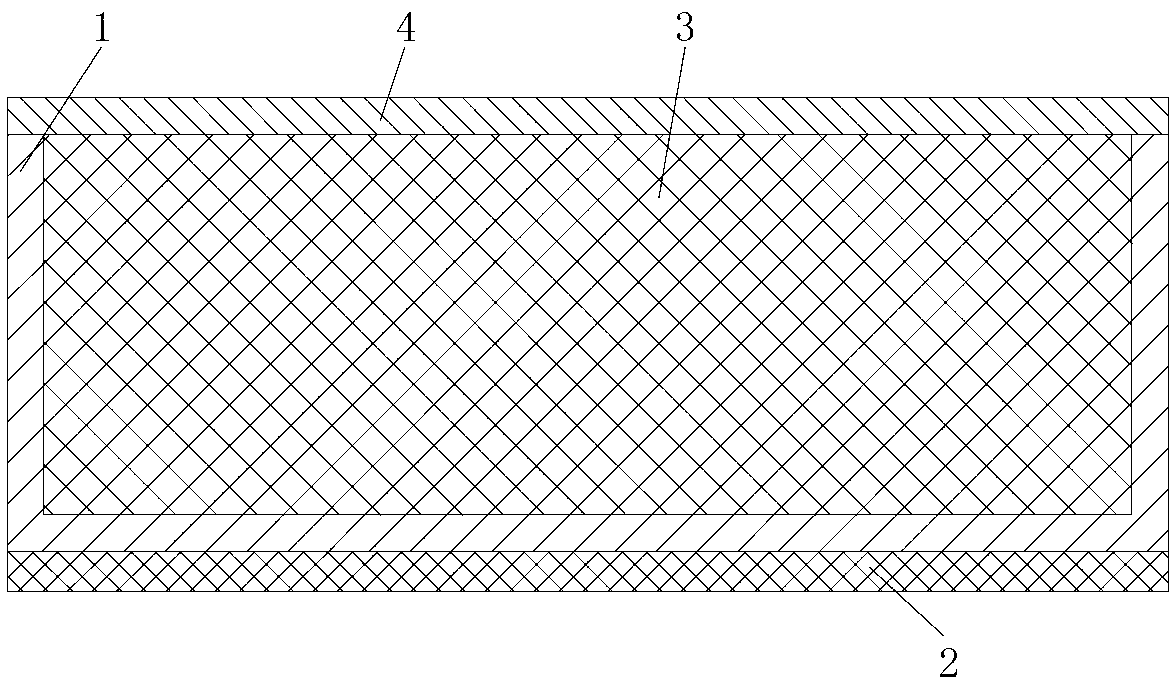

Metal hard foam polyurethane composite decorative sheet and production process thereof

A rigid polyurethane foam and production process technology, applied in covering/lining, construction, building construction, etc., can solve problems such as difficult control of construction quality, poor sound insulation effect, poor fire prevention function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, prefabricating coated metal coils, the specific process of prefabricating coated metal coils is: cleaning the metal coils after uncoiling, and drying after cleaning. Cleaning the metal coils is to spray the metal coils with acid and alkali solution Spray, remove the grease on the surface of the metal coil to passivate the metal surface, and dry the cleaned metal coil in a temperature environment of 180°C. Apply an adhesive to the cleaned and dried metal coil, and the adhesive is a PU type two-component oily polyurethane. Send the metal sheet coated with adhesive to the laminating machine with oven, glue and coat the PVC decorative film on the metal coil to obtain the coated metal coil, wherein the thickness of the PVC decorative film is 0.12mm, Bake the glued PVC decorative film for 1 minute at a temperature of 120°C.

