Patents

Literature

31results about How to "Never fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

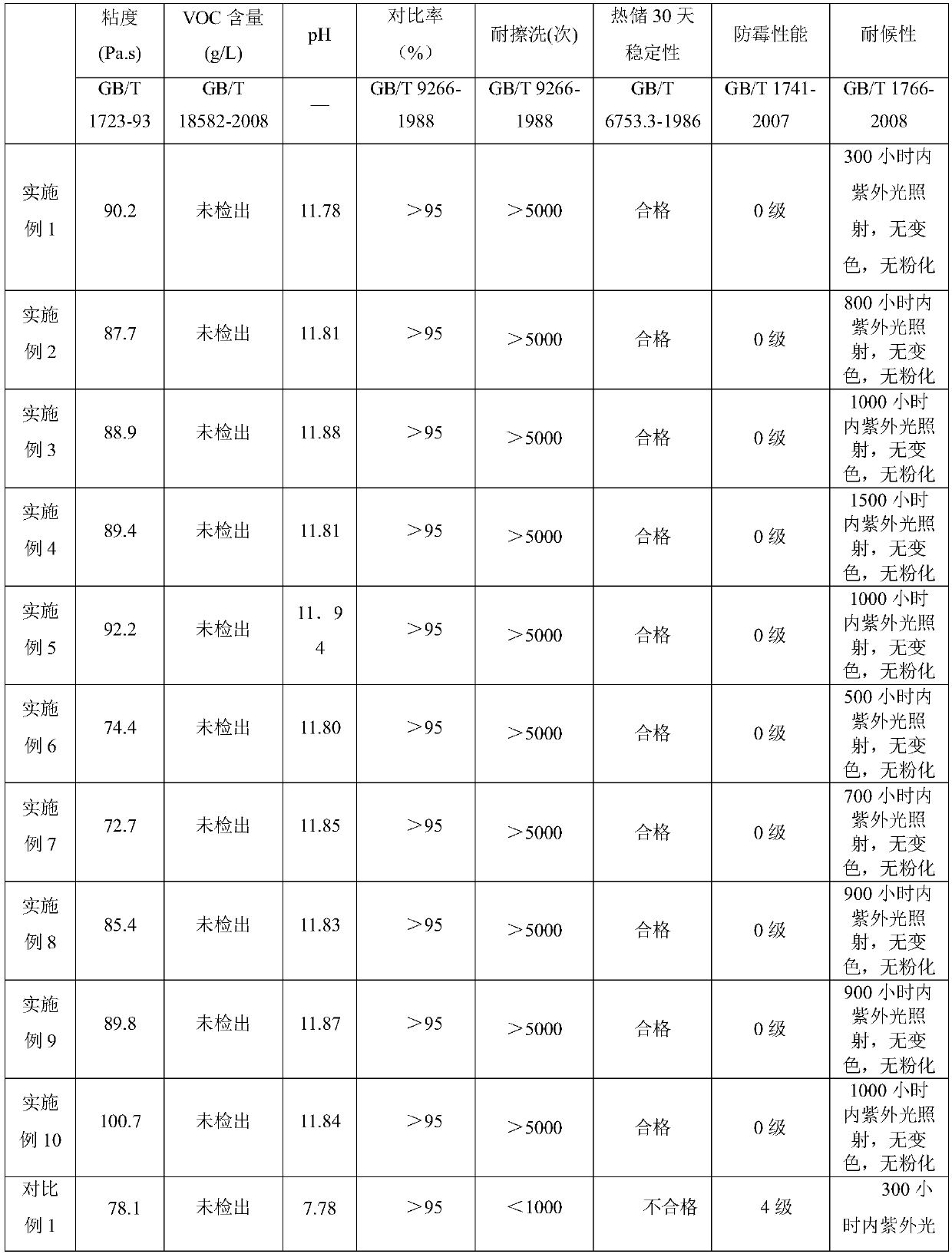

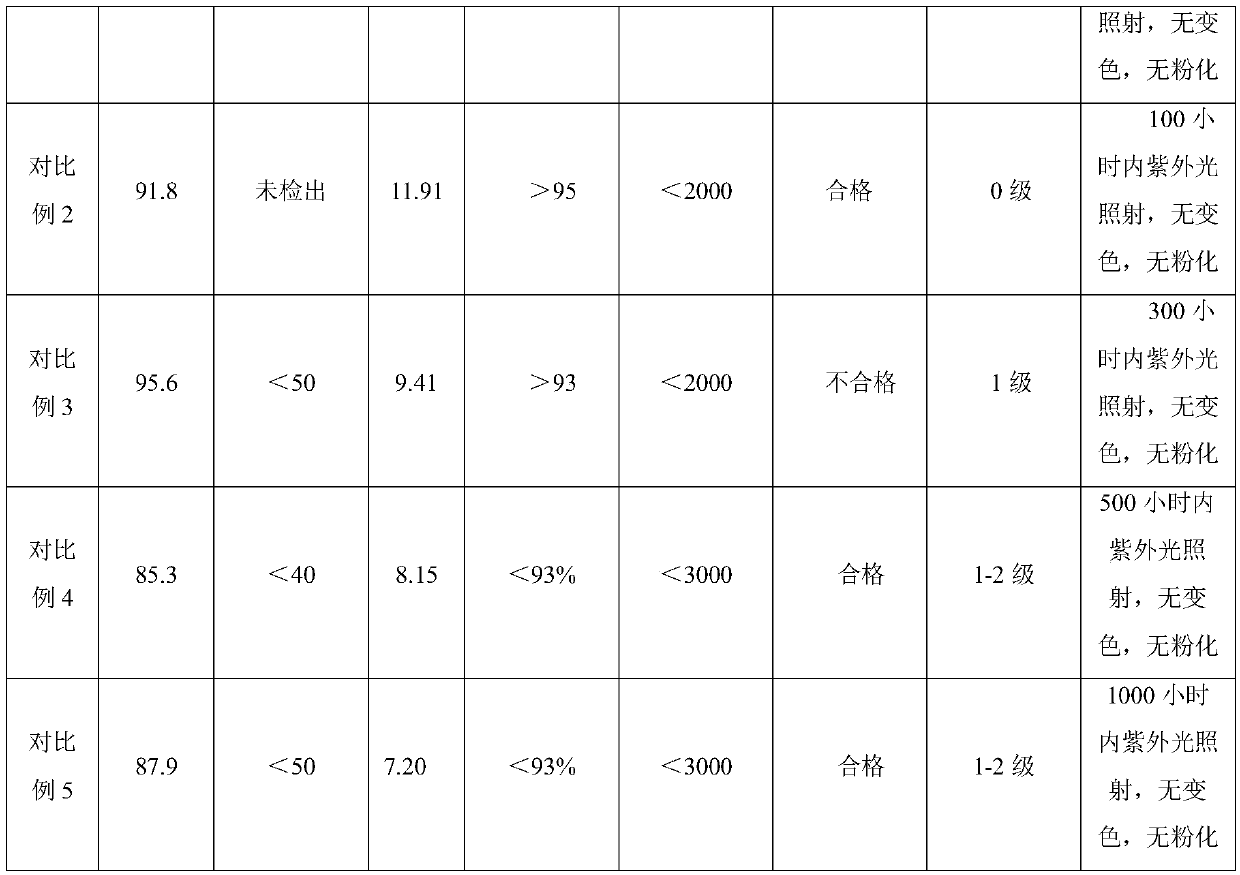

Inorganic silicate coating, preparation method thereof and application of coating

InactiveCN109575659AImprove mildew resistanceNever fall offFireproof paintsAntifouling/underwater paintsCelluloseEmulsion

The invention relates to the technical field of coatings for inner walls and outer walls of buildings, in particular to an inorganic silicate coating, a preparation method thereof and an application of the coating. The inorganic silicate coating is prepared from, by weight, 18-30 parts of deionized water, 0.1-0.8 part of cellulose, 0.5-1.5 parts of dispersing agents, 0.01-1.0 part of wetting agents, 0.01-1.0 part of defoaming agents, 10-20 parts of titanium dioxide, 10-20 parts of ground calcium carbonate, 10-20 parts of talcum powder, 5-10 parts of emulsion, 20-30 parts of modified potassiumsilicate, 0.01-5 parts of stabilizing agents and 0.01-5 parts of hydrophobic agents. The modified potassium silicate is selected from one or more of VB-2837 and INOCOT 955 or K-2837, and the emulsionis selected form one or more of styrene-acrylic ester and pure acrylic emulsion. The coating reaches the standard without a detected VOC (volatile organic compound) and good in fungus resistant and falling-off prevention performances.

Owner:北京莱恩斯新材料科技有限公司

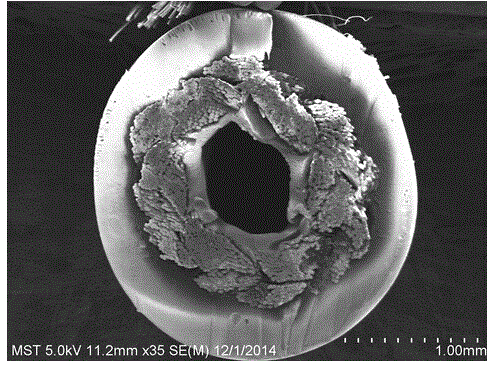

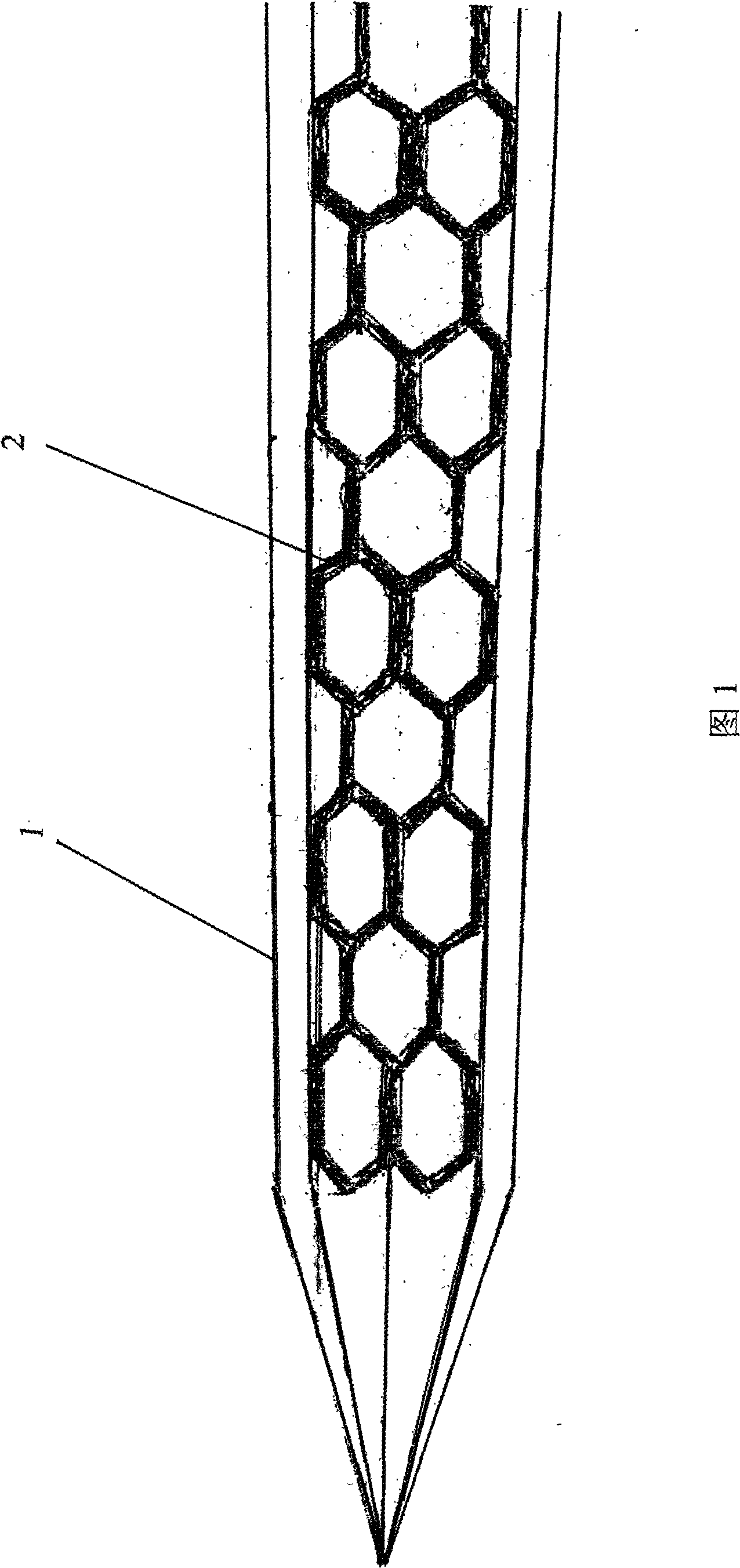

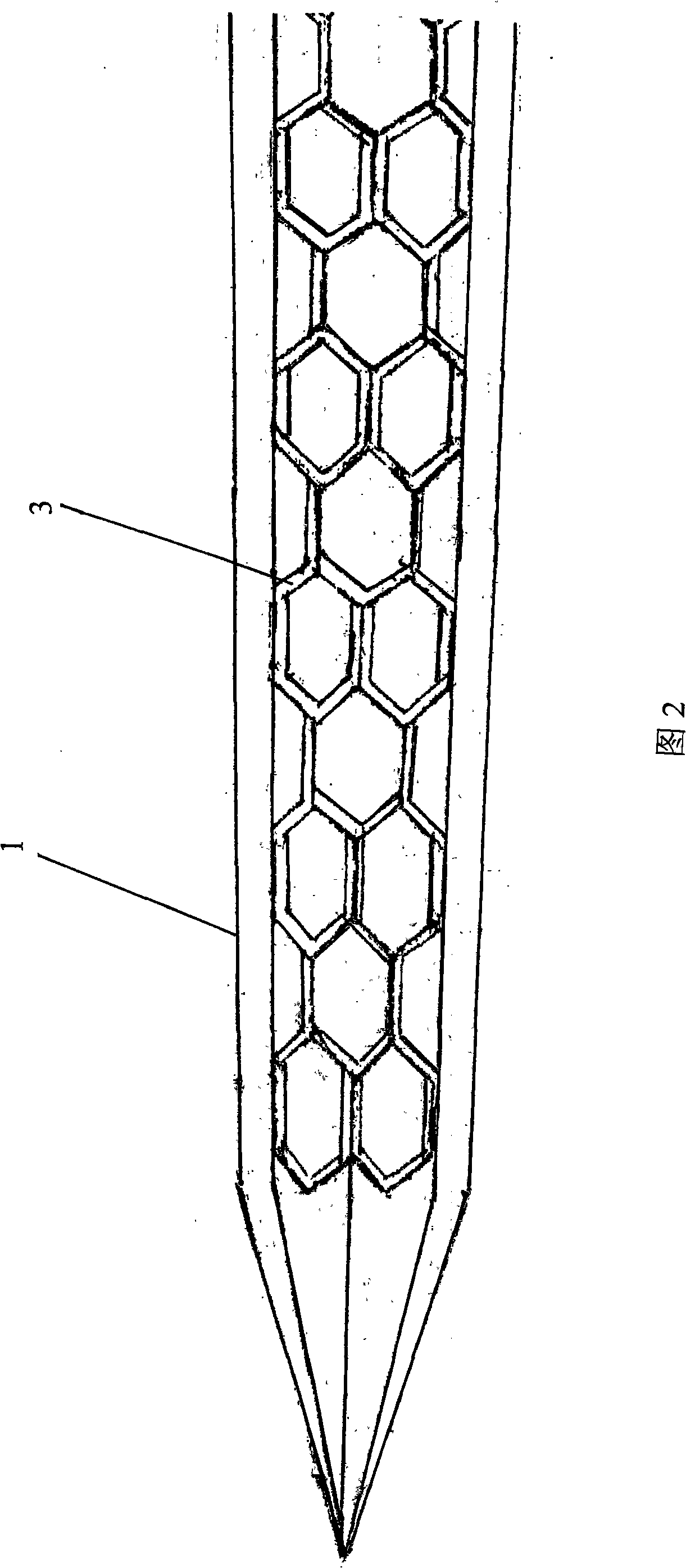

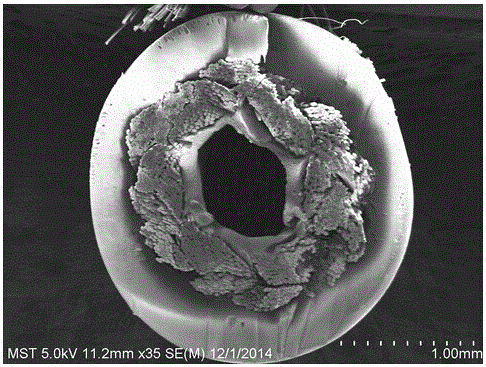

A braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film and a preparing method thereof

The invention discloses a preparing method of a braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film, and belongs to the field of polymer film product preparation. The preparing method includes firstly preparing a polyvinylidene fluoride solution A having a certain low concentration, dipping a braided tube with the solution A to allow the polyvinylidene fluoride solution to penetrate into the inside of the braided tube, coating the outside of the braided tube with a high-concentration polyvinylidene fluoride film casting solution B having a certain formula, and putting the braided tube coated with the solution A and the solution B into a coagulating bath to allow the polyvinylidene fluoride coated in the two times to be subjected to phase separation simultaneously. The polyvinylidene fluoride hollow fiber film prepared by the method is advantageous in that 1) the inner low-concentration polyvinylidene fluoride solution tightly surrounds fibers of the braided tube, is tightly connected to an outer film layer after phase transition, and is not liable to shed; 2) a high-aperture-ratio compact surface layer is formed from the outer high-concentration film casting solution and provides effects of filtration; and 3) the braided tube with high strength provides excellent film fiber longitudinal stretching strength.

Owner:安徽指南针科创园发展有限公司

Under-glaze colored decoration method of bone china

The invention relates to an under-glaze colored decoration method of bone china. The method includes an under-glaze colored decoration firing process and a pigment preparation technology, which includes transferring figures through pigment paint or labels for porcelain to a biscuit after lower temperature biscuit firing at a temperature of 700-800 DEG C, covering a protective layer, buckling a decorated ware on a profiling kiln furniture, performing firing at a temperature of 1250-1290 DEG C, wherein figure surfaces cannot be bruised, performing polishing on figure bases after firing, spraying fritted glaze slip, and performing glaze firing at a temperature of 1170-1200 DEG C. The figure surfaces are arranged under a glaze layer completely, and the method is a novel color decoration different from bone china over-glaze color figure for in-glaze decoration. Blanks are performed biscuit firing at a low temperature, the figure bases are fired through oxidizing flames at a high temperature (1250-1290 DEG C), and vitreous enamels are fired through oxidizing flames at an intermediate temperature (1170-1200 DEG C). Compared with once-firing of under-glaze color figure through reducing flames at a high temperature, the method is a firing method in which the temperature and the flame property are completely different. Bottoms of high range gift porcelain products are glazed through lowtemperature glazes, and smooth and non-discoloring forever after firing at a temperature of about 800-850 DEG C.

