A kind of sample preparation and determination method of high thermal conductivity metal material compression

A technology of metal materials and high thermal conductivity, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of copper alloy samples and thermocouples, burning spot welders, etc. Problems such as working anvil, heat input and energy loss are too fast, etc., to achieve the effect of convenient process simulation test, simple and easy operation process, and avoiding burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific implementation of the present invention will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the present invention is not limited to the following examples.

[0074] Sample Example

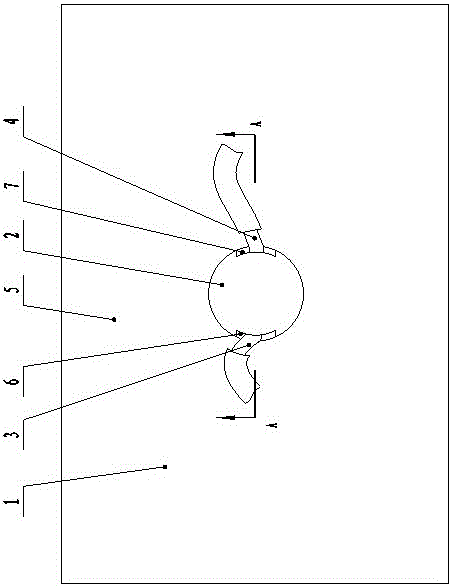

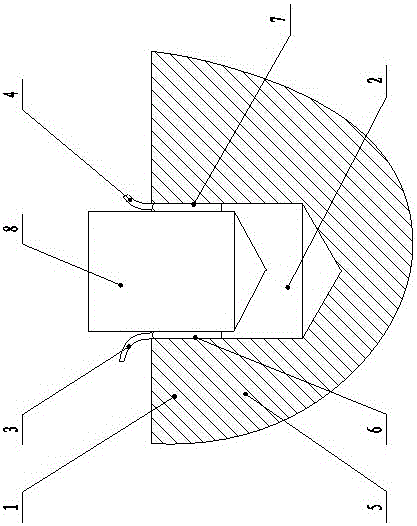

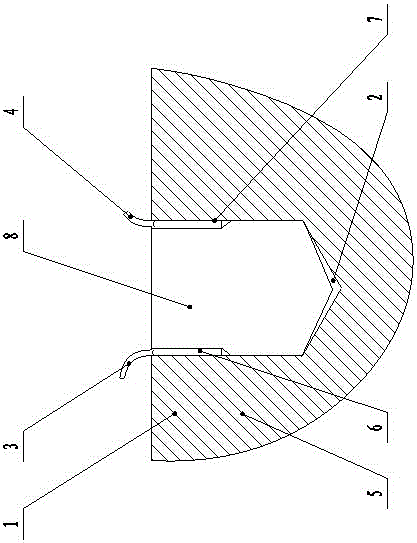

[0075] This embodiment is a sample preparation method for compressing a high thermal conductivity metal material on a thermodynamic simulation testing machine, which is directly applied to a thermodynamic simulation testing machine Gleeble 3800 general-purpose unit for a flow stress simulation test. The material selected in this embodiment is copper alloy H65, and the size of the metal cylinder for manufacturing the sample is Ф8mm×12mm.

[0076] Concretely include the following sequential steps:

[0077] Ⅰ Put the direction of the axis of the metal cylinder 1 flat, so that the axial direction of the metal cylinder 1 is clamped on the vise, and the direction of the axis of the metal cylinder 1 is stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com