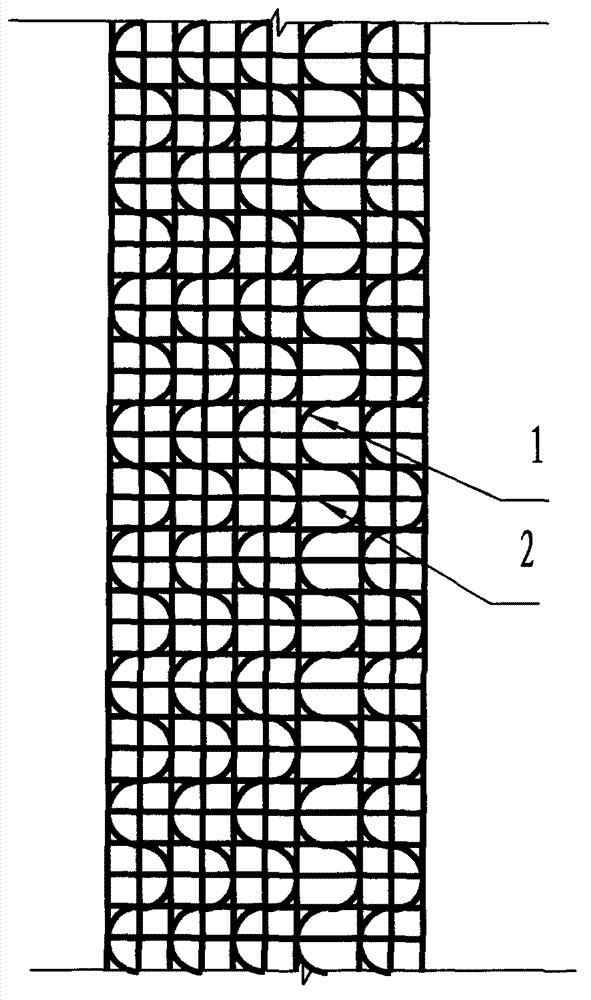

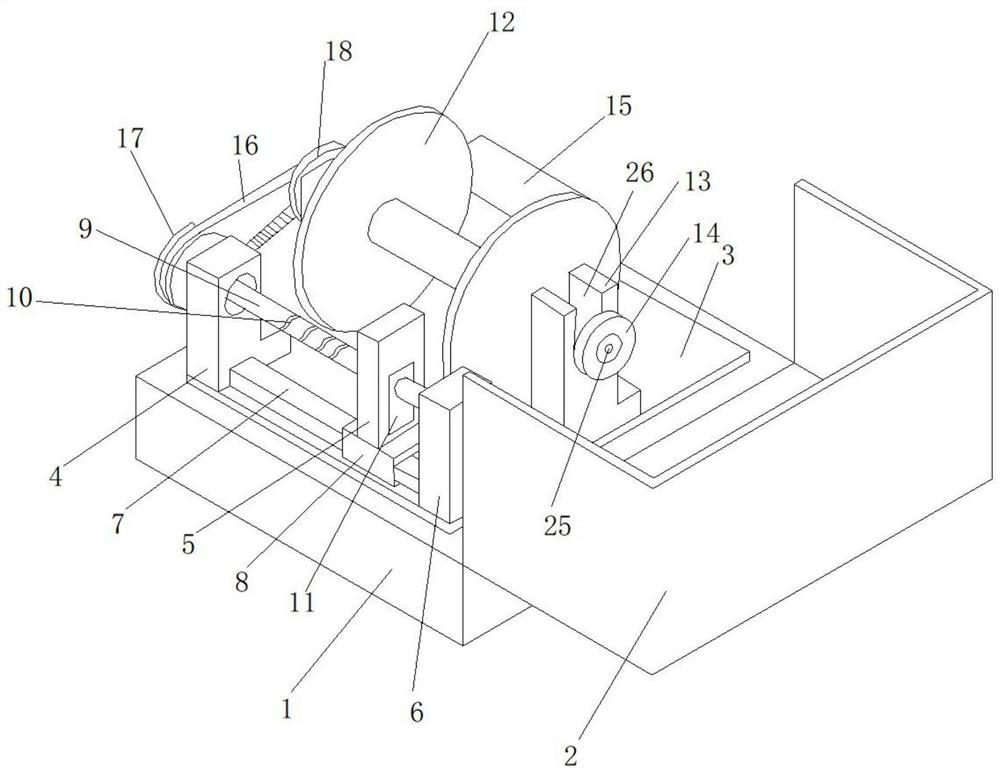

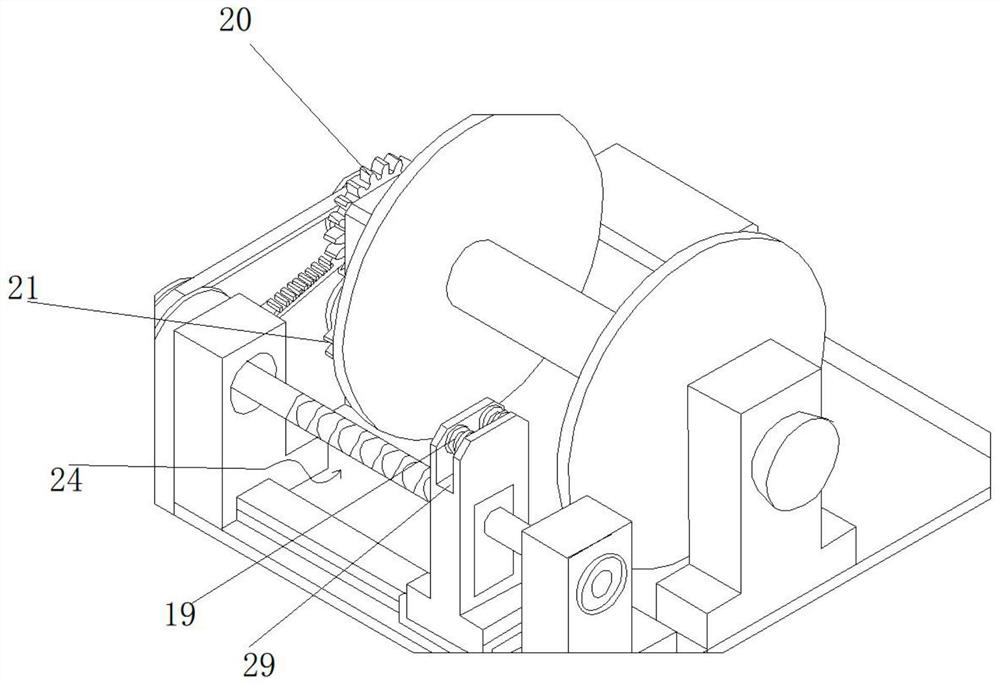

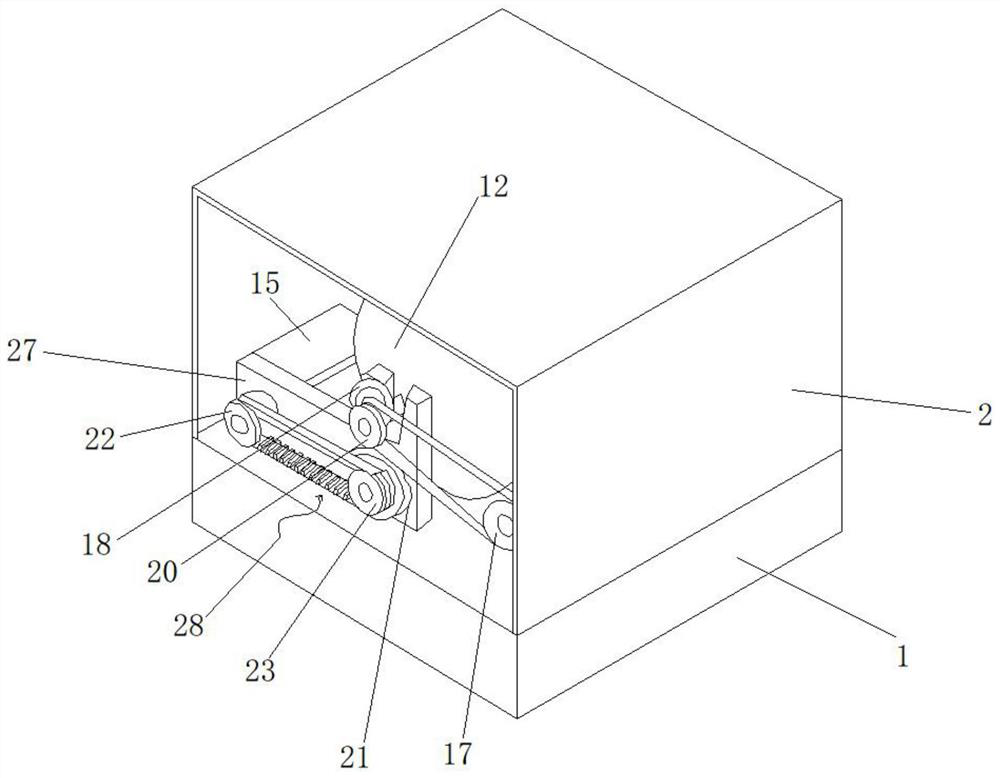

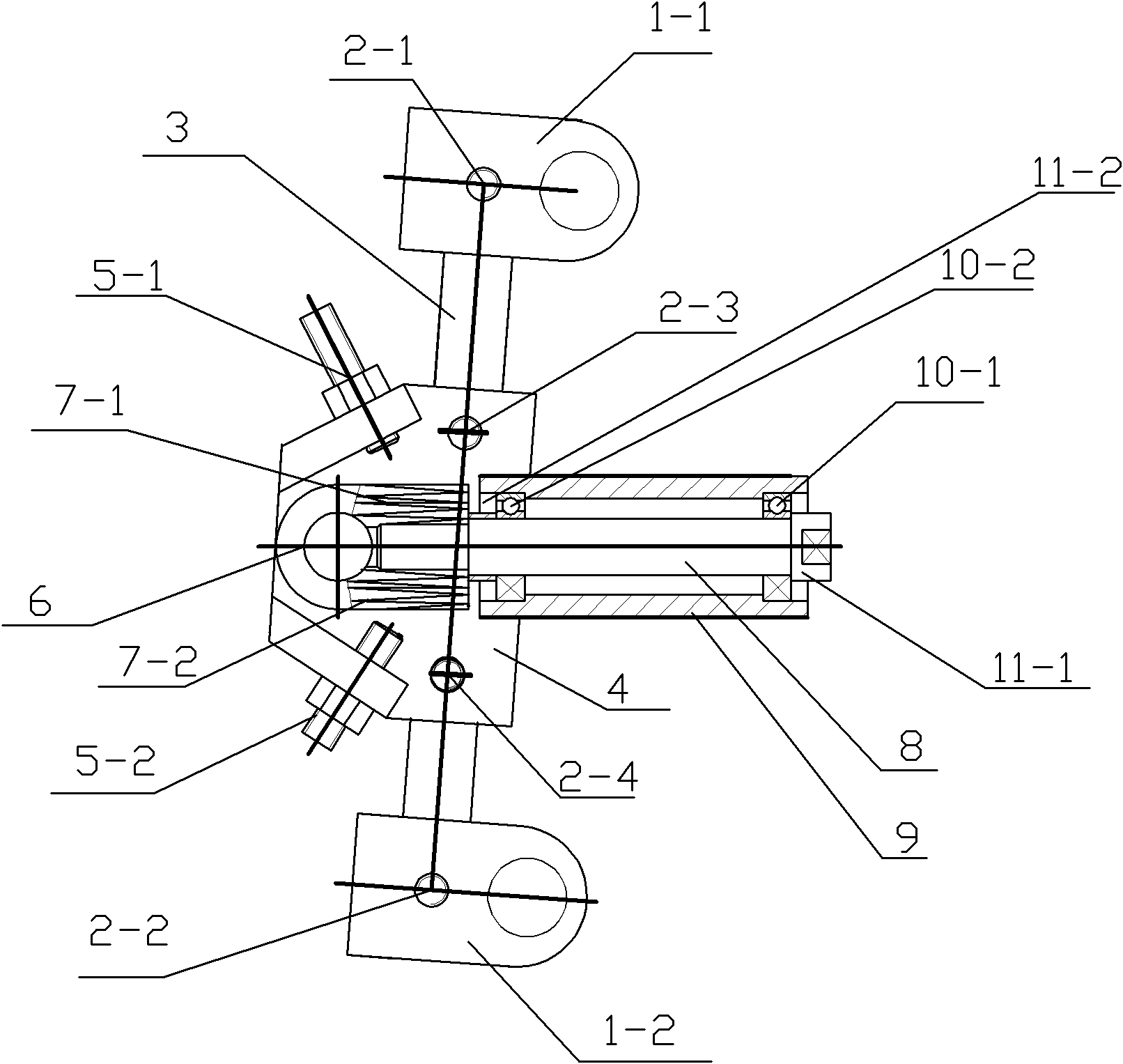

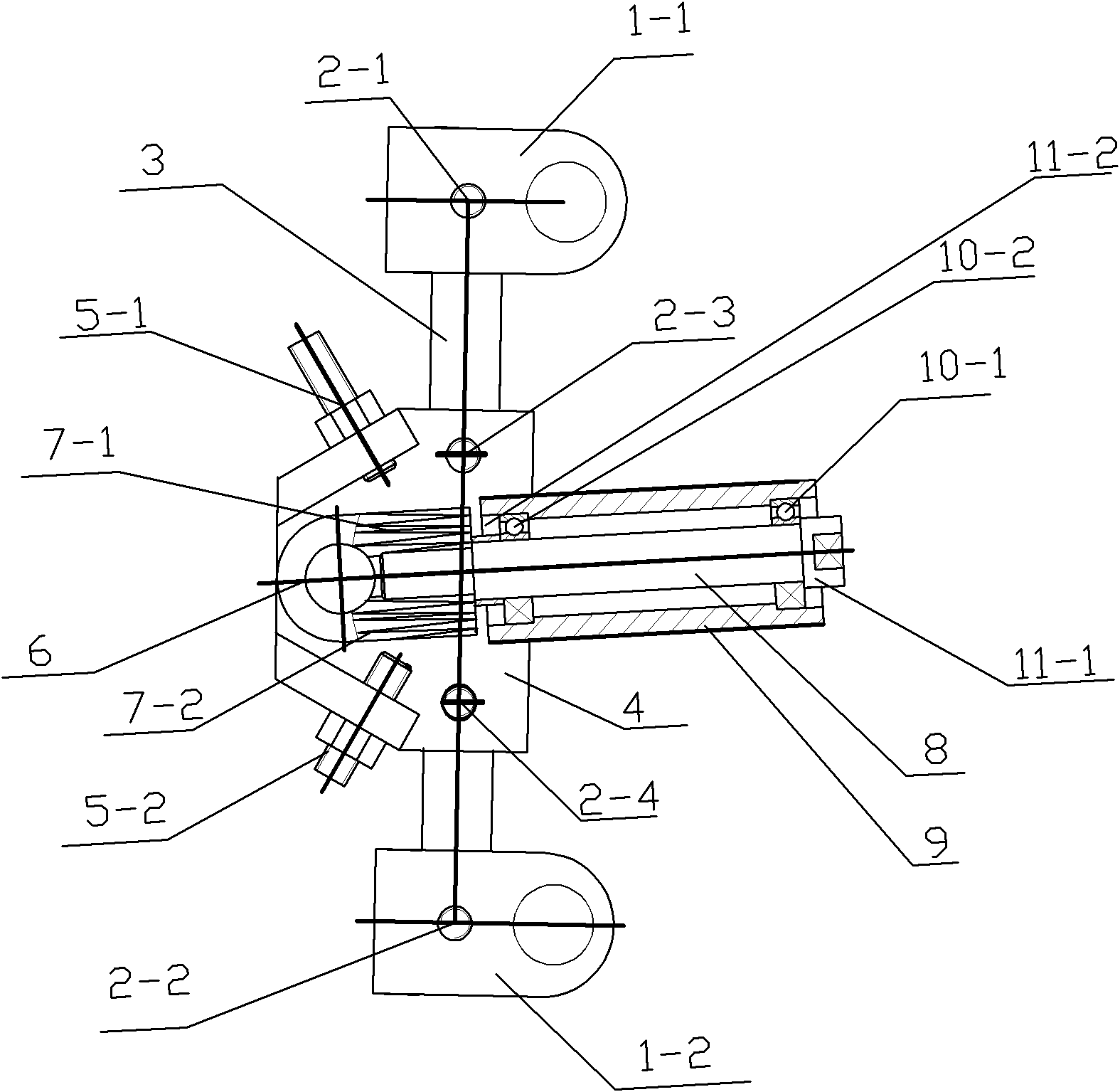

Super-smooth warping method of yarns with many drafted fibers

ActiveCN105274695AAvoid gatheringWrap tightlyWarping machinesOther manufacturing equipments/toolsFiberYarn

The invention relates to a super-smooth warping method of yarns with many drafted fibers and belongs to the textile processing technical field. According to the method of the invention, on each yarn warping mechanism of a warping machine, a false twisting device is adopted to make the trunk of a yarn rotate; a drafted fiber directional stretching device is adopted to directionally eject steam flows so as to directionally stretch the drafted fibers of the yarn, so that some of the drafted fibers of the yarn forwards and orderly wrap the trunk of the yarn, and therefore, the drafted fibers can be prevented from being entangled to from neps when randomly or vertically winding the trunk of the yarn; a drafted fiber vortex wrapping device is adopted to reversely wrap the other drafted fibers of the yarn on the trunk of the yarn, so that the other drafted fibers of the yarn and the forwards and orderly wrapped drafted fibers can be closely tangled in a cross manner; and therefore, progressive complete wrapping and cross tight wrapping of the drafted fibers of the yarns can be realized, and winding tightness and firmness of the drafted fibers can be greatly increased, and the problem of series rebound of the drafted fibers of the yarns in a warping procedure and subsequent procedures of warping can be solved, and super-smooth warping of the yarns with many drafted fibers can be realized. The device of the invention has the advantages of reasonable structure and convenient operation.

