Patents

Literature

94results about How to "Reduce film production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

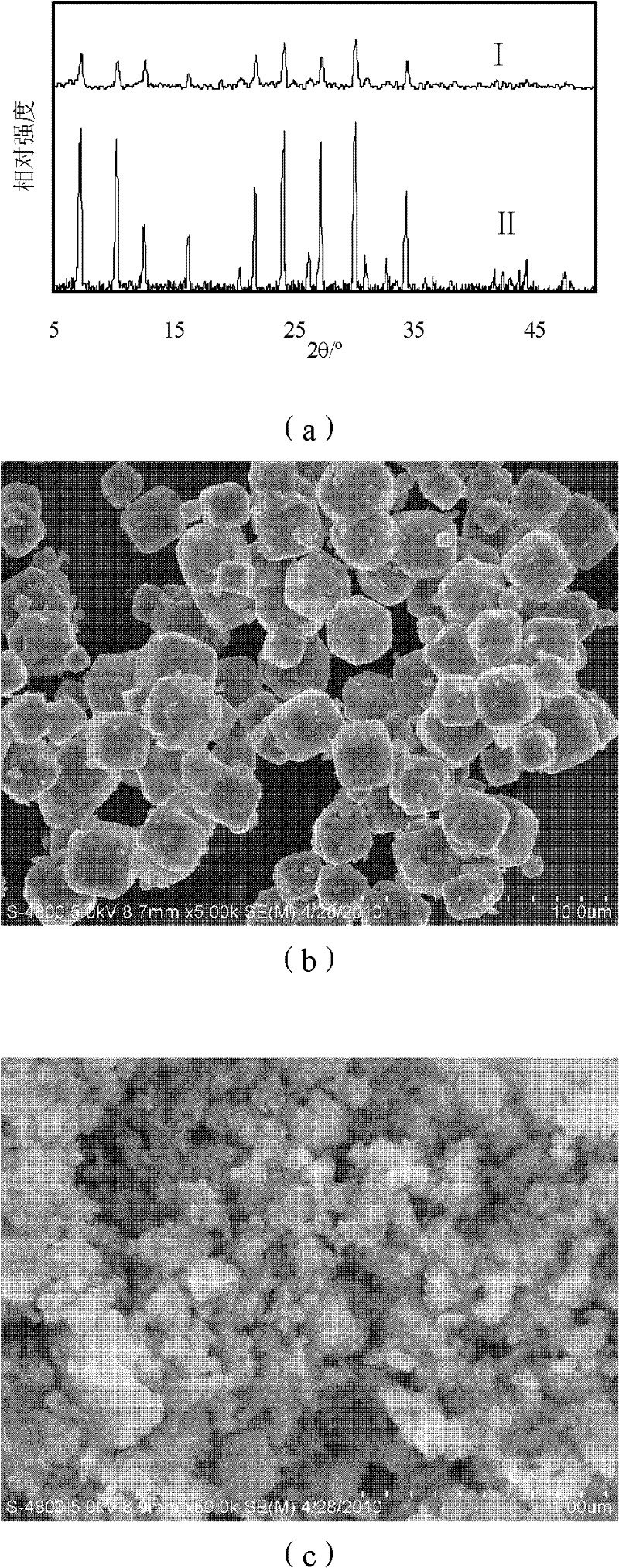

Method for preparing NaA molecular sieve membrane through induction of nanocrystal seeds

InactiveCN102247767AShort cycleSimple methodSemi-permeable membranesMolecular sieveHydrothermal synthesis

The invention relates to a method for preparing a NaA molecular sieve membrane through the induction of nanocrystal seeds, which comprises the following steps of: crushing NaA molecular sieve particles with a large size by using a ball mill to obtain nano-scale molecular sieve particles serving as the crystal seeds; and coating a crystal seed layer on the surface of a carrier, and preparing the NaA molecular sieve membrane by a hydrothermal synthesis method through induction. The NaA molecular sieve membrane synthesized by the method has high separating property, penetration flux and membrane formation repeatability, and a short synthesis period, and is suitable for mass scale-up production.