Owner:湖南丰德利瓷业有限公司

Preparation and determination method of sample for compression of metal material with high thermal conductivity

ActiveCN104155166AAchieving surface contactSolve the inability to carry out thermocouplePreparing sample for investigationMaterial strength using tensile/compressive forcesMetallic materialsThermocouple Wire

The invention relates to a preparation and determination method of a sample for compression of a metal material with high thermal conductivity. The preparation method comprises the following steps of I, preparing a metal cylinder by a sample of the metal material with high thermal conductivity, the metal cylinder having a diameter of [Phi]8 mm-[Phi]10 mm and a length of 10 mm-15 mm, and punching a point at an axial middle point position of the metal cylinder as a marker; II, drilling a blind hole with a diameter of [Phi]1.6 mm-[Phi]2.0 mm and a depth of 1.8 mm-2.2 mm; III, preparing a plug pin by selecting a wire made of a material the same metal cylinder or copper; and IV, putting a negative electrode end of an K-type thermocouple and a positive electrode end of the K-type thermocouple at two sides in the blind hole, and plugging the blind hole with the plug pin. The determination method comprises a step of measuring the sample on a thermodynamic simulation test machine to obtain a stress-strain curve of copper alloy. The preparation and determination method of the sample are simple and practicable; and flow stress test data results are accurate and stable.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

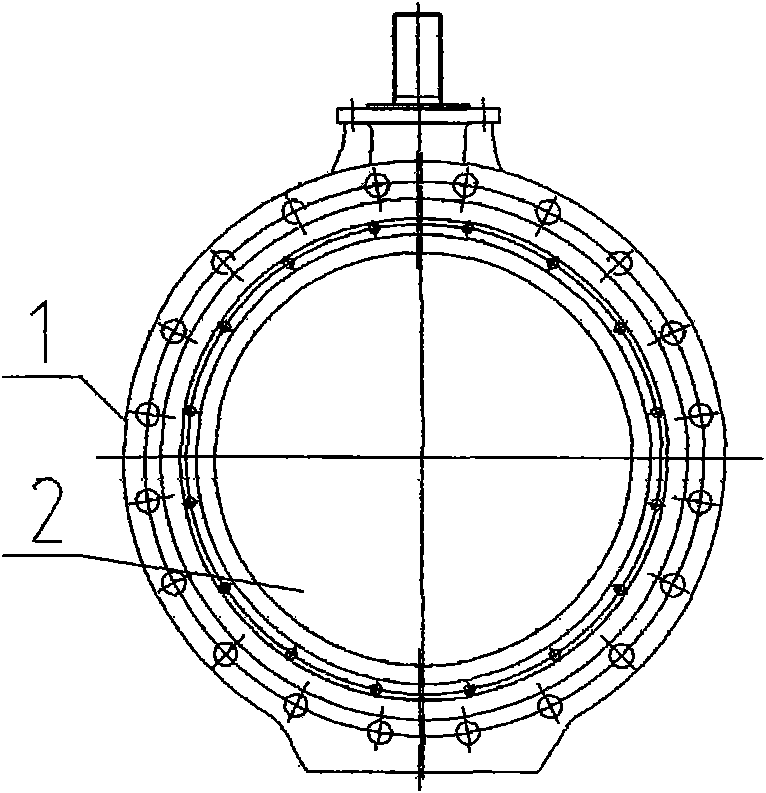

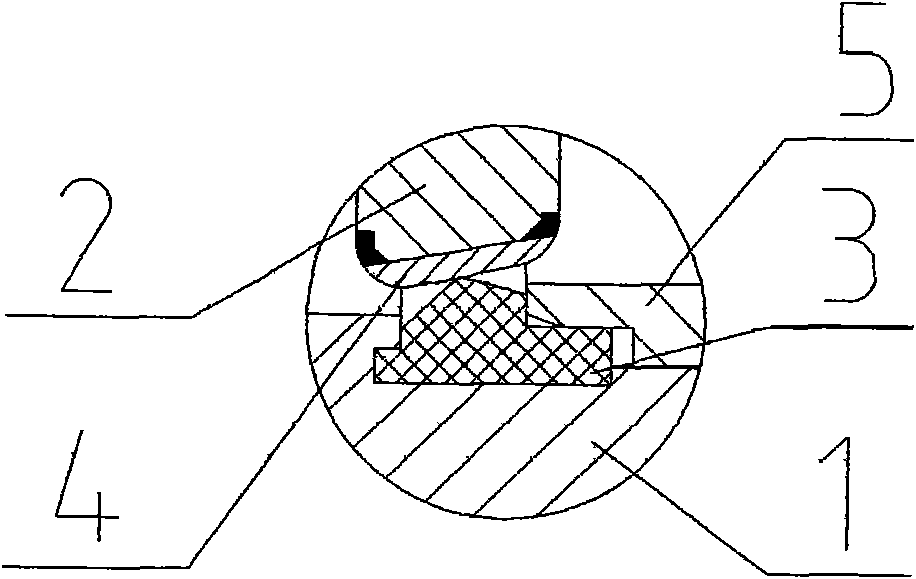

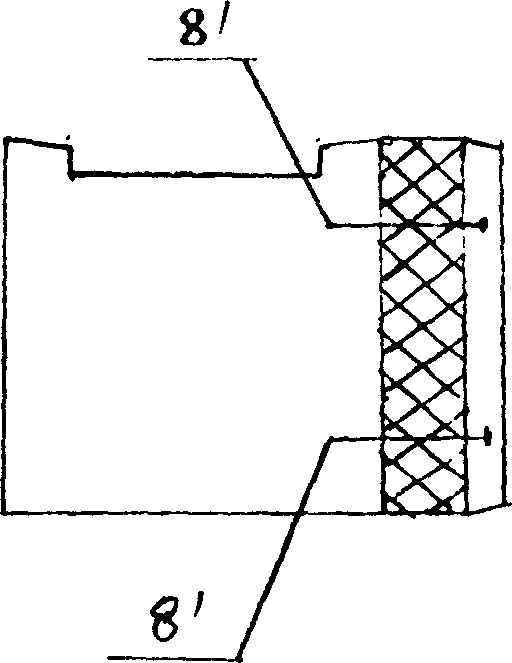

Method for manufacturing stainless steel sealing ring of double eccentric butterfly valve plate

The invention greatly technically improves a method for manufacturing a stainless steel sealing ring of a double eccentric butterfly valve plate. In the prior art, the sealing ring which forms a double eccentric butterfly valve sealing pair is generally made from metal materials such as copper or stainless steel and the like, and is fixed on a boss lug of the vale plate by bolts, in order to prevent a joint surface between the sealing ring and the valve plate from leaking to lead the sealing to be invalid, a sealing gasket have to be installed; and the copper or the stainless steel is directlywelded on the external ring of the vale plate and is machined in a cutting way, thereby causing great waste. The method changes the traditional manufacture method that the metal seal ring on the valve plate is cut from thicker big metal plant material into ring shaped, is machined in a cutting way, and is located and fixed by the bolts or piled; and adopts thinner stainless steel plate material to be cut into long strips, rolled and pressed, welt, shaped, pressed and sleeved, cut and reinforced on the outer ring of the vale plate. By using the manufacture method, the stainless steel sealing ring of the vale plate has less material, low machining cost, flat and smooth sealing surface, corrosion resistance, wear resistance, leakage resistance, never falling off and long service life.

Owner:宁波一机阀门制造有限公司

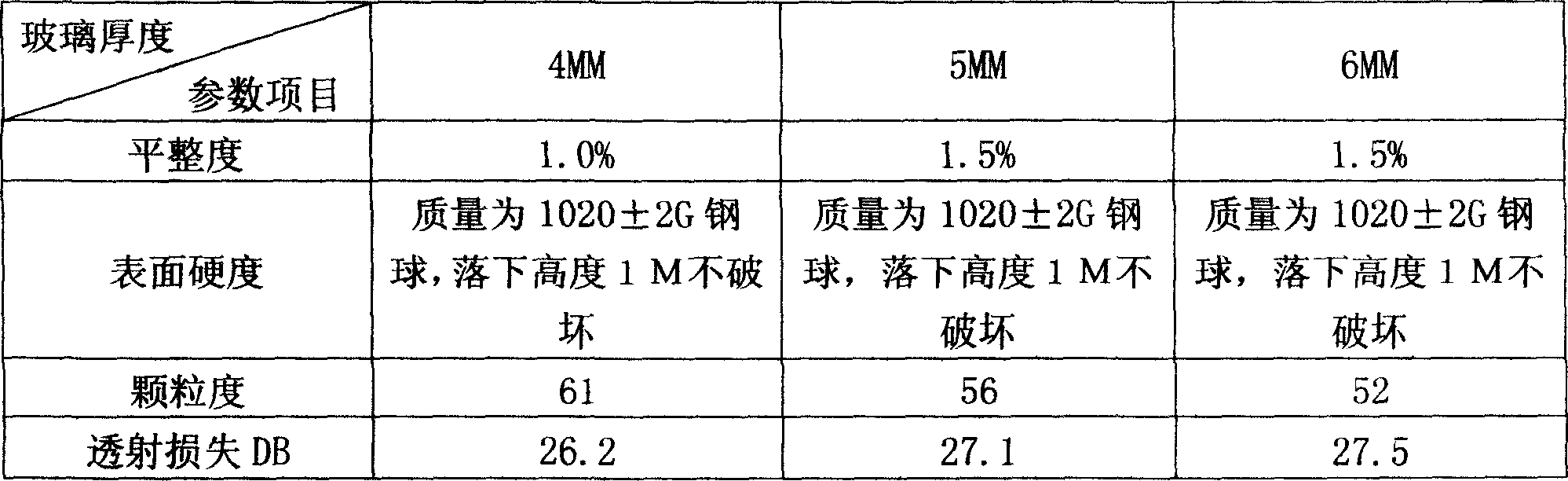

Method for producing computer mouse pad from glass

InactiveCN101092285AEasy to scrubPrecise positioningGlass tempering apparatusInput/output processes for data processingFurnace temperatureSurface layer

This invention discloses a method for producing glass mouse pad for computer. The method comprises: (1) preparing emulsified glass, washing the surface, spraying an acidic solution containing HF 3-7 wt.%, H2SO4 3-5 wt.%, HF gas 58-67 wt.%, K2SO4 6-9 wt.%, HNO3 1-3 wt.% and water 15-25 wt.%, washing the acidic solution with circulating water, and drying; (2) cutting emulsified glass with appropriate thickness, shaping, washing and drying; (3) mixing ink and diluting agent, printing ink onto emulsified glass, baking, taking off printed emulsified glass; (4) strengthening the colored glaze at a furnace temperature of 680-720 deg.C, a wind pressure of 70-90 Pa, and a feeding speed of 1.5-2.5 m / s, and taking off to obtain the final product. The transmission loss DB of the obtained glass mouse pad is within 26-28. The mouse can be precisely positioned, and the surface layer and the bottom layer are not easily worn.

Owner:新福兴玻璃工业集团有限公司

High-emulation art drawing tile copying method

ActiveCN105082857ARealistic color effectImprove controllabilityImage analysisDecorative surface effectsColor effectComputer graphics (images)

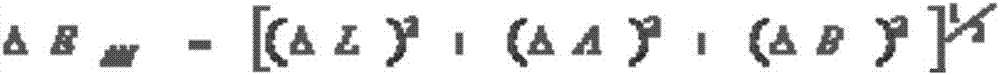

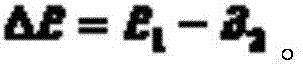

The invention relates to a high-emulation art drawing tile copying method. The method includes the following steps that firstly, a laser radiation device is arranged on a digital scanner, an existing drawing is scanned through the digital scanner under the effect of laser radiation, and the existing drawing is converted into a digital image; secondly, color comparison and color difference management are conducted on the obtained digital image; thirdly, printed materials are selected, and printing is conducted through a high-end inkjet printer; and fourthly, high-temperature fidelity color sintering is performed, and then post-processing is conducted. Compared with the prior art, the method has the beneficial effects of being realistic in product color effect, high in controllability and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

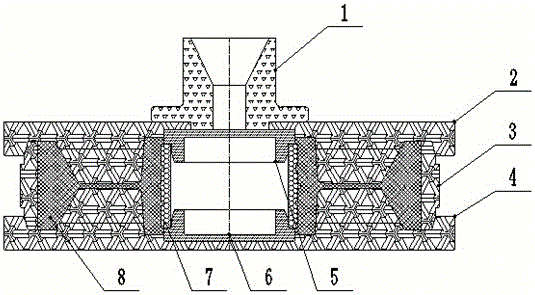

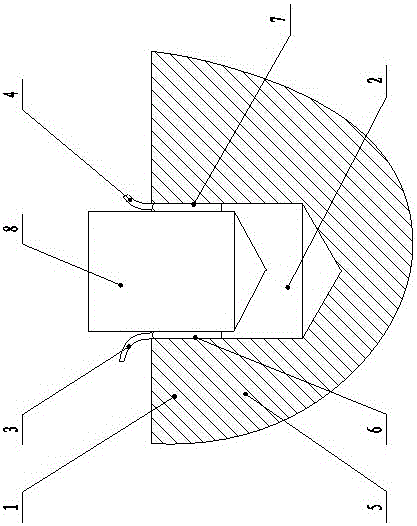

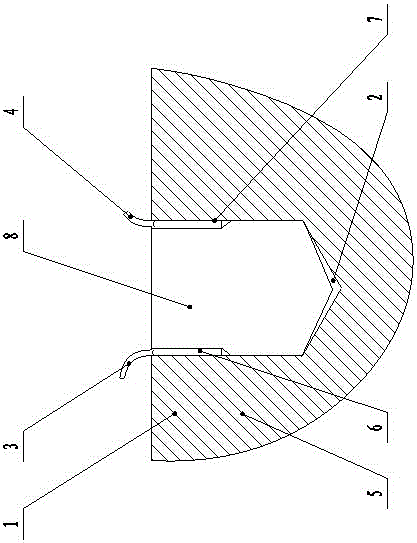

Centrifugation polymerization integrated metal lining nylon wheel and processing method thereof

InactiveCN105904634AOvercome stabilityOvercome strengthShaft and bearingsDomestic articlesCentrifugationEngineering plastic

The invention relates to a centrifugation polymerization integrated metal lining nylon wheel and a processing method thereof. The centrifugation polymerization integrated metal lining nylon wheel comprises an MC nylon rope wheel and a metal lining, the front side and back side of the MC nylon rope wheel are both provided with a 3's integral multiple number of reinforcing ribs, a plurality of annular grooves and / or bulges are arranged in a "-" shape along the axial direction on the outer ring of the metal lining, and a part of the MC nylon rope wheel is embedded in the annular grooves, the bulges are embedded into the MC nylon rope wheel, the front end and tail end of the metal lining's inner ring are symmetrically equipped with two or four check rings for holes. The front end and tail end of the metal lining are also provided with seal end covers, in which framework oil seals are embedded. The method reasonably combines metal and engineering plastics together, effectively overcomes the disadvantages of instability and poor strength of plastic products, and guarantees a permanent clasping force between the metal lining and the MC nylon rope wheel.

Owner:江苏利德尔新材料科技有限公司

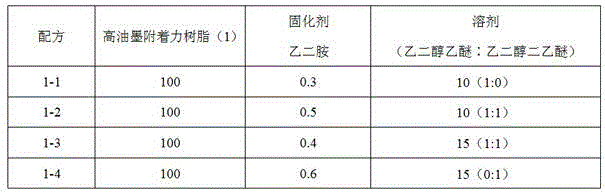

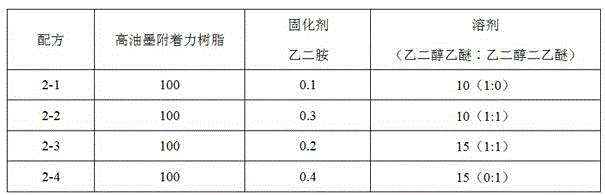

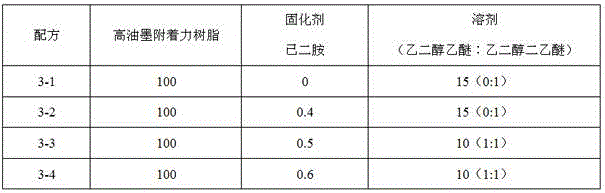

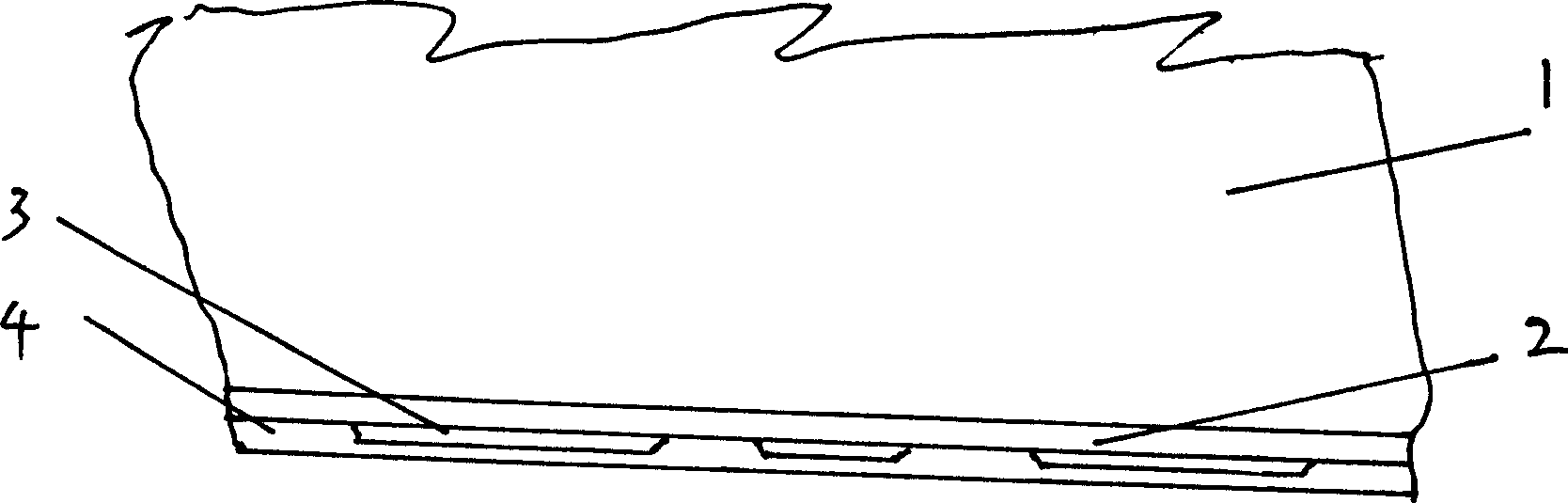

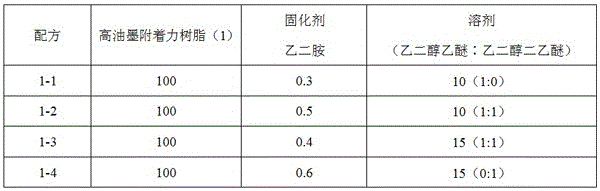

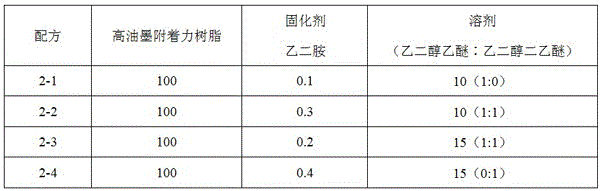

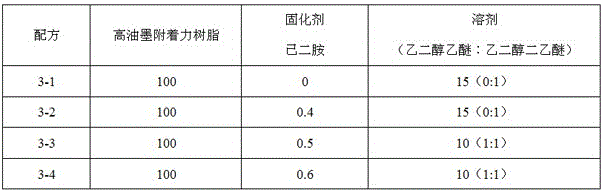

Polyester film used for bar code printing, and making method thereof

ActiveCN104129185AImprove adaptabilityHigh glossDuplicating/marking methodsFlat articlesAcetic acidPolyester

