Method for producing computer mouse pad from glass

A production method and technology for mouse pads, applied in the field of mouse pads, can solve the problems of not easy to scrub, inaccurate positioning, and delicate hand feel, and achieve the effects of fine hand feeling, accurate positioning, and easy-to-control hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

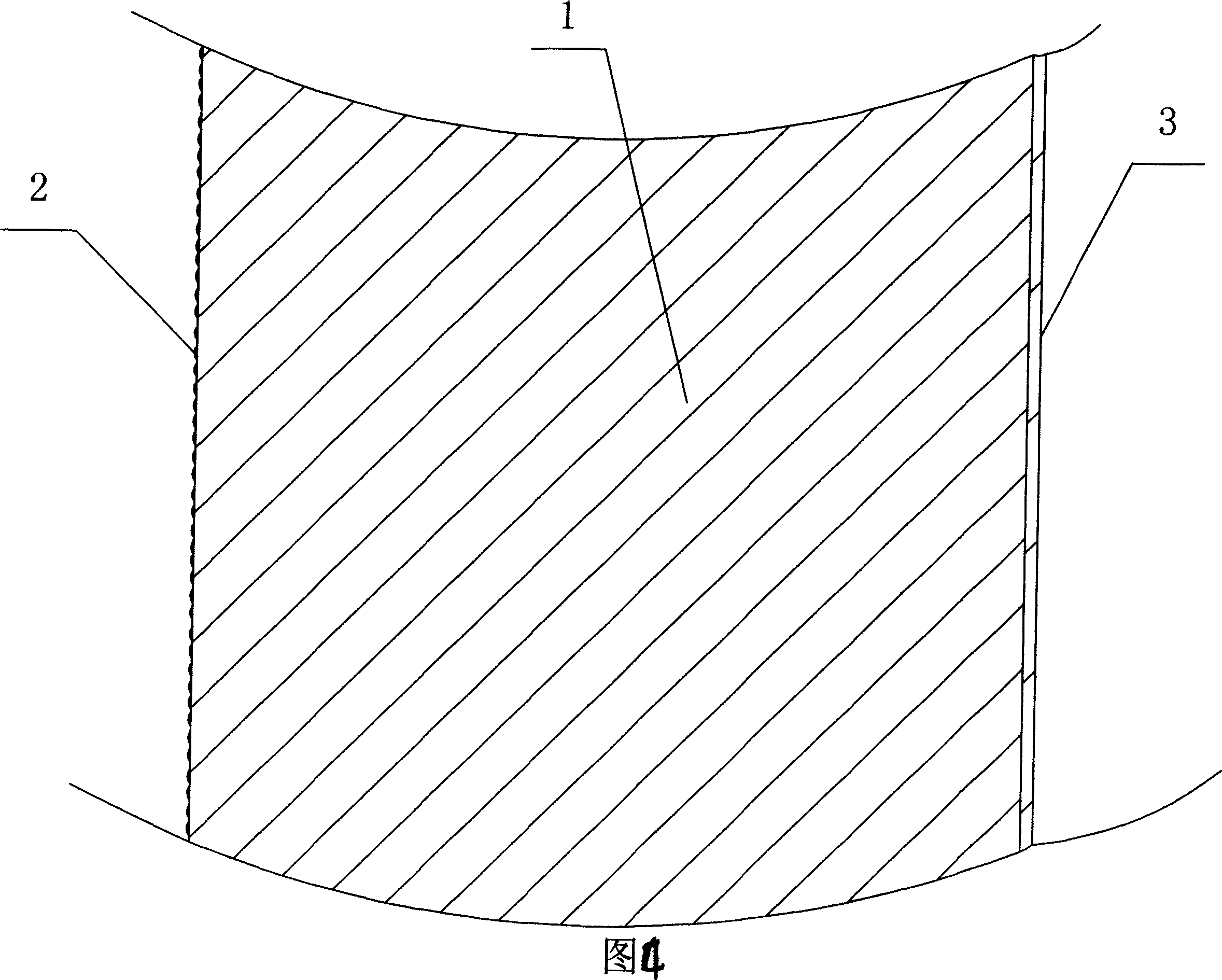

Image

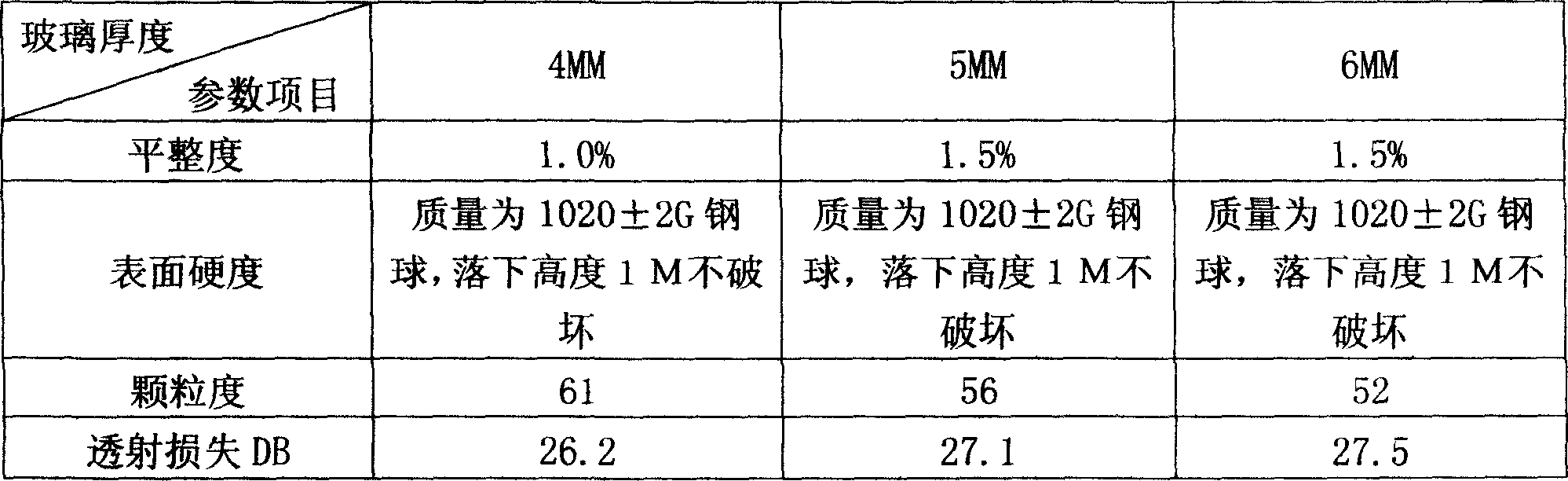

Examples

Embodiment

[0029] 1) Put the glass products on the provided tooling equipment, and spray acid solution to emulsify during the operation, which saves the cycle and adjustment links of the process. There are mainly four sub-processes: ① Pretreatment: add a small amount of hydrofluoric acid to circulating water at a temperature of 25°C to remove grease and stains on the surface of glass products, or add sodium tripolyphosphate to soft water , to clean the glass surface. ②Acid spraying: Use multiple nozzles to spray the adjusted acid solution on the glass surface at a temperature of 45°C, and then use the airflow to blow away the acid droplets attached to the glass surface until no acid droplets can be seen. ③Cleaning: Cleaning is divided into two steps. Wash with circulating water at 65°C for the first time, which can improve the solubility of surface reactants in water. Wash with circulating water at 45°C for the second time to remove all reaction residues. ④Drying: Two sets of general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com