Method of forming pattern using second casting using different metal

A pattern and metal technology, which is applied in the field of secondary casting of different metals to form patterns, which can solve the problems of patterns being easy to fall off and easy to wear

Inactive Publication Date: 2008-10-15

吕建新

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of these methods to form different metal patterns is that the pattern is easy to fall off and easy to wear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

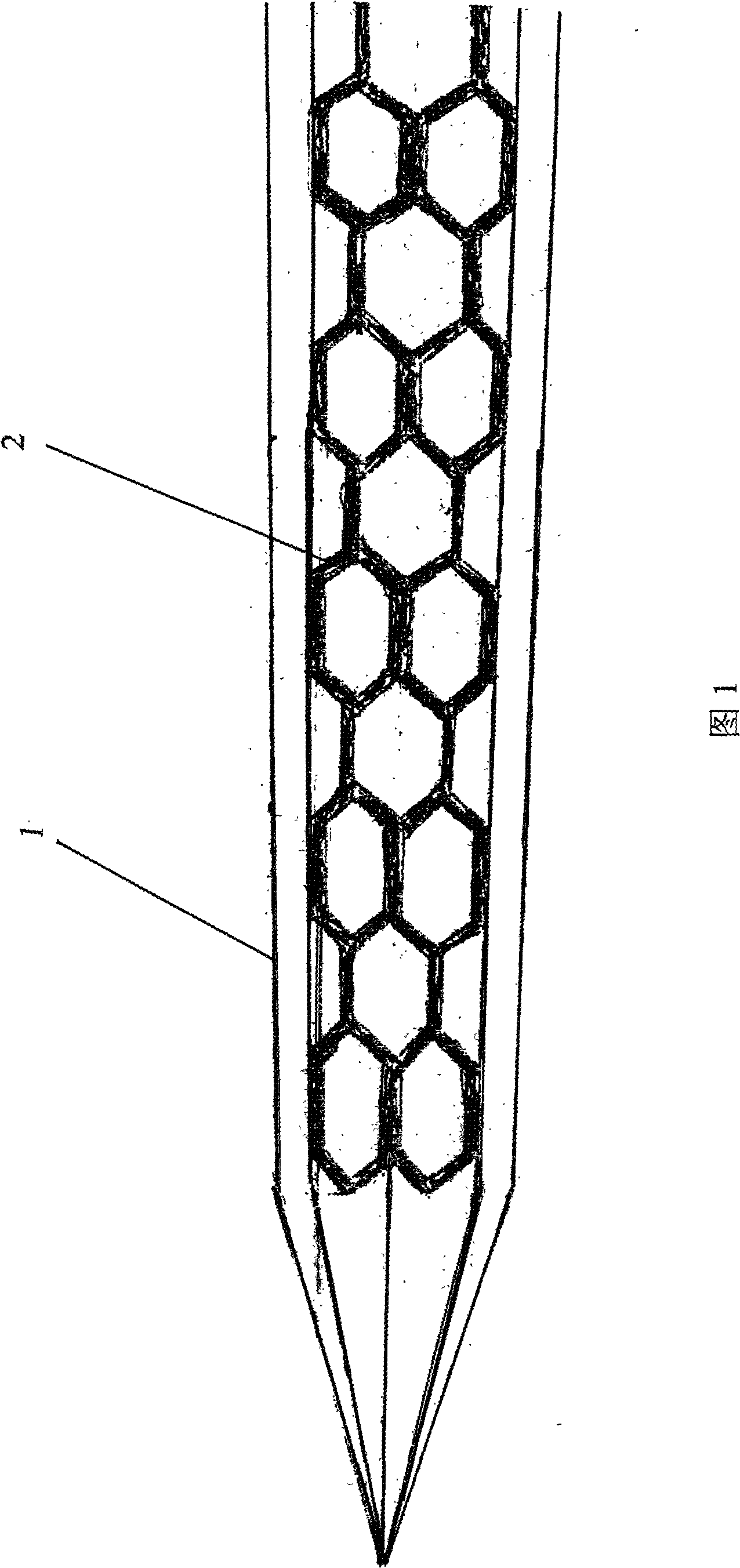

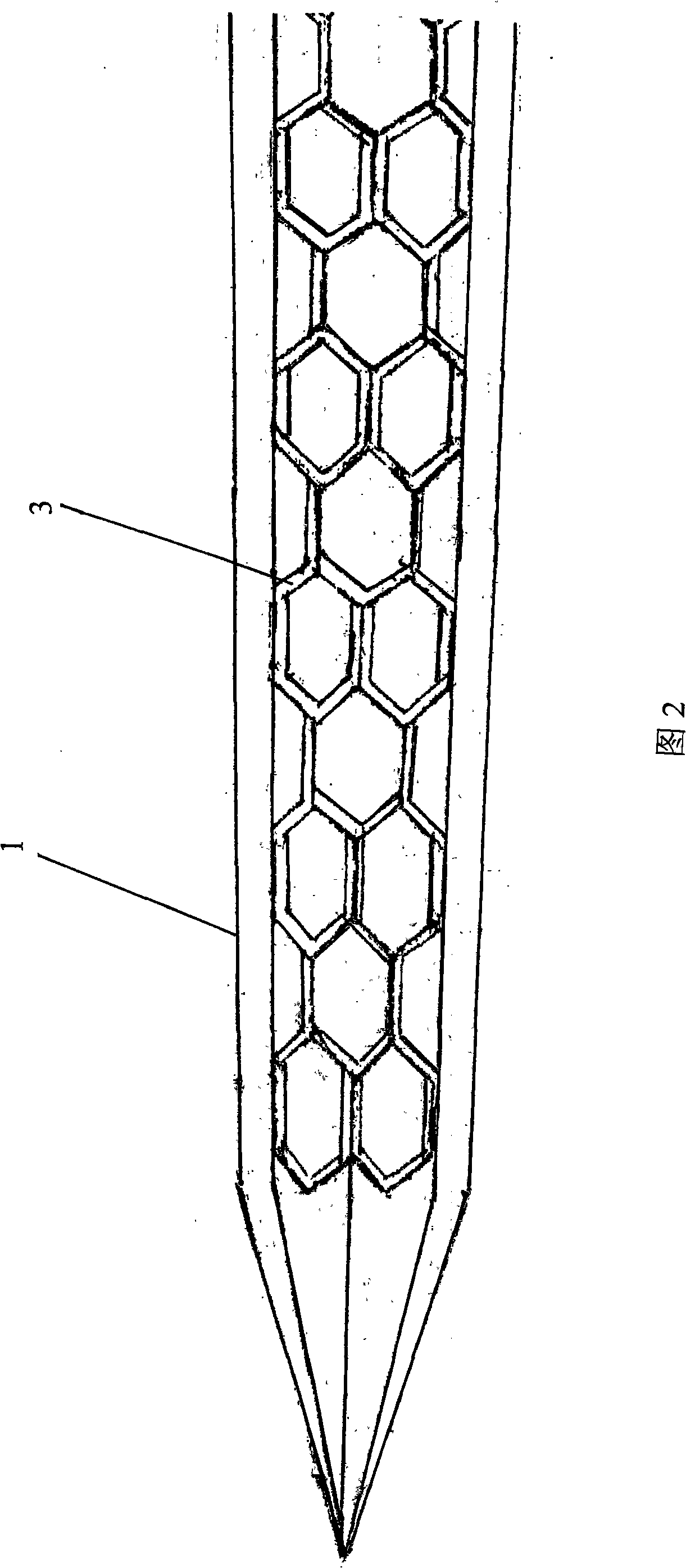

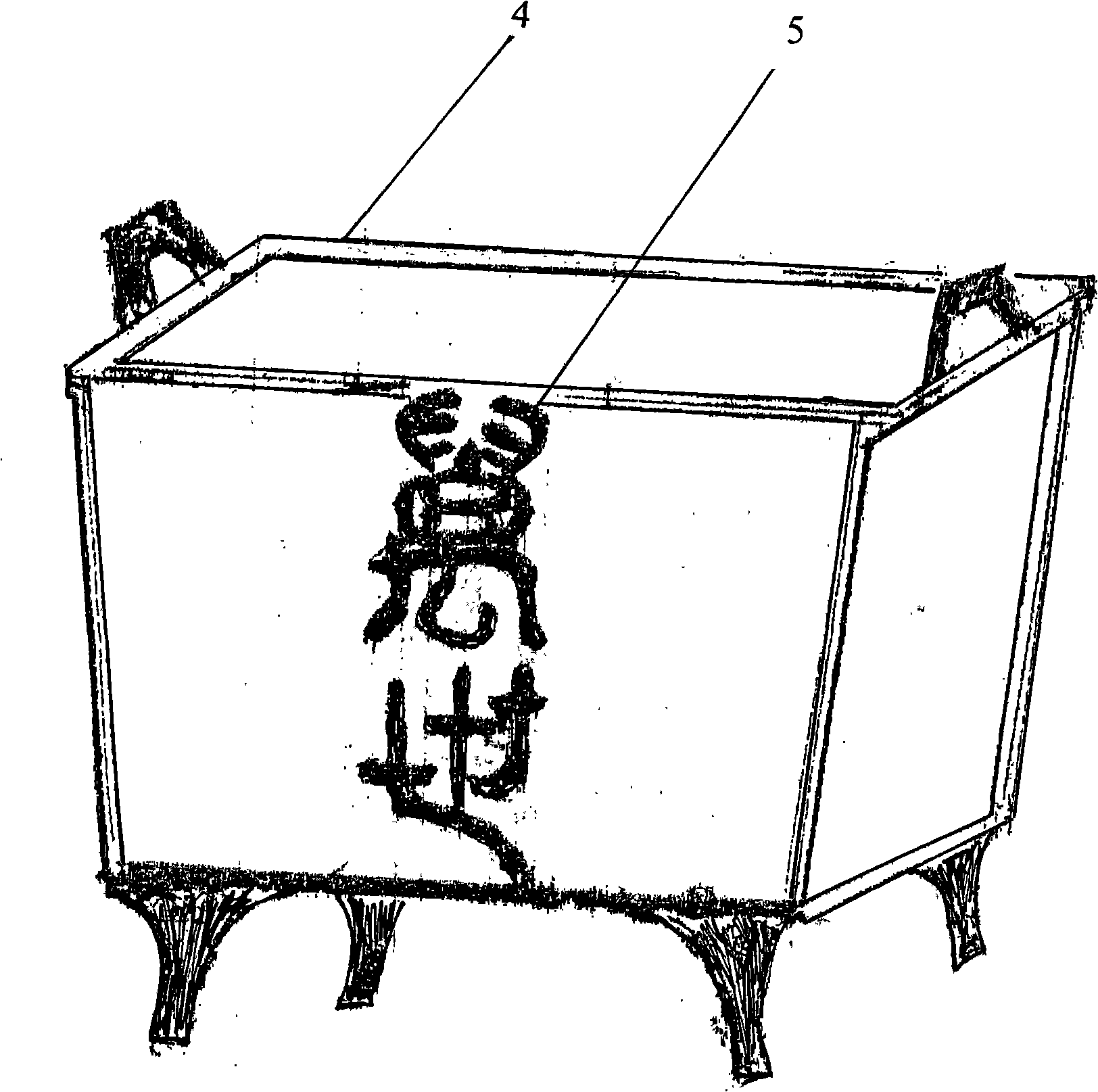

The invention provides a method for forming patterns on different metals by secondary casting, which comprises the steps of manufacturing a matrix model with a pattern groove according to the shape of a metal object; melting a metal and casting the metal into a matrix with a pattern groove; melting more than one metals with different colors and injecting the metals into the pattern groove of the matrix; and forming metal objects with different colors and patterns on the surface thereof. The patterns formed by the method have the advantages of no detachment, no deformation, and wear resistance.

Description

Method for forming pattern by secondary casting of different metals Technical field The present invention relates to a method of forming a pattern by secondary casting of different metals. Background technique The method that different metals form patterns now is to utilize the color difference of different metals, form patterns with other metals on a kind of metal object with the method of mosaic or plating, coating. The disadvantage of these methods to form different metal patterns is that the patterns are easy to fall off and easy to wear. Contents of the invention The object of the present invention is to provide a method for forming patterns by secondary casting of different metals, which can make the patterns formed by different metals never fall off and be wear-resistant. The present invention is achieved in this way, using different metal secondary casting method to form pattern: 1. Make a carcass model with patterned grooves according to the shape of the re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D19/16

Inventor 吕建新

Owner 吕建新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com