Owner:NANJING UNIV OF TECH

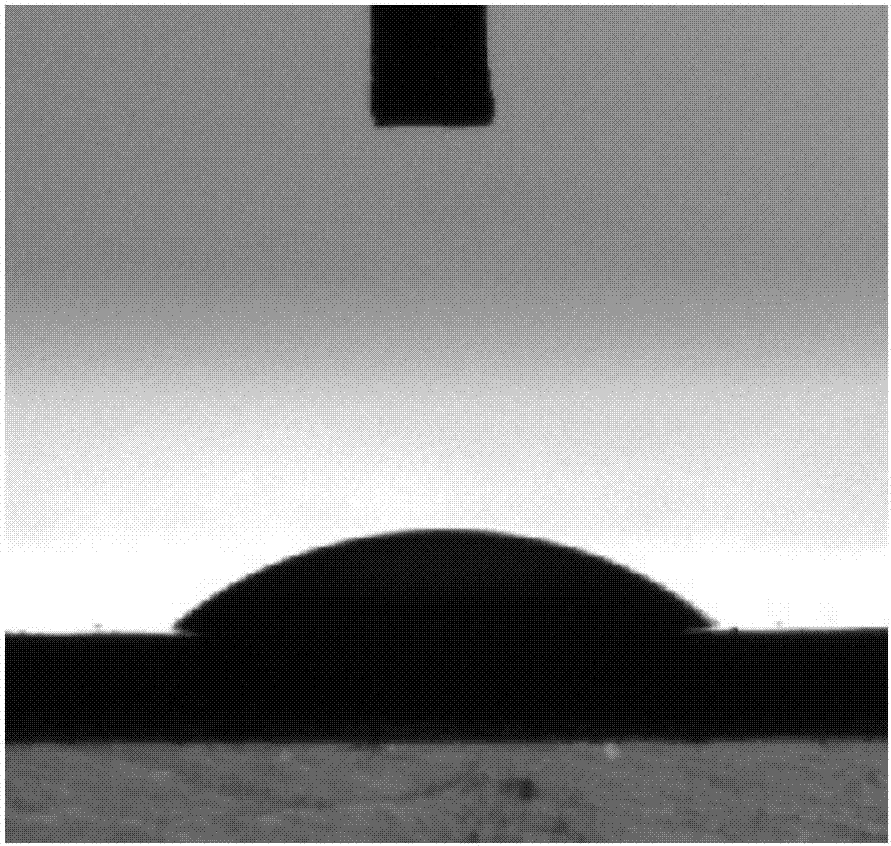

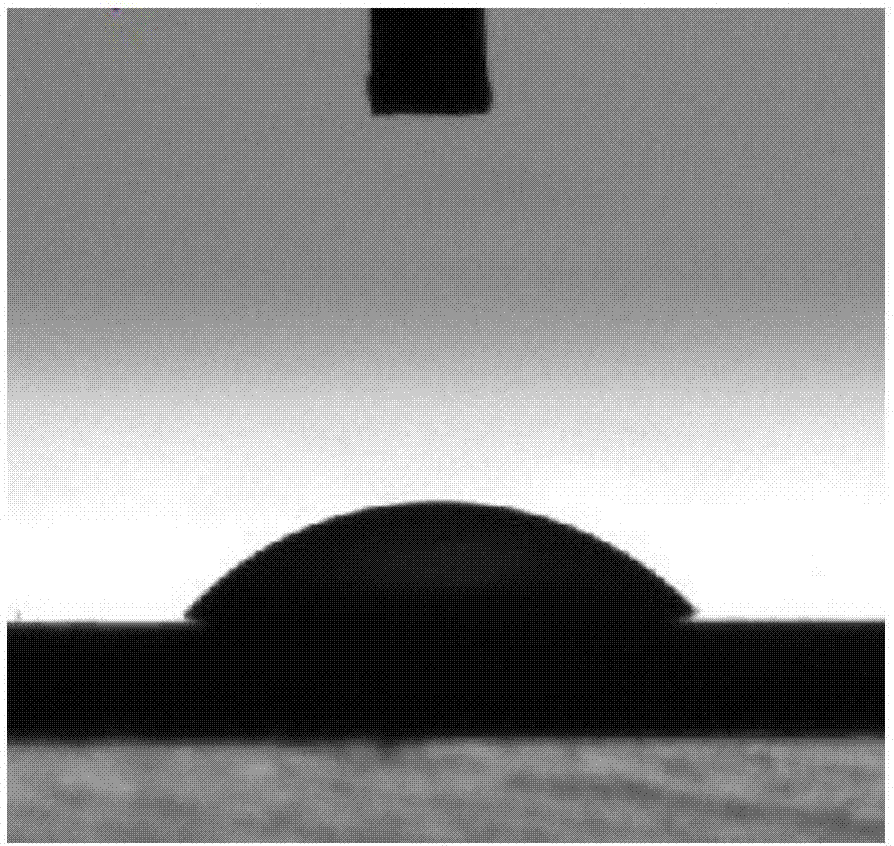

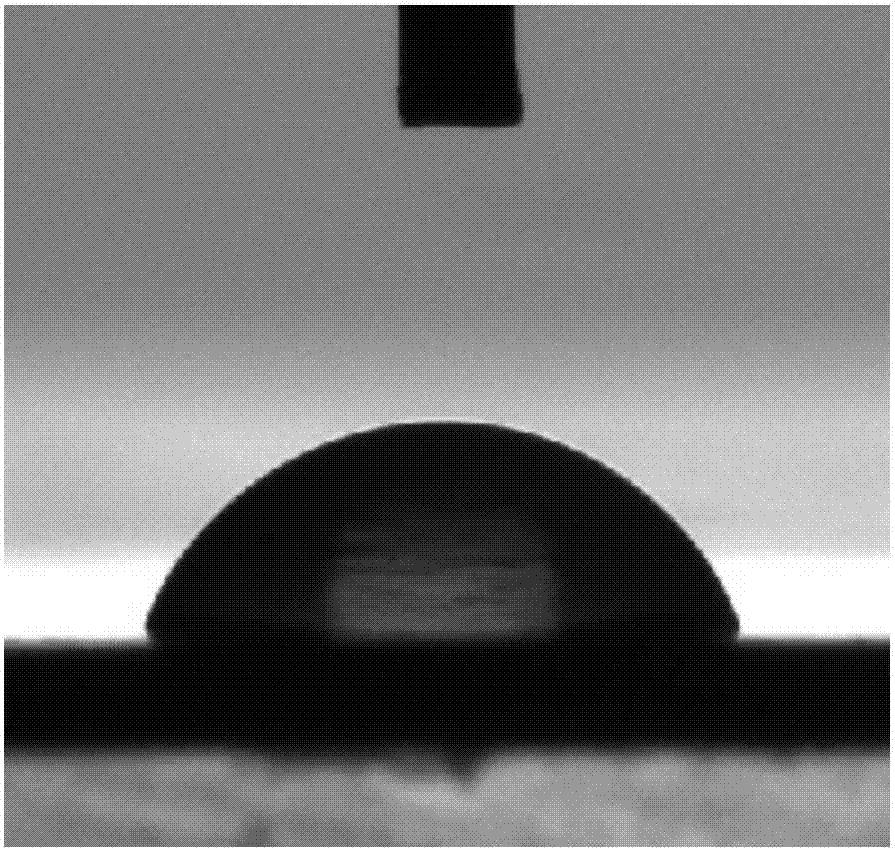

Method for preparing high-hydrophobicity microporous membrane

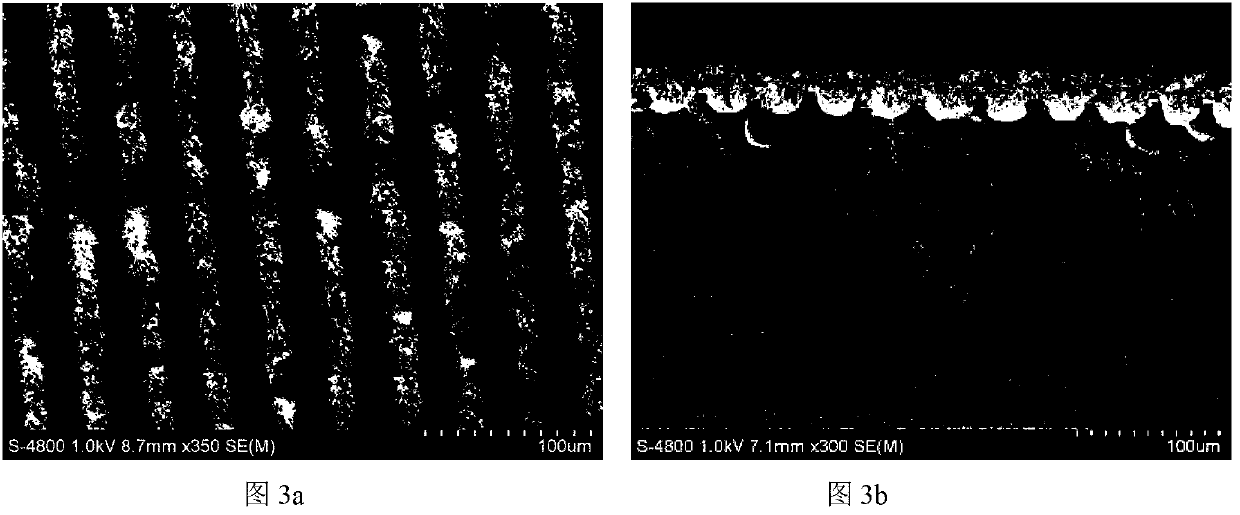

The invention relates to a method for preparing a high-hydrophobicity microporous membrane. A polymer and a membrane-making diluent membrane liquid are uniformly mixed and then are coated on a solid template on the surface of a micro structure by virtue of a thermally induced phase separation method under assistance of a solid template; the microporous membrane is prepared by the thermally induced phase separation method; and under the synergistic effect of the template and phase separation, the hydrophobicity of the membrane surface and other membrane properties are improved. The microporous membrane is high in hydrophobicity; a water contact angle is up to 165 degrees at most, and a rolling