Ultrasonic auxiliary device and method for pyrolysis oil desulfurization

An ultrasonic-assisted, oil-cracking technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, and only multi-stage serial refining process, can solve the problems of no device and supporting method, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

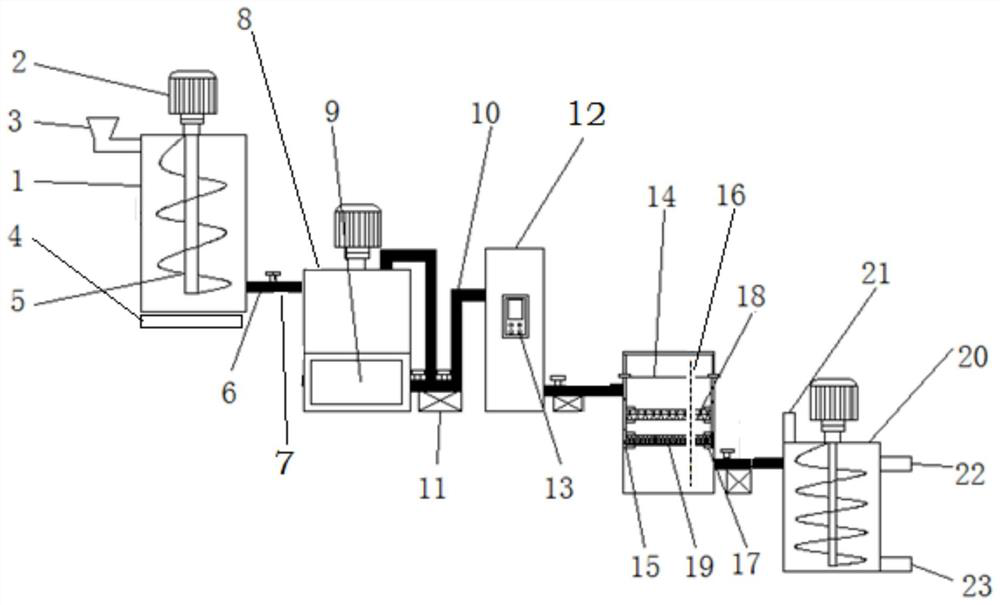

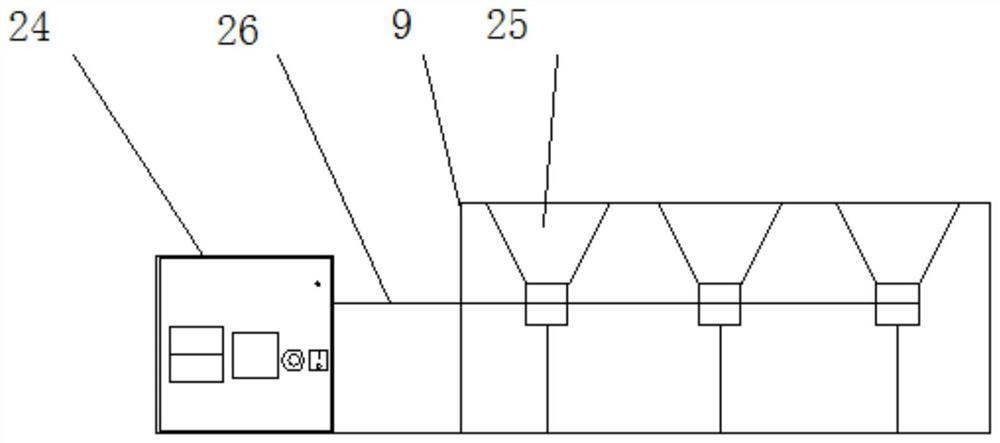

[0026] see Figure 1-2, the present invention provides a technical solution: an ultrasonic auxiliary device for pyrolysis oil desulfurization, comprising a pyrolysis oil preparator 1, an ultrasonic reactor 8, a static device 12, a filter 14, and an extractor 20, characterized in that: Described pyrolysis oil preparator 1 is cylindrical barrel type, and the upper end of described pyrolysis oil preparator 1 is equipped with servo motor 2, and the left end of pyrolysis oil preparator 1 is connected with feed hopper 3, and described electronic balance 4 is arranged on the pyrolysis Directly below the oil preparer 1, the auger 5 is connected to the servo motor 2, and the auger 5 is placed inside the cracking oil preparer 1, and the first screw is connected between the cracking oil preparer 1 and the ultrasonic reactor 8. A pipeline 6, an electromagnetic valve 7 is installed on the first pipeline 6, an ultrasonic system equipment 9 is installed on the lower end of the ultrasonic rea...

Embodiment 2

[0034] The invention provides a technical solution: an ultrasonic auxiliary device and method for cracking oil desulfurization, including a cracking oil preparer 1, a servo motor 2, a feeding hopper 3, an electronic scale 4, an auger 5, a first pipeline 6, an electromagnetic Valve 7, ultrasonic reactor 8, ultrasonic system equipment 9, second pipeline 10, hydraulic pump 11, static device 12, time controller 13, filter 14, hanging rod 15, lifting rod 16, block 17, first Screen cloth 18, second screen cloth 19, extractor 20, feeding port 21, extraction agent outlet 22, desulfurization cracking oil outlet 23, ultrasonic generator 24, transducer 25 and electric wire 26, the upper end of cracking oil preparation device 1 is installed There is a servo motor 2, and the left end of the cracking oil preparer 1 is connected with a feed hopper 3, the electronic scale 4 is arranged under the cracking oil preparer 1, the auger 5 is connected with the servo motor 2, and the auger 5 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com