Owner:WUHAN TEXTILE UNIV

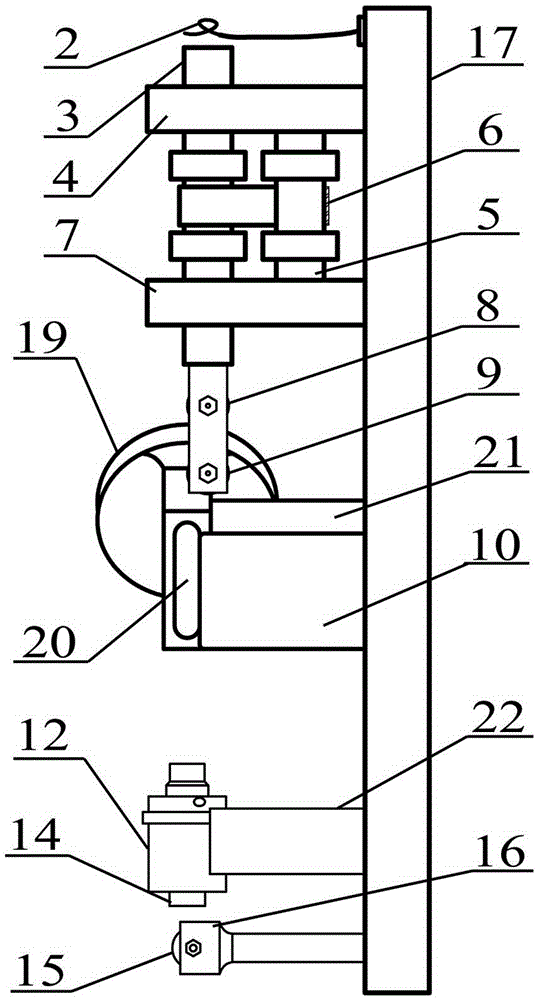

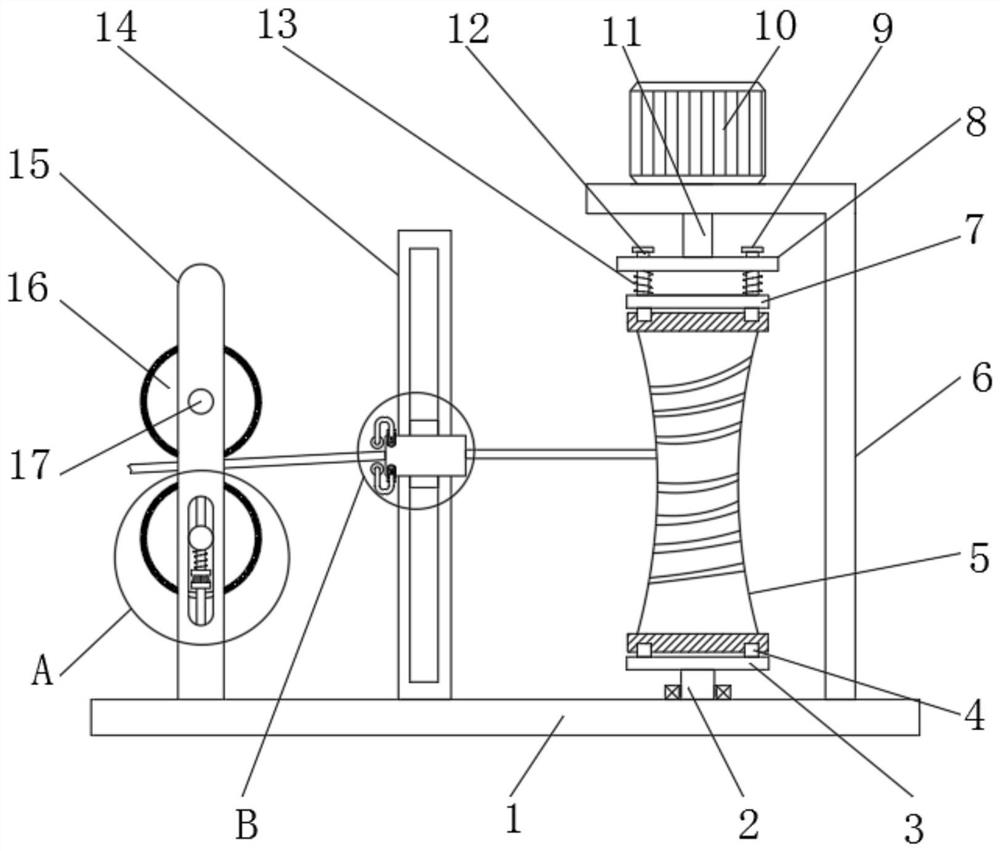

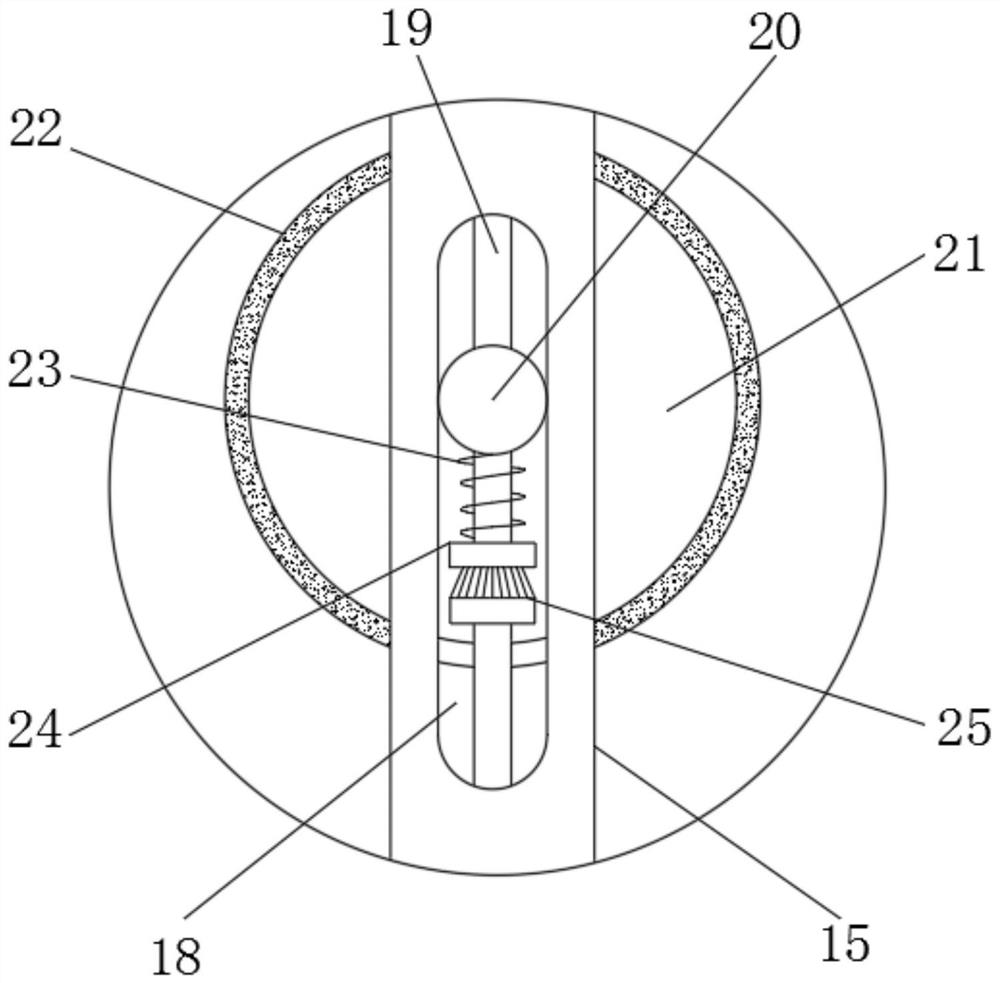

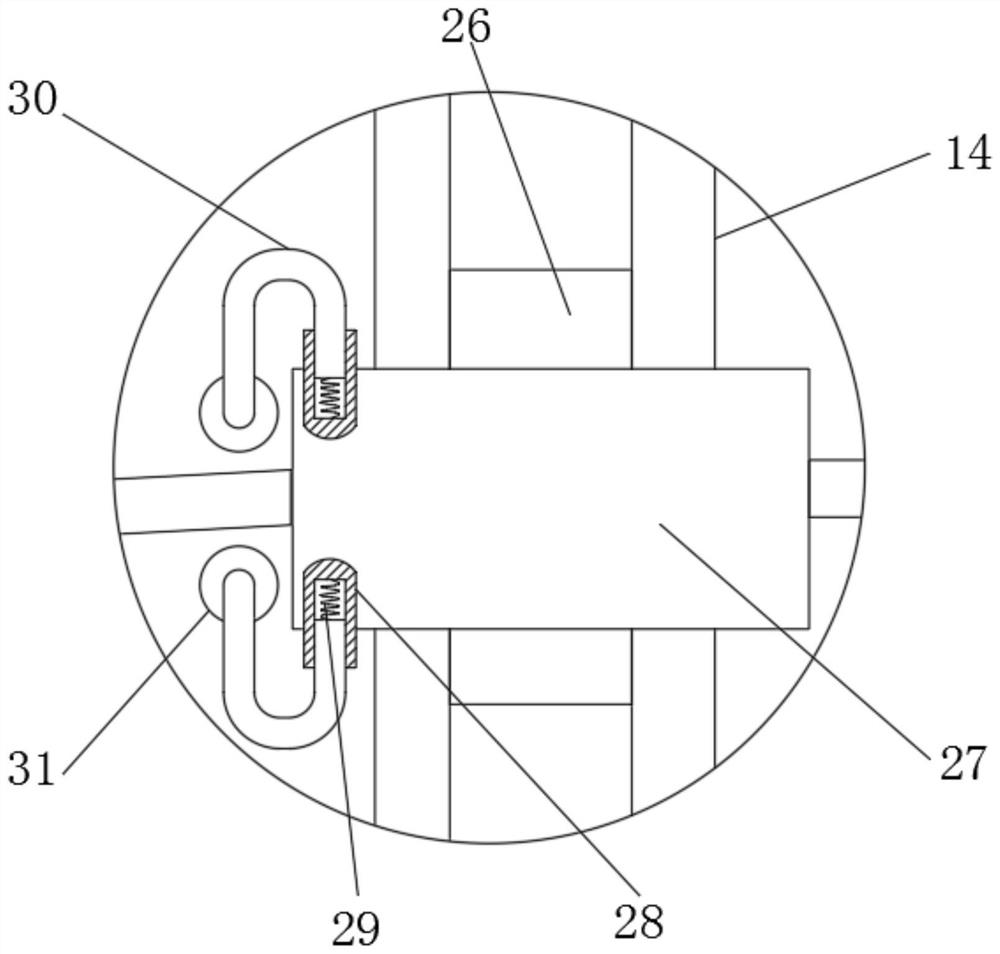

Winding device for cable production

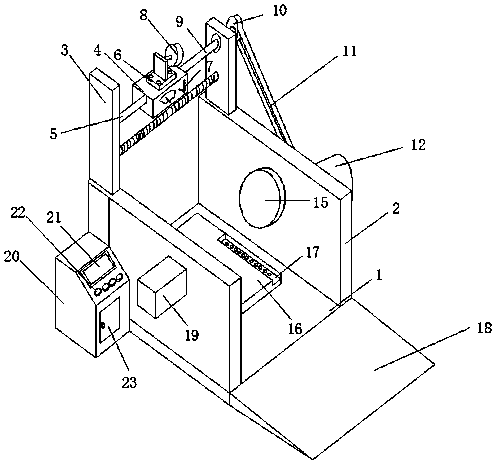

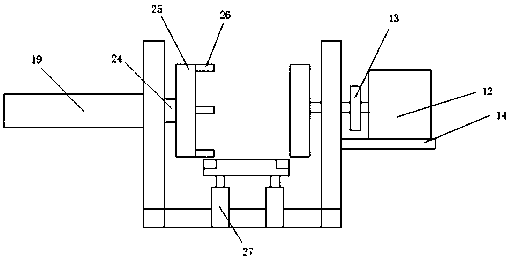

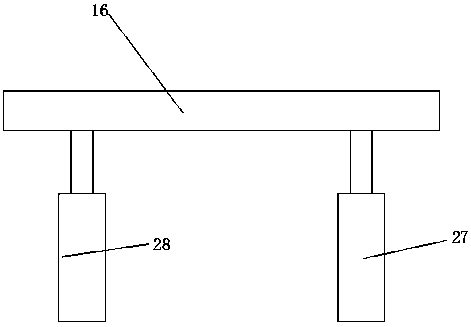

The invention discloses a winding device for cable production. The winding device for cable production comprises a bottom plate and a winding roller; a mounting frame is fixedly connected to the outer wall of the top of the bottom plate, a motor is arranged on the outer wall of the top of the mounting frame, a rotating shaft is arranged at one end of an output shaft of the motor, and a rotating disc is arranged at the bottom end of the rotating shaft; through holes which are annularly distributed at equal intervals are formed in the outer wall of the top of the rotating disc, limiting pins are slidably arranged on the inner walls of the through holes, stop blocks are arranged at the top ends of the limiting pins, an upper clamping plate is arranged at the bottom ends of the limiting pins, the outer walls of the limiting pins are sleeved with first springs, a movable shaft is rotatably arranged on the outer wall of the top of the bottom plate through a bearing, and a lower clamping plate is arranged at the top end of the movable shaft. By means of the winding device, the winding roller can be easily taken down, replacement with a new winding roller can be conveniently carried out, use is quite convenient, a cable can be evenly wound around the winding roller, abrasion caused by contact between the cable and the inner wall of a cable guide cylinder is effectively avoided, and the use effect is better.

Owner:湖南鑫亿电缆有限公司

Thermal shrinkage bonding nut structure

InactiveCN104696343AThe connection is tight and firmAvoid the problem of insufficient bite force and easy fall offNutsBoltsEngineeringHot melt

Owner:SHENXUN COMP KUNSHAN

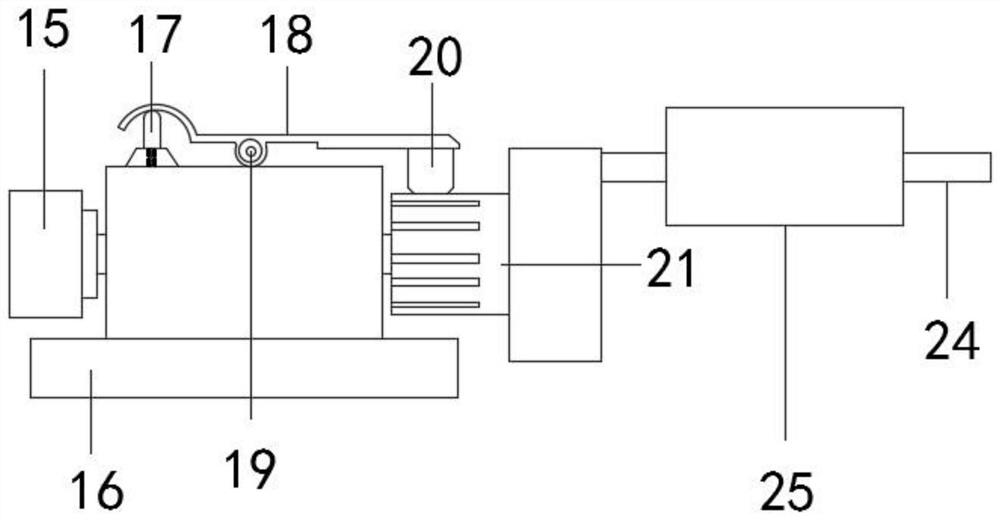

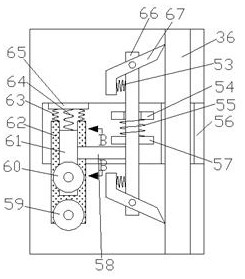

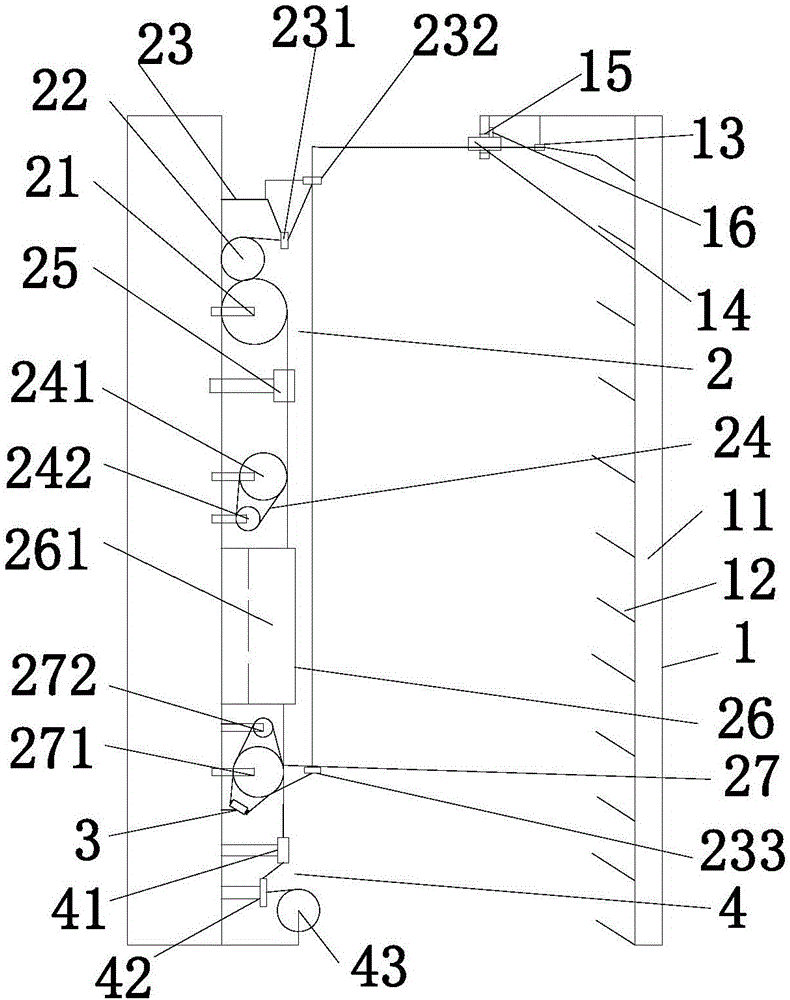

Wire stripping device for electrical engineering

ActiveCN112447336ATo achieve the peeling effectAchieve the effect of automatic wire windingBasic electric elementsApparatus for removing/armouring cablesElectric wireElectrical and Electronics engineering

The invention relates to a wire stripping device, in particular to a wire stripping device for electrical engineering. The invention provides a wire stripping device for electrical engineering, whichcan automatically store and cut off a wire. The wire stripping device for electrical engineering comprises a floor, a first supporting frame and a second supporting frame, the first supporting frame is arranged on one side of the floor, the second supporting frame is arranged on the other side of the floor, a straightening mechanism is arranged between the first supporting frame and the second supporting frame, a collecting mechanism is arranged on the floor, the collecting mechanism is connected with the straightening mechanism, and a peeling mechanism is arranged between the first supportingframe and the second supporting frame. By arranging the straightening mechanism, the collecting mechanism and the peeling mechanism, the straightening mechanism can straighten a bent electric wire, the peeling mechanism peels the electric wire, the collecting mechanism collects the peeled electric wire, and the effect of automatically peeling the electric wire is achieved.

Owner:桂林实创真空数控设备有限公司

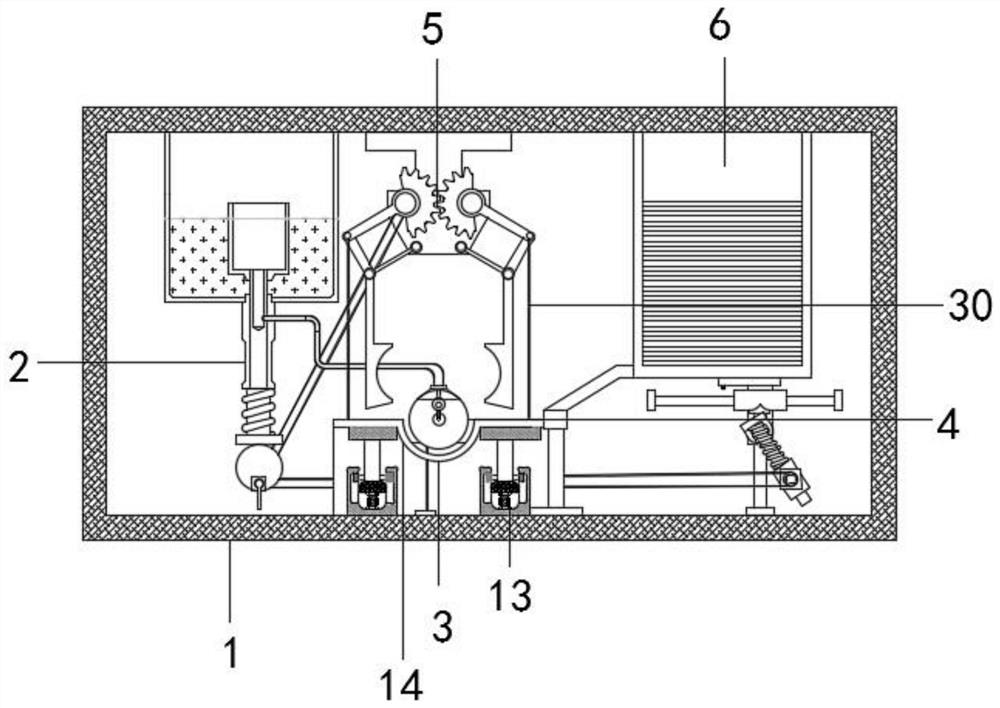

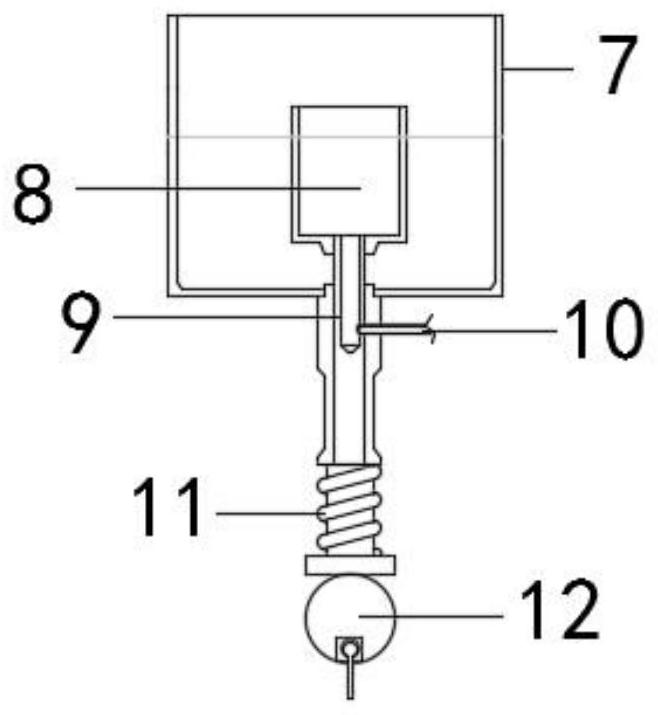

Convenient surgical disinfecting and binding device with high automation degree

ActiveCN114366451AHigh degree of automationImprove work efficiencyMedical applicatorsBandagesBandageBiomedical engineering

The invention relates to the technical field of surgical bandaging, and discloses a high-automation-degree convenient surgical disinfecting and bandaging device which comprises a box body, a disinfecting device is fixedly connected to the left side of the box body, an arm placing device is arranged on the lower right portion of the disinfecting device, and a bandage winding device is arranged above the arm placing device; an automatic clamping device is arranged above the bandage winding device, a linkage feeding device is arranged on the right side of the automatic clamping device, a pressure buffering device is driven to move through the arm placing device, and the pressure buffering device drives the automatic clamping device to clamp limbs of a patient through an elastic rope; meanwhile, the automatic clamping device drives the disinfection device to disinfect the wound and then drives the linkage feeding device to apply the medicine patch to the wound of the patient, and disinfectant fluid residual liquid in the disinfection device drives the bandage winding device to bind the wound; therefore, the effects of high working efficiency, reduced pressure of medical staff, timely wound treatment, high automation degree and relatively wide application are achieved.

Owner:SANWE MEDICAL TECH JIANGSU

Method for weaving blended yarn branched twisted yarn

The invention discloses a method for weaving blended yarn branched twisted yarn. The method comprises the steps of wool yarn making, stranding and doubling, twisting and yarn steaming. Through the design of processes and parameters, the processed branched twisted yarn is wrapped tightly, the bright yarn has fewer broken ends, the high break rate during direct wool spinning processing of metallic yarn is overcome, exposed shining points of the twisted yarn are continuous, the shining is strong, the yarn is smooth, the brute force is high, the product weavability is high, and the method is suitable for marketing applications.