angle is 3 degrees, so that the ultra-high hydrophobicity is reflected; the permeation performance is high; the nitrogen flux under the 0.1MPa membrane penetration pressure difference is more than or equal to 260 m<3> / (m<2>.h); an aperture distribution range is small; the maximum aperture is less than or equal to 0.5 microns; the mechanical performance is high; the tensile strength is more than or equal to 3.0 MPa; and the breakage elongation is more than or equal to 68 percent.

Owner:HEBEI UNIV OF TECH

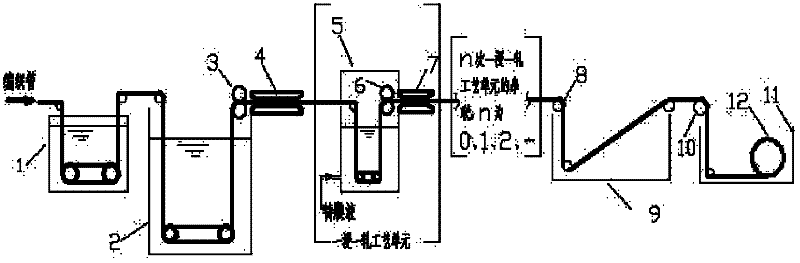

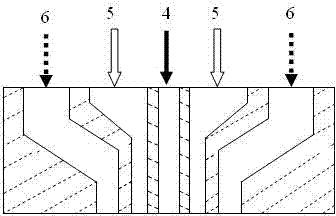

Preparation method of hollow fiber pipe in overlay film

The invention discloses a preparation method of a hollow fiber pipe in an overlay film, which comprises the following steps 1) preparing a high-molecular polymer, an organic solvent, an additive and a pore forming agent to a plurality of homogeneous casting solutions according to different proportions; 2) removing the PET fiber braiding tube surface spot objects; 3) using a modifier for modifying the PET fiber braiding pipe, fixing a circular pipe at high temperature; 4) using a multi-immersing multi-rolling (several primary immersing-technology in series) technology for cladding various homogeneous casting solutions to the internal and external walls of the PET fiber braiding pipe in order, carrying out a process of circular pipe heat fixing after each time of immersing and rolling, placing the obtained the composite braiding pipe in a gel bath for splitting the phase after the multi-immersing multi-rolling process is finished to obtain the hollow fiber pipe. According to the invention, the PET fiber braiding pipe is taken as a main body, the multi-immersing multi-rolling technology is used, the micro casting solution is coated to the internal and external walls of the braiding pipe, the anti-pollution capability of the braiding pipe can be improved, and