Hollow concrete building block and its productive method and apparatus

A hollow block and composite thermal insulation technology, which is applied in the field of decoration, load-bearing wall concrete composite hollow block, and thermal insulation, can solve the problems of destroying land resources, insulation layer and wall falling off, land loss, etc., and achieve the effect of solving water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

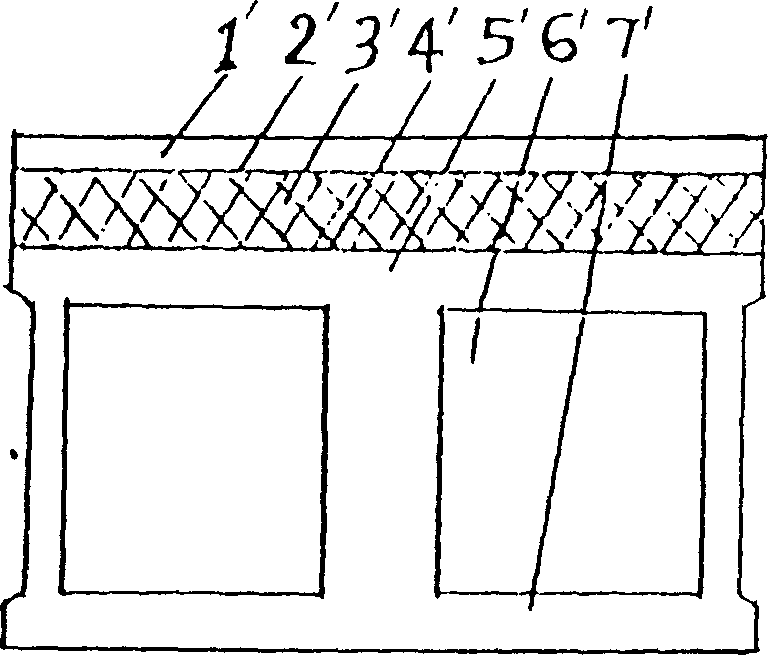

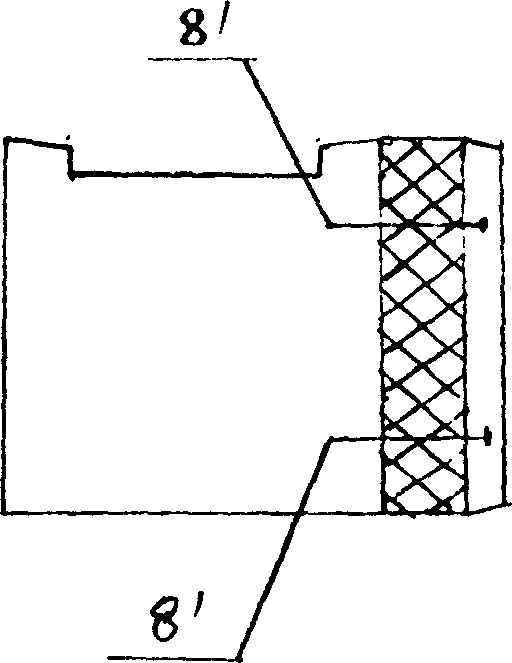

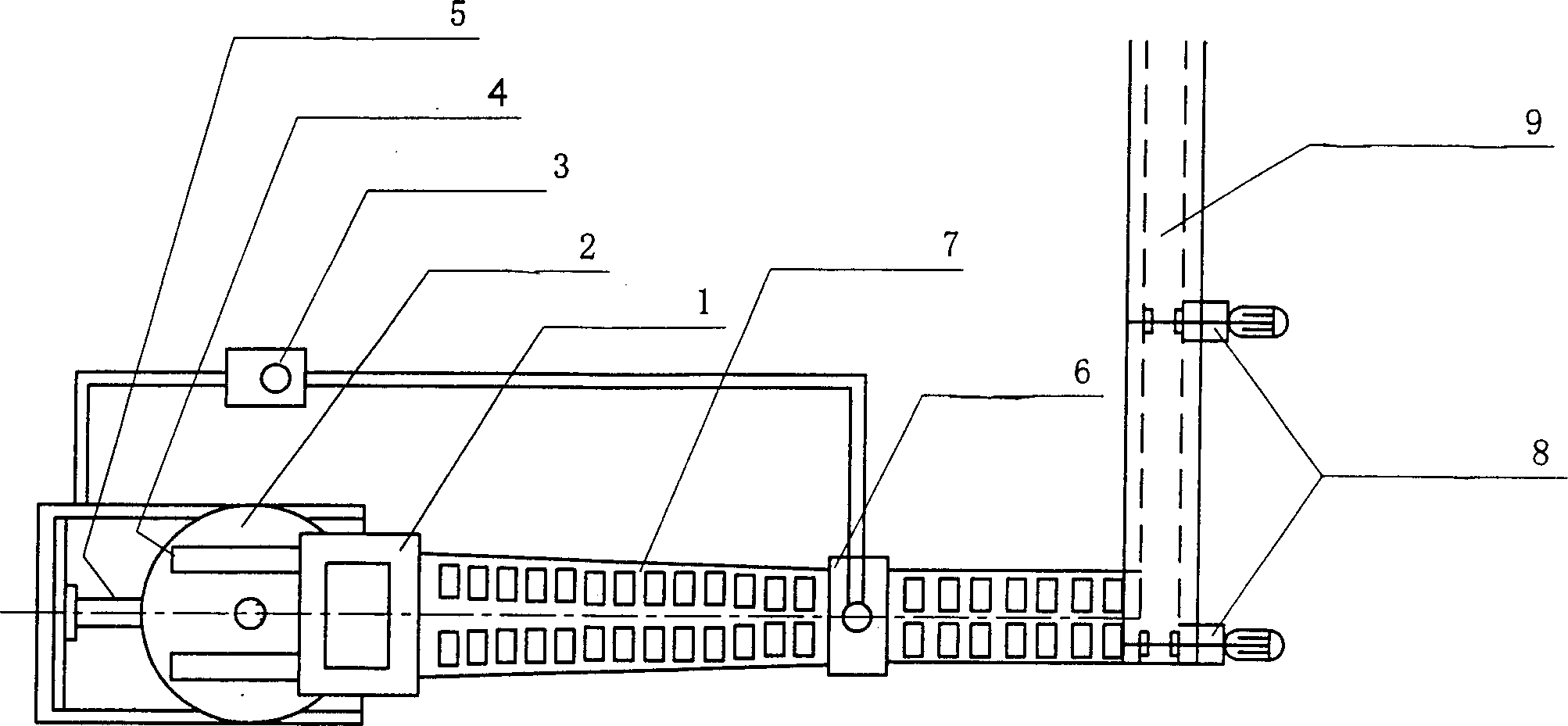

[0025] like figure 1 , 2 As shown, the concrete load-bearing wall composite thermal insulation hollow block of the present invention includes an outer finish layer, an insulation layer, pins and a load-bearing hollow block, wherein the outer finish layer is composed of concrete layers 1', 5' and self-extinguishing Type polystyrene board insulation layer 3' is composed of adhesive, cement and water mixed layers 2' and 4'; the load-bearing hollow block is provided with two walls in the middle of the load-bearing block 7' It is formed by building holes 6'; there is a bevel for pointing and anti-seepage around the outer finish layer; there is an insertion between the outer finish layer, the insulation layer 3' and the load-bearing block 7'. Pin 8', and use pin 8' to connect the outer decorative surface layer, insulation layer and load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com