Owner:JIANGYIN HAITE NETWORK TECH CO LTD

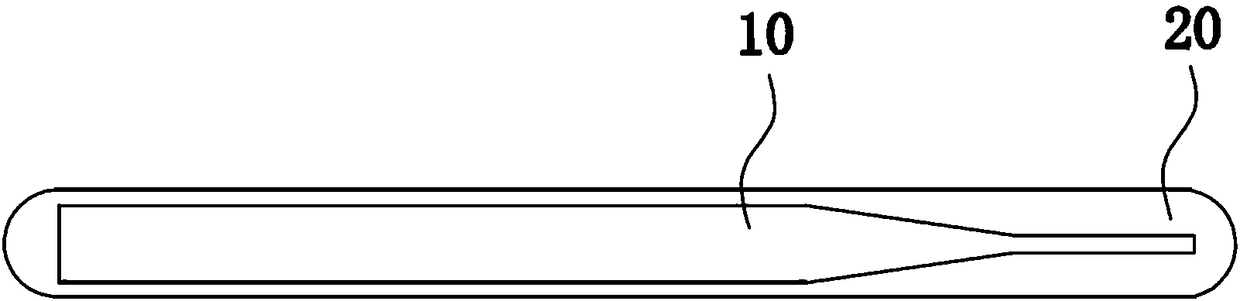

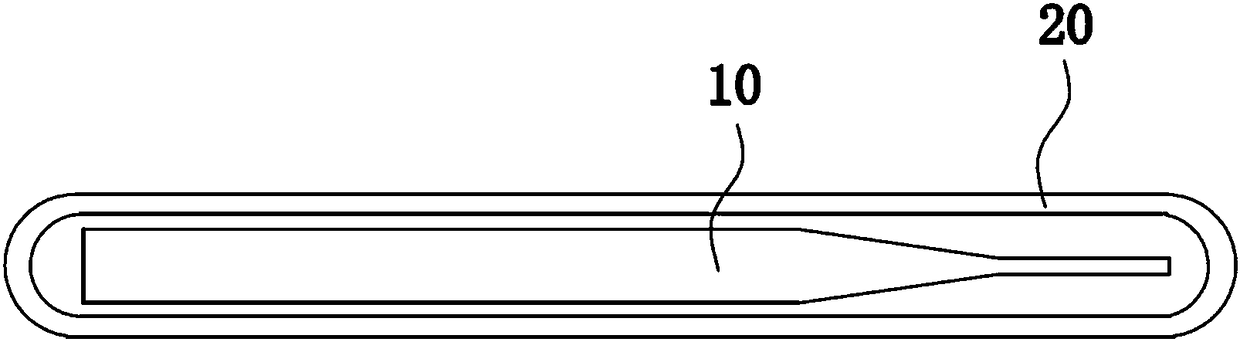

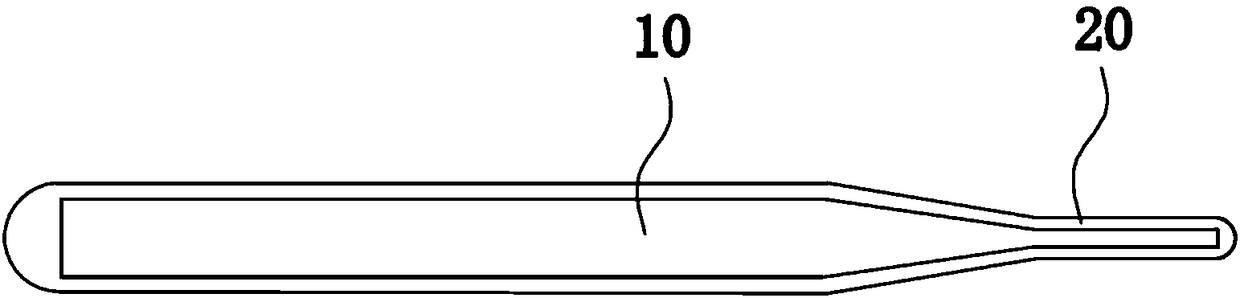

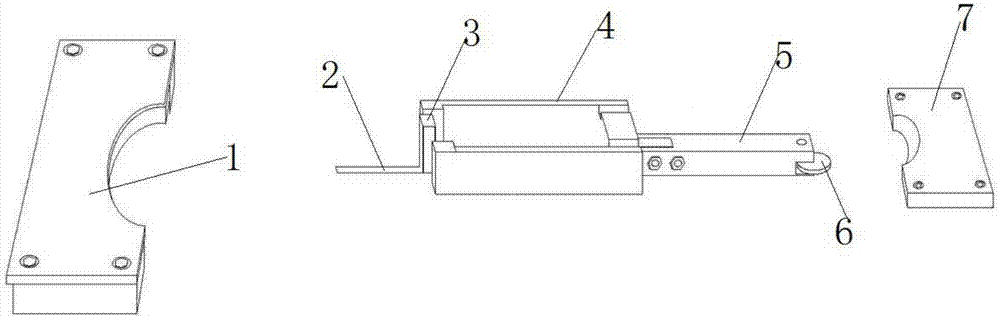

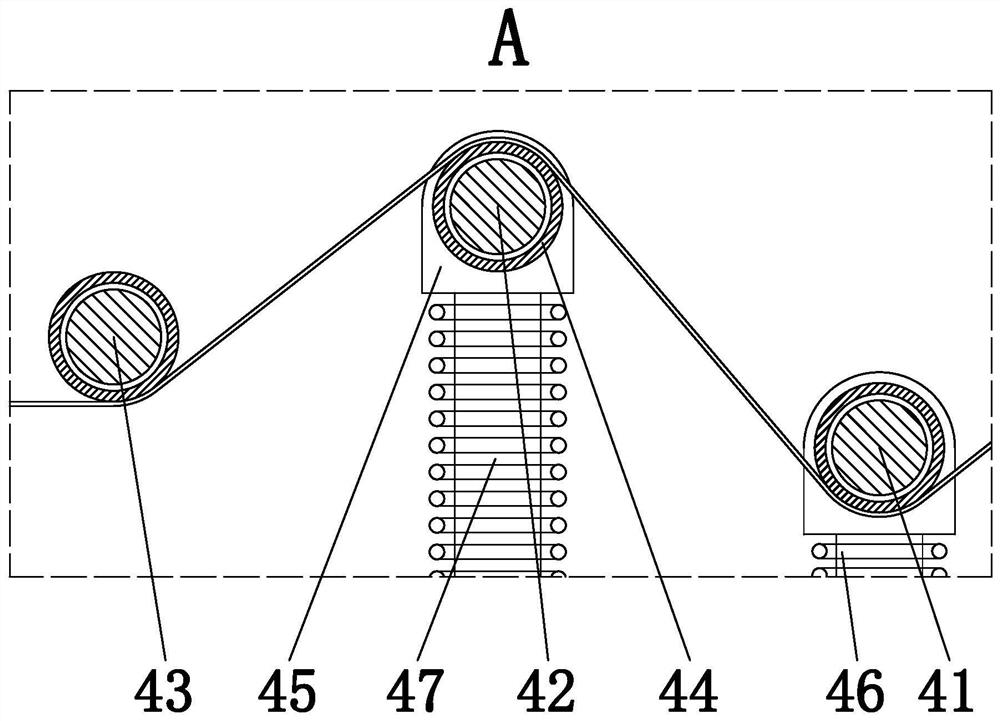

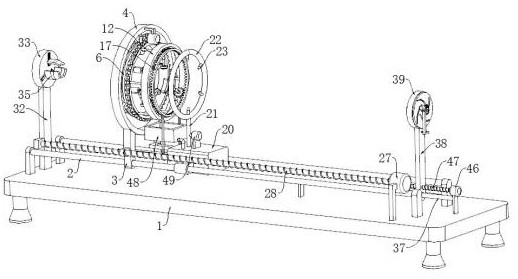

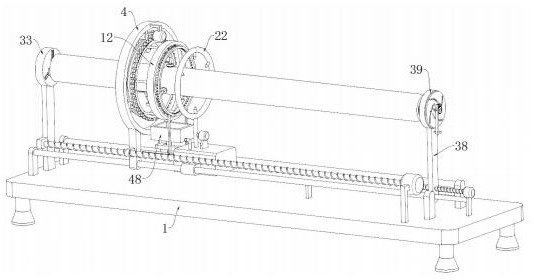

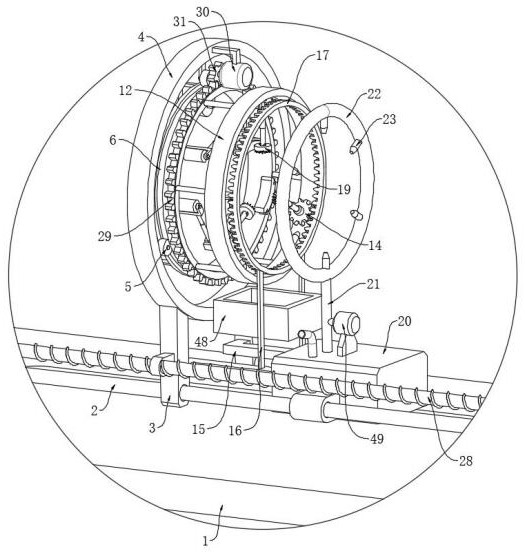

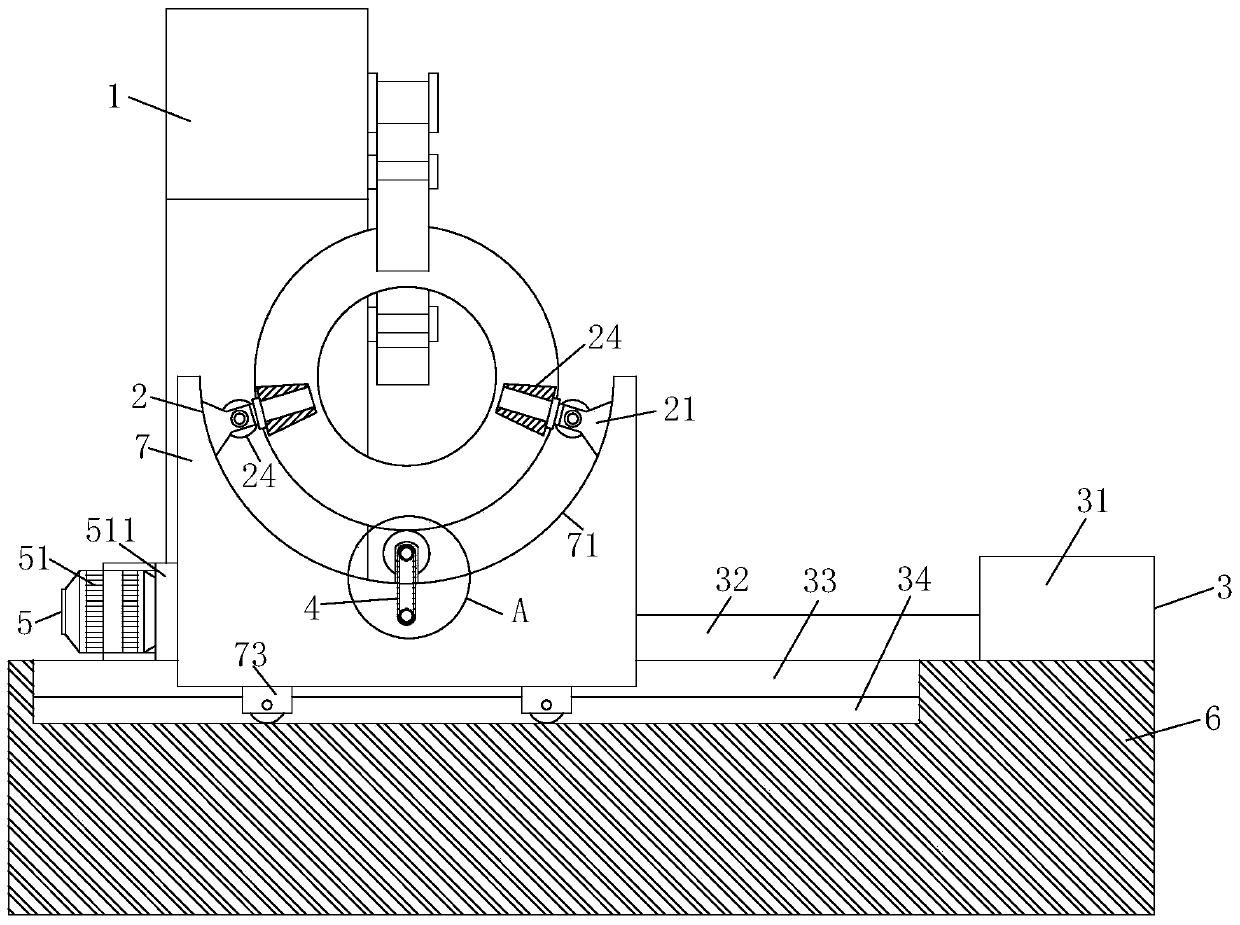

Super-slip guide wire outer wrapped layer solid solution molding device and wrapping method thereof

The invention discloses a super-slip guide wire outer wrapped layer solid solution molding device including a wrapping mold, a wrapping material supply device, a variable speed traction device and a cooling device; a molding channel for a core wire to pass through and a melt runner intersected with the molding channel are formed on the wrapping mold; the wrapping material supply device is used forproviding a wrapping material melt for the wrapping mold; the variable speed traction device is used for pulling a core wire out from the molding channel at different speeds according to the diametersizes of the core wire in different regions, wherein the core wire passes through the molding channel and is coaxial with a second molding channel of the molding channel; the cooling device is used for cooling the core wire removed out of the wrapping mold. The core wire is wrapped tightly by a solid solution way, so slipping is not easy, a head end of the core wire is prevented from puncturing the outer wrapping layer, and the risk of scrapping a chamber channel by a guide wire is reduced; at the same time, with adopting of the variable speed traction way, different-diameter regions of the core wire have more fit wrapping time and wrapping material melt amount, and uniform, smooth and reliable outer diameter of the guide wire after wrapping can be guaranteed.

Owner:SUZHOU HIGHWIRE MEDICAL DEVICES CO LTD

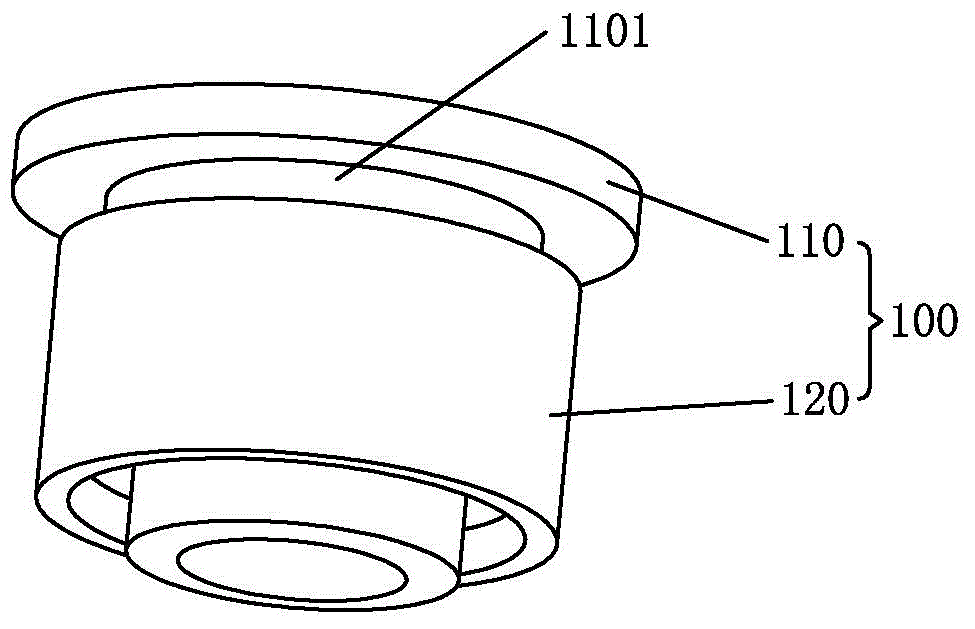

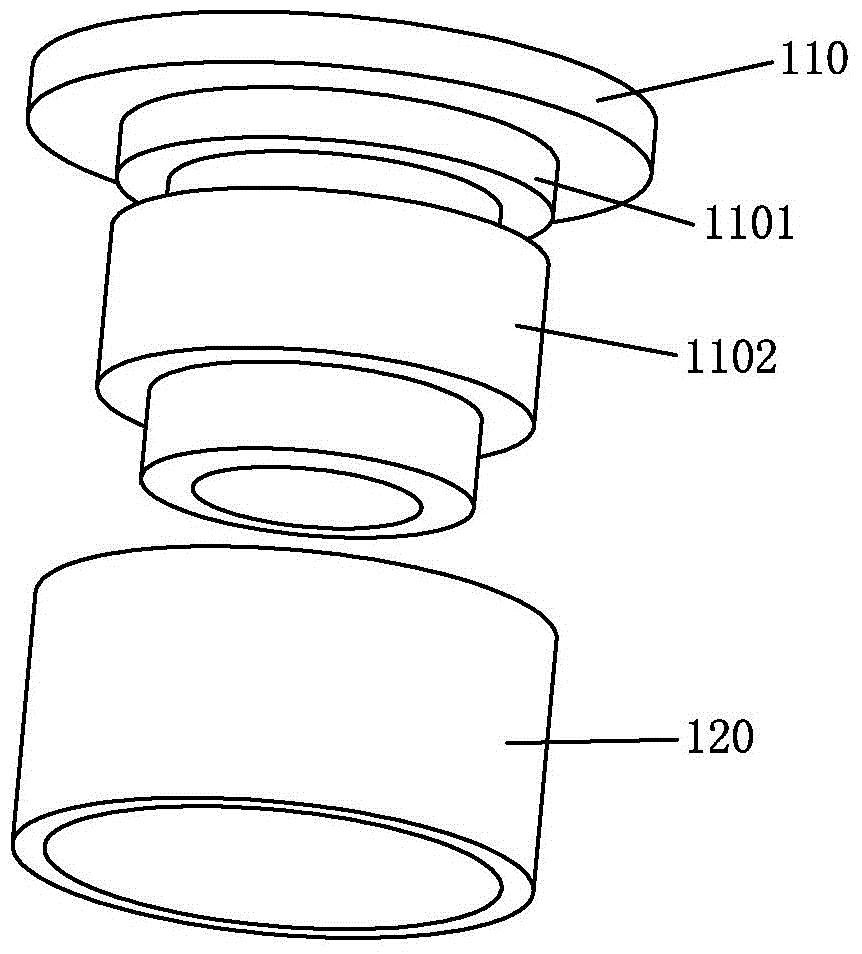

Matrix used for high layering

InactiveCN108887137AImprove survival rateReduce browning rateGrowth substratesCulture mediaBeta-CarotenePeat

The invention belongs to the field of plant propagation, and relates to a cultivation matrix, in particular to a matrix which is capable of effectively increasing the survival rate and used for high layering. The matrix comprises 20-30 parts of edible fungus residues, 300-600 parts of peat, 200-400 parts of perlite, 110-150 parts of soybean dregs, 7-14 parts of root-promoting growth composition, 10-15 parts of bagasse, 5-8 parts of beta-carotene, 3-7 parts of trehalose and 15-20 parts of active polypeptide calcium-zinc chelate. According to the matrix, extracts of plants capable of easily rooting serve as root-promoting factors, the matrix can be used in a plant organic planting system, natural nutrients are provided for growth of branch layering, and then the survival rate of layering isfurther increased. Plant extracts rich in antioxidant substance serve as anti-browning factors, the browning rate of girdling branches is reduced, the natural nutrients are provided for growth of branch layering, and the survival rate of plant high layering is increased.

Owner:HANGZHOU BOTANICAL GARDEN

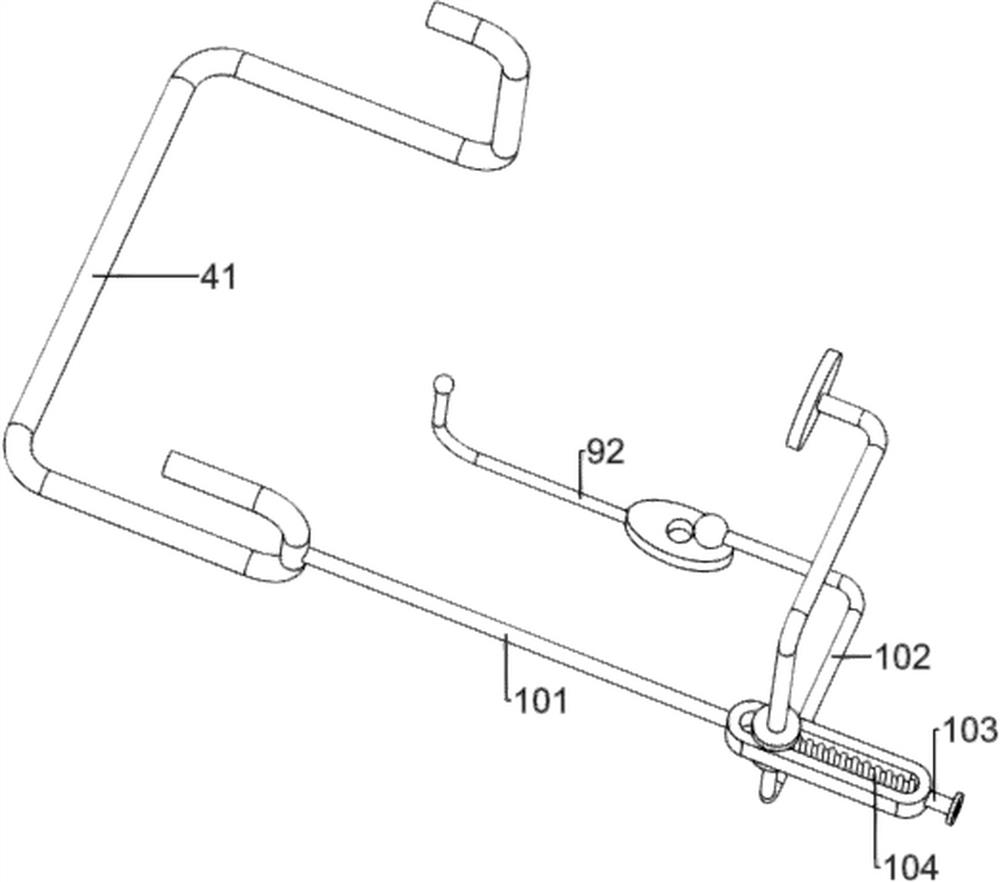

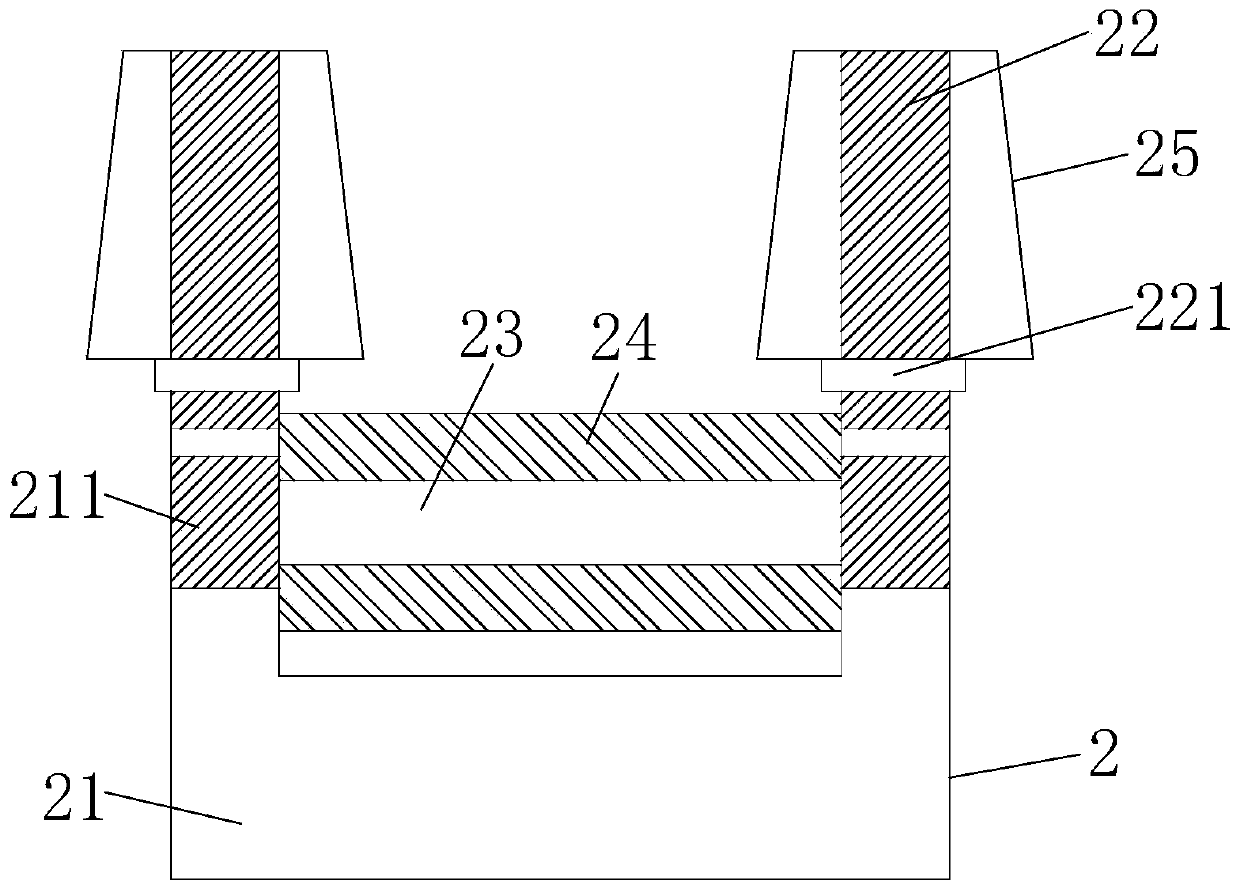

Combined device for manufacturing stay wire of overhead line

The invention discloses a combined device for manufacturing a stay wire of an overhead line. The combined device comprises a model fixing die, a sliding groove, a wedge-shaped core pushing die, a wedge-shaped pushing die, a lower die pushing rod, a lower die and a steel strand bending forming upper die; the sliding groove, the wedge-shaped core pushing die , the wedge-shaped pushing die, the lower die pushing rod and the lower die are located between the model fixing die and the steel strand bending forming upper die; one end of the sliding groove is arranged in the wedge-shaped pushing die; the wedge-shaped core pushing die can move in the sliding groove; one end of the lower die pushing rod is connected to the wedge-shaped pushing die; and the other end of the lower die pushing rod is fixedly provided with a lower die. According to the combined device, bend forming of a steel strand is good, and the strand is not broken; and the goodness of fit of a wedge-shaped wire clamp and the steel strand is high, and the wedge-shaped wire clamp and the steel strand are very tight.