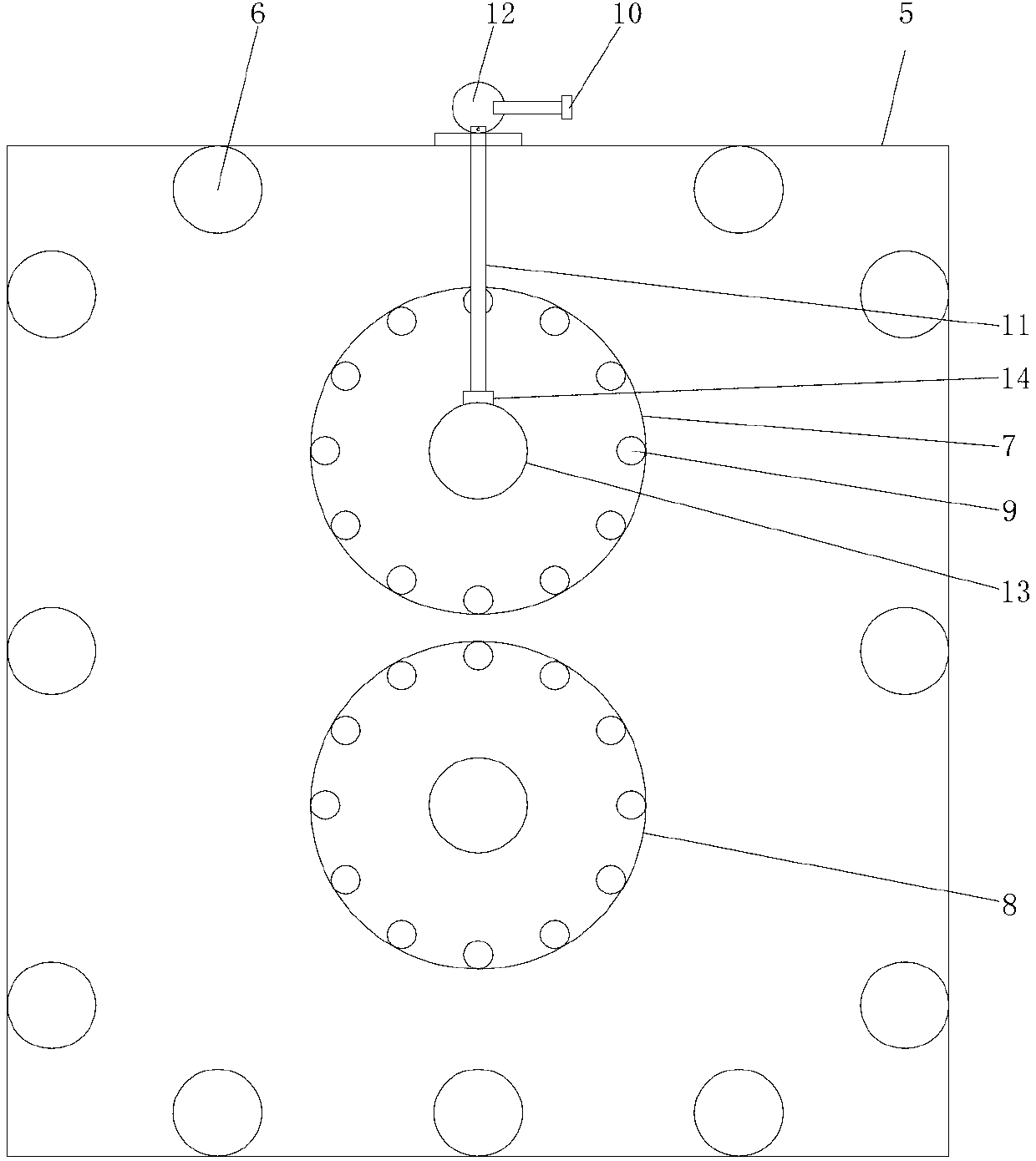

[0027] In step 2, the prefabricated film-coated metal coil is shaped by a roll bender to form a basic mold with a groove body. During the roll...

Embodiment 2

[0030] Step 1, prefabricating coated metal coils, the specific process of prefabricating coated metal coils is: cleaning the metal coils after uncoiling, and drying after cleaning. Cleaning the metal coils is to spray the metal coils with acid and alkali solution Spraying, remove the grease on the surface of the metal coil to passivate the metal surface, drying is to dry the cleaned metal coil in a temperature environment of 190 °C. Apply an adhesive to the cleaned and dried metal coil, and the adhesive is a PU type two-component oily polyurethane. Send the metal sheet coated with the adhesive into the laminating machine with an oven, glue and coat the PVC decorative film on the metal coil to obtain a coated metal coil, in which the thickness of the PVC decorative film is 0.15mm, Bake the glued PVC decorative film for 2 minutes at a temperature of 160°C.

[0031] In step 2, the prefabricated film-coated metal coil is shaped by a roll bender to form a basic mold with a groove ...

Embodiment 3

[0034]Step 1, prefabricating coated metal coils, the specific process of prefabricating coated metal coils is: cleaning the metal coils after uncoiling, and drying after cleaning. Cleaning the metal coils is to spray the metal coils with acid and alkali solution Shower, remove the grease on the surface of the metal coil to passivate the metal surface, and dry the cleaned metal coil in a temperature environment of 200°C. Apply an adhesive to the cleaned and dried metal coil, and the adhesive is a PU type two-component oily polyurethane. Send the metal plate coated with adhesive to the laminating machine with oven, glue and coat the PVC decorative film on the metal coil to obtain the coated metal coil, in which the thickness of the PVC decorative film is 0.18mm, Bake the glued PVC decorative film for 3 minutes at a temperature of 200°C.

[0035] In step 2, the prefabricated film-coated metal coil is shaped by a roll bender to form a basic mold with a groove body. During the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com