Clamp feeding mechanism

A feeding mechanism and clamp technology, applied in the field of automatic feeding, can solve the problems of time-consuming and laborious, damaged clamps, and inability to parallelize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

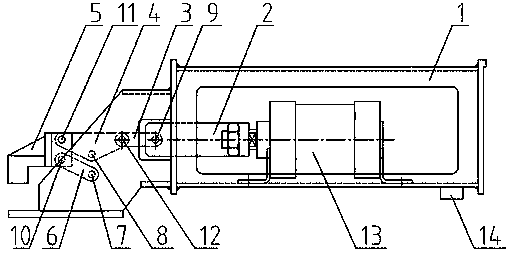

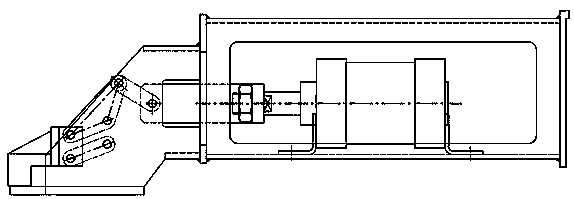

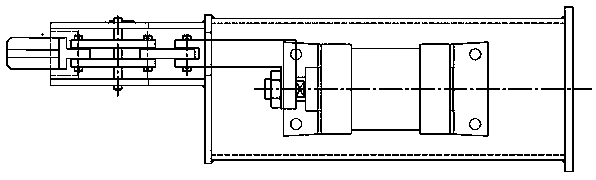

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] like figure 1 As shown, a clamp feeding mechanism provided by the embodiment of the present invention includes a clamp 5, a bracket 1, a transmission system, a cylinder 13 fixed on the bracket 1, and a solenoid valve 14. The solenoid valve 14 controls the extension of the output end of the cylinder 13. Out and back, the output end of the cylinder 13 is fixedly connected with the connection plate 2, the action of the cylinder 13 drives the connection plate 2 to make a reciprocating linear motion in the groove of the bracket 1, and the setting of the groove further ensures the linear motion state of the connection plate 2 .

[0023] One end of connecting rod one 3 is rotationally connected with connection plate 2 through shaft three 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com