Flat plate type tidying candy packaging machine

A flat-panel packaging machine technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as no good solution, large size of chocolate candy, slow production progress, etc., achieve huge benefits, compact structure layout, Ensure the effect of packaging effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

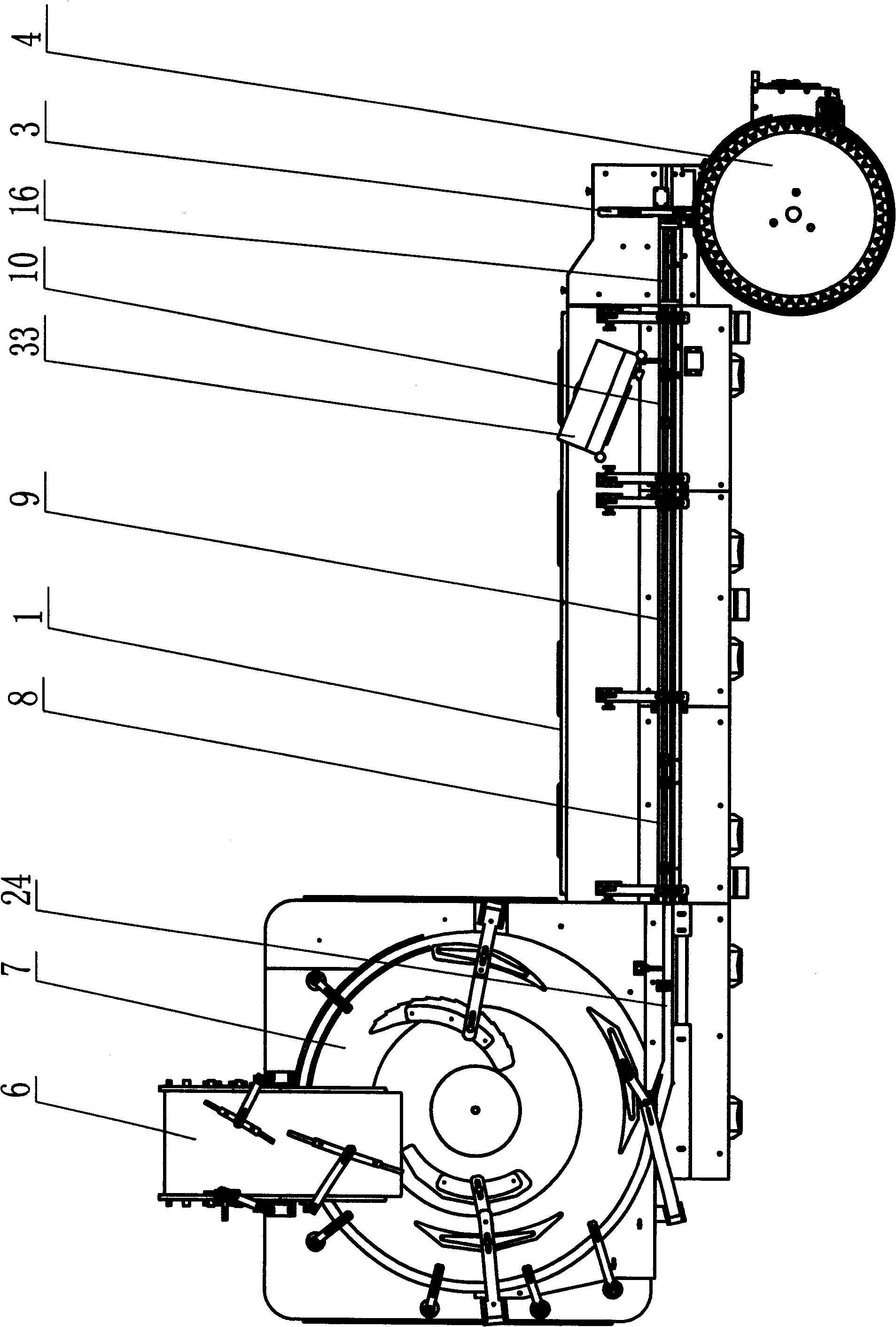

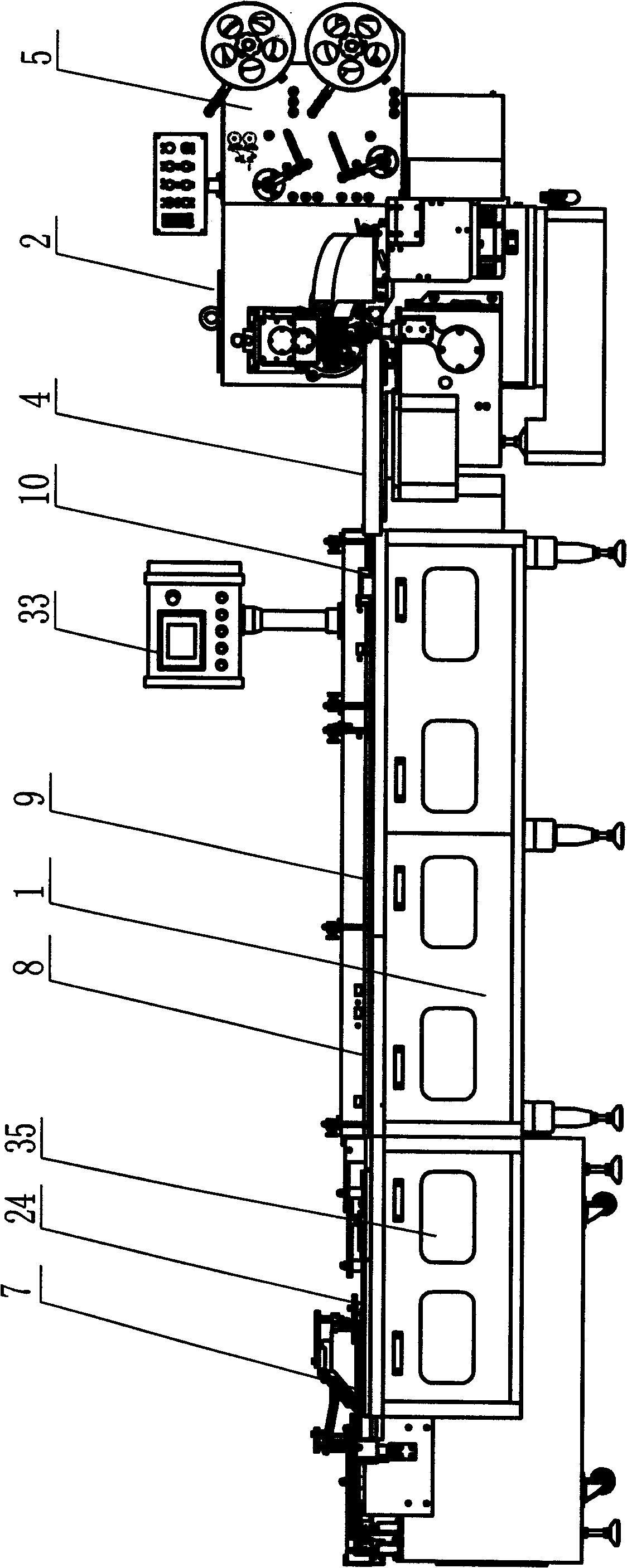

