Method for manufacturing stainless steel sealing ring of double eccentric butterfly valve plate

A production method, stainless steel technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of large processing allowance, unavoidable processing costs, and high comprehensive costs, and achieve smooth sealing surfaces, low processing costs, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

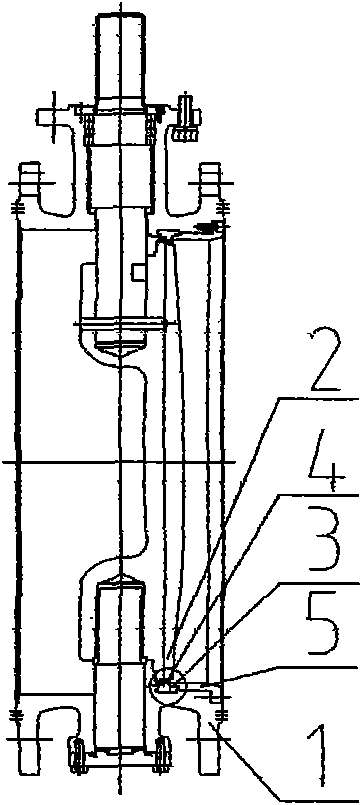

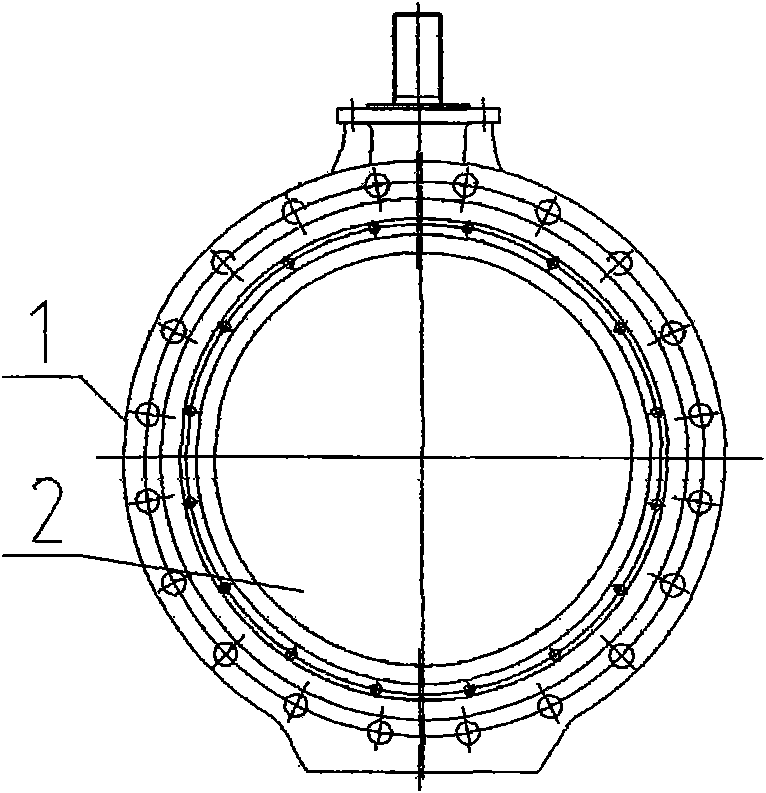

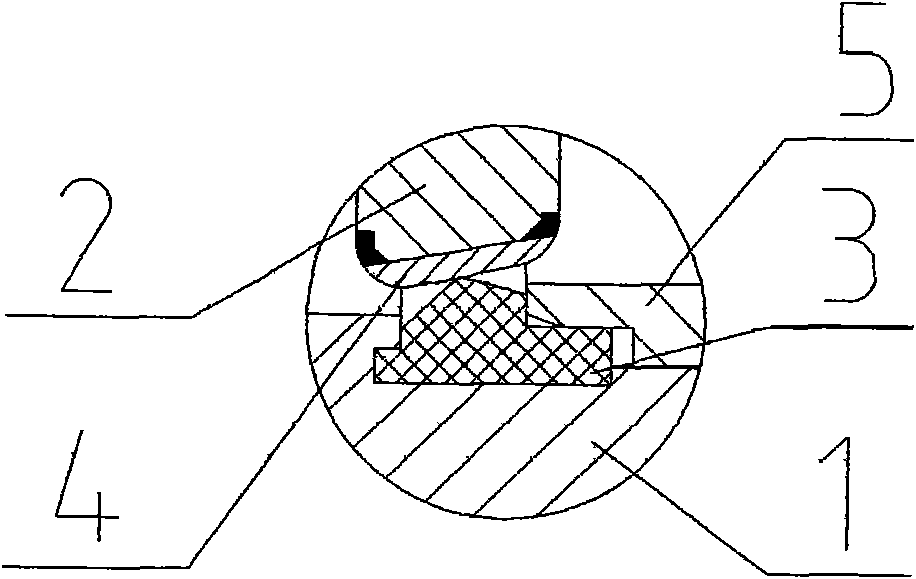

[0018] Embodiment: the present invention is realized with following method: as Figure 1 to Figure 3 As shown, there is a valve plate 2 inside the valve body 1, and there is a sealing pair between the valve body 1 and the valve plate 2. The sealing ring consists of 4. This embodiment is a stainless steel sealing ring on the outer circle of the valve plate of a double eccentric butterfly valve, which is set on the outer circle of the valve plate 2 after blanking, rolling, welding, shaping, sleeve pressing, cutting, and reinforcement of stainless steel plates . A sealing rubber ring 3 is inlaid in the groove of the valve seat in the valve body 1, and is fixed with a pressure sleeve 5. The stainless steel sealing ring 4 on the valve plate 2 is pressed on the outer circle of the valve plate 2 after being rolled and welded with a long strip of stainless steel plate. The convex ring-shaped cone of the valve plate 2 rolls the stainless steel sealing ring 4 into a conical ring with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com