Pull ring type rivet

A rivet and ring technology, applied in the direction of rivets, thin plate connections, connecting components, etc., can solve problems such as affecting the sustainable development of products and increasing costs, and achieve the effect of improving connection reliability, reliable connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

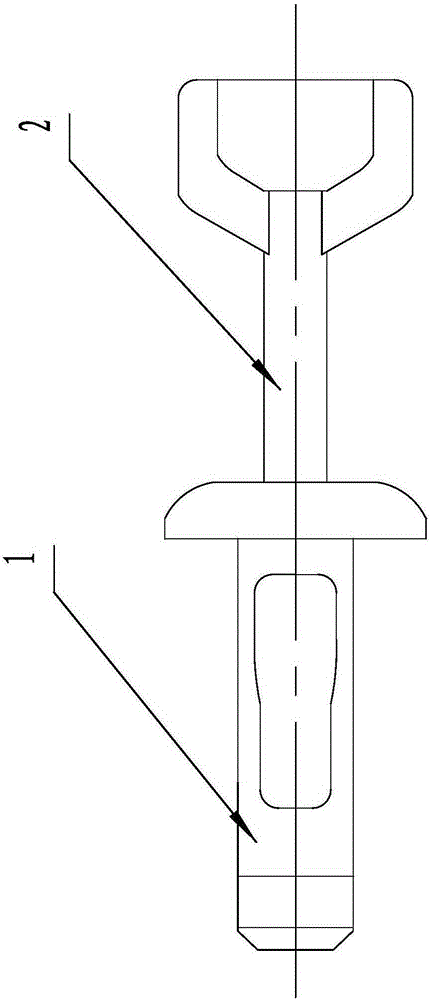

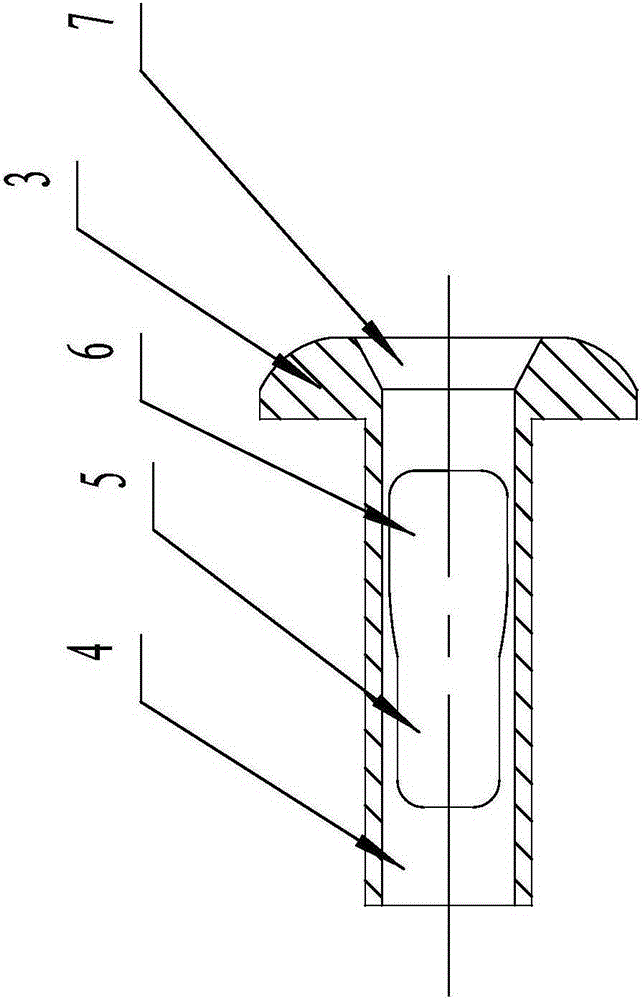

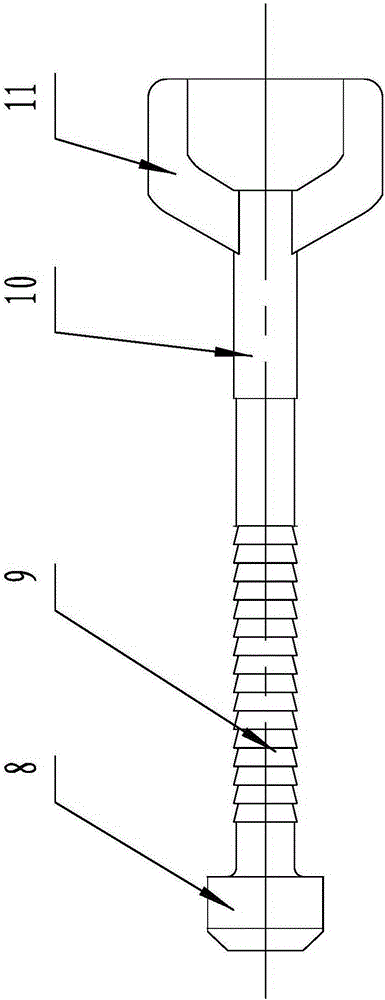

[0021] like Figure 1~3 As shown, the present invention mainly comprises nail body 1 and nail core 2, and nail body 1 is tubular structure, and nail body 1 is provided with oblate nail body head 3 facing nail core 2 end, and the diameter of nail body head 3 is greater than nail body 1 diameter.

[0022] The nail body 1 is provided with a nail body central hole 4 along the axis direction of the nail body 1, and the center of the nail body head 3 is provided with a nail head hole 7, and the nail head hole 7 communicates with the nail body center hole 4. The diameter of the nail head hole 7 is greater than the diameter of the nail body center hole 4, and the setting of the nail head hole 7 is to avoid burrs after the riveting of the first riveted plate body A and the second riveted plate body B.

[0023] For easy and effective positioning during rivetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com