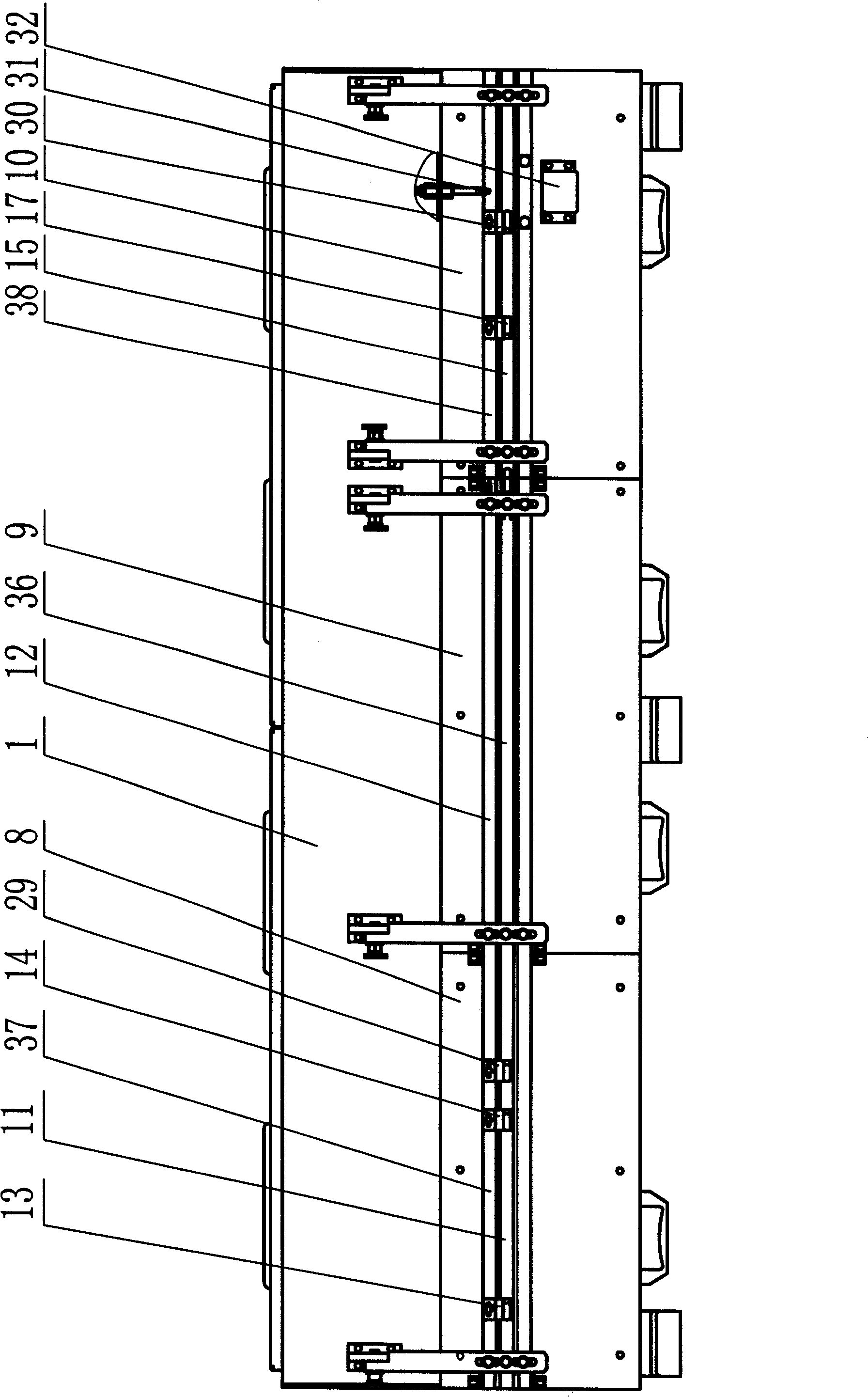

[0030] Such as Figure 1 to Figure 12As shown, the present invention includes a frame 1, and a feed conveyor 6 is arranged below the feed plate of sugar grains on the frame 1. Below the feeding conveyor 6, an inner and outer sugar pan differential mechanism 7 is established. On the frame 1, the output end of the inner and outer sugar plate differential mechanism 7 is provided with the first conveying line part 24, the second conveying line part 8, the third conveying line part 9, the fourth conveying line part 10, the chain hook transmission Part 16.

[0031] A main frame 2 is established on the frame 1, and the main frame 2 includes a control circuit, a sugar sending part 3, a sugar management part 4, a sugar wrapping part 5 and each drive motor. The control circuit includes a programmable controller and its control panel. The sugar sendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com