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

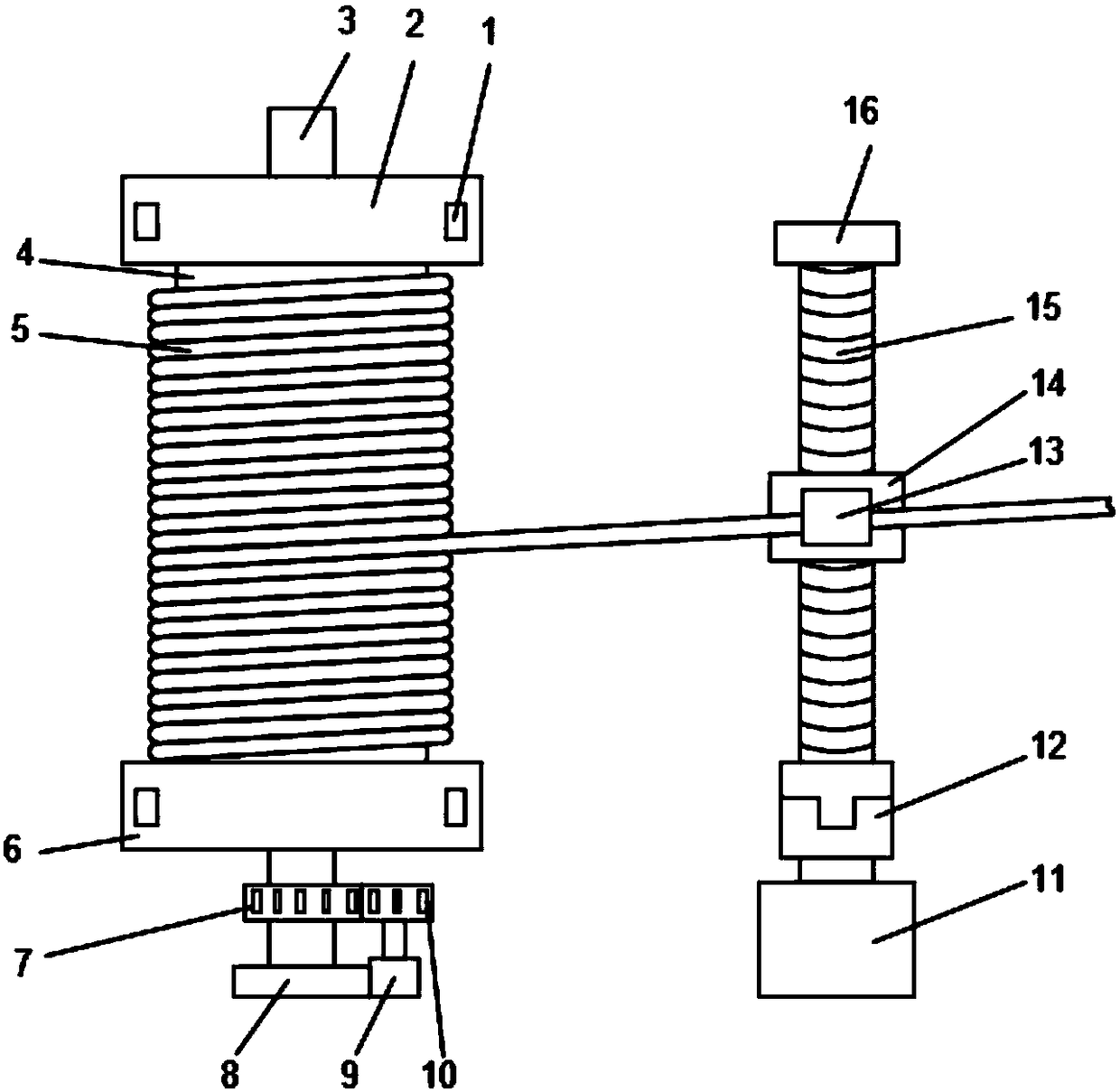

Wire winding device for enamelled wire production

The invention discloses a wire winding device for enamelled wire production. The wire winding device comprises a device main body. According to the wire winding device for the enamelled wire production, by means of the manner that the upper portion of a rack is provided with a polished rod wire arranging device, automatic adjustment can be performed in the wire winding process to keep the windingtension unchanged, the wire material walking pitch can be adjusted according to the wire material diameter, the linear speed of wire winding is made to coordinate with a previous working procedure toperform coordination work, wire materials in the wire winding are winded tightly, the appearance wire materials are neat and beautiful, the product quality is guaranteed, after the wire winding work is finished, an I-shaped wheel disc after the wire winding can be taken down by adjusting the positions of an I-shaped wheel disc placing platform and a clamping disc, then the inclination angle of theI-shaped wheel disc placing platform is adjusted through the coordination work of a second hydraulic cylinder and a third hydraulic cylinder, the I-shaped wheel disc is made to slide down through a guide plate utilizing a sliding rail, the time consumed by replacing the I-shaped wheel disc is greatly saved, the labor intensity of workers is reduced, the production efficiency is improved, and popularization and promotion are facilitated.

Owner:GUANGDONG JINGDA REA SPECIAL ENAMELED WIRE CO LTD

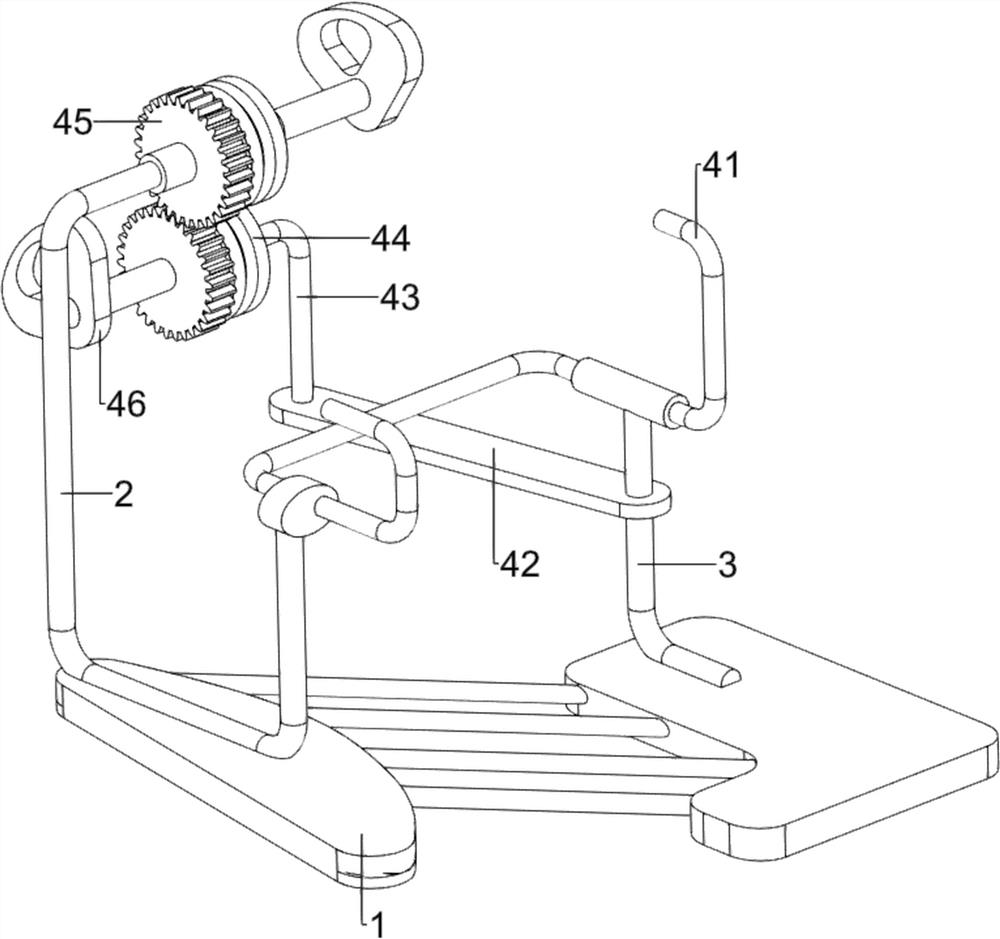

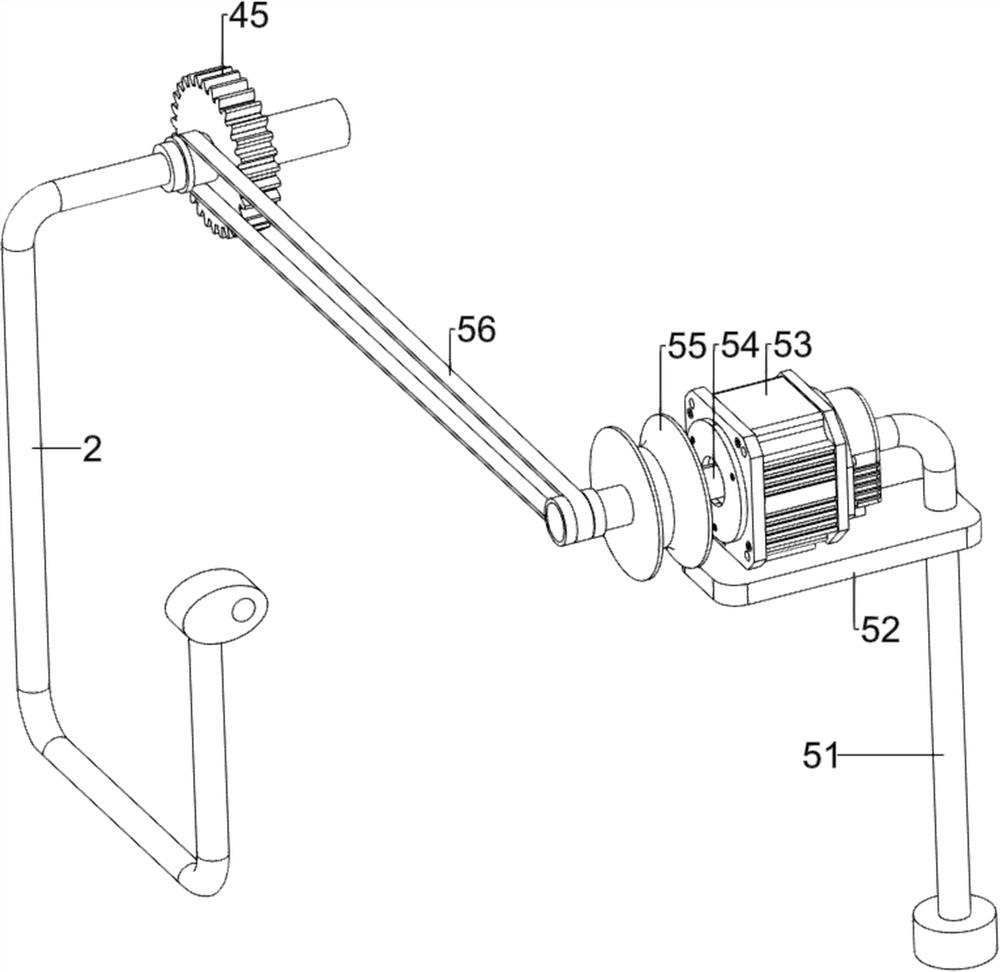

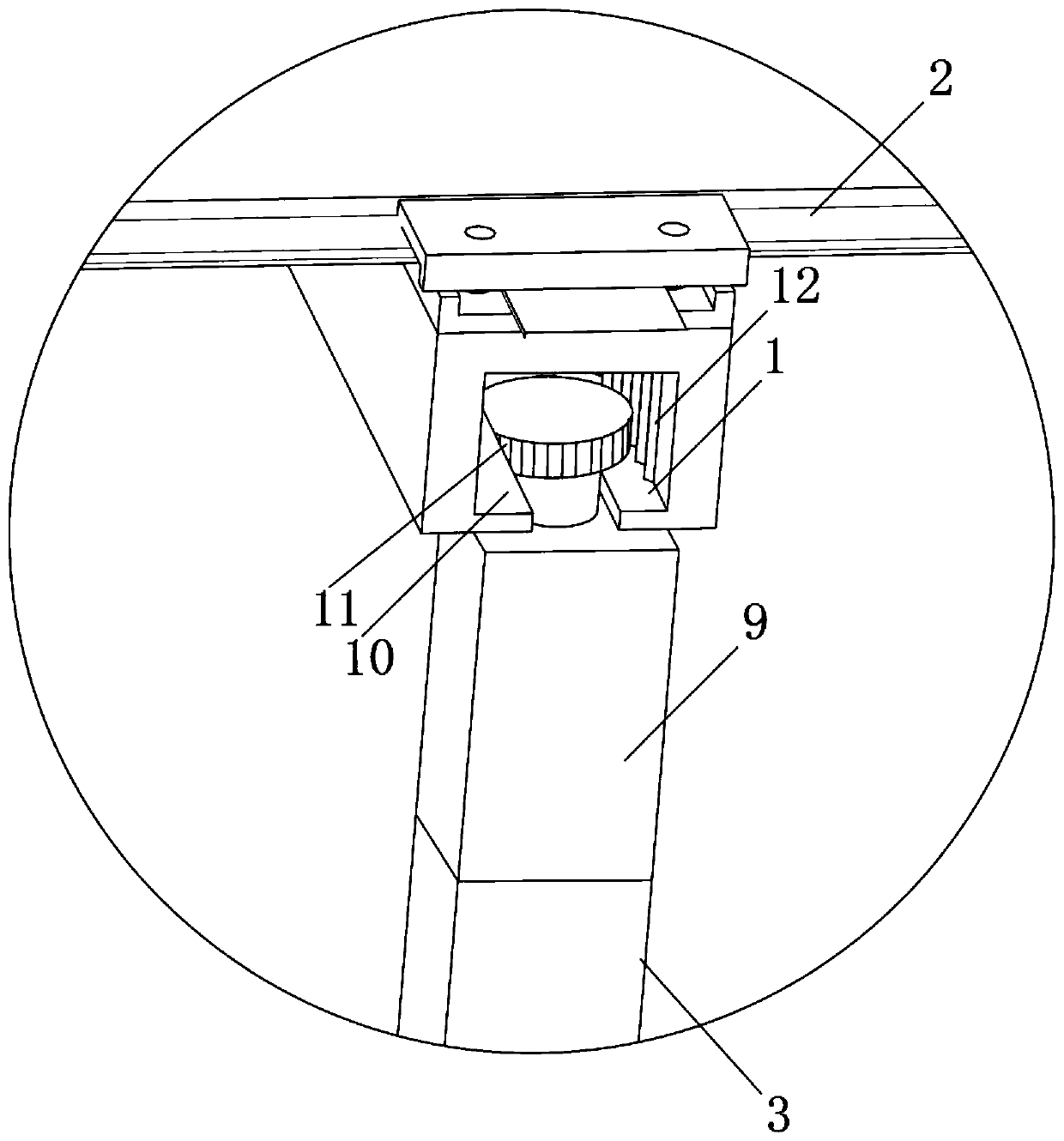

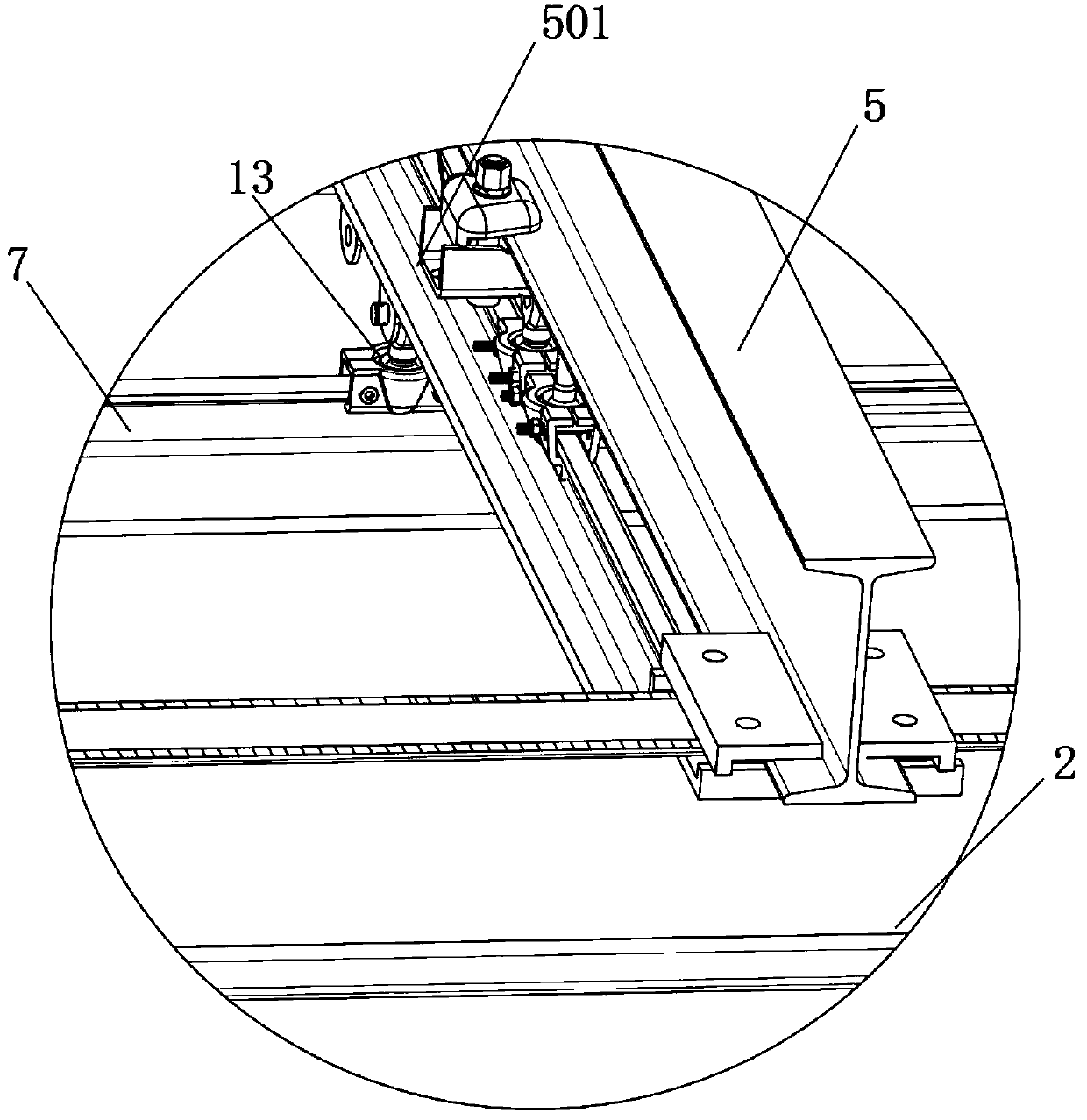

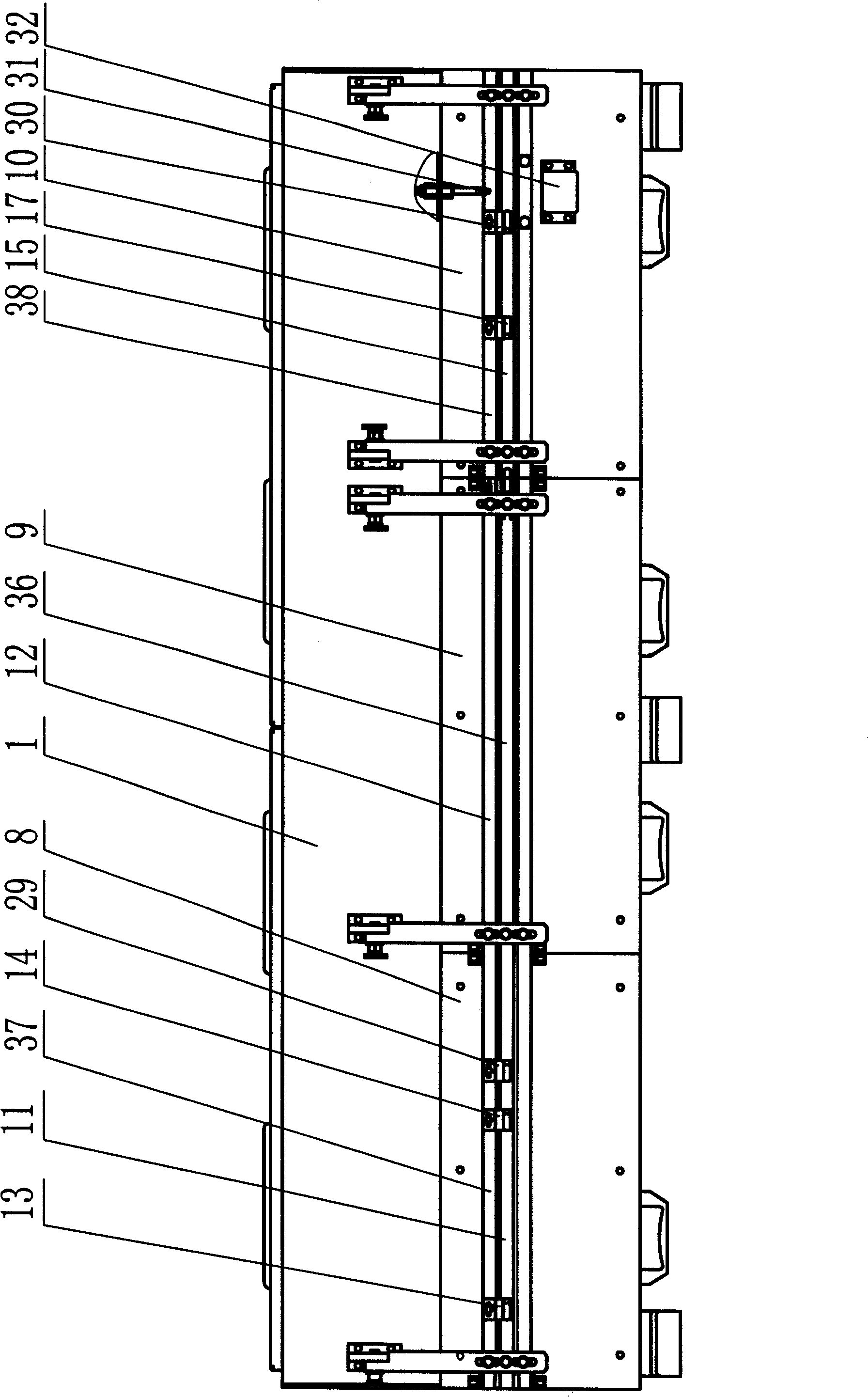

Intelligent setting-out device for rail traffic cable

ActiveCN110950159AEasy to moveAvoid entanglementFilament handlingConveyor partsGear wheelElectric machinery

The invention discloses an intelligent setting-out device for a rail traffic cable. The device comprises two side sleeving frames I, two upper end plates, two top carrying frames and a transfer disk,wherein the two side sleeving frames are disposed in parallel; the two upper end plates are disposed on two ends between the two side sleeving frames I; vertical struts are vertically disposed under two ends of the two side sleeving frames; and the top carrying frames are disposed on two sides above the upper end plates. The device disclosed by the invention has the beneficial effects that a motorI on the top of the vertical struts is fitted with rolling of rolling teech I in a rolling slot I by a gear I so as to adjust an interval between the vertical struts on two sides of the device, and thus electric wheels can be arranged on rail plates which are located on two sides of rails with different widths. On one side, the device is connected to the two sides of the rail by the electric wheels and the device can be driven to realize movable work, so the device can carry out setting-out work more efficiently; and on the other side, the device can be fitted with the rails which have different widths, so extensive fitting is ensured, and the device can move on the rails more stably and smoothly.

