Thermal shrinkage bonding nut structure

A nut and heat-shrinkable technology, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of easy falling off of nuts and the cost of nail planting, and achieve the effect of avoiding insufficient bite force and easy falling off, saving costs and avoiding high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

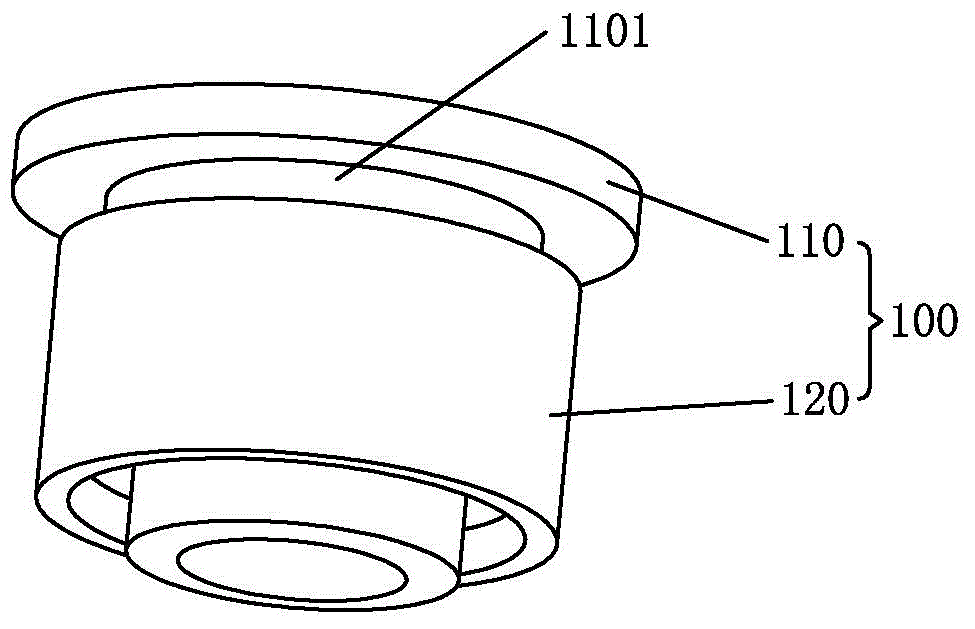

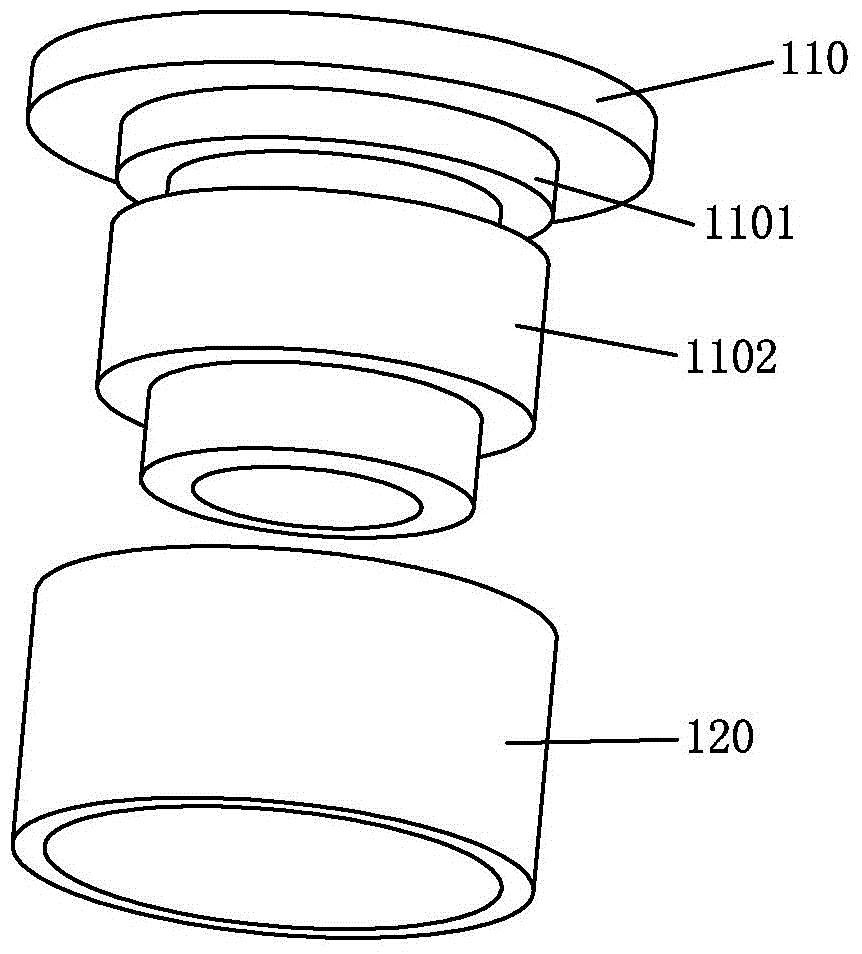

[0022] For this purpose, please refer to the figure 2 and image 3 As shown, the heat-shrinkable adhesive nut structure 100 provided by the present invention is implanted in the screw column 200 for locking screws, and the heat-shrinkable adhesive nut structure 100 includes:

[0023] Nut 110, the inside of which is hollow cylindrical, the outer periphery of the nut 110 has a first raised portion 1101 and a second raised portion 1102 arranged parallel thereto, and the outer diameter R1 of the nut 110 is smaller than that of the screw column 200 Inner diameter R2;

[0024] The heat shrinkable tube 120 is sheathed on the second protruding portion 1102 .

[0025] In this embodiment, after the nail is implanted, the inside of the heat-shrinkable tube 120 is in close contact with the second protrusion 1102 .

[0026] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com