The invention discloses a polyester film used for bar code printing. The polyester film comprises a polyester film layer, at least one surface of the polyester film layer is covered with a high ink adhesion resin layer, the high ink adhesion resin layer is formed by coating a solution prepared by using a high ink adhesion resin, the high adhesion printing ink resin is obtained through a copolymerization reaction of glycidyl methacrylate, hydroxypropyl methacrylate, N-hydroxyethyl acrylamide and 2-(methacryloyloxy)ethyl acetoacetate mixed solvent and an initiator, contains a large amount of double bonds and ink-wet groups and improves the ink adhesion and printing property, and ink has strong stability on the polyester film and does not shed and has high gloss. The high ink adhesion resin solution is uniformly coated on the surface of the polyester film by adopting a micro-concave roll coating technology through controlling the specific parameters in the process to form a certain thickness in order to make the high ink adhesion resin layer tightly attached to the polyester film layer, and drying tunnel baking is carried out to make the high ink adhesion resin layer and the polyester film layer solidified and compounded in order to realize no shedding.

Owner:SICHUAN YUXI ELECTRONICS TECH CO LTD

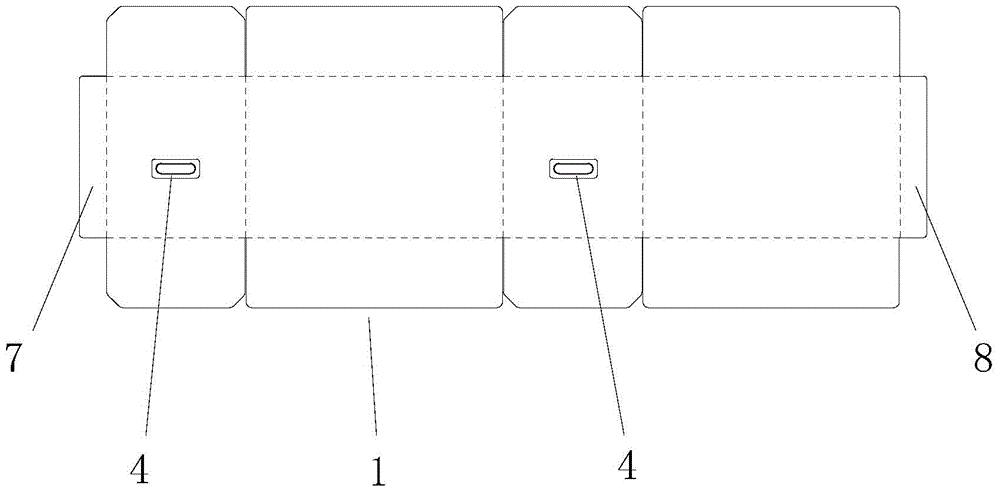

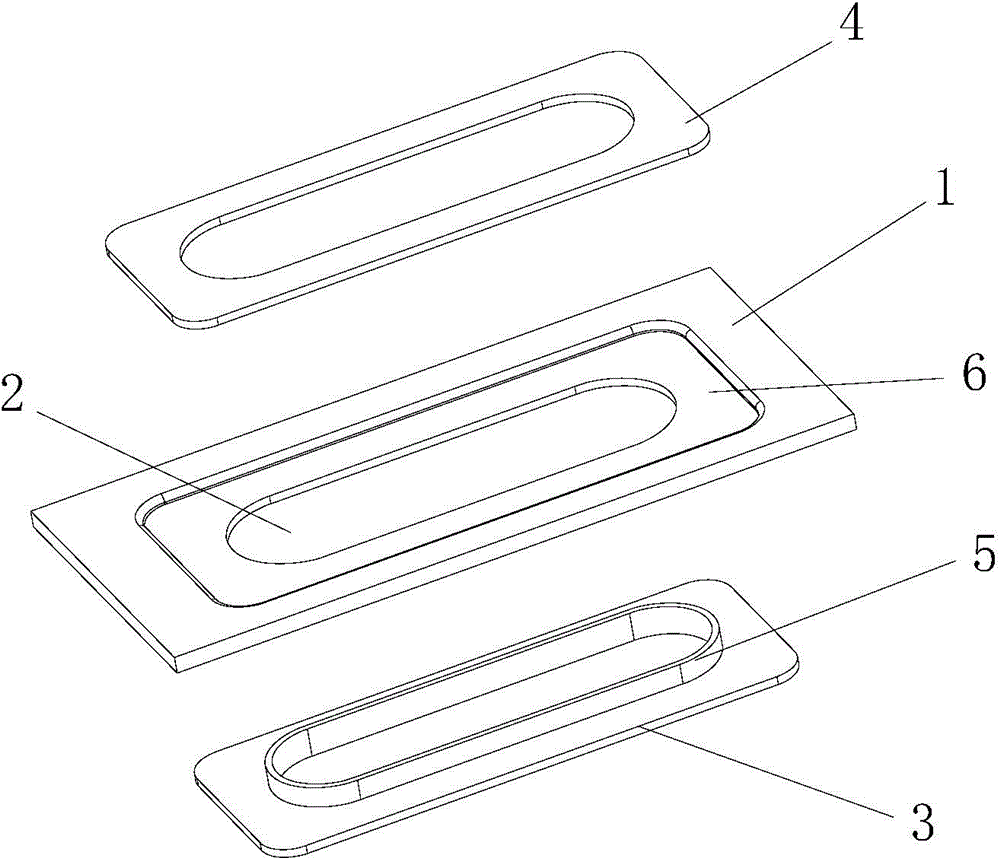

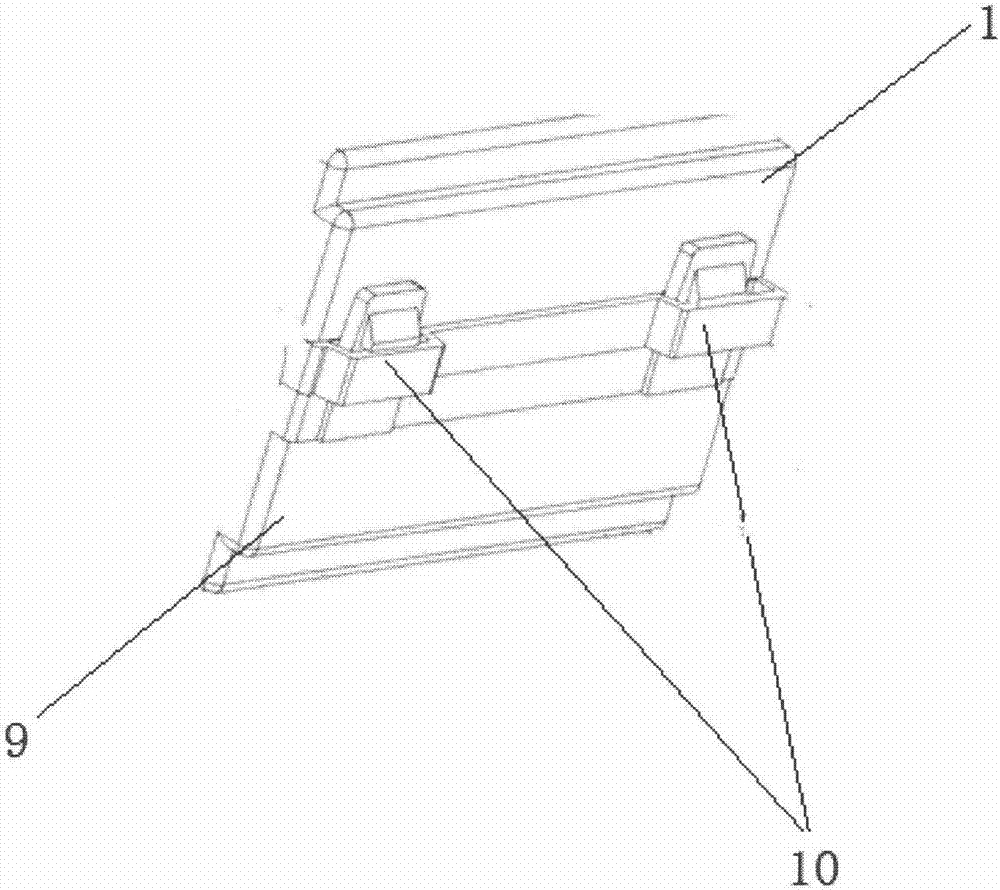

Special flexible plastic circulation box for tobacco and manufacturing method thereof

InactiveCN104554971ASolve the problem of deformation of extruded rodsSolve the deformationRigid containersUltrasonic weldingEngineering

The invention discloses a special flexible plastic circulation box for tobacco and a manufacturing method of the special flexible plastic circulation box for the tobacco. The special flexible plastic circulation box for the tobacco comprises a box body, wherein hand buckle positions are arranged on the side surfaces of the box body, hand buckles are installed at the hand buckle positions, the inner surface of each hand buckle is lower than the inner side surface of the box body or is flush with the inner side surface of the box body, and edges and corners of inner hand buckle parts are hidden in inner concave portions around the hand buckle positions. In the process of cigarette loading, cigarettes cannot be scratched by the edges and the corners of the inner hand buckle parts, the problem that inner hand buckle parts which are higher than the inner side surface of a box body press cigarettes to cause deformation of the cigarettes is solved, insertion connecting portions and the inner hand buckle parts are processed through ultrasonic welding, the inner hand buckle parts and outer hand buckle parts are welded together, and cannot fall off.

Owner:有限会社林平

Method of forming pattern using second casting using different metal

The invention provides a method for forming patterns on different metals by secondary casting, which comprises the steps of manufacturing a matrix model with a pattern groove according to the shape of a metal object; melting a metal and casting the metal into a matrix with a pattern groove; melting more than one metals with different colors and injecting the metals into the pattern groove of the matrix; and forming metal objects with different colors and patterns on the surface thereof. The patterns formed by the method have the advantages of no detachment, no deformation, and wear resistance.