Owner:苏州科亿嘉科技发展有限公司

Self-bearing tensile wind energy power cable

InactiveCN105405513APrevent moistureWrap tightlyInsulated cablesPower cablesUltrasound attenuationPower cable

The invention discloses a self-bearing tensile wind energy power cable. The self-bearing tensile wind energy power cable comprises a cable core, an isolation strip wrapped outside the cable core in an extruded manner and an outer sheath; a plurality of tubular conductors and rubber filling strips extruded among the tubular conductors are stranded, such that the cable core is formed; a bearing core is arranged in the centre of the tubular conductor; and a metal tensile tube is arranged between the isolation strip and the outer sheath. The self-bearing tensile wind energy power cable disclosed by the invention is high in self-bearing performance, low in attenuation, good in shielding effect and good in tensile performance, moisture resistance and sealing performance.

Owner:JIANGSU LONG E CABLE

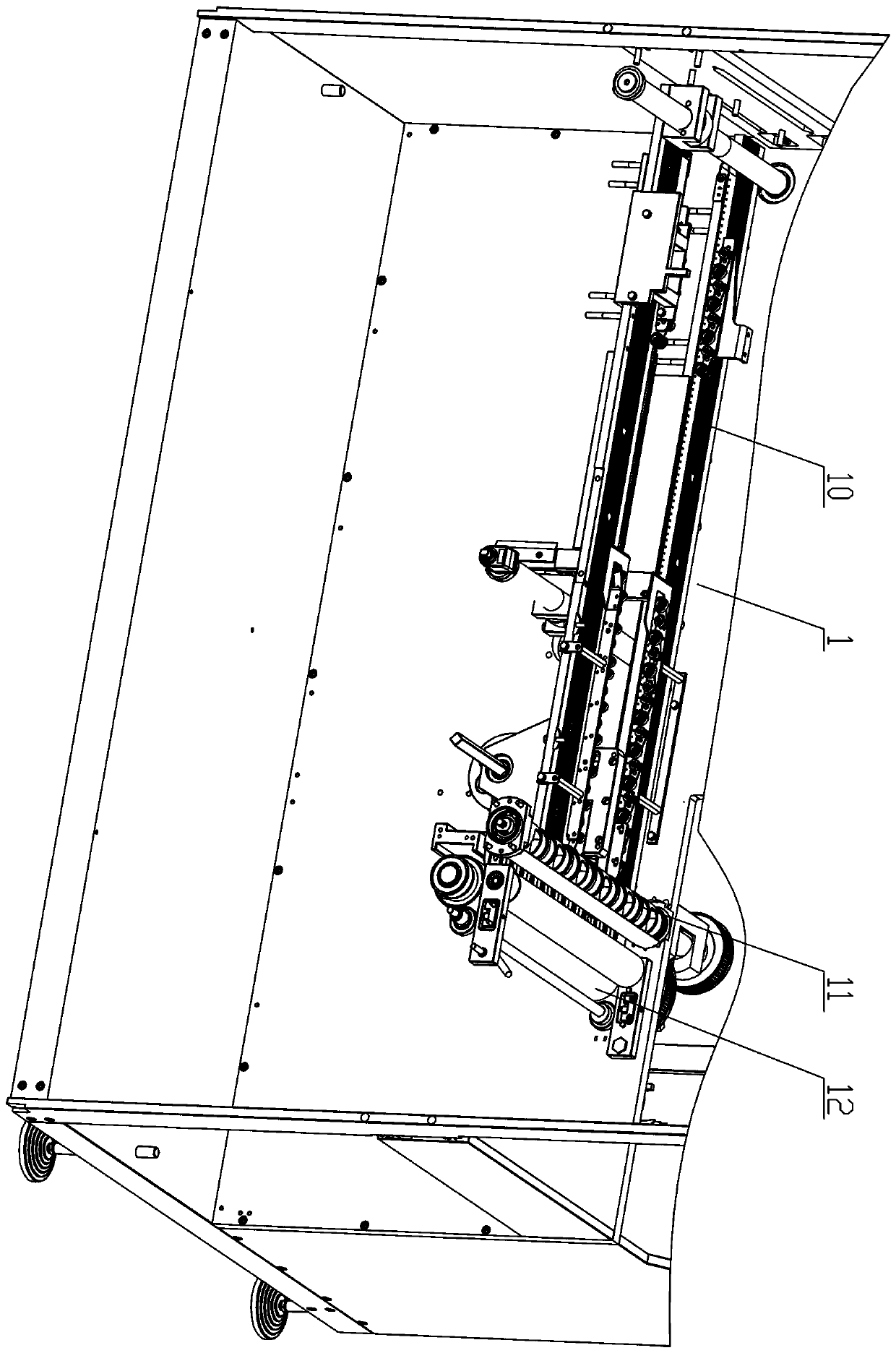

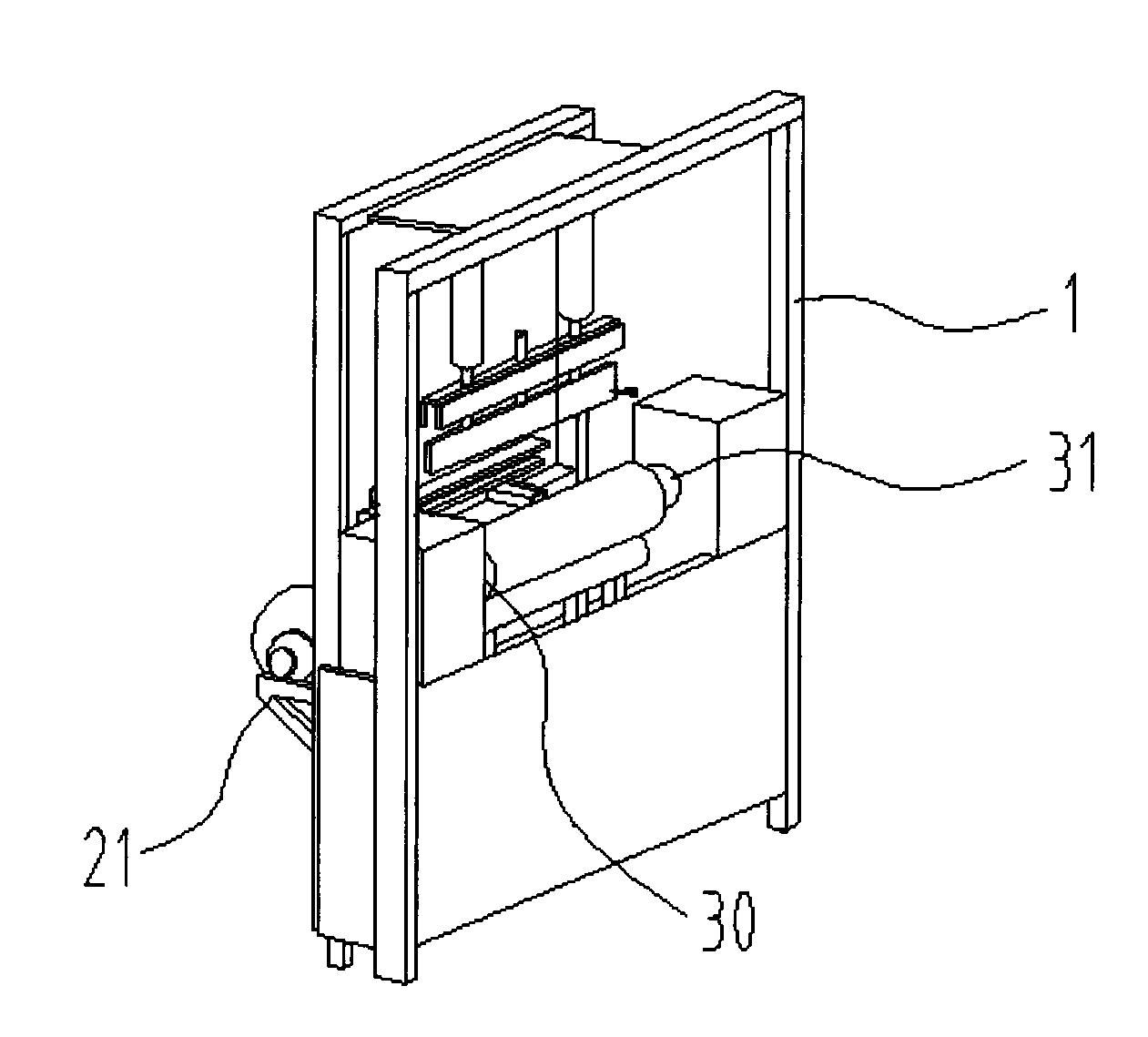

Three-dimensional wrapping machine

PendingCN111547311ADoes not affect product qualityCompact structureWrapping material feeding apparatusWrapper folding/bending apparatusMechanical engineeringPhysics

The invention discloses a three-dimensional wrapping machine. The machine comprises a rack, a film feeding mechanism, a material feeding mechanism, a wrapping mechanism and a side sealing mechanism, wherein the material feeding mechanism comprises a material feeding component, the tail end of the material feeding component is provided with a push plate lifting up and down, the wrapping mechanism is arranged above the material feeding component, the wrapping mechanism comprises a main body folding device and a side surface folding device, the side sealing mechanism comprises an overturning seatwhich swings up and down as well as a left heat sealing component and a right heat sealing component which are arranged on the overturning seat, the side end of the overturning seat is hinged to therack, the film feeding mechanism comprises a traction device, a film cutting device and a positioning film feeding device, the traction device and the film cutting device are arranged below the overturning seat, and the positioning film feeding device is arranged between the main body folding device and the material feeding component. The machine is compact in structure, reasonable in design, small in overall size, convenient to arrange, compact in wrapping, free of looseness and good in wrapping quality.

Owner:温州优博特机械有限公司

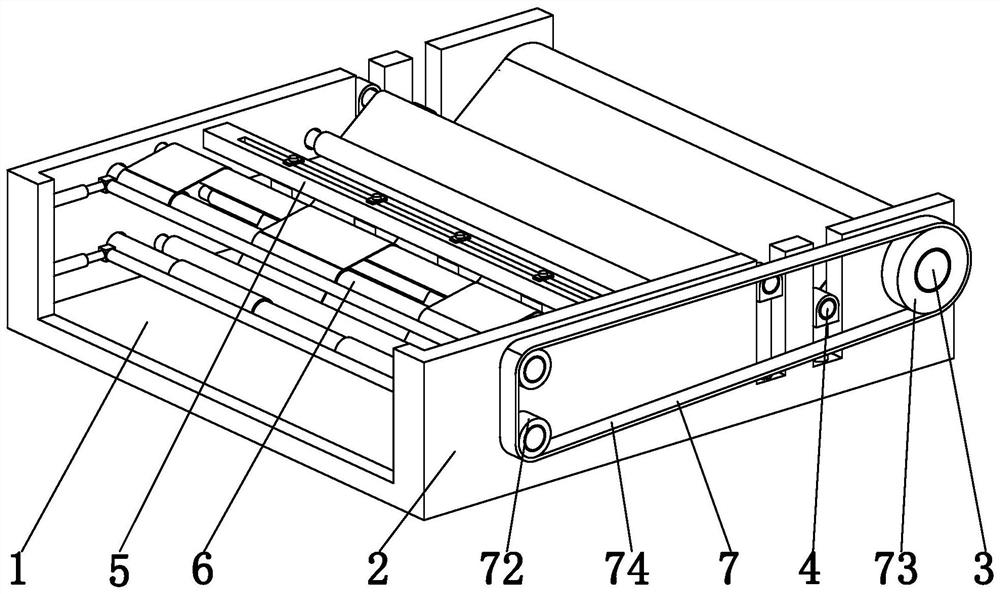

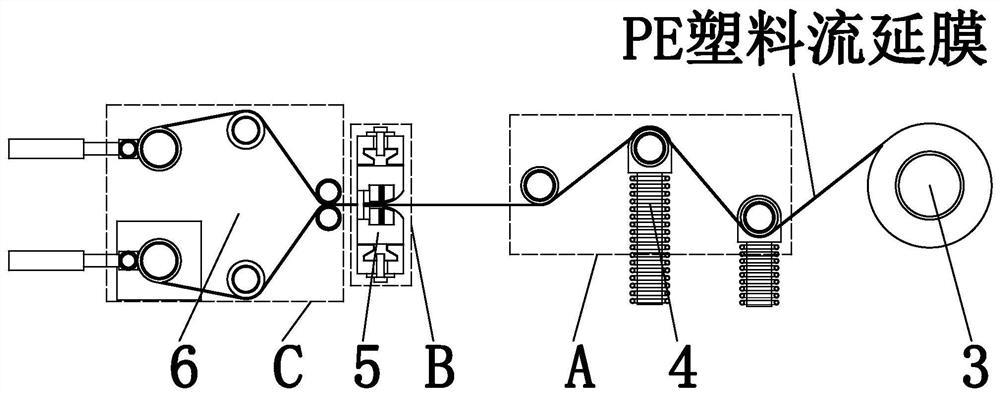

Automatic PE plastic cast film slitting machine and technology

InactiveCN111776831ALow efficiencySlicing to achieveArticle deliveryWebs handlingElectric machineryEngineering

The invention provides an automatic PE plastic cast film slitting machine and technology. A base, an installing frame, an unreeling shaft, a tensioning mechanism, a slitting mechanism, a winding mechanism and a drive mechanism are included. The automatic PE plastic cast film slitting machine is provided, and the following problems that a, when a cast film slitting machine is adopted for slitting acast film, an unreeling shaft and a reeling shaft rotate at the same time under the action of a motor, the cast film is likely to wrinkle and roll when not slit, consequently, uneven cutting or inclination can happen after cast film slitting, and the slitting effect is influenced; and b, according to cast films with different required sizes, different cutter devices commonly need to be replaced for the existing slitting machine, accordingly, the needed-specification cast film is adjusted, consequently, slitting devices different in specification need to be manufactured, cost is high, and efficiency is low, wherein the problems exist in the PE plastic cast film slitting process.

Owner:合肥新胜塑料科技有限公司

Automatic packaging equipment for pipe film coating

ActiveCN114291322AWrap tightlyImprove lamination efficiencyWrappingCleaning using toolsEngineeringStructural engineering

The invention discloses automatic packaging equipment for pipe film covering, and relates to the technical field of pipe packaging equipment. The automatic packaging equipment for pipe film covering comprises a base and two sets of sliding rods symmetrically and fixedly connected to the upper end face of the base through fixing blocks, a mounting base is fixedly connected between the sliding blocks, the right end of a connecting rod is fixedly connected to the left end of the mounting base, and an annular pipe is arranged at the upper end of the mounting base through a conveying pipe; nozzles are communicated with the circumference of the outer surface wall of the annular pipe at equal intervals and point to the center direction of the annular pipe; according to the device, a pipe can be automatically subjected to film covering operation, time and labor are saved, heating and compacting can be conducted after film covering is completed, so that an adhesive film can be tightly wound around the outer portion of the pipe, the situation of loosening and falling is avoided, dust on the surface of the pipe can be cleaned, the adhesive film can be tightly attached to the surface wall of the pipe, and the service life of the pipe is prolonged. The film covering quality is improved.

Owner:JIANGSU RUNSOO PIPELINE TECH CO LTD

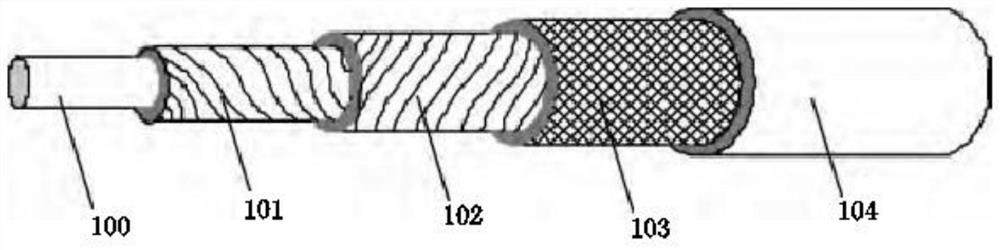

Low-loss stable-phase cable

InactiveCN111899947AConvenient loading workEasy to draw workInsulated cablesManufacturing extensible conductors/cablesElectrical conductorCopper wire

The invention discloses a low-loss stable-phase cable. The cable comprises a silver-plated soft round copper wire inner conductor, a microporous polytetrafluoroethylene tape insulator, a silver-platedcopper flat tape outer conductor, a silver-plated soft round copper wire outer conductor and a fluorinated ethylene propylene sheath, wherein the outer side of the silver-plated soft round copper wire inner conductor is wrapped with the microporous polytetrafluoroethylene tape insulator, the outer side of the microporous polytetrafluoroethylene tape insulator is wrapped with the silver-plated copper flat tape outer conductor, the outer side of the silver-plated copper flat tape outer conductor is wrapped with the silver-plated soft round copper wire outer conductor, and the soft round copperwire drawing is realized through the size difference between the two wire drawing wheels; wire drawing is convenient, the efficiency is high, wire drawing is carried out in water, so that the phenomenon that a copper wire is easy to deform and break during traditional wire drawing is avoided, the copper wire is ensured to be in a low-temperature environment through underwater wire drawing, deformation of the copper wire due to local heating is avoided, the soft round copper wire is ensured to be tightly wound on the collecting roller through supporting and tightening of the first guide wheel and the second guide wheel, and the elastic retraction phenomenon of the soft round copper wire is avoided.

Owner:王社兵

Copper strip packaging tool

ActiveCN110654594APrevent affecting the packaging effectWrapped tightlyWrapping material feeding apparatusDrive wheelEngineering

The invention relates to the field of copper strip packaging, in particular to a copper strip packaging tool which comprises a shell, a clamping structure, a first driving mechanism, a transmission mechanism and a second driving mechanism. An operating platform is fixedly connected to the bottom of the shell, the first driving mechanism is arranged on the upper surface of the operating platform, an objective table is arranged in the shell, and an arc-shaped groove is formed in the upper surface of the objective table. Since a clamping structure and a driving wheel are arranged, a copper stripcan be prevented from being inclined and affecting the packaging effect when packaged, a second sleeve can continuously clamp the two sides of the copper strip, folds of packaging strips on the two sides of the copper strip can be flattened, a first sleeve can flatten the folds of a packaging strip on the outer side of the copper strip to enable the packaging strips to wind and pack the copper coil more tightly and firmly, the objective table can be extracted from the shell through the arrangement of the first driving mechanism, the copper strip can be conveniently taken and placed by workers,and workers can conveniently carry out feeding and discharging on the copper strip packaging tool.

