A kind of polyester film for barcode printing and preparation method thereof

A technology of polyester film and polyester film layer, which is applied in the field of polyester film and its preparation, and can solve the problems of aging resistance, high temperature resistance and tear resistance defects, fast decay of surface corona value, and influence on ink gloss, etc. , to achieve stability and not easy to fall off, improve ink adhesion and printability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of resin with high ink adhesion

[0041] At room temperature, 70kg glycidyl methacrylate, 24kg hydroxypropyl methacrylate, 3kgN-hydroxyethyl acrylamide, 3kg methacrylic acid acetoacetate ethylene glycol diester, 100kg solvent (mass ratio is ethylene glycol ether: Ethylene glycol diethyl ether = 20:1), and 0.5kg of benzoyl peroxide were added to the reactor with a condensing reflux device, stirred at a rotation speed of 200rpm, and mixed evenly; Gradually raise the temperature to 95°C, carry out the solution copolymerization reaction for 4 hours, stop heating, and the reaction ends. Then add 100kg of ethylene glycol ether and mix evenly, cool to room temperature and discharge to obtain a high ink adhesion resin with a solid content of 28%.

[0042] 2. Prepare high ink adhesion resin solution

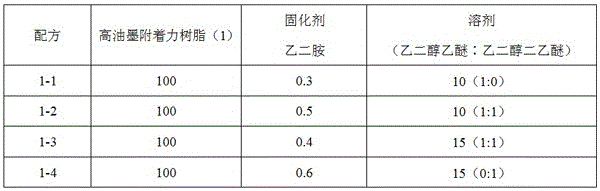

[0043] (1) Formula (unit: kg)

[0044]

[0045] Preparation process:

[0046] According to the above formula, add the high ink adhesion resin into the mixing ...

Embodiment 2

[0048] 1. Preparation of resin with high ink adhesion

[0049]At room temperature, mix 60kg glycidyl methacrylate, 20kg hydroxypropyl methacrylate, 10kg N-hydroxyethylacrylamide, 10kg methacrylic acid acetoacetate ethylene glycol diester, 100kg solvent (mass ratio ethylene glycol ether: ethyl ether) Glycol diethyl ether = 1:20), and 0.5 kg of benzoyl peroxide were added to the reaction kettle with a condensing reflux device, stirred at a rotation speed of 200 rpm, and mixed evenly; the stirring rotation speed was increased to 330 rpm, and gradually The temperature was raised to 90° C., and the solution copolymerization reaction was carried out for 4.5 hours, and the heating was stopped to complete the reaction. Then add 100kg of ethylene glycol ether and mix evenly, cool to room temperature and discharge to obtain a high ink adhesion resin with a solid content of 29%.

[0050] 2. Prepare high ink adhesion resin solution

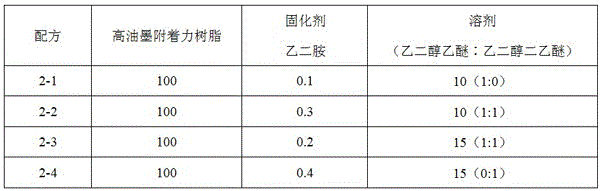

[0051] (1) Formula (unit: kg)

[0052]

[0053] P...

Embodiment 3

[0056] 1. Preparation of resin with high ink adhesion

[0057] At room temperature, mix 55kg glycidyl methacrylate, 15kg hydroxypropyl methacrylate, 15kg N-hydroxyethylacrylamide, 15kg methacrylic acid acetoacetate ethylene glycol diester, 100kg solvent (mass ratio ethylene glycol ether: ethyl ether) Glycol diethyl ether = 1:20), and 2kg of azobisisobutylcyanide were added to the reaction kettle with a condensing reflux device, stirred at a rotation speed of 200rpm, and mixed evenly; the stirring rotation number was increased to 330rpm, and gradually Raise the temperature to 100°C, carry out the solution copolymerization reaction for 4 hours, stop heating, and the reaction ends. Then add 100 kg of ethylene glycol ether and mix evenly, cool to room temperature and discharge to obtain a high ink adhesion resin with a solid content of 30%.

[0058] 2. Prepare high ink adhesion resin solution

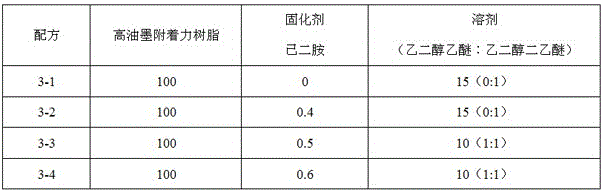

[0059] (1) Formula (unit: kg)

[0060]

[0061] Preparation process:

[0062] Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com