Owner:吕建新

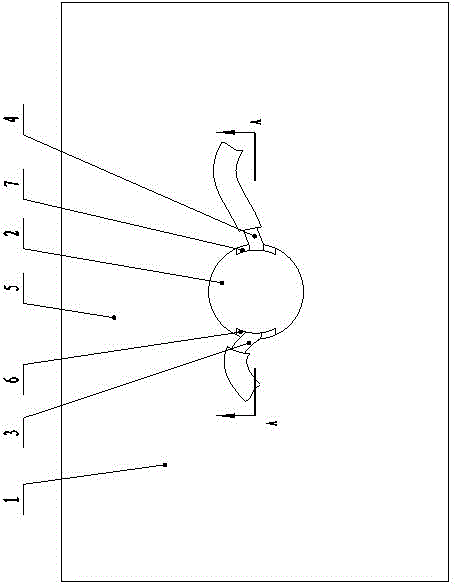

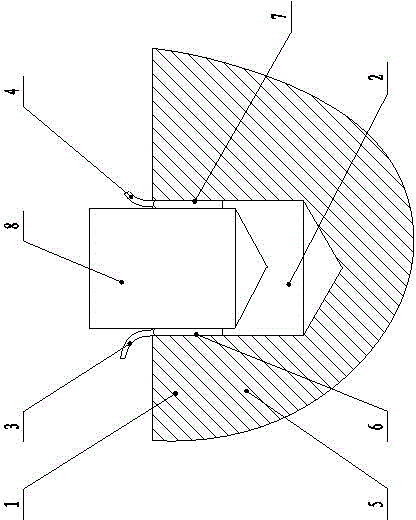

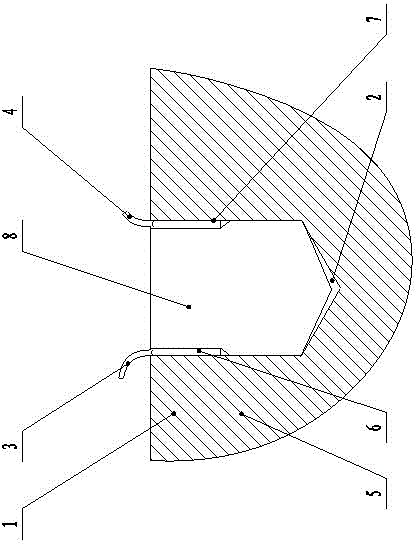

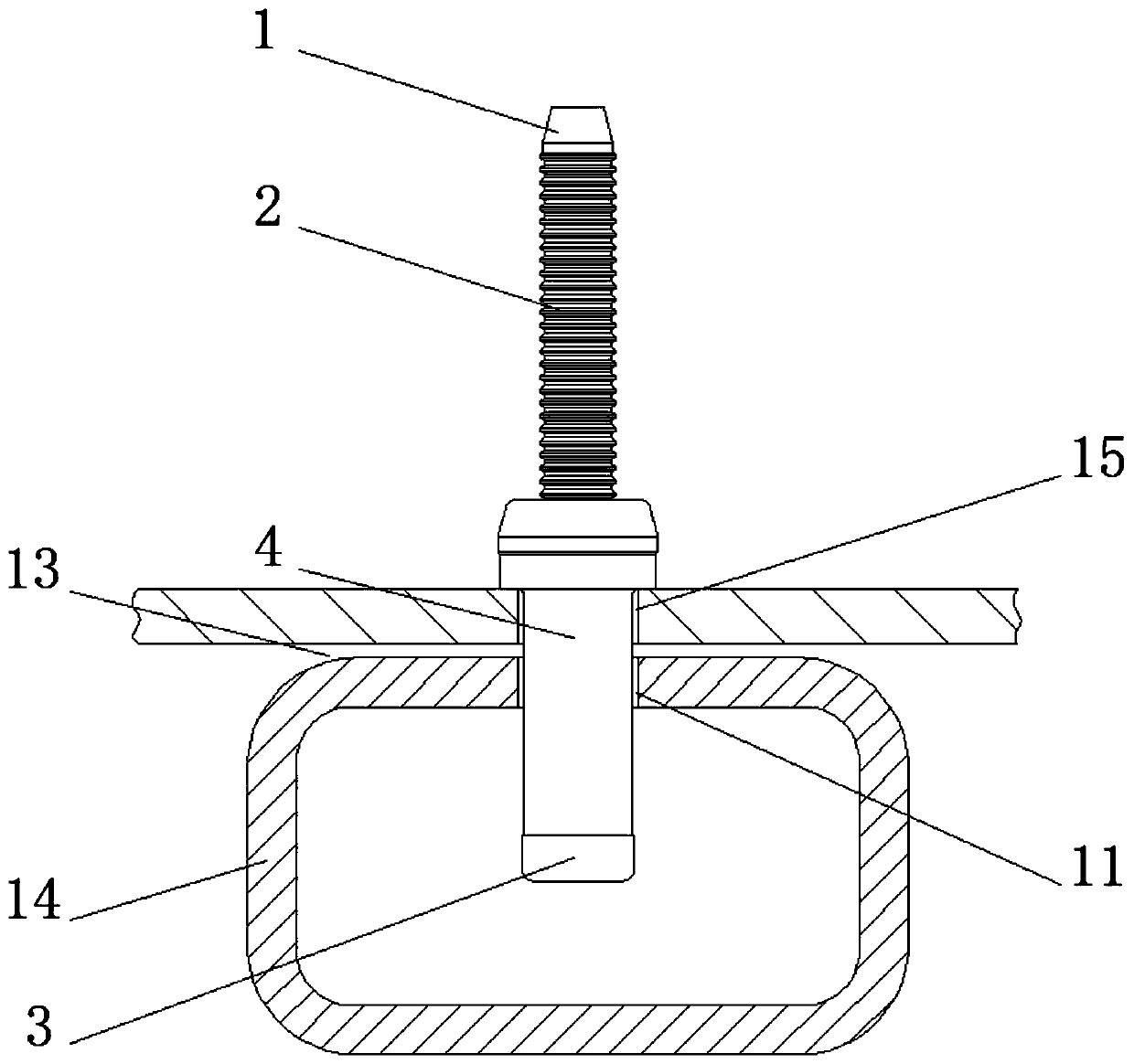

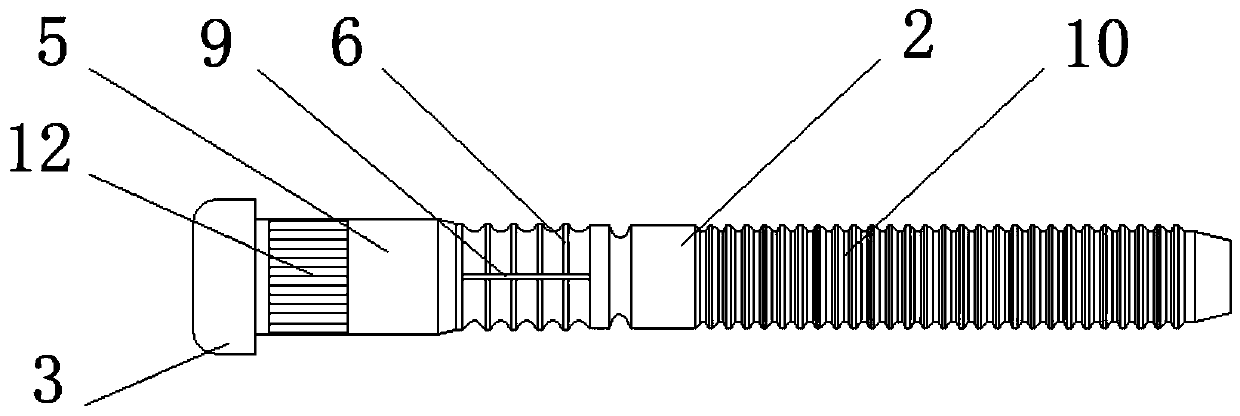

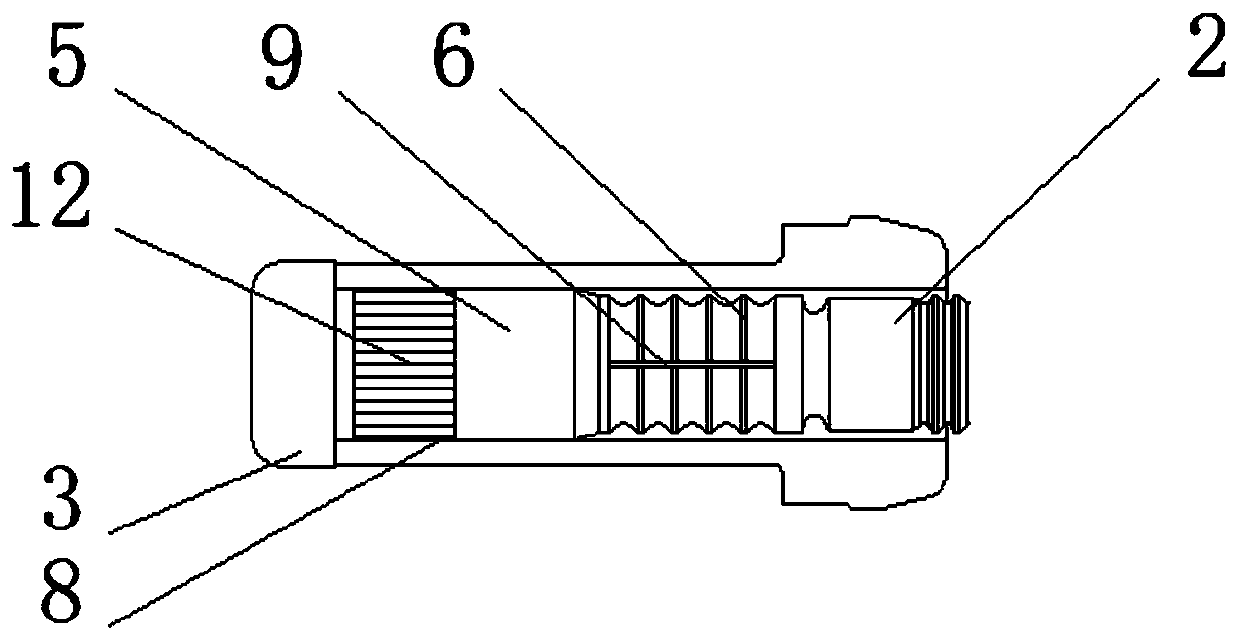

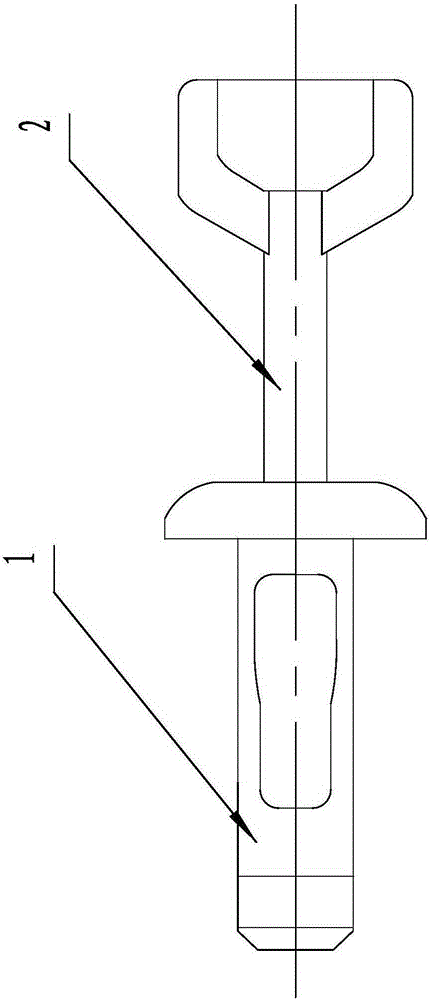

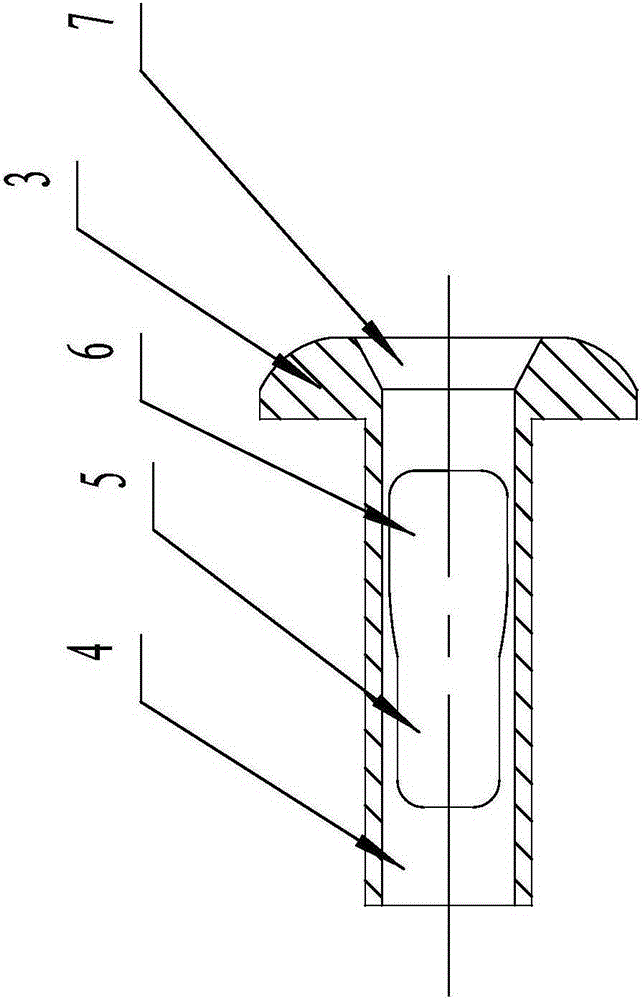

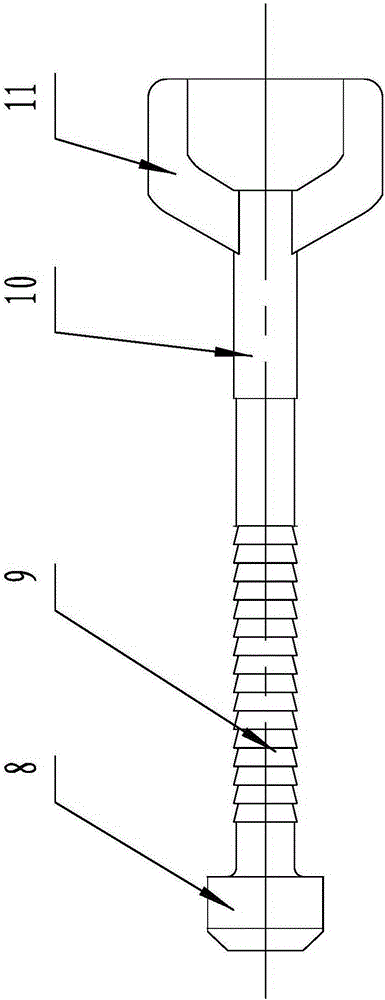

Blind pulling rivet

InactiveCN109764046ATo achieve a fixed connectionAvoid situations that take up excess spaceRivetsEngineeringRivet

The invention discloses a blind pulling rivet. The blind pulling rivet comprises a rivet body, wherein the rivet body is combined by a shank and a sleeve tube; the inner side of the rivet body is fixedly connected with the shank; the outside of the top of the shank is uniformly distributed with snap threads; the bottom of the shank is fixedly connected with a cap head; the top of the cap head is fixedly connected with a shank portion; the encircle portion of the shank portion is uniformly distributed with anti-slip threads; the outside of the shank portion is uniformly distributed with lockingthreads; the outside of the locking threads are provided with anti-rotating threads; and the outside of the rivet body is fixedly connected with the sleeve tube. According to the blind pulling rivet,a tube portion of the sleeve tube is arranged at the outside of the shank portion, and the rivet body penetrates through a first connecting plate and a second connecting plate, so that fixed connection between the first connecting plate and the second connecting plate is achieved; and the rivet body is arranged at the connection point of the first connecting plate and the second connecting body,so that the connection between special workpieces such as blind hole workpieces and connectors with insufficient single edge space is achieved, and the problems of single function and low practicalityof an existing connecting mechanism are solved.

Owner:嘉兴久固五金科技有限公司

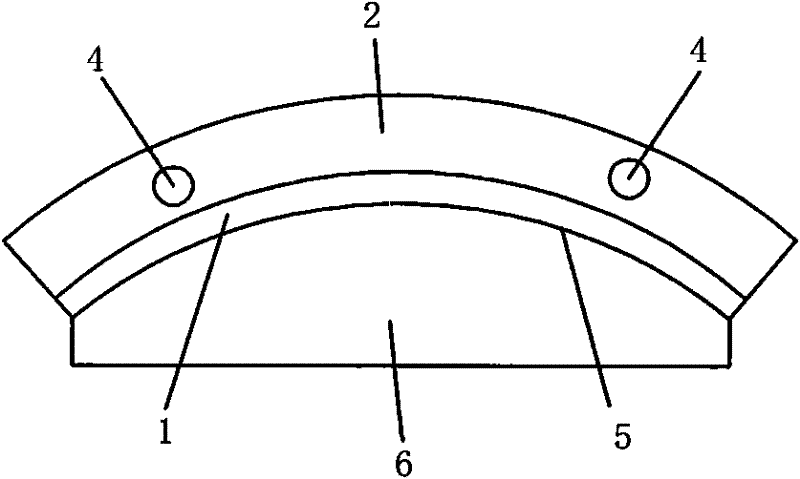

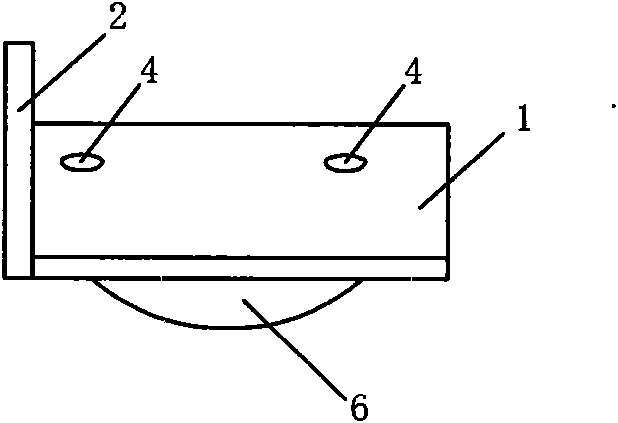

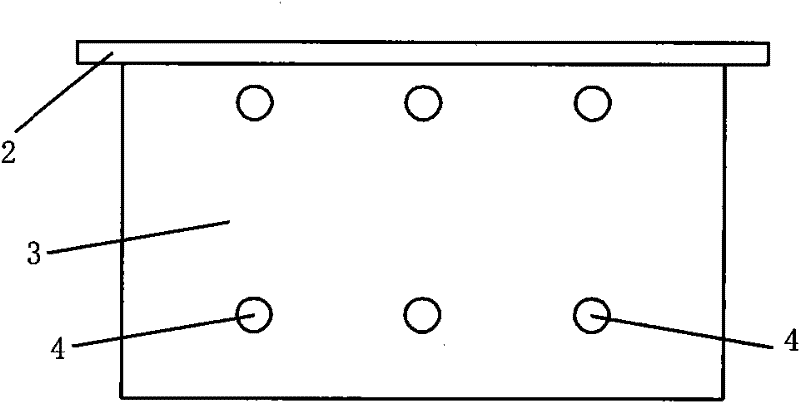

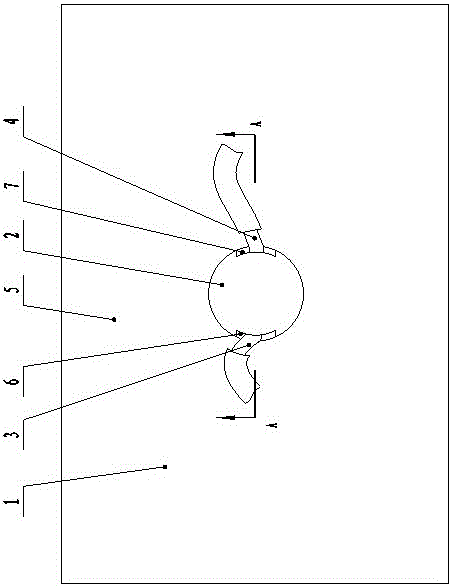

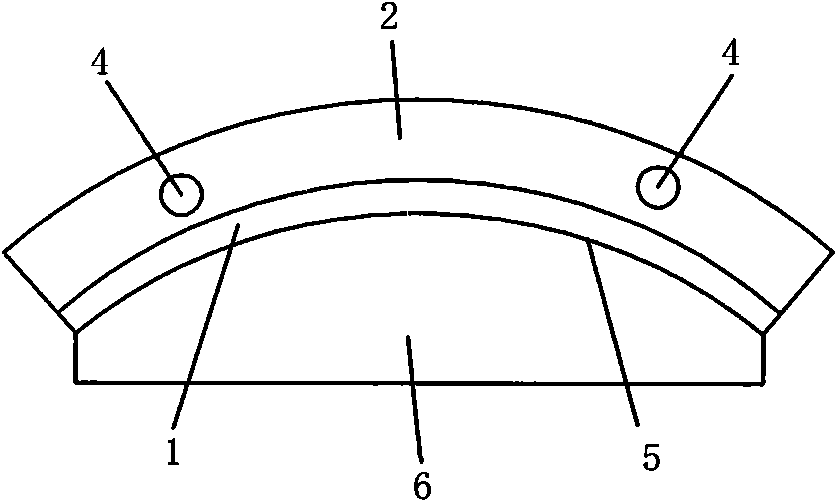

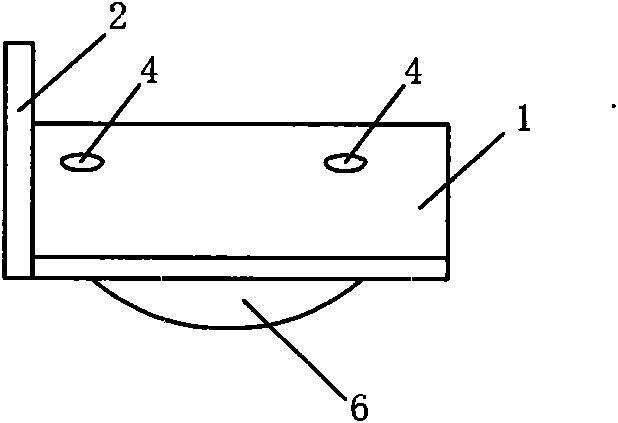

Coil Lifting Pad

The invention relates to a rolled plate hoisting gasket, belonging to the technical field of hoisting tools. The gasket comprises a length of arc-shaped bending plate mainly identical to an inner ring of the rolled plate, the bending plate is provided with a vertical baffle along an arc side thereof, an external arc surface of the bending plate and an inner surface of the vertical baffle are respectively provided with ferromagnets at intervals, and an inner arc surface of the bending plate is provided with a bump. In comparison with the existing rolled plate gasket, the gasket provided by theinvention has the following advantages that: 1) with the ferromagnets, the gasket can be closely attached to the inner ring of the rolled plate just by only a small length of the arc-shaped bending plate, and the gasket not only has small volume, low cost and convenient use, but also cannot fall off in the process of use; 2) the vertical baffle can further prevent a nylon hoisting belt from contacting an external end surface of the rolled plate, so that the external end surface of the rolled plate is protected; 3) with the bump, an extrusion force applied on the whole gasket by the hoisting belt can be transferred from a corner of the vertical plate to the bump, so that the extrusion force applied on the inner ring of the cold-rolled plate by the hoisting belt is further reduced, and abrasion of the bending plate and the corner of the vertical plate is avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