Owner:浙江金桥铜业科技有限公司

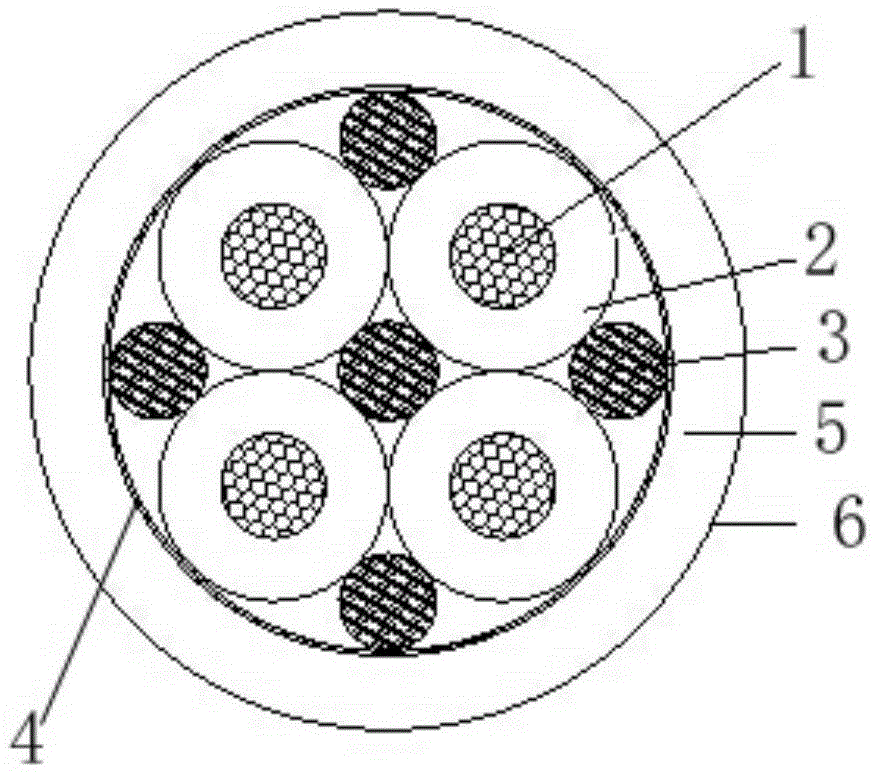

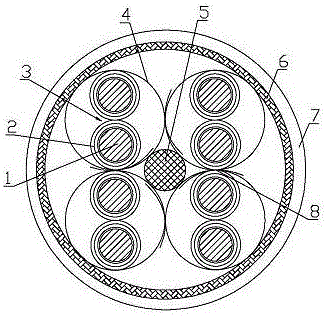

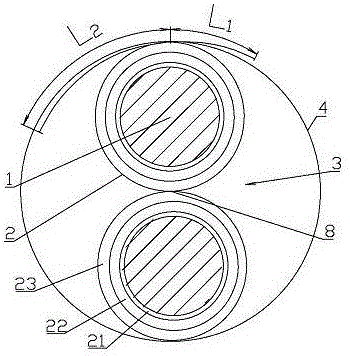

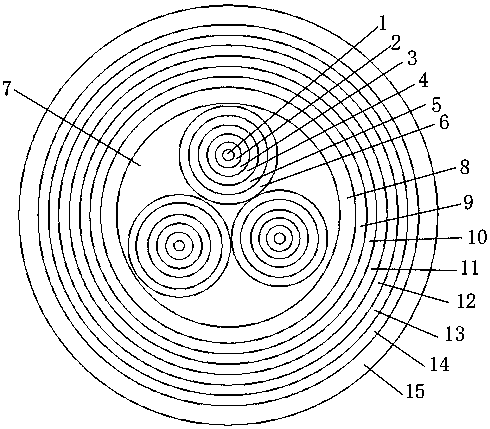

UHF digital communication cable and its preparation method

ActiveCN105551677BReduce contact stressPrevent intrusionInsulated cablesCable/conductor manufactureCopper conductorInsulation layer

An ultra-high frequency digital communication cable, comprising a cable core, a total shielding layer (6), an outer protection layer (7) and branch shielding layers (4) on twisted pair wire groups (3), wherein overlapping sides of the branch shielding layers (4) are clamped between two adjacent insulated single wires to form a branch shielding overlapping wire (8); the branch shielding overlapping wires (8) corresponding to two adjacent pairs of twisted pair wire groups (3) are arranged in a staggered manner; and the length for overlapping, outward-stretching sides of the branch shielding layers (4) to extend outwards from the branch shielding overlapping wires (8) is L1, L1 being 10%-15% of the width of a clad foil band of the branch shielding layers (4). The preparation method comprises the following steps: (1), drawing a copper conductor (1); (2), extruding an insulation layer; (3), twisting twisted pair wire groups (3); (4), cladding branch shielding layers (4); (5), twisting same into a cable; (6), weaving a total shielding layer (6); and (7), extruding an outer protection layer (7) into a finished cable. The communication cable not only has a good shielding effect and can effectively prevent intrusion and leakage of an electromagnetic wave, but also has a firm cable structure and stable transmission performance, and is particularly applicable to transmitting an ultra-high frequency band digital signal.

