Multi-claw floating pressure head special for casting blank machining

A technology of casting blanks and floating indenters, applied in the direction of the chuck, etc., can solve the problems of clamping force reduction, affecting work efficiency, and large casting jumps, and achieve the effect of preventing relative displacement and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

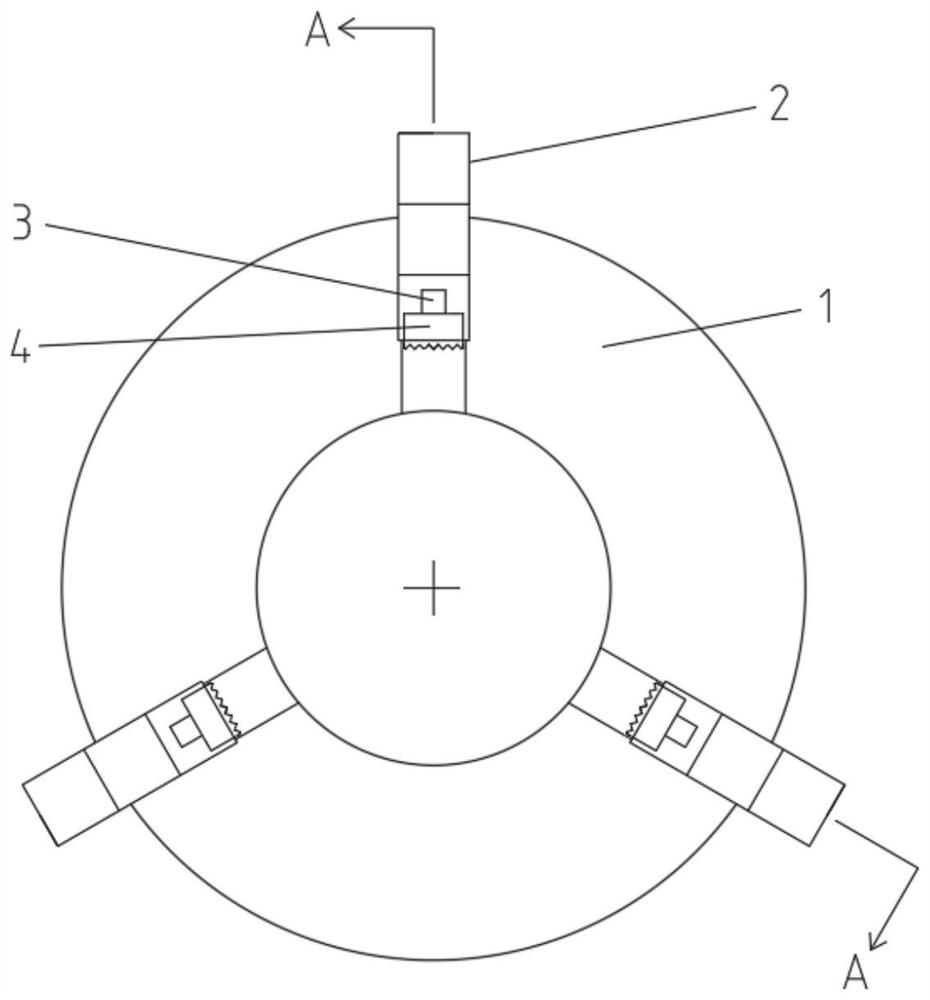

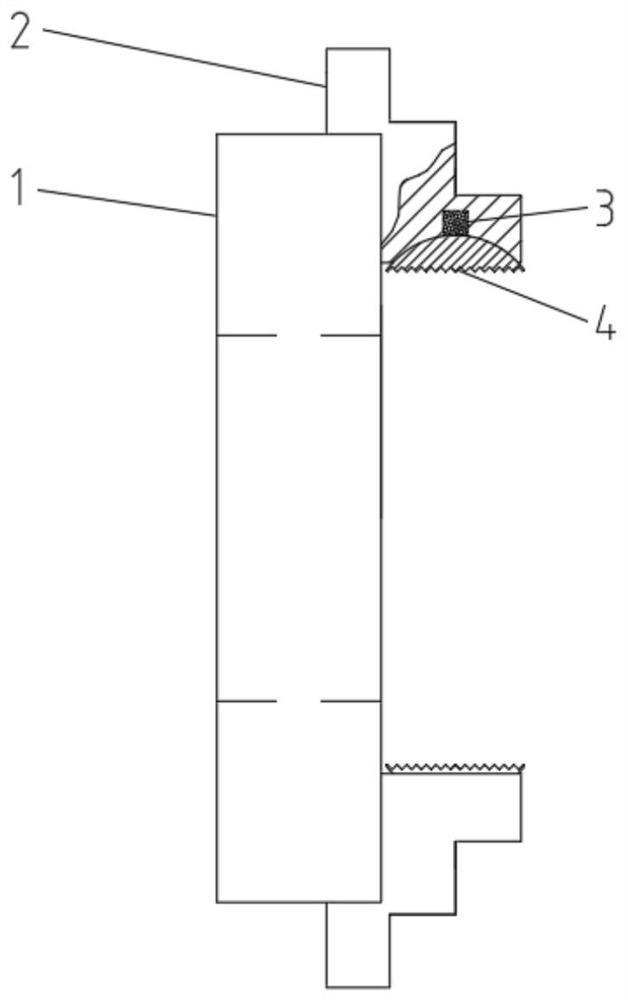

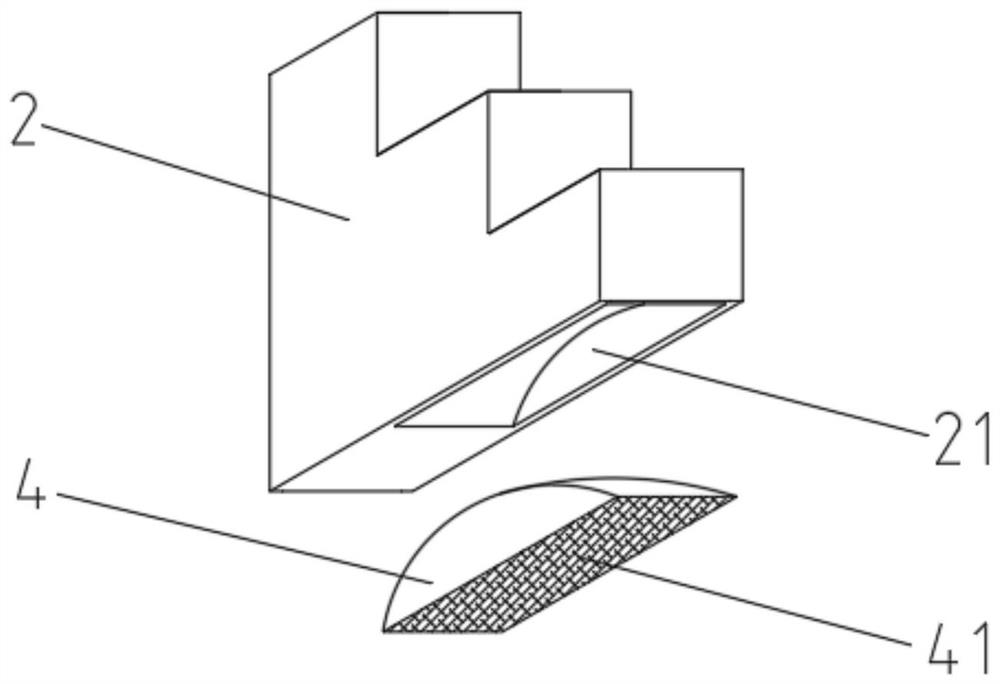

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] Such as Figures 1 to 6 As shown in the figure, a multi-jaw floating indenter dedicated to the processing of cast blanks includes a chuck 1, jaws 2 and an indenter 4, and a plurality of jaws 2 are installed on the chuck 1 at equal intervals, and the clamping jaws 2 An arc groove 21 is arranged on the surface, and at least one installation hole 22 is arranged on the top wall in the arc groove 21, which is set as an installation hole in the present invention, which is located at the central axis of the arc groove, and the installation hole 22 is fixed with a magnet 3, and the indenter 4 has an arc-shaped top surface that matches the arc-shaped groove 21. The indenter 4 is attracted by the magnet 3 and embedded in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com