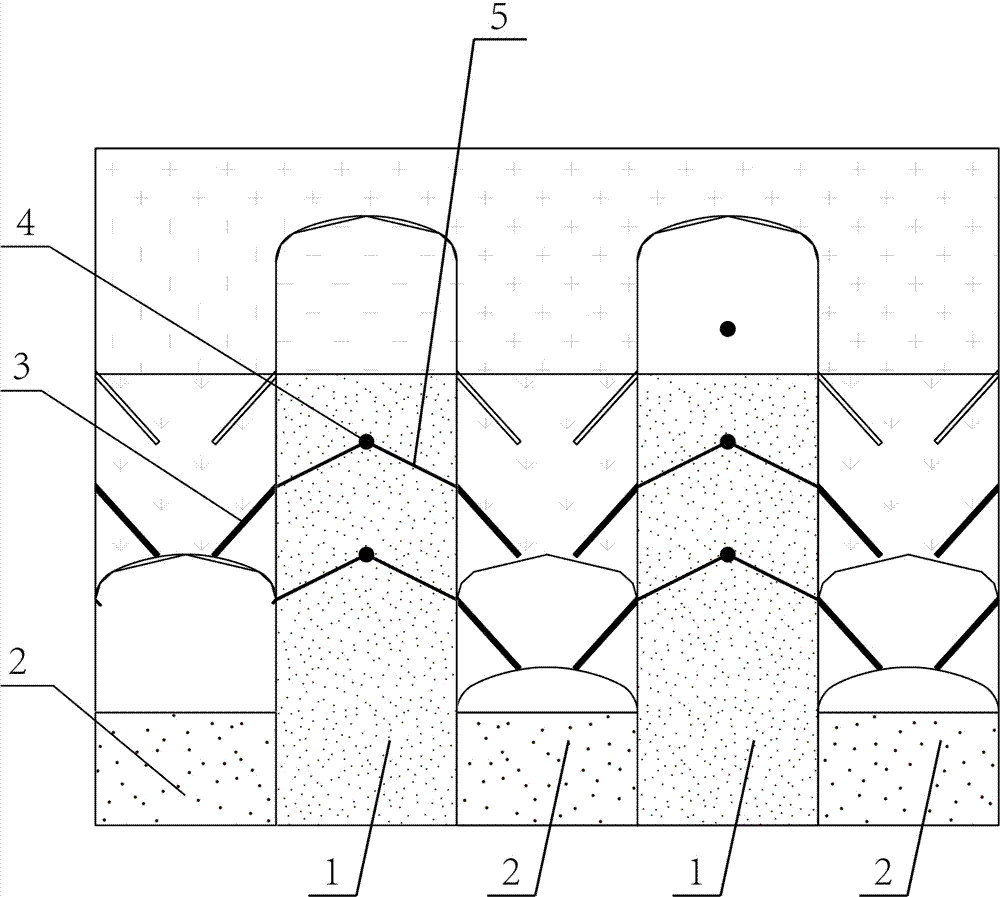

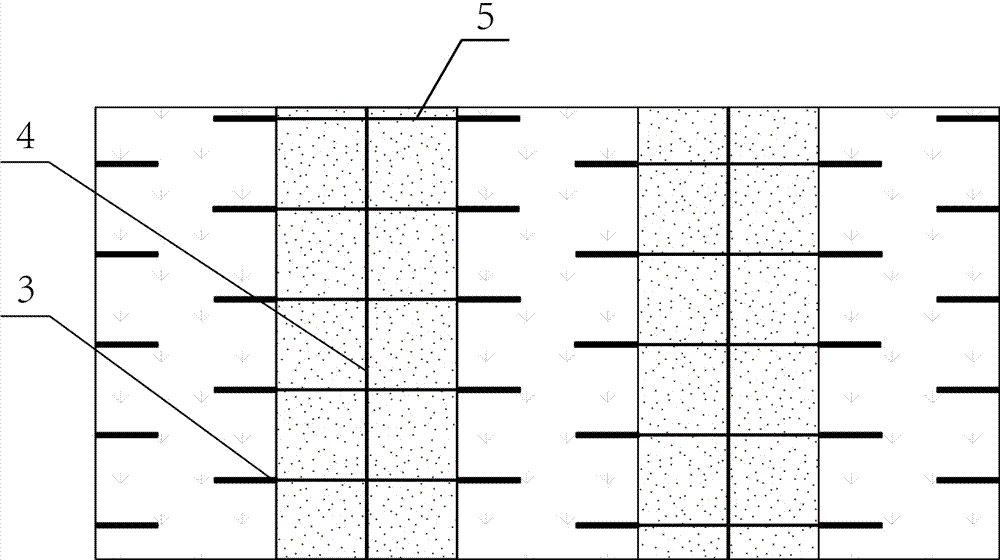

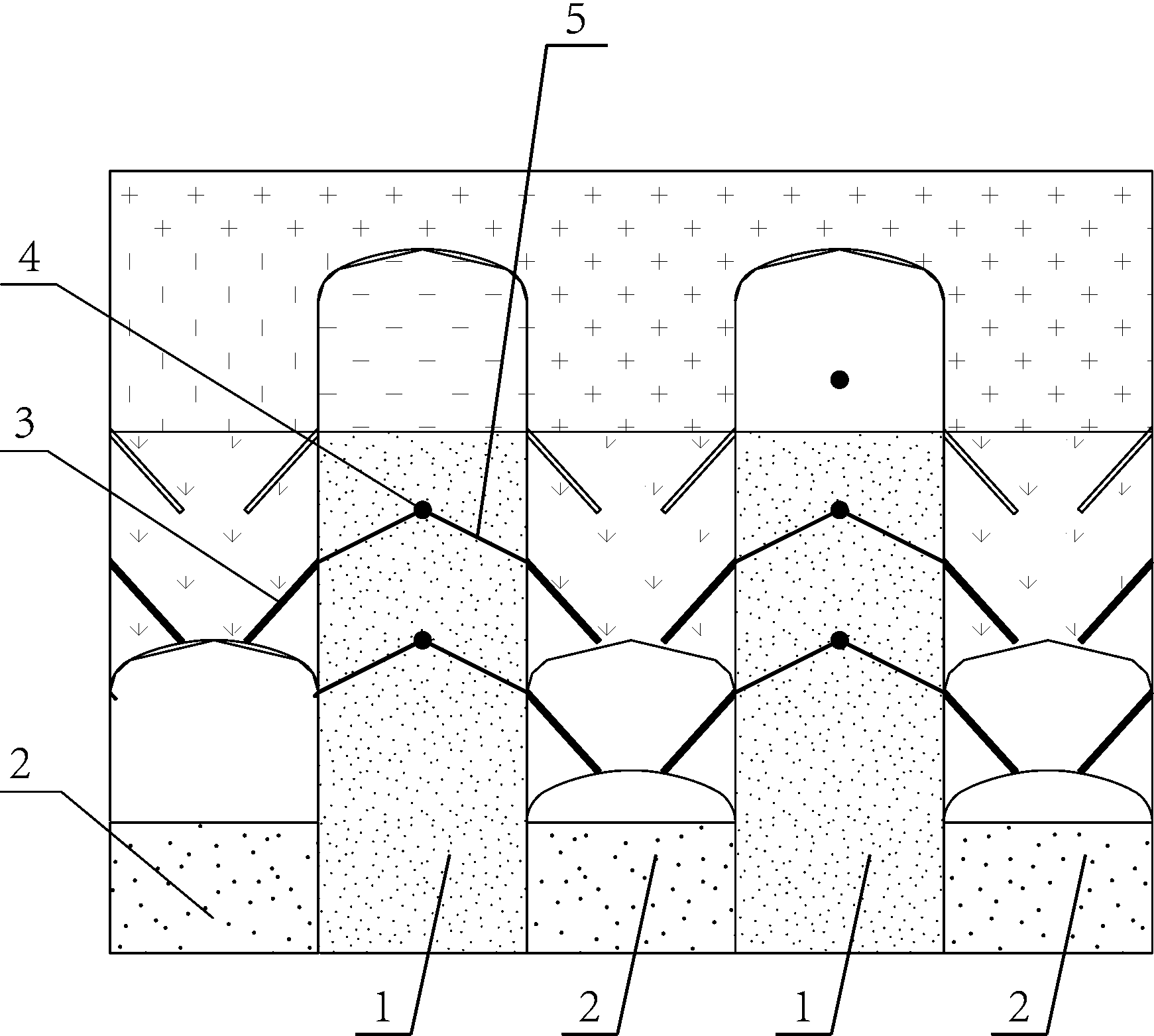

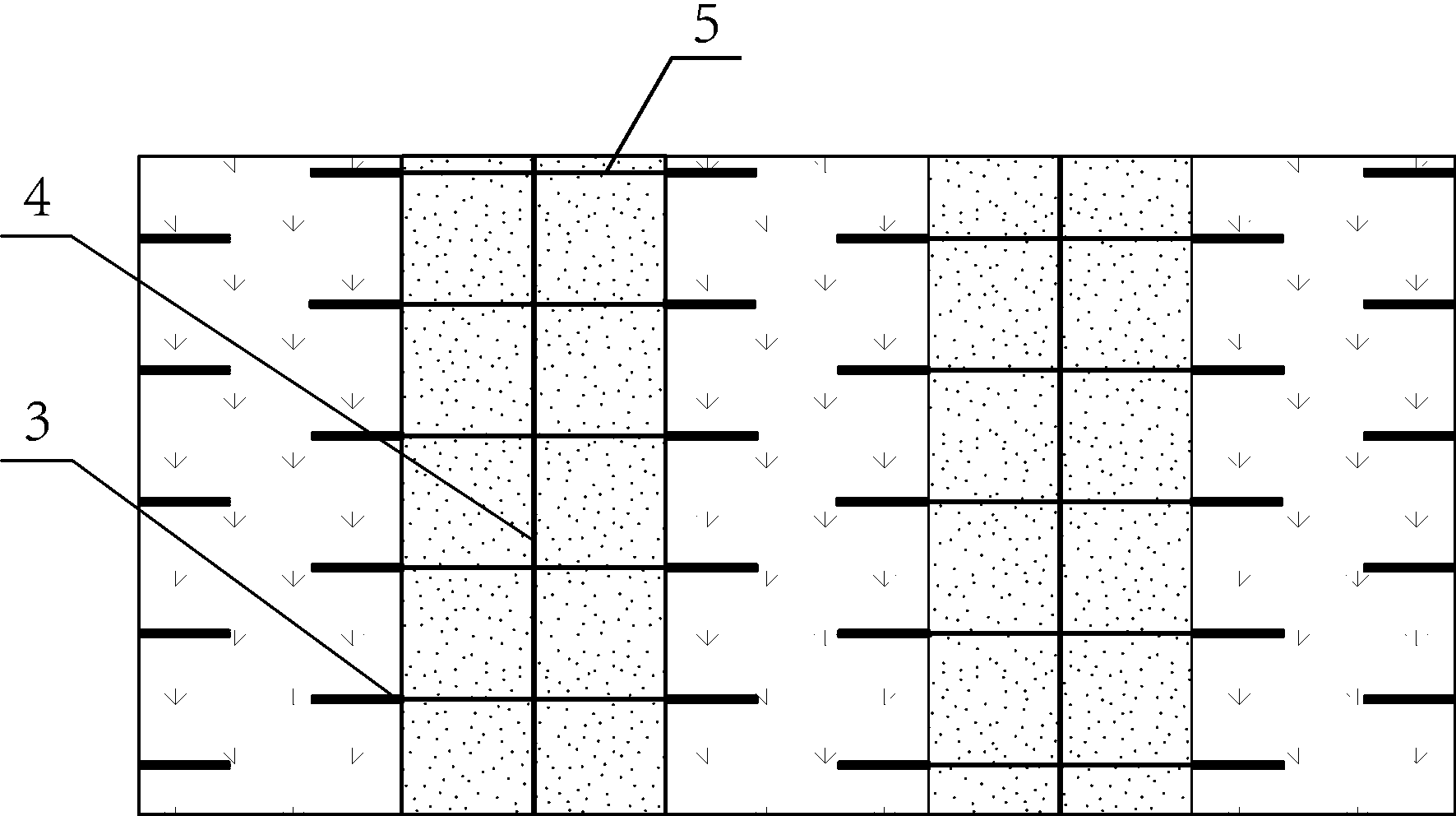

Continuous and multilayer pre-support method of short downward anchor cable

ActiveCN102926776ASimplify the installation processReduce work intensityAnchoring boltsMining engineeringStructural engineering

The invention provides a continuous and multilayer pre-support method of a short downward anchor cable. In the method, by starting from a second layer, after one-step mining stripping backstopping, the pre-support operations are conducted as follows: firstly, drilling downwards inclining drill holes along slightly upper positions of two rib bottom plates of one-step mining stripping; mounting support deformed steel bars in the drill holes and pouring cement paste; utilizing the same one rooting deformed steel bar to connect tails of the support deformed steel bars at the same strip in the one-step mining strpping backstopping together; and performing cemented filling in a stope. Milltailings are filled after two-step mining backstopping. By using the method, look-head, continuous and multilayer supports are performed on an orebody to be mined, so that roof falling in the stope can be completely eliminated.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

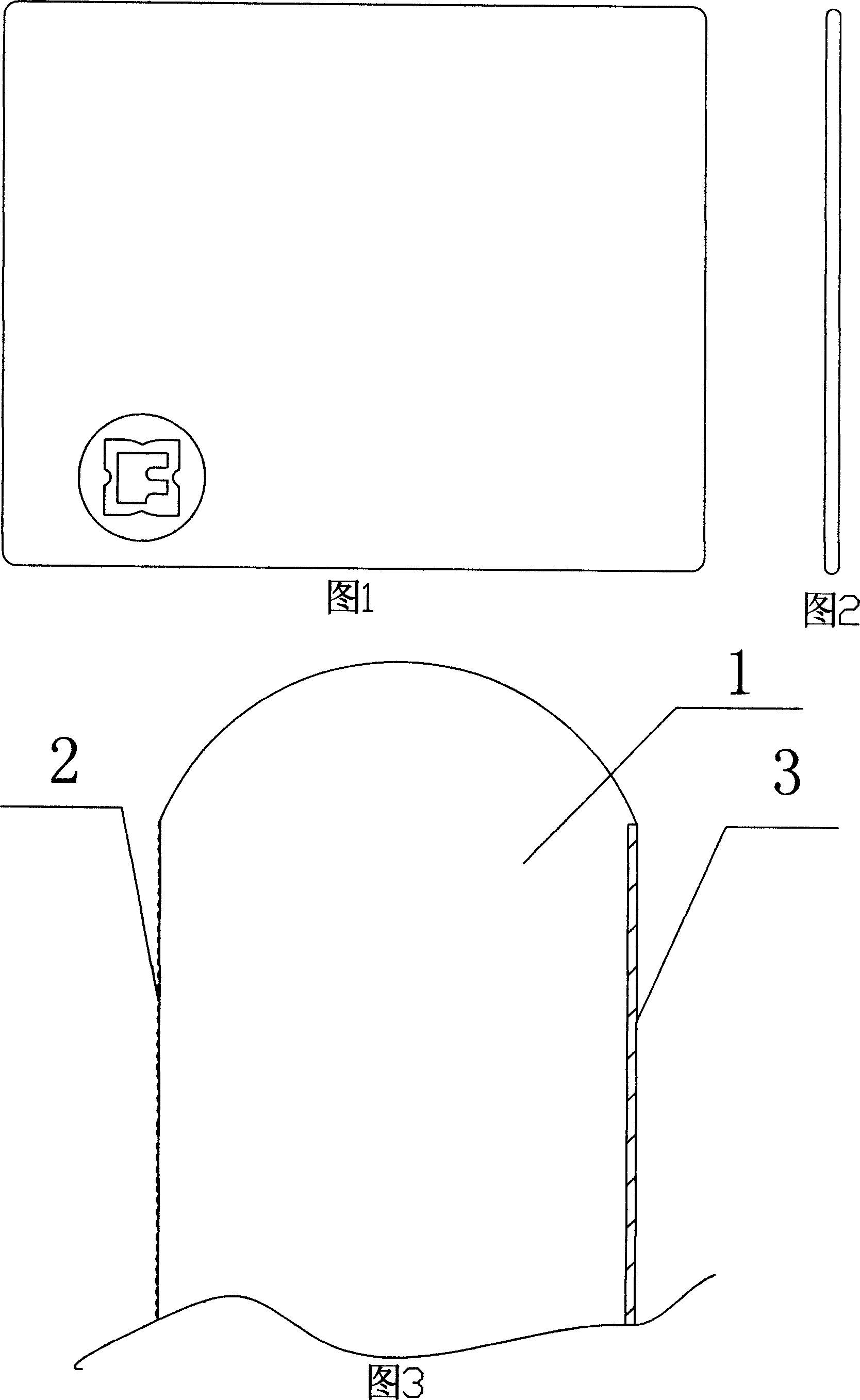

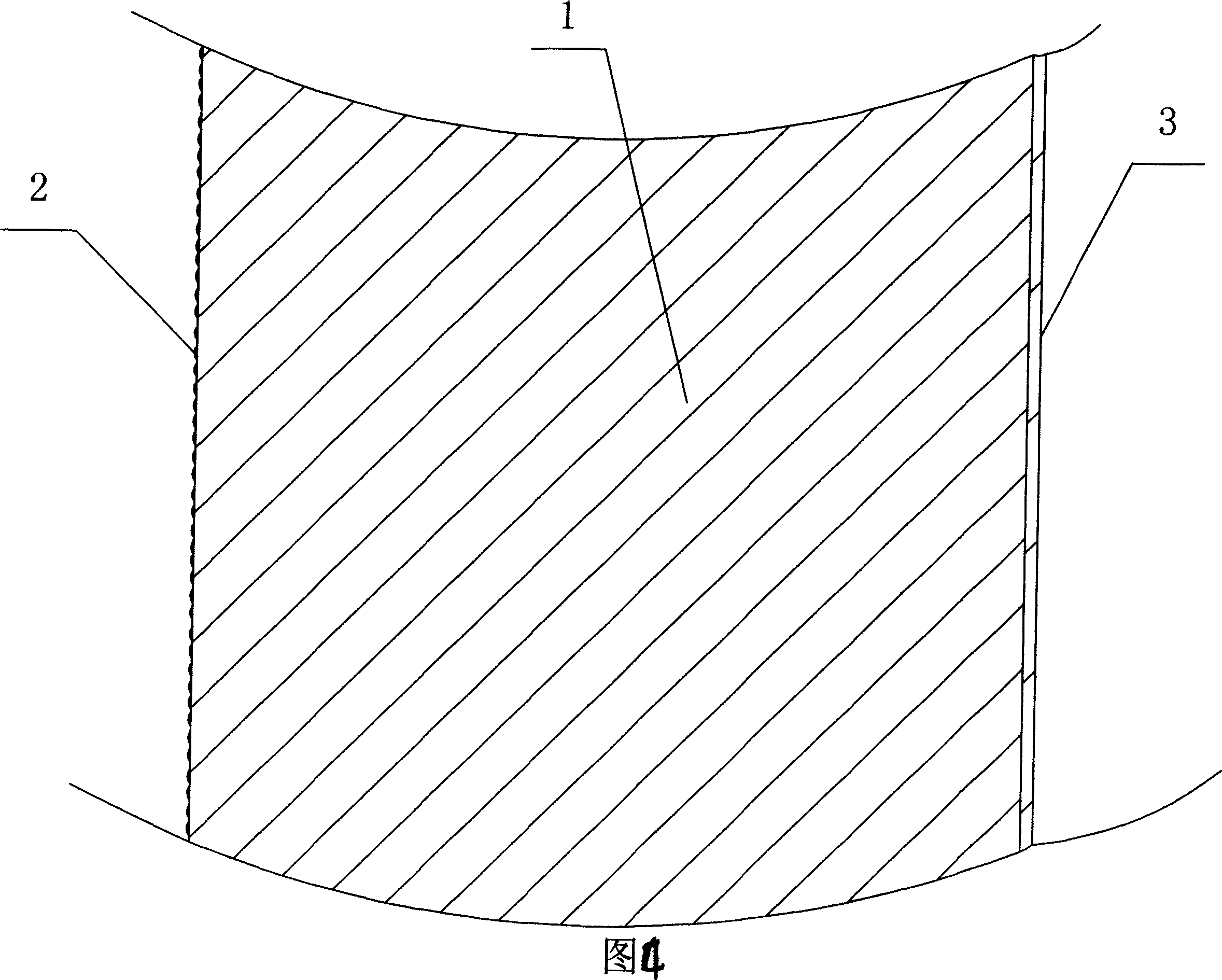

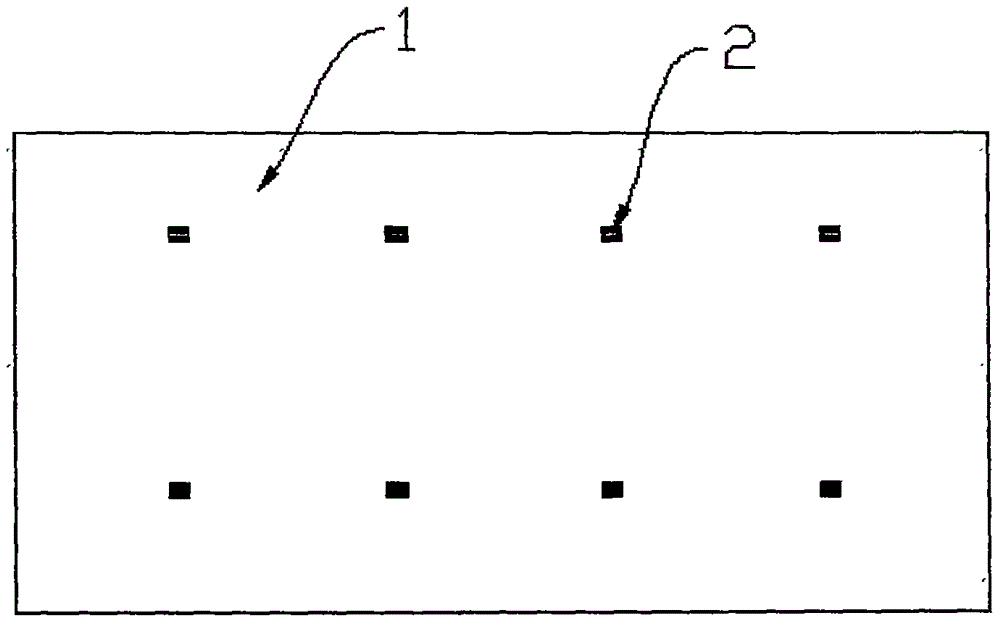

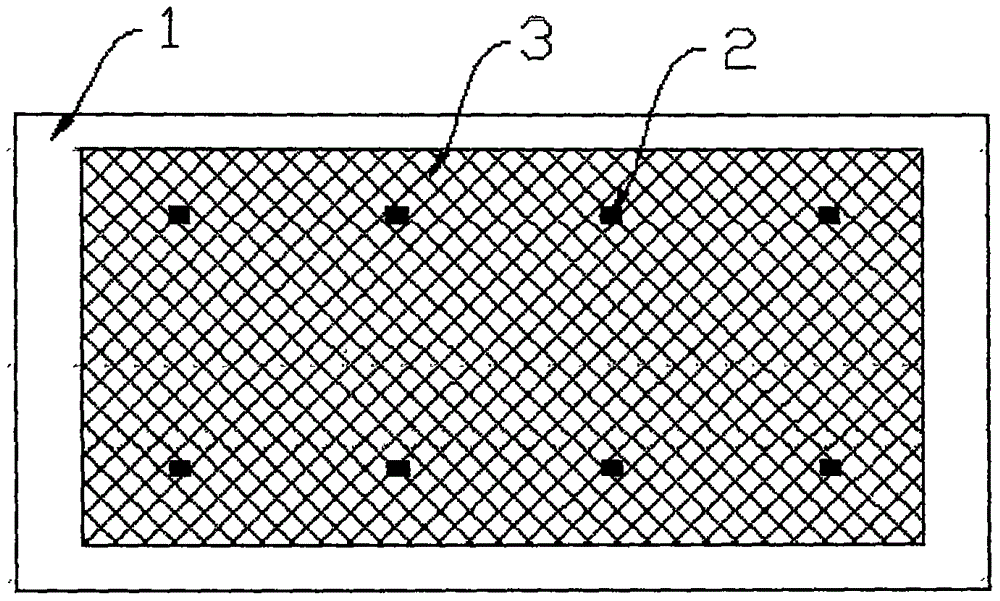

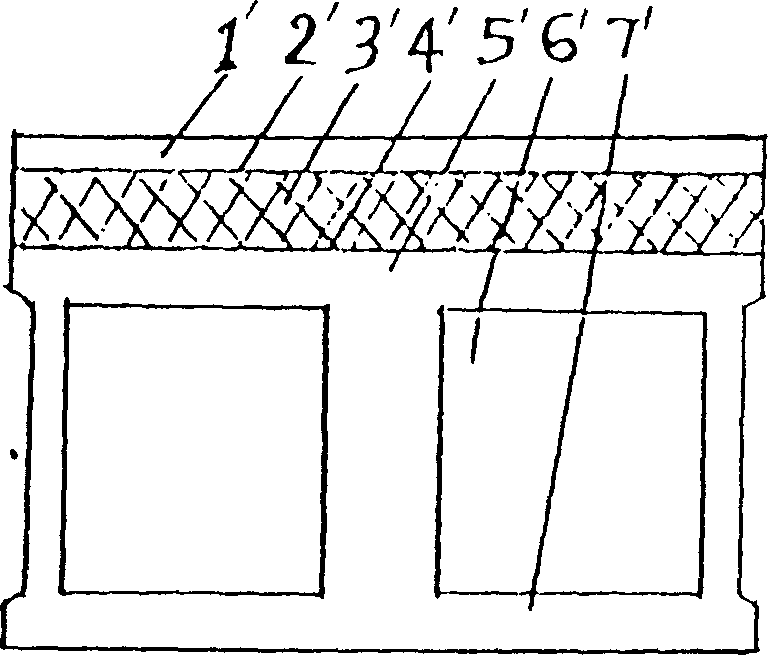

Full-ceramic tile wall attaching anti-falling technology

InactiveCN106013680APaste firmlyDoes not increase installation footprintCovering/liningsAdhesiveCement

The invention specifically discloses a full-ceramic tile wall attaching anti-falling technology. The technology is characterized by including the following steps that firstly, ceramic tiles of 800 mm*800 mm are machined into the ceramic tiles of 400 mm*800 mm, the ceramic tiles of 400 mm*800 mm are flatly placed on the ground, steel plates of 10 mm*10 mm*5 mm are selected, eight fixing points are evenly distributed on each ceramic tile, and then the steel plates are fixed to the set fixing points through a marble adhesive; secondly, a steel wire net is laid on the ceramic tiles provided with the steel plates, and the steel wire net and the steel plates are fixed through the marble adhesive; thirdly, after the steel wire net is fixed, a gap of 5 mm is reserved between the steel wire net and each ceramic tile, and the gaps are coated with cement after the marble adhesive is dried; and fourthly, after a wall is coated with cement, the ceramic tiles coated with the cement are attached to the wall. The technology has the following beneficial effects that the full-ceramic tile wall attaching anti-falling technology is simple in installation process, the full-ceramic tiles difficult to adhere can firmly adhere to the wall, and the installation occupation space of the ceramic tiles cannot be increased.

Owner:张国俊

A kind of sample preparation and determination method of high thermal conductivity metal material compression

ActiveCN104155166BAchieving surface contactNever fall offPreparing sample for investigationMaterial strength using tensile/compressive forcesStress–strain curveThermocouple Wire

The invention relates to a sample preparation and measurement method for compression of a metal material with high thermal conductivity. The preparation method includes the following steps in sequence: Ⅰ. Take a high thermal conductivity metal material sample to make a metal cylinder. The diameter of the metal cylinder is Ф8 mm to Ф10 mm, and the length is 10 mm to 15 mm. Point as a mark; Ⅱ. Drill a blind hole with a diameter of Ф1.6mm to Ф2.0mm and a depth of 1.8mm to 2.2mm at the mark; Ⅲ. Select a wire material of the same material as the metal cylinder or copper material to make a plug pin; Ⅳ. Place the negative end of the K-type thermocouple wire and the positive end of the K-type thermocouple wire on both sides of the blind hole, and plug the blind hole with a plug pin. The measurement method is to measure the sample on a thermodynamic simulation testing machine to obtain the stress-strain curve of the copper alloy. The process of sample preparation and measuring method of the present invention is simple and easy, and the result of rheological stress test data is accurate and stable.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Under-glaze colored decoration method of bone china

The invention relates to an under-glaze colored decoration method of bone china. The method includes an under-glaze colored decoration firing process and a pigment preparation technology, which includes transferring figures through pigment paint or labels for porcelain to a biscuit after lower temperature biscuit firing at a temperature of 700-800 DEG C, covering a protective layer, buckling a decorated ware on a profiling kiln furniture, performing firing at a temperature of 1250-1290 DEG C, wherein figure surfaces cannot be bruised, performing polishing on figure bases after firing, spraying fritted glaze slip, and performing glaze firing at a temperature of 1170-1200 DEG C. The figure surfaces are arranged under a glaze layer completely, and the method is a novel color decoration different from bone china over-glaze color figure for in-glaze decoration. Blanks are performed biscuit firing at a low temperature, the figure bases are fired through oxidizing flames at a high temperature (1250-1290 DEG C), and vitreous enamels are fired through oxidizing flames at an intermediate temperature (1170-1200 DEG C). Compared with once-firing of under-glaze color figure through reducing flames at a high temperature, the method is a firing method in which the temperature and the flame property are completely different. Bottoms of high range gift porcelain products are glazed through lowtemperature glazes, and smooth and non-discoloring forever after firing at a temperature of about 800-850 DEG C.

Owner:湖南丰德利瓷业有限公司

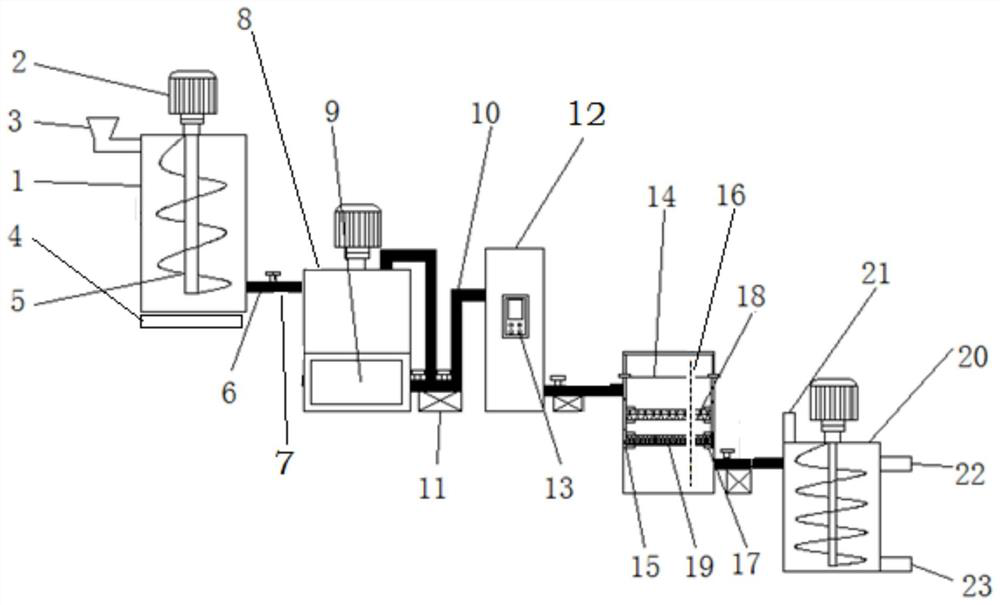

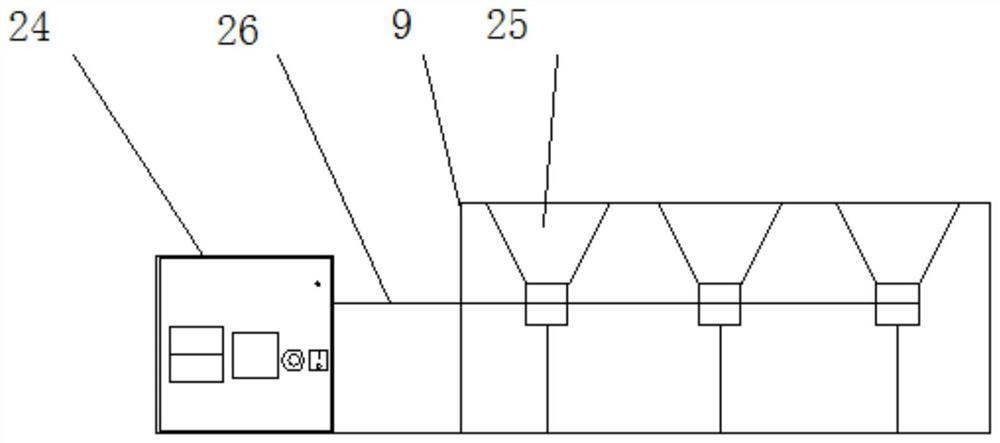

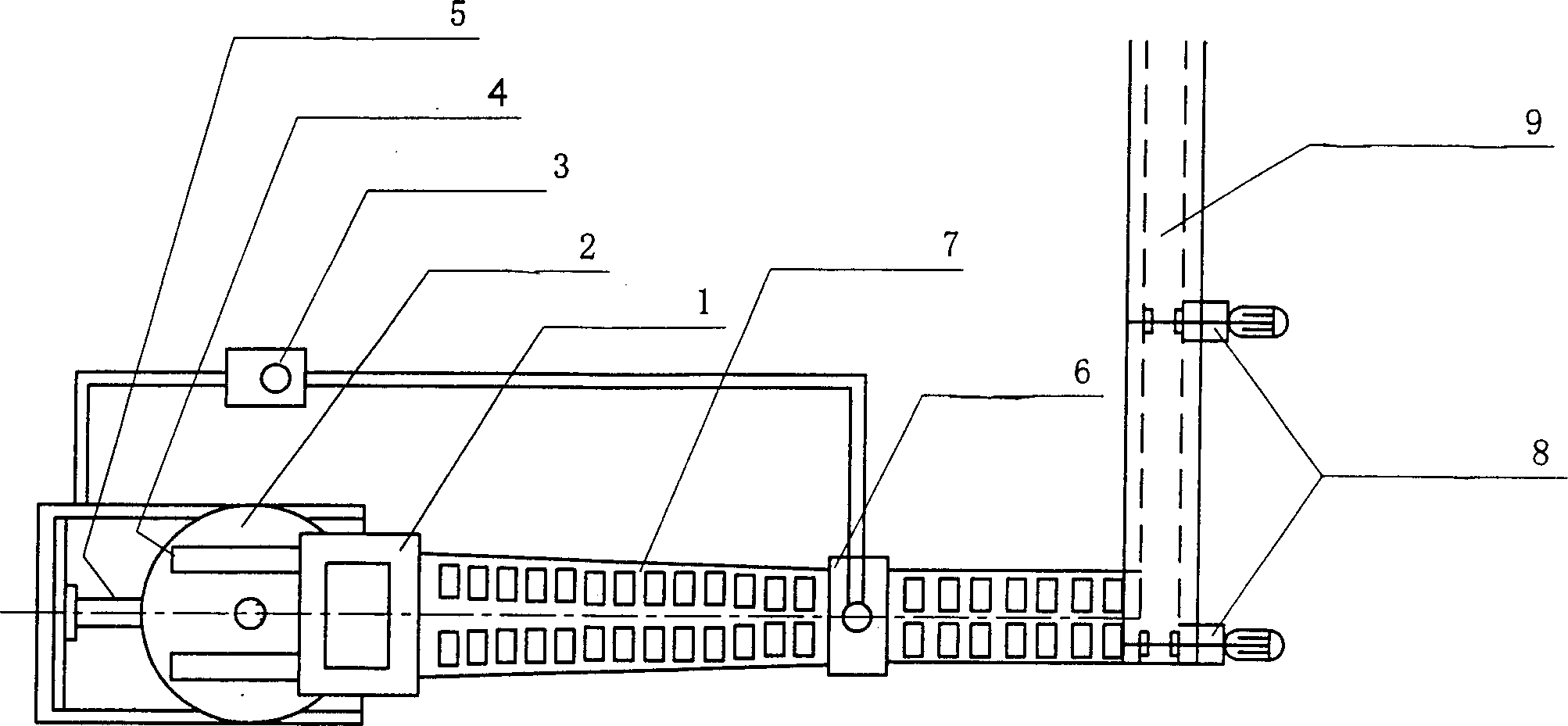

Ultrasonic auxiliary device and method for pyrolysis oil desulfurization

ActiveCN108822887BNever fall offRealize multiple ultrasonic assisted desulfurizationTreatment with plural serial refining stagesThermodynamicsUltrasonic assisted

The invention discloses an ultrasonic assisted device for desulfurization of pyrolysis oil. The device comprises a pyrolysis oil preparation device, a screw conveyer, a first screen, an ultrasonic reactor, a standing device, a filter and an extractor, wherein a first pipeline is connected between the pyrolysis oil preparation device and the ultrasonic reactor, ultrasonic system equipment is mounted at the lower end of the ultrasonic reactor, an alternating current connecting wire is connected between an ultrasonic generator and an energy converter, and the pyrolysis oil preparation device, theultrasonic reactor, the standing device, the filter and the extractor are arranged in sequence and have height difference, so that the pyrolysis oil flows by means of gravity. The invention also provides an ultrasonic assisted method for desulfurization of the pyrolysis oil.

Owner:国宏中晶集团有限公司

Downward short anchor cable continuous, multi-layer pre-support method

ActiveCN102926776BSimplify the installation processReduce work intensityAnchoring boltsMining engineeringStructural engineering

The present invention is a continuous and multi-layer pre-supporting method with downward short anchor cables. Starting from the second layer, the following pre-supporting operation is carried out after the one-step mining and slitting is completed: first, along the one-step mining and slitting, the upper position of the two sides of the bottom plate is Excavate a downwardly inclined drilling hole, then install the supporting threaded steel in the borehole and pour cement slurry, and then use the same rooting threaded steel to connect the tails of the supporting threaded steel in the same one-step mining section together, and then Carry out stope cement filling operations. After the two-step mining operation is completed, the tailings are filled. The method implements advanced, continuous and multi-layer support for the mining body, and can completely cure the roof caving of the stope.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

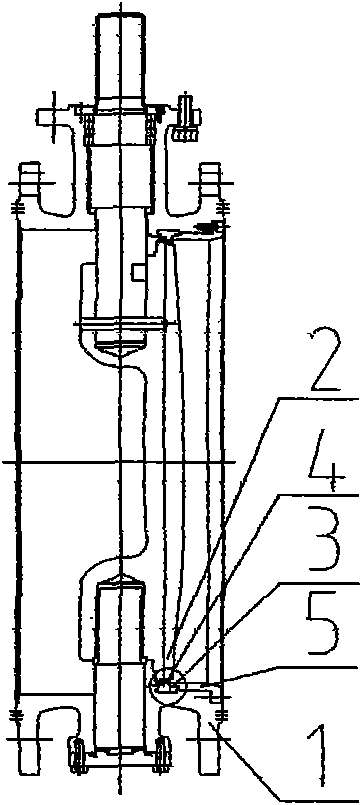

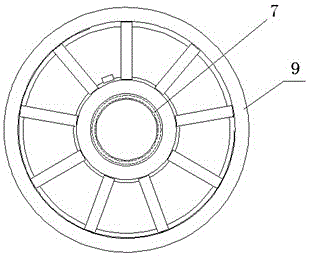

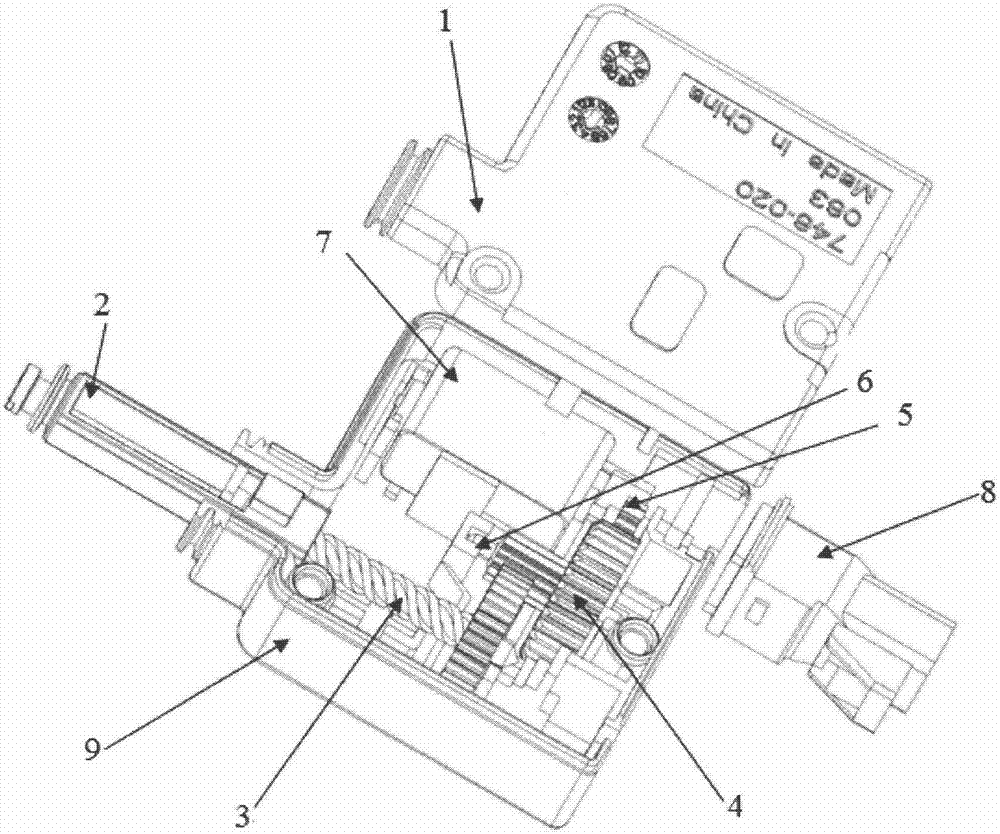

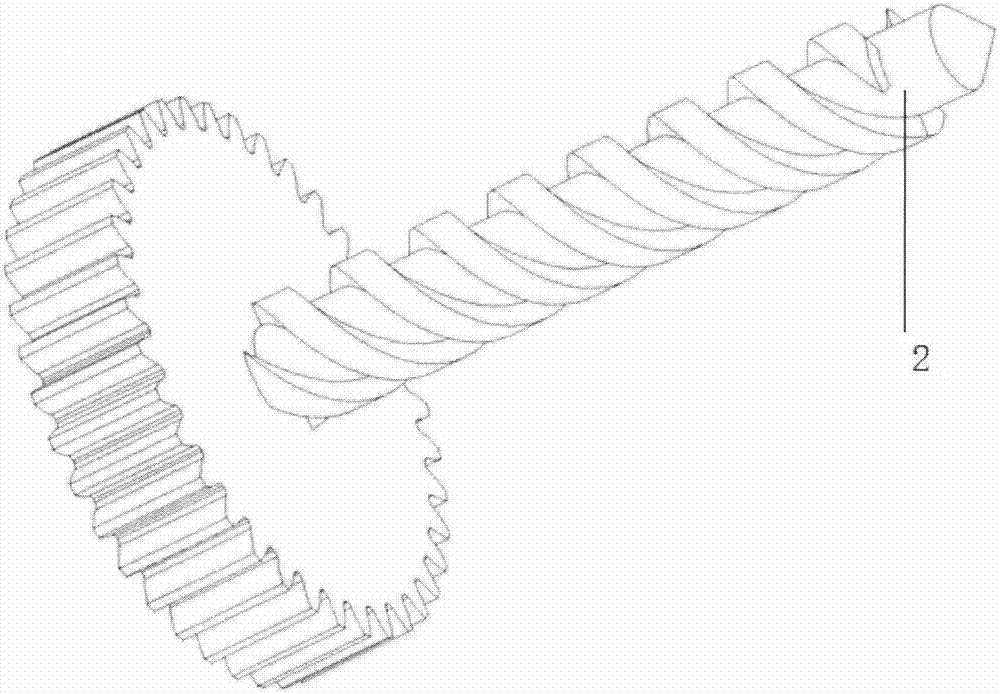

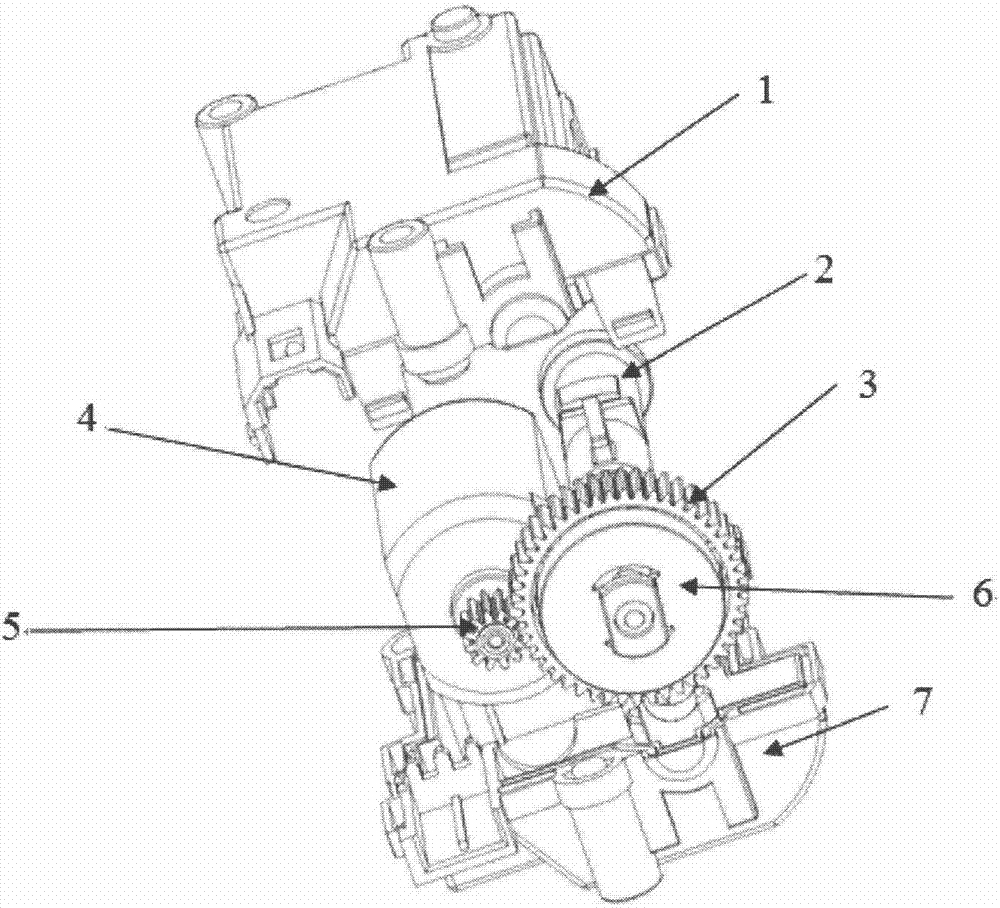

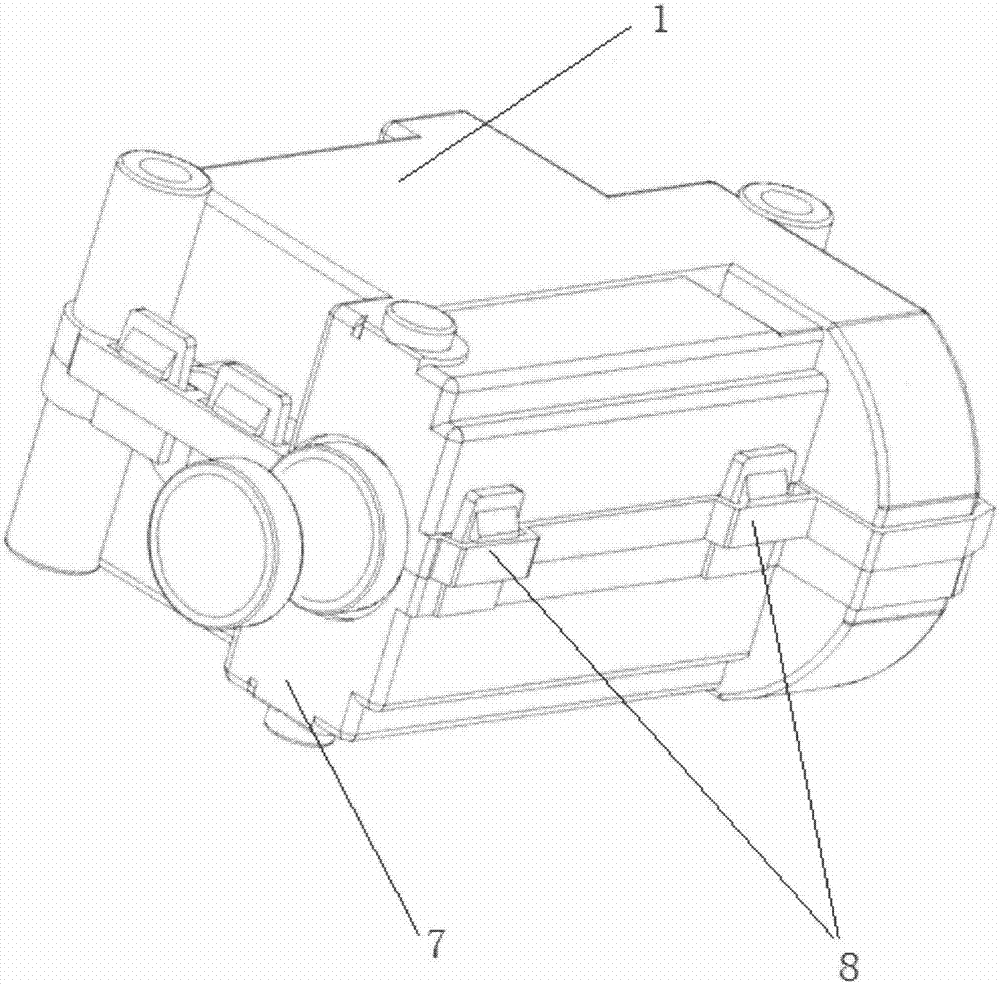

Automobile electric door lock device

InactiveCN107355151AHigh speedSimple structurePower transmission/actuator featuresElectrical locking actuatorsPower door locksEngineering

The invention relates to an automobile electric door lock device comprising an upper lid, a pull rod, a transmission shaft, a middle gear, a small gear, a central spindle, a small motor, a protective sleeve and a lower lid. The upper lid is fixed on the lower lid; one end of the lower lid is provided with the pull rod and the other end is provided with the protective sleeve; the small motor is disposed in the lower lid; the small motor drives the small gear; the small gear drives the middle gear; the middle gear is connected with the transmission shaft; the transmission shaft is connected with the pull rod; and the middle gear is fixed on the lower lid via the central spindle. The automobile electric door lock device is simply structured and rationally designed; on one hand, a traditional single-thread transmission shaft is changed into a three-thread transmission shaft; with the improvement, motion speed of the pull rod is improved by three times; on the other hand, a traditional way of welding the upper lid and the lower lid via a welding way is changed into a buckling technology, so the upper lid and the lower lid can be buckled together; the upper lid and the lower lid can be fixed with firmness and beautiful contour; and the upper lid and the lower lid cannot fall; and the automobile electric door lock device is easy to assemble and adjust.

Owner:UNITED TOP TECH

A kind of braided tube homogenous reinforced polyvinylidene fluoride hollow fiber membrane and preparation method thereof

ActiveCN104888621BEasy to makeMature technologySemi-permeable membranesHigh concentrationPolymer science

The invention discloses a preparing method of a braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film, and belongs to the field of polymer film product preparation. The preparing method includes firstly preparing a polyvinylidene fluoride solution A having a certain low concentration, dipping a braided tube with the solution A to allow the polyvinylidene fluoride solution to penetrate into the inside of the braided tube, coating the outside of the braided tube with a high-concentration polyvinylidene fluoride film casting solution B having a certain formula, and putting the braided tube coated with the solution A and the solution B into a coagulating bath to allow the polyvinylidene fluoride coated in the two times to be subjected to phase separation simultaneously. The polyvinylidene fluoride hollow fiber film prepared by the method is advantageous in that 1) the inner low-concentration polyvinylidene fluoride solution tightly surrounds fibers of the braided tube, is tightly connected to an outer film layer after phase transition, and is not liable to shed; 2) a high-aperture-ratio compact surface layer is formed from the outer high-concentration film casting solution and provides effects of filtration; and 3) the braided tube with high strength provides excellent film fiber longitudinal stretching strength.

Owner:安徽指南针科创园发展有限公司

Rolled plate hoisting gasket

The invention relates to a rolled plate hoisting gasket, belonging to the technical field of hoisting tools. The gasket comprises a length of arc-shaped bending plate mainly identical to an inner ring of the rolled plate, the bending plate is provided with a vertical baffle along an arc side thereof, an external arc surface of the bending plate and an inner surface of the vertical baffle are respectively provided with ferromagnets at intervals, and an inner arc surface of the bending plate is provided with a bump. In comparison with the existing rolled plate gasket, the gasket provided by theinvention has the following advantages that: 1) with the ferromagnets, the gasket can be closely attached to the inner ring of the rolled plate just by only a small length of the arc-shaped bending plate, and the gasket not only has small volume, low cost and convenient use, but also cannot fall off in the process of use; 2) the vertical baffle can further prevent a nylon hoisting belt from contacting an external end surface of the rolled plate, so that the external end surface of the rolled plate is protected; 3) with the bump, an extrusion force applied on the whole gasket by the hoisting belt can be transferred from a corner of the vertical plate to the bump, so that the extrusion force applied on the inner ring of the cold-rolled plate by the hoisting belt is further reduced, and abrasion of the bending plate and the corner of the vertical plate is avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

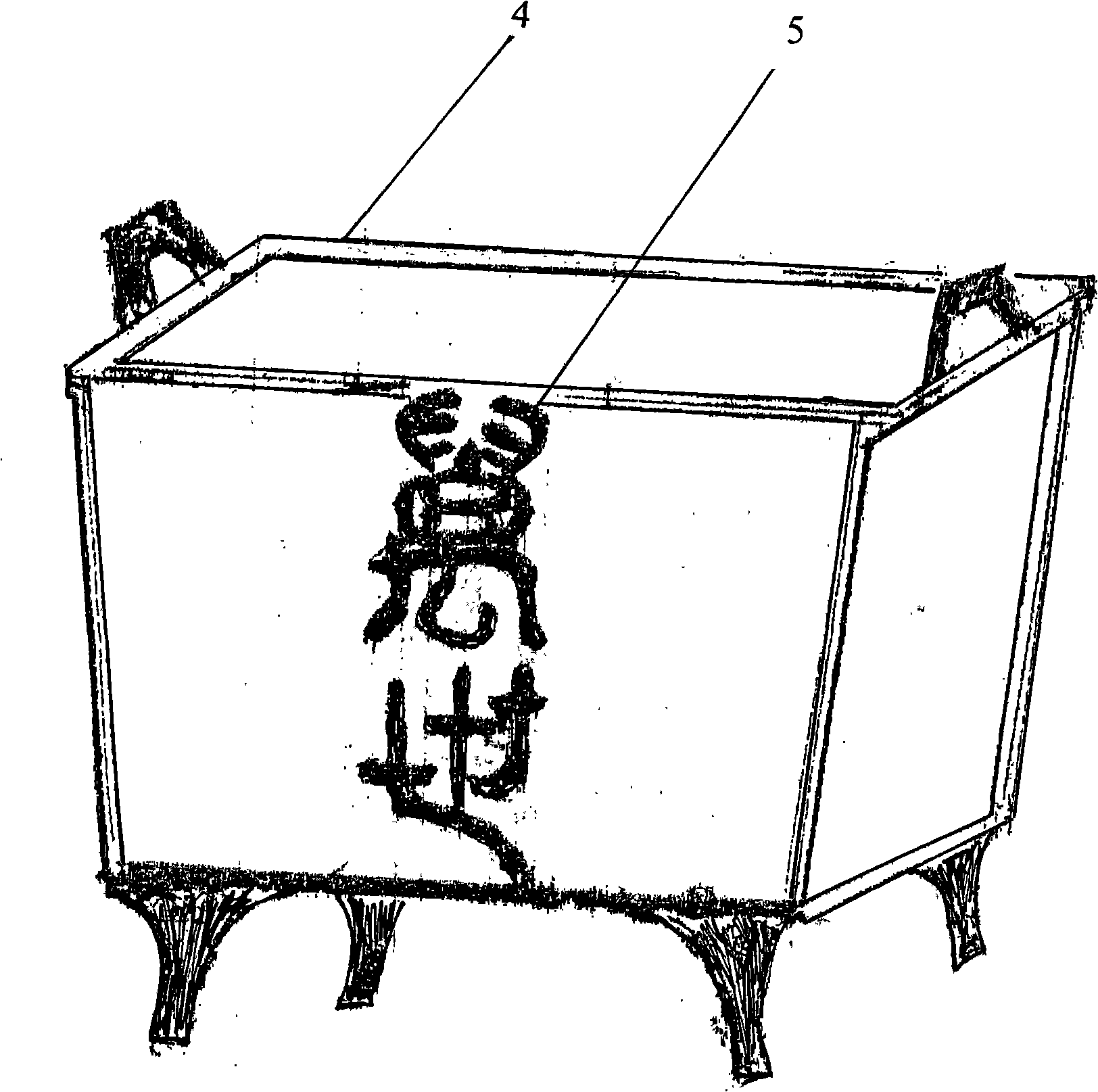

A combination of ceramic and silver inlay technology

ActiveCN107443992BUse healthy and environmentally friendlyEasy to useDecorative surface effectsPottery fractureSilver paste

The invention discloses a ceramic and silver inlaying combination process. The process comprises the following steps: (1) a ceramic cup with an upper port smaller than a blank body is selected; (2) silver is smelted; (3) a cast plate is rolled as a sheet; and the molten silver is cast as a plate; (4) molding and stretching: the silver plate is hardened in the process of repeatedly rolling as a silver coil; the silver coil is heated to 200 DEG C for softening; and a silver sheet part is repeatedly punched and stretched by multiple times to form a cylindrical silver liner matched with the inner diameter of ceramic; and (5) silver and ceramic are combined in an inlaying manner. The ceramic and silver inlaying combination process breaks through a conventional method of bonding silver with ceramic by glue, so that prepared silver and ceramic are more healthy and environment-friendly in use without falling forever, and are longer in life; and in addition, silica gel with a hardness of 55A is selected, and the pressure tonnage in extrusion of the silver liner and the ceramic cup is strictly controlled, so that the damage rate caused by ceramic breakage and burning deformation can be effectively reduced.