Owner:JIANGSU DONGQIANG

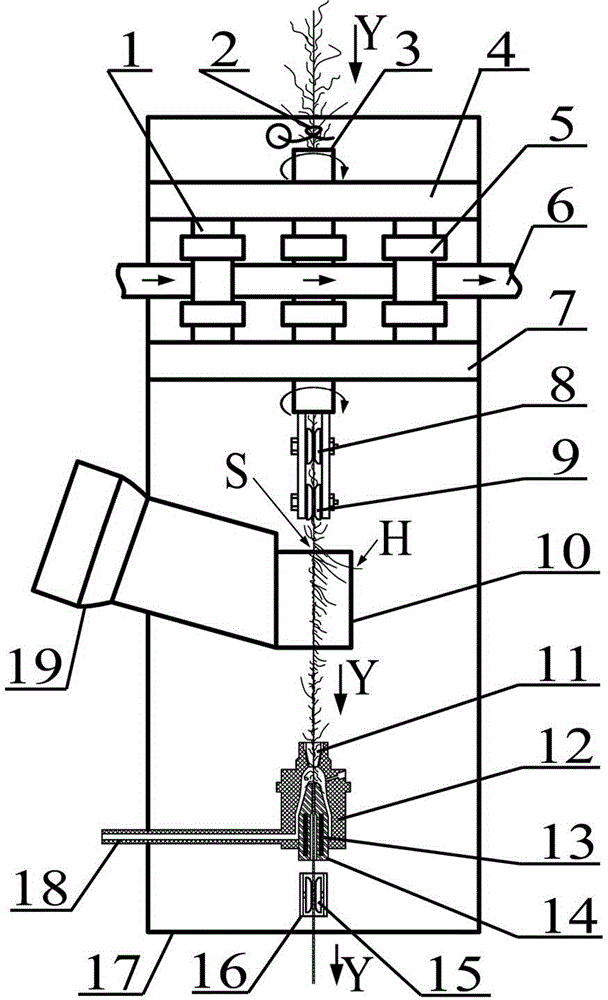

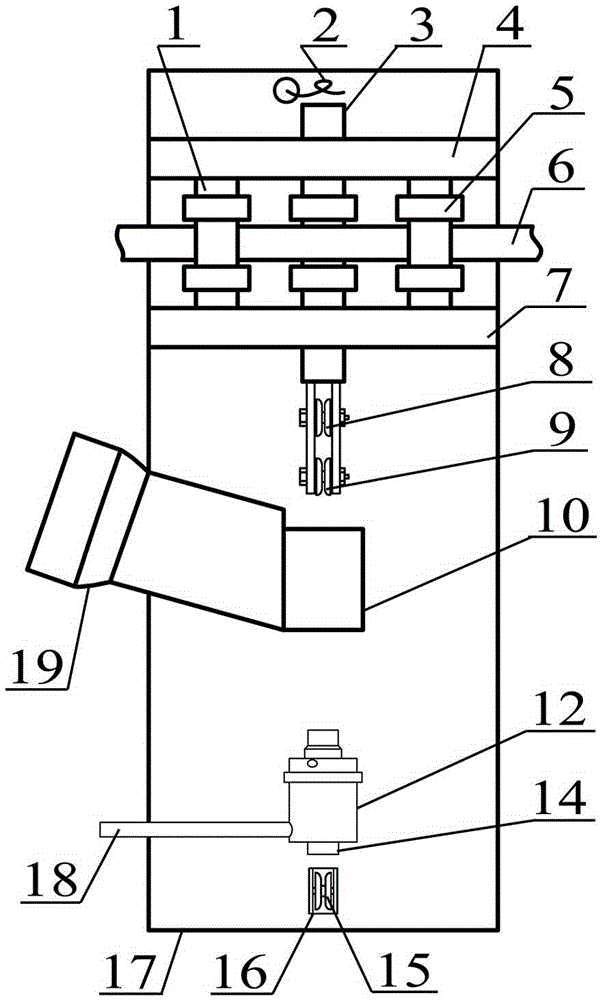

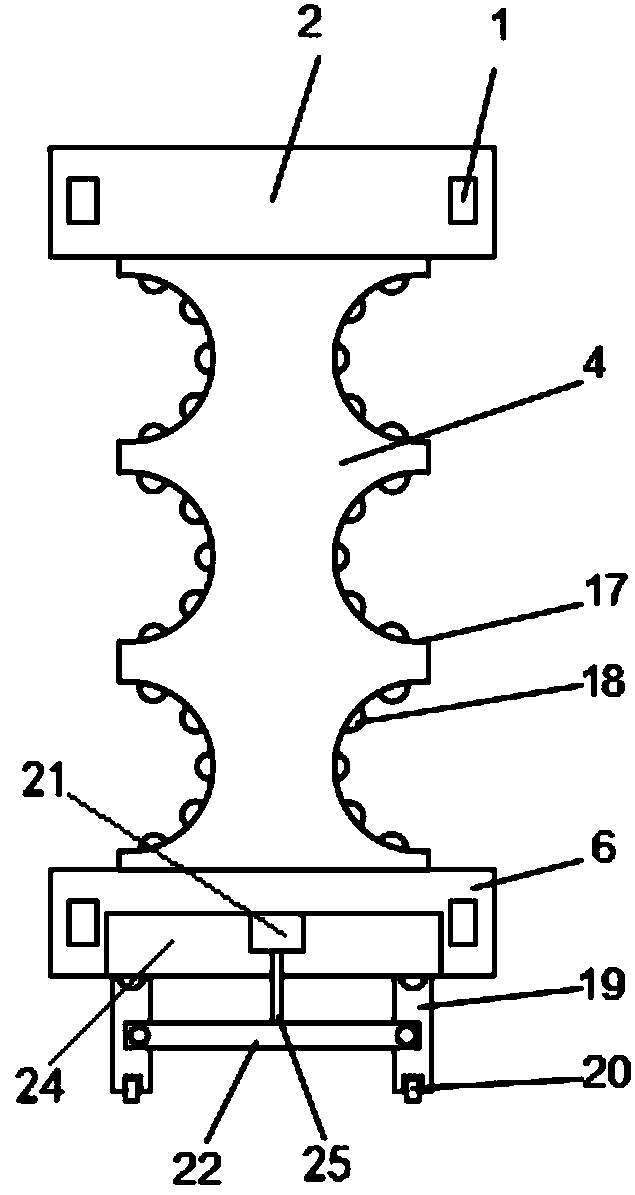

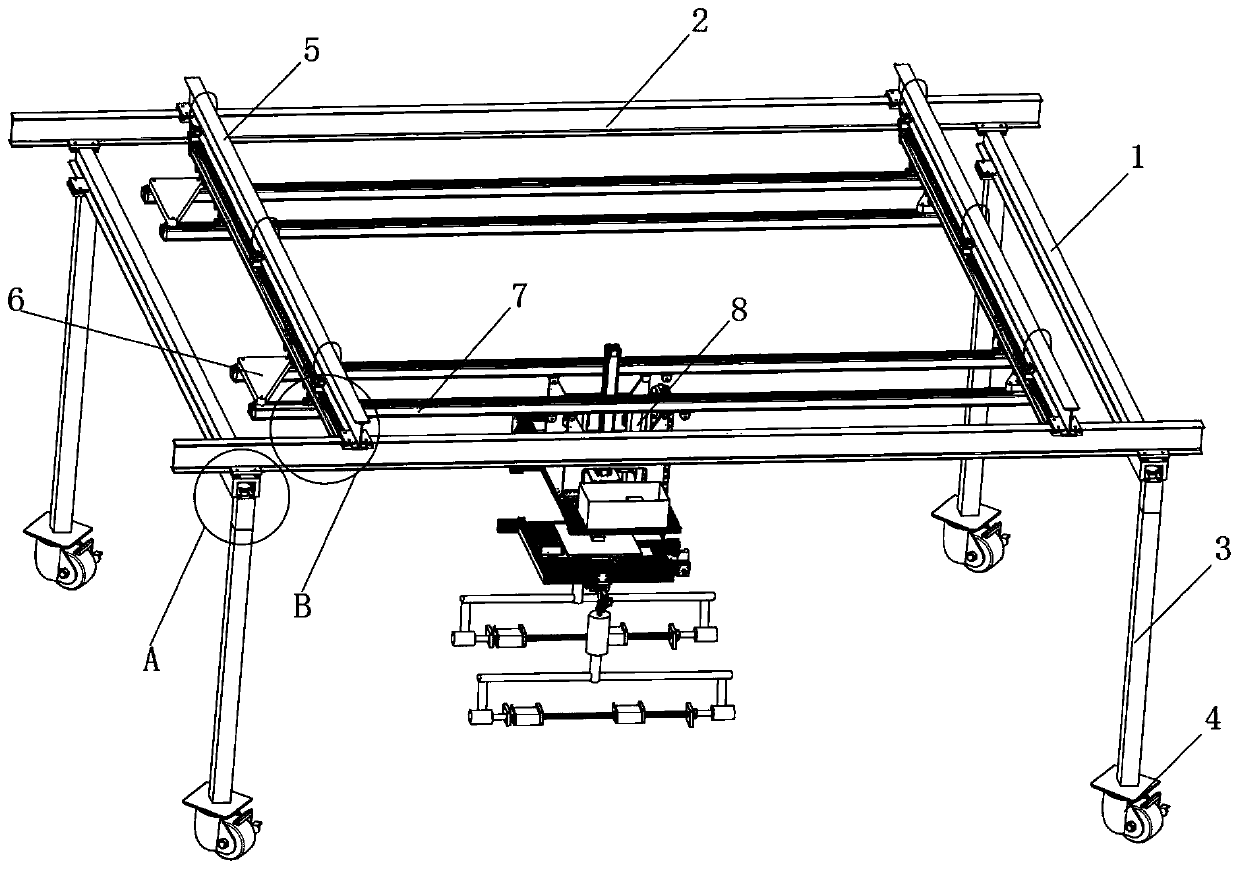

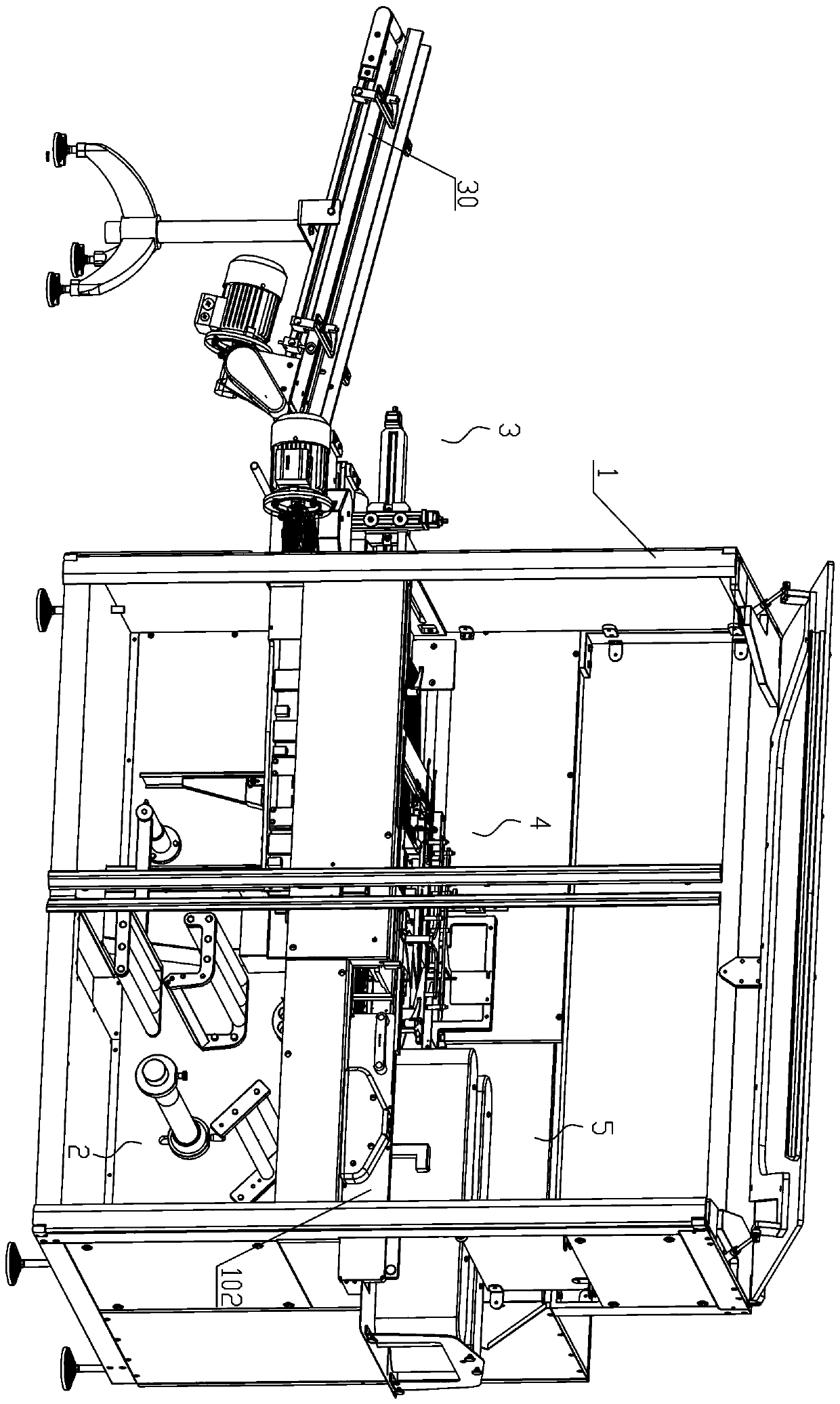

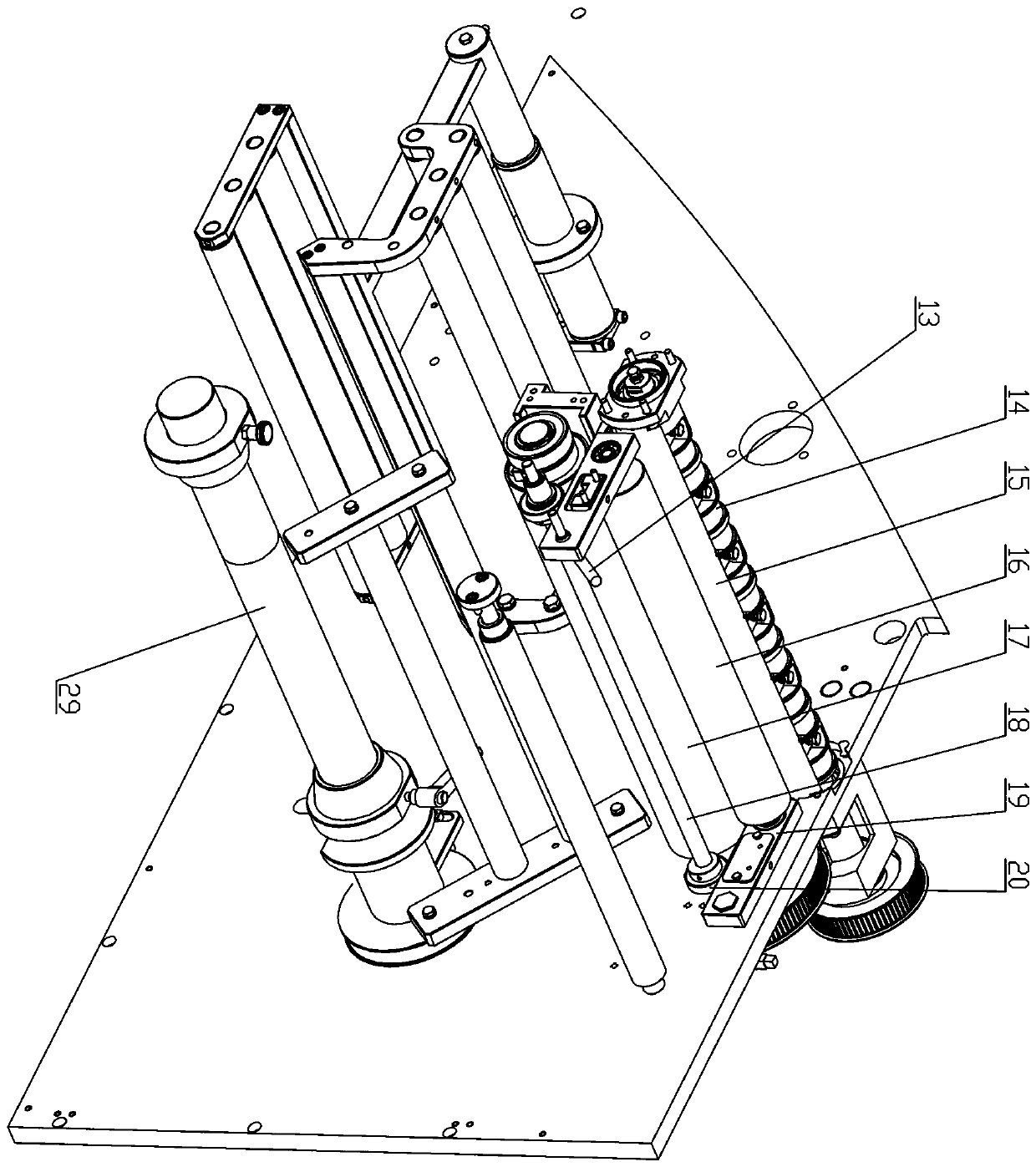

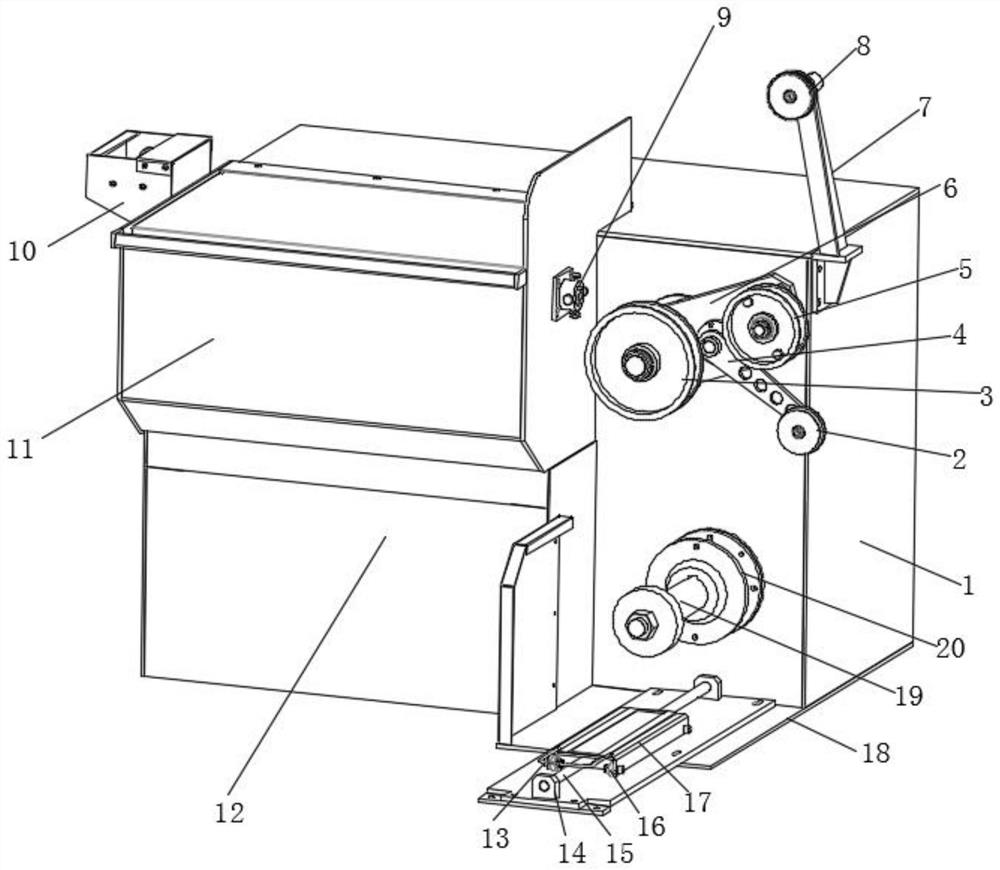

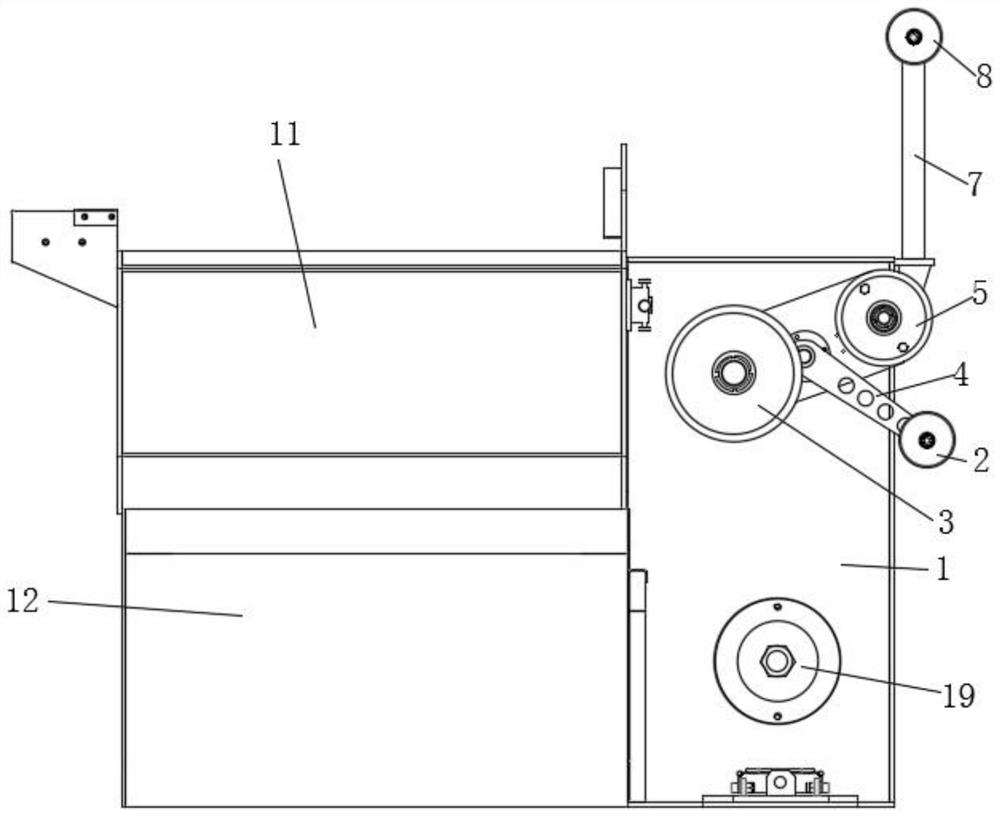

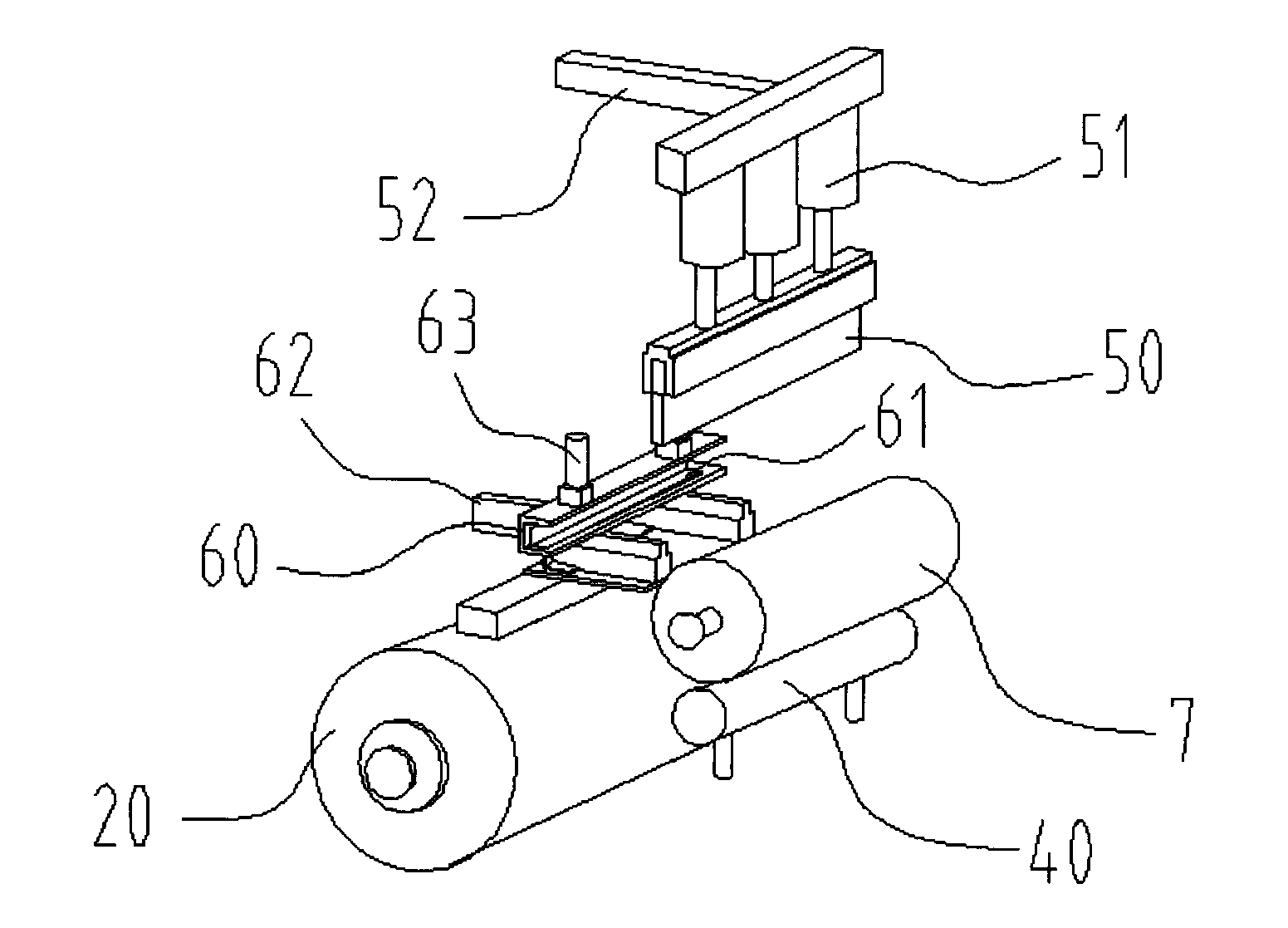

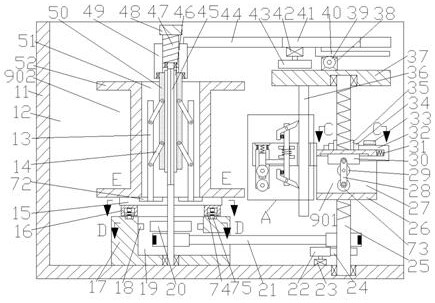

Automatic winding machine and winding method for roll type membrane element protective net

InactiveCN104043336AWrap tightlyIncrease productivitySemi-permeable membranesWinding machineReciprocating motion

The invention discloses an automatic winding machine and a winding method for a roll type membrane element protective net, and the automatic winding machine for the roll type membrane element protective net comprises a machine frame, a feeding system, a position system, a clamping system, a heating system and an auxiliary system; the heating system comprises a heater, a heater upper and lower driving device driving the upper and lower reciprocating motion of the heater, and a heater front and back driving device driving the front and back reciprocating motion of the heater; the auxiliary system comprises a clamping groove, a pressing plate parallelly arranged in the clamping groove, a clamping groove driving device driving the front and back reciprocating motion of the clamping groove, and a pressing plate driving device driving the front and back reciprocating motion of the pressing plate. The automatic winding machine semi automation equipment, by use of the automatic winding machine, only one person can complete winding of an outer protective net, the outer protective net is tightly wound, the production efficiency is high, the cost is low, the length of the heater is not shorter than the length of a to-be-processed membrane element, the thermal bonding process can be once completed, and the adhesion is rapid.

Owner:SYNDER TAIZHOU MEMBRANE TECH CO LTD

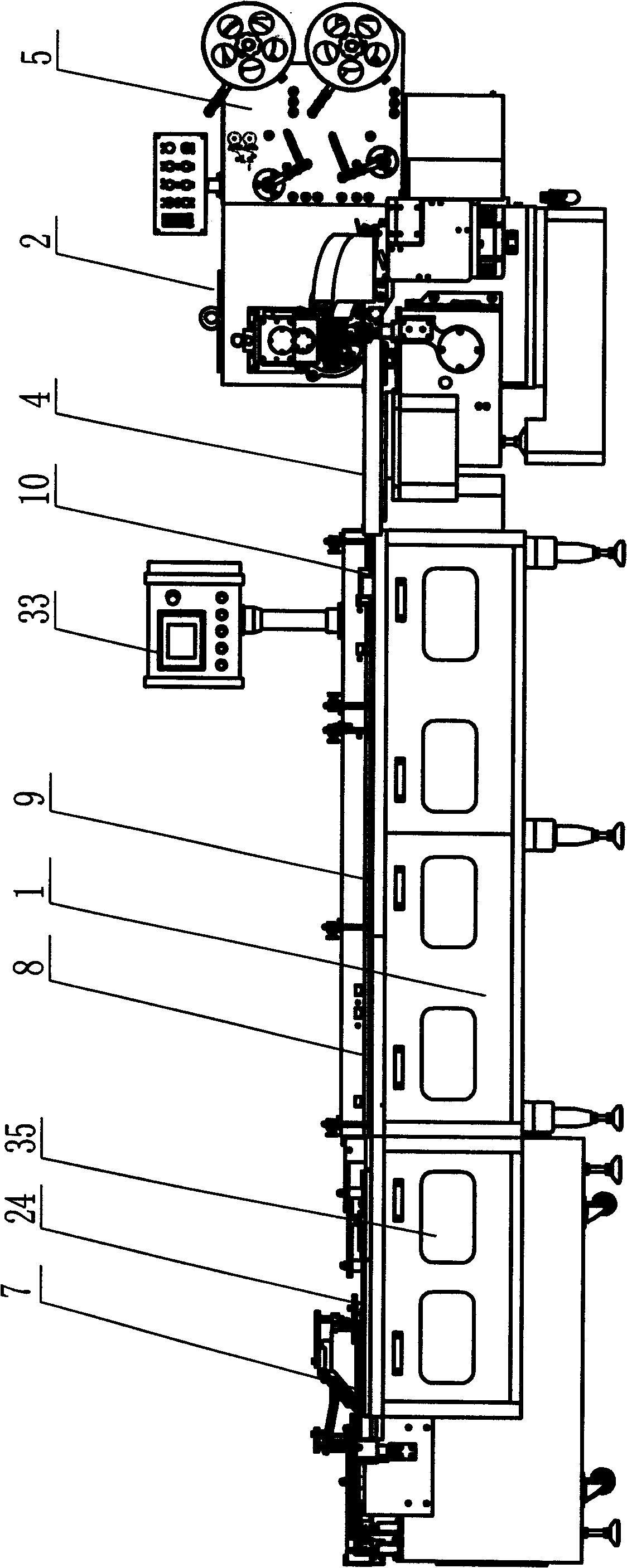

Flat plate type tidying candy packaging machine

InactiveCN101596948BCompact structureNice appearanceWrappingPackaging automatic controlDrive motorControl circuit

The invention discloses a flat plate type tidying candy packaging machine which comprises a stand. The stand is provided with a host which comprises a control circuit, a candy feeding part, a candy tidying part, a candy packaging part and each drive motor. The candy feeding part, the candy tidying part and the candy packaging part are sequentially connected, and each drive motor is connected withthe control circuit; a feeding conveyor is arranged below a feeding plate on the stand, and an inside-and-outside candy disk difference mechanism is arranged below the feeding conveyor; on the stand,a second conveyor line part, a third conveyor line part, a fourth conveyor line part and a chain hook transmission part are sequentially arranged at the output end of the inside-and-outside candy disk difference mechanism; the second conveyor line part, the third conveyor line part and the fourth conveyor line part are respectively provided with a transmission synchronous belt and a drive component thereof, and a photoelectric detection sensor is arranged at one side outside a second transmission groove hole; a laser detection sensor is arranged at one side outside the front part of a fourth transmission groove hole, and the laser detection sensor is connected with a control circuit of the chain hook transmission part and a control circuit of each drive component of the host; and the conveying tail end of the chain hook transmission part is connected with the candy feeding part. The invention has favorable automation for tidying and packaging candies.

Owner:浙江金鸿智能科技有限公司

Galvanized iron wire winding device

The invention relates to the technical field of mechanical equipment production, in particular to a galvanized iron wire winding device which comprises a base, a protective cover, a wire leading mechanism and a transmission mechanism, wherein the wire leading mechanism can guide an iron wire according to a set speed, so that the iron wire is uniformly wound on a collecting roller, and the iron wire is wound more compactly. The equipment is further provided with a protective cover which covers the whole equipment, so that on one hand, the dangerous accident that related personnel approaches to wind clothes can be avoided, and on the other hand, the situation that iron wires are thrown away and drawn to workers due to sudden breakage of the iron wires in the winding process can be eradicated. The galvanized iron wire winding device has the advantages that the winding effect is good, the cost and the operation and maintenance cost are low, the personal safety of personnel can be greatly protected, and the work efficiency of production is improved.

Owner:天津五星金属制品有限公司

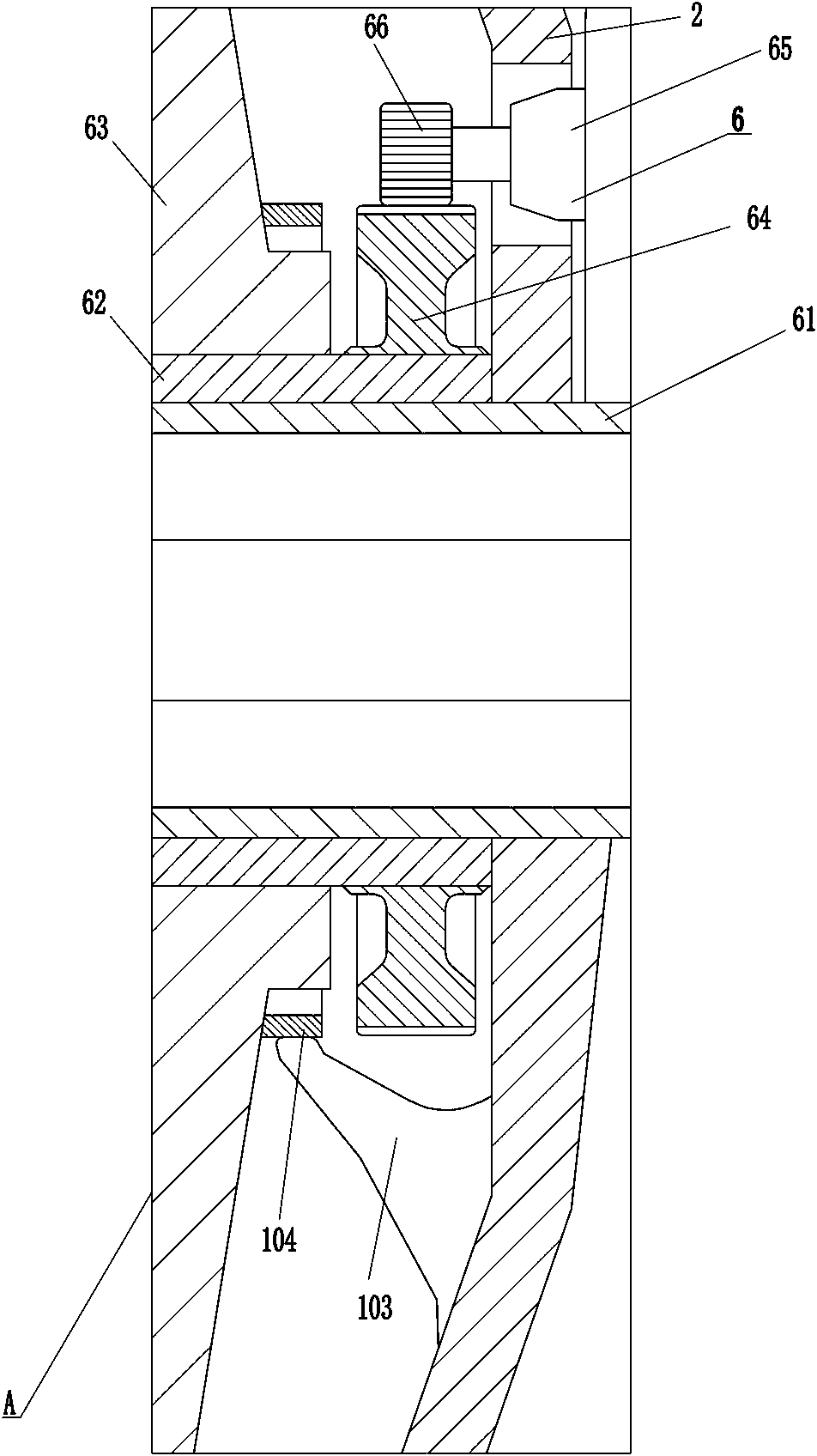

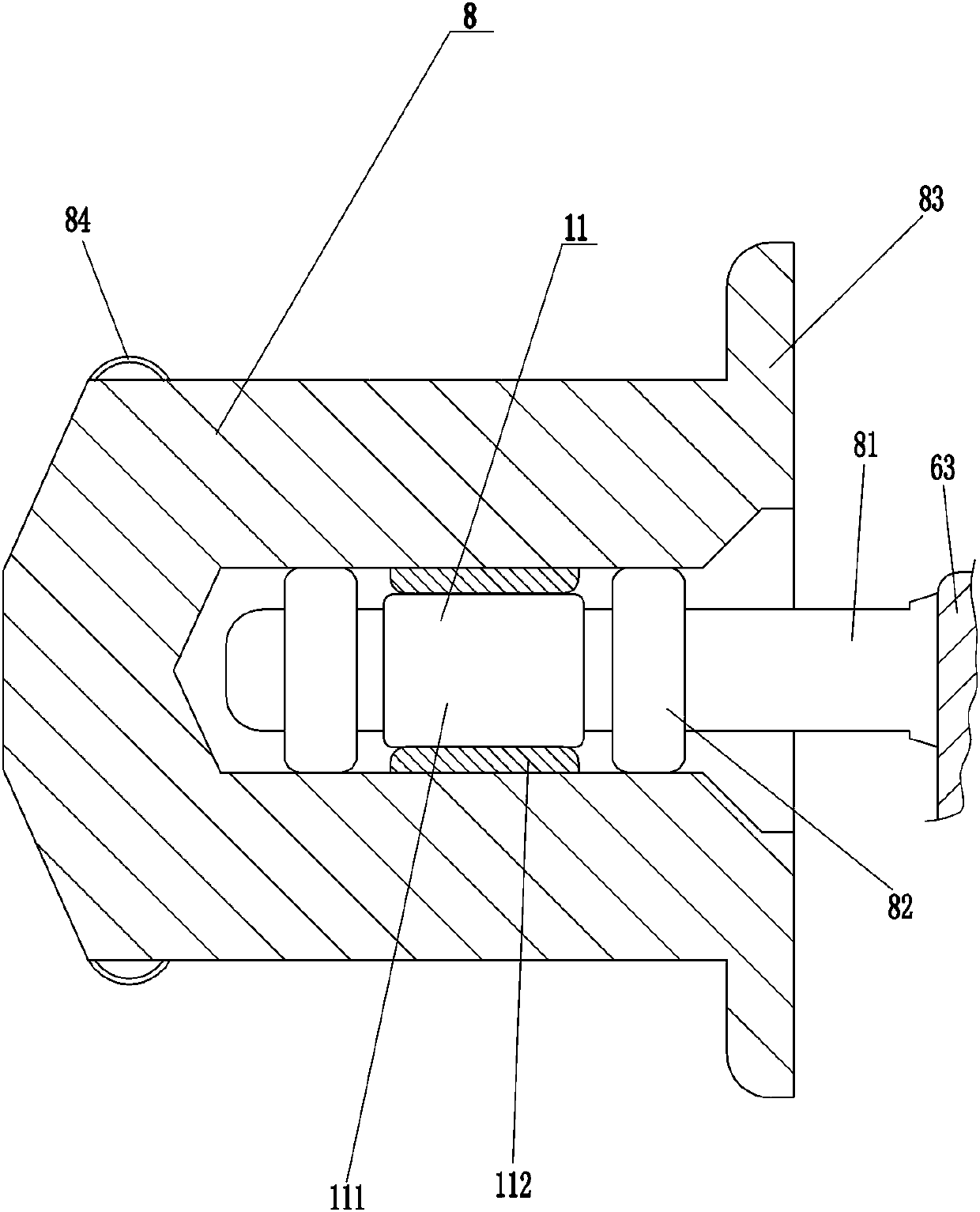

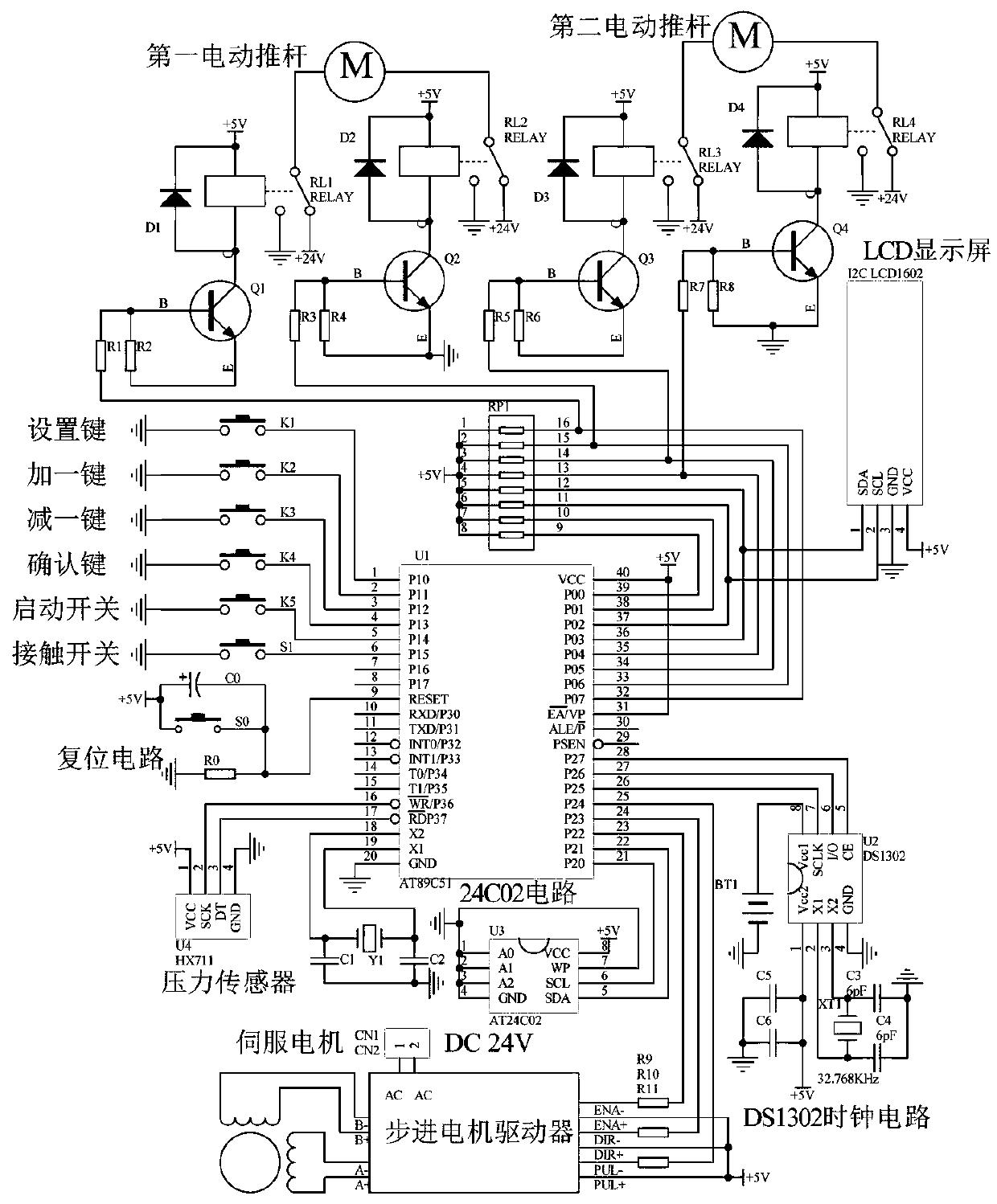

Water pipe threaded opening thread seal tape winder for road construction

ActiveCN110980402AFirmly connectedSealing is not affectedFilament handlingArchitectural engineeringThread seal tape

The invention relates to a thread seal tape winder, in particular to a water pipe threaded opening thread seal tape winder for road construction. With the water pipe threaded opening thread seal tapewinder for road construction of the invention adopted, winding thickness can be guaranteed, the connection of water pipes can be facilitated, and the sealing performance of the water pipes will not beinfluenced. The water pipe threaded opening thread seal tape winder for road construction comprises a handle, a protective cover and the like, wherein the handle is connected with the protective cover. According to the water pipe threaded opening thread seal tape winder for road construction of the invention, the working time of a rotating mechanism can be set according to the diameter of a waterpipe through a setting key, a one-plus key, a one-minus key and a confirmation key, and therefore, winding thickness can be guaranteed, the connection of water pipes can be facilitated, the sealing performance of the water pipes is not affected; and a centering assembly can play a role in centering, so that the device of the invention can be fixed, and therefore, a thread seal tape can be wound more orderly.

Owner:ZHENGTAI GRP

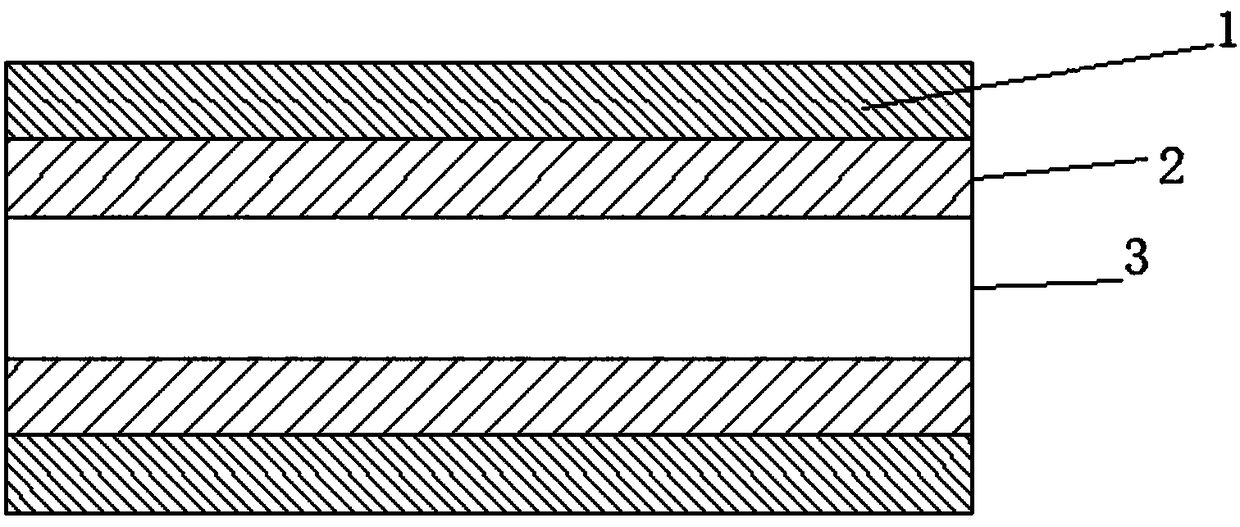

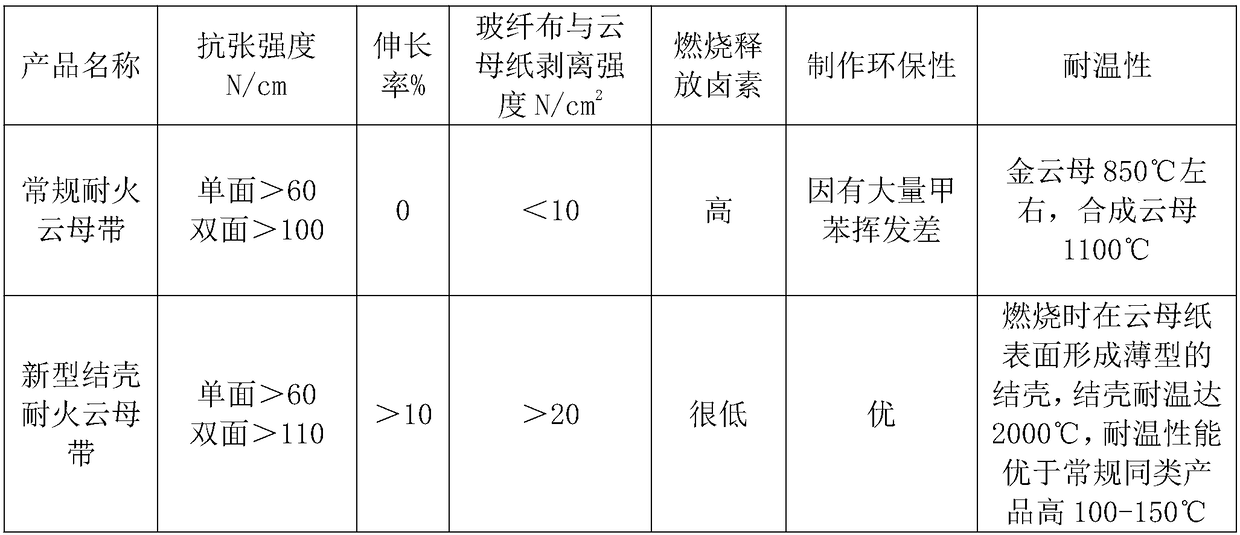

Novel crusted fire-resistant mica tape and production process thereof

InactiveCN108615578AThe preparation process is environmentally friendlyReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsState of artSilica gel

The invention discloses a novel crusted fire-resistant mica tape and a production process thereof. The novel crusted fire-resistant mica tape comprises enhanced protective layers, bonding layers and mica paper, wherein the enhanced protective layers are respectively arranged at the upper side and lower side of the mica paper through the bonding layers, and the bonding layer comprises waterborne ceramic silica gel and tritium trioxide. The novel crusted fire-resistant mica tape solves the technical problems of easy layering, easy breakage, no elasticity and environmental pollution of the fire-resistant mica tape in the prior art.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Water blocking power cable

InactiveCN107945973AExtended service lifeStrong water blocking functionPower cables with screens/conductive layersInsulated cablesElectrical conductorPower cable

The invention discloses a water blocking power cable, comprising a cable core, wherein the cable core is formed by twisting a plurality of insulated water blocking cores; the gap of the cable core isfilled with a water blocking rope, a first semi-conductive water blocking tape is lapped after a copper strip shielding layer is arranged outside the cable core, then a first water blocking tape is lapped, a PVC inner sheath layer is extruded outside the first water blocking tape, a buffer water blocking tape is continuously lapped outside the PVC inner sheath layer and then a galvanized round steel wire armored layer is wound, a second water blocking tape is lapped outside the galvanized round steel wire armored layer, and an MDPE outer sheath is extruded outside the second water blocking tape. The water blocking power cable has very strong water blocking function, rainwater cannot enter the conductor, and the oxidation and corrosion of the conductor due to water infiltration are prevented from affecting the electrical performance of the cable and even causing cable breakage, so that the service life of the cable is greatly prolonged.

Owner:WUXI JIANGNAN CABLE

Cable winding and withdrawing device

InactiveCN112340539ATightly woundEasy to transportFilament handlingEngineeringStructural engineering

Owner:宁波变雪电子科技有限公司

Multi-directional regulating belt roller for wrapping device

Owner:WUXI TOLY ELECTRIC WORKS

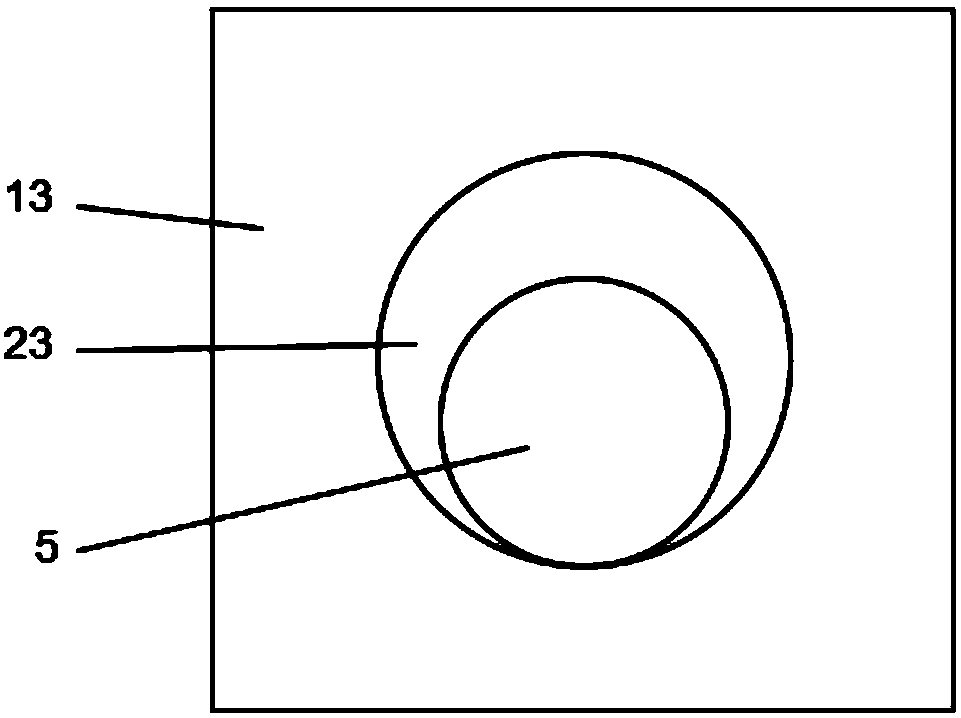

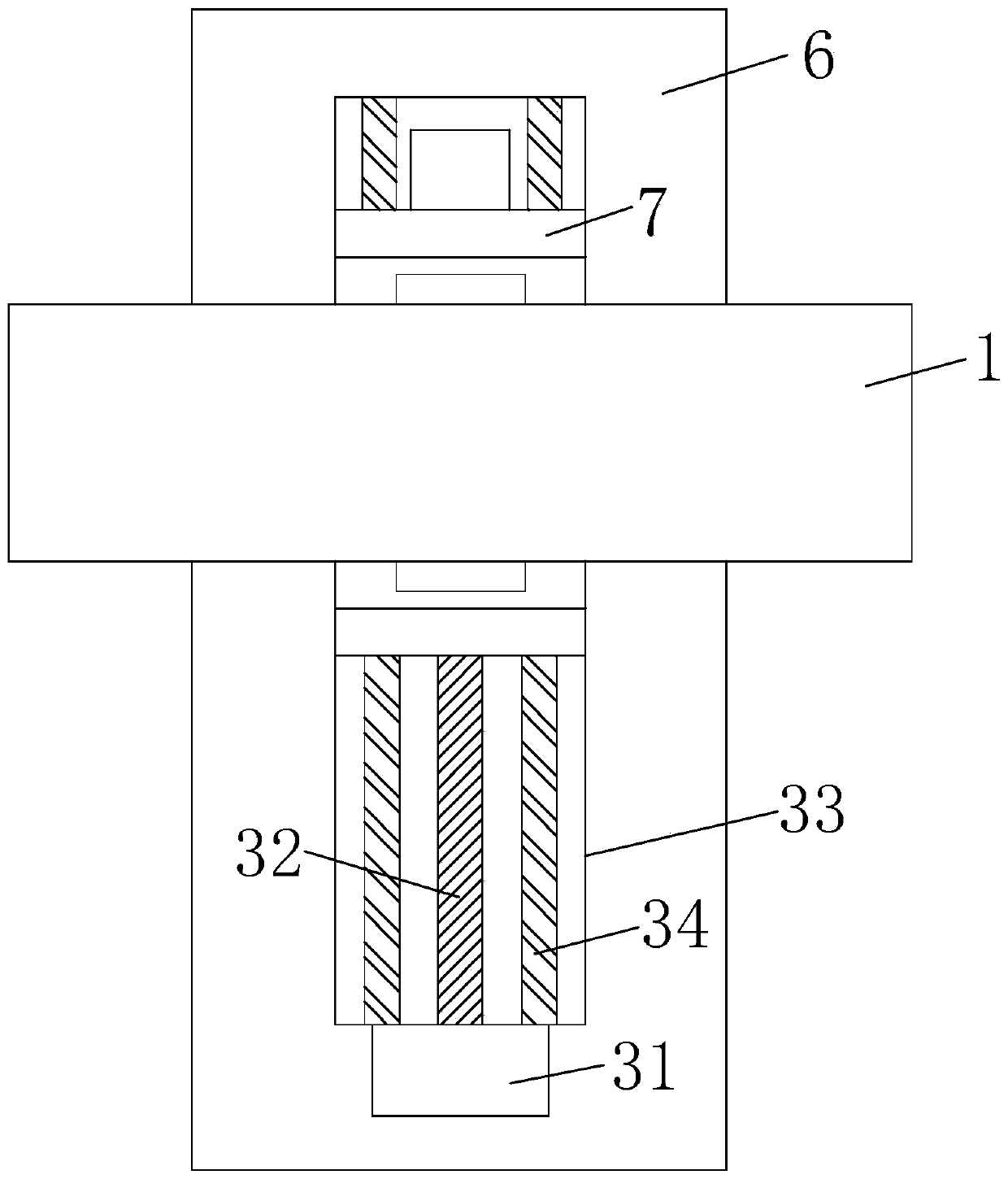

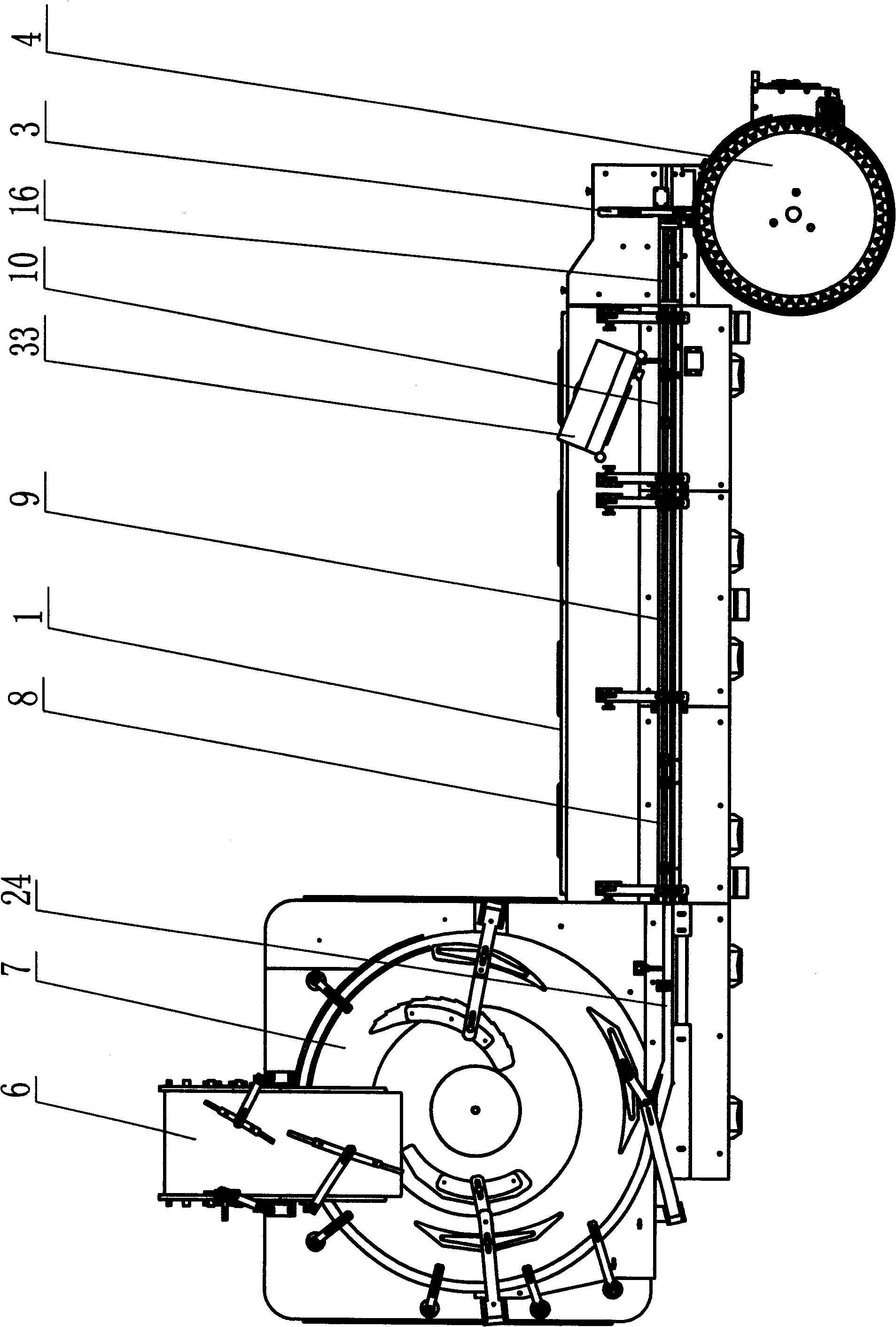

Air-jet vortex polyester yarn spinning device

InactiveCN105926102ASmooth rotationSmooth turningContinuous wound-up machinesOpen-end spinning machinesPolyesterYarn

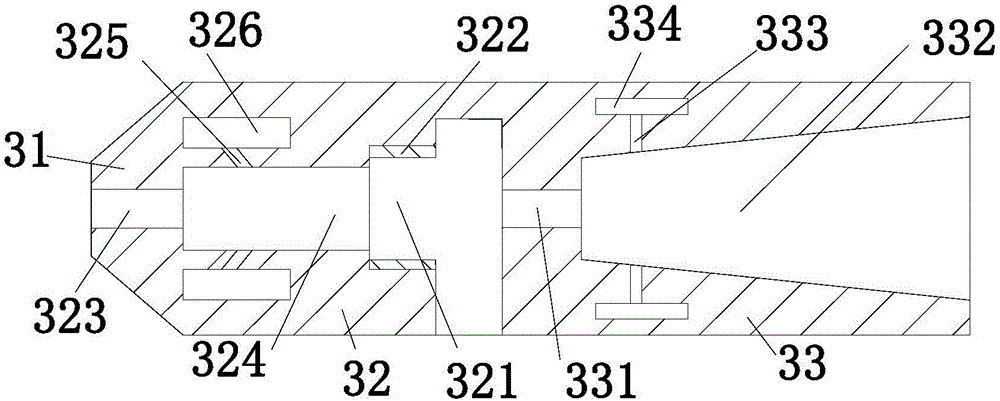

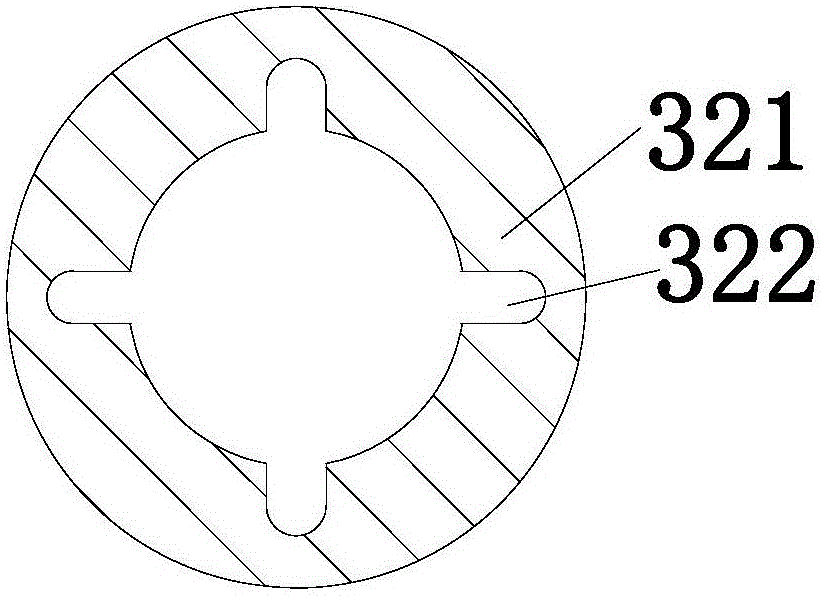

The invention discloses an air-jet vortex polyester yarn spinning device. The air-jet vortex polyester yarn spinning device comprises a raw material supply device (1), wherein the raw material supply device (1) is connected with a yarn drafting device (2); the yarn drafting device (2) is connected with a yarn twisting device (3); the yarn twisting device (3) is connected with a finished-product winding device (4); the yarn twisting device (3) comprises a shell body (31); the shell body (31) is internally provided with a first nozzle (32); the first nozzle (32) is connected with a second nozzle (33); the first nozzle (32) comprises a first splitting pipe (321); a plurality of grooves (322) with a spiral structure are uniformly formed in an inner wall of the first splitting pipe (321). The air-jet vortex polyester yarn spinning device has the characteristics of increasing the crossing depth between yarns, improving the twisting uniformity of the yarns, improving the twisting strength and improving the spinning quality.

Owner:HUZHOU JINGCHENG TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com