Owner:温州金瑞祥金银制品有限公司

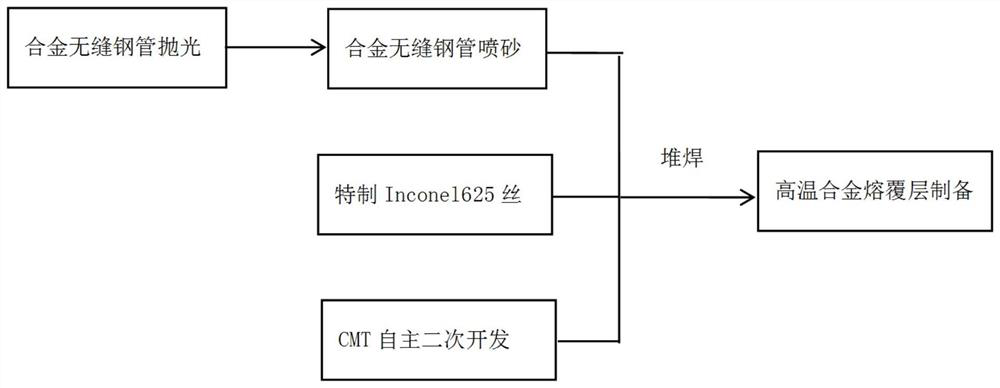

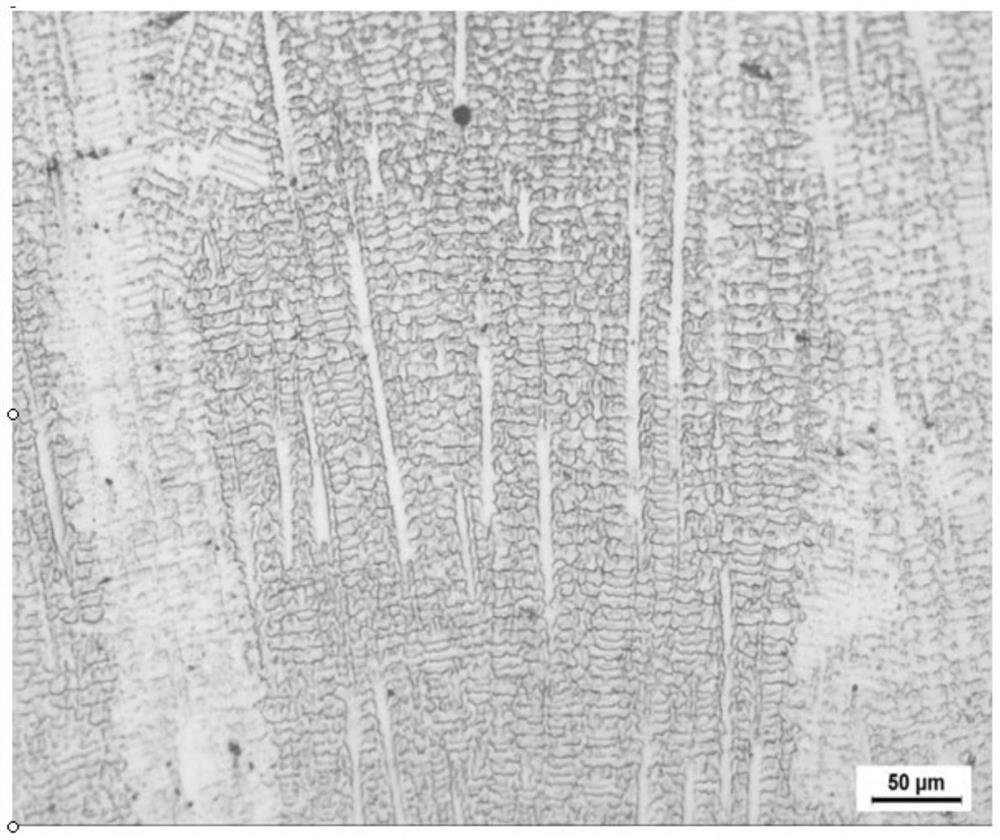

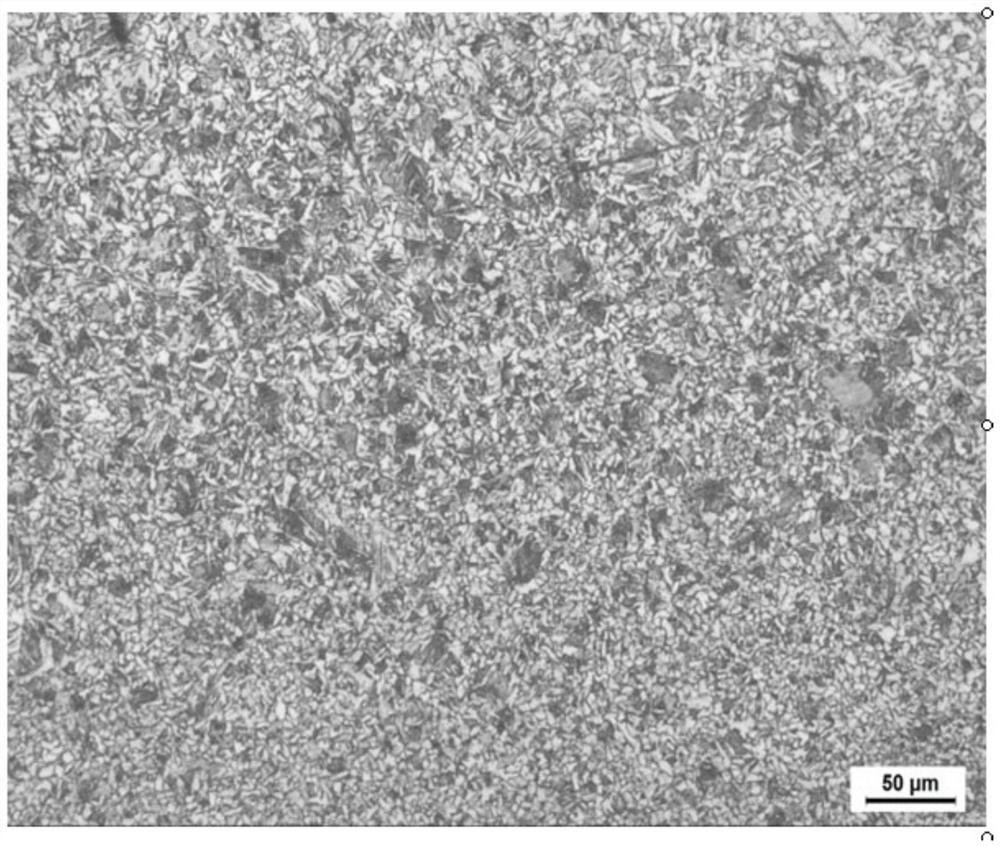

Preparation method of ultra-thin ultra-low dilution rate high-temperature alloy cladding layer for garbage incinerator

PendingCN113369639AThickness is easy to controlImprove control stabilityArc welding apparatusChemistryProcess engineering

The invention relates to a preparation method of an ultra-thin and ultra-low dilution rate high-temperature alloy cladding layer for a garbage incinerator, and belongs to the technical field of new material surface protection. The preparation method of the ultra-thin and ultra-low dilution rate high-temperature alloy cladding layer for the garbage incinerator aims at a protection process for preparing the high-temperature alloy cladding layer for preventing high-temperature corrosion of fused salts such as chlorine, sulfur and compounds thereof on a heating surface of the garbage incinerator. The cladding layer has a good anti-corrosion effect on the heating surface of the garbage incinerator, and the service life of the garbage incinerator can be effectively and greatly prolonged; and safe and efficient operation of a garbage incineration power station boiler is guaranteed, environmental protection is achieved, and social harmonious development is promoted.

Owner:JIANGXI HENGDA HI TECH CO LTD +1

Pull ring type rivet

The invention belongs to the technical field of rivets and relates to a rivet, in particular to a pull ring type rivet. The pull ring type rivet comprises a rivet body and a rivet core. The end, facing the rivet core, of the rivet body is provided with an oblate rivet body head. A rivet body center hole is formed in the rivet body in the axis direction of the rivet body. A rivet head hole is formed in the center of the rivet body head. The rivet core is arranged in the rivet body. The end, facing the rivet body, of the rivet core is provided with an oblate rivet core head. The end, back on to the rivet body, of the rivet core is provided with a pull ring. The end, close to the rivet core head, of the rivet core is provided with a cone fracture part. The end, close to the pull ring, of the rivet core is provided with a rivet core connecting part. The rivet core stretches into the rivet body center hole and the rivet head hole. The rivet core head extends out of the rivet body center hole of the rivet core, and the rivet core head and the end face of the rivet core form front end positioning. The pull ring and the tail end of the rivet core extend out of the rivet head hole. By adopting the pull ring type rivet, a user can conduct riveting by pulling the rivet with the hand without a riveting tool, time and labor are saved, and connection is reliable; the pull ring type rivet is convenient to mount and use, and the connection reliability is improved.

Owner:WUXI ANSHIDA HARDWARE

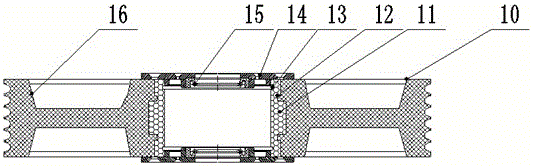

Automobile electric door lock device with telescopic pull rod

InactiveCN107355149ASimple structureReasonable designPower transmission/actuator featuresElectrical locking actuatorsGear driveDrive shaft

The invention relates to an automobile electric door lock device with a telescopic pull rod. The automobile electric door lock device comprises an upper lid, a pull rod, a transmission shaft, a small motor, a small gear, a rotation block and an upper lid, wherein the upper lid is fixed on the lower lid; the lower lid is provided with the small motor and the pull rod; the small motor is connected with the small gear and drives the same; the pull rod is connected with the transmission shaft; an end part of the transmission shaft is provided with a rotation block; and the small gear drives the transmission shaft. The automobile electric door lock device with the telescopic pull rod is simply structured and rationally designed; a traditional way of welding the upper lid and the lower lid via ultrasonic waves is changed into a buckling technology, by which the upper lid and the lower lid can be buckled together; the technology can firmly fix the upper lid and the lower lid; beautiful and firm fixation can be achieved and falling off of the upper lid and the lower lid can be prevented; product precision can be ensured; and the automobile electric door lock device has long service life and is easy to assemble and adjust.

Owner:UNITED TOP TECH

Technique for painting bathtub or faceplate of ventilator and surcace

InactiveCN1696576ANever fall offImprove visual effectsLighting and heating apparatusSpace heating and ventilation detailsLacquerSpray coating

The present invention relates to a panel and surface coating process of bathroom electroheating device or air exchange fan. Said coating process includes the following steps: firstly, spraying a layer of color paint on the surface of formed panel of bathroom electroheating device or air exchange fan, naturally drying by airing or stove-drying below 60 deg.C, printing product marker with a certain pattern and / or characters on its surface, then spray-coating a layer of bright transparent paint on its surface, drying by airing or stove-drying below 55 deg.C and solidifying so as to implement the coating process.

Owner:徐迹

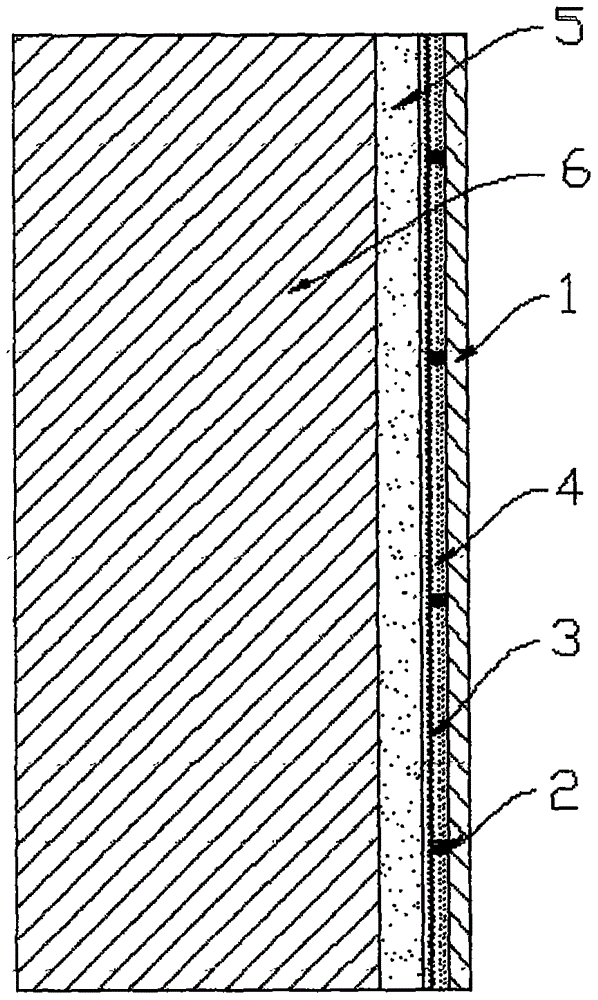

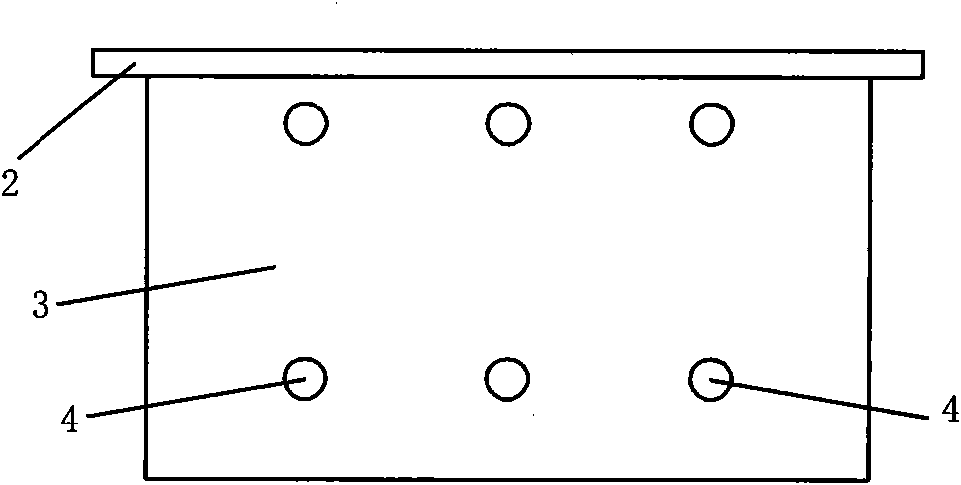

Hollow concrete building block and its productive method and apparatus

InactiveCN1111237CImprove composite effectExternal insulation hasConstruction materialWallsSurface layerAdhesive

A composite hollow building concrete block with decoration, insulating and load-bearing functions is composed of decorative surface layer, insulating layer, inserting needles and load-bearing hollow building blocks. Said decorative surface layer consists of concrete layer, self-flame-extinguishing polybenzene board, and mixed layer of adhesive, cement and water. Said hollow layer consists of two load-bearing building blocks. Its making method and equipment are also disclosed. Its advantages are high adhesion, insulating nature and durability.

Owner:杨书文 +1

A kind of polyester film for barcode printing and preparation method thereof

ActiveCN104129185BHigh glossGood adhesionDuplicating/marking methodsFlat articlesMethacrylateAcetic acid

Owner:SICHUAN YUXI ELECTRONICS TECH CO LTD

A kind of high imitation artistic painting ceramic tile duplication method

ActiveCN105082857BRealistic color effectImprove controllabilityImage enhancementDecorative surface effectsDigital imageControllability

The invention relates to a method for duplicating high-simulation art painting ceramic tiles. The method comprises the following steps: (1) installing a laser laser device on a digital scanner, scanning the original painting through the digital scanner under the action of the laser laser, and converting the original picture (2) Perform color comparison processing and color difference management on the obtained digital image; (3) Select the printing material and print it through a high-end inkjet printer; (4) Burn the high-temperature fidelity color, and then perform post-processing. Can. Compared with the prior art, the invention has the advantages of lifelike product color effects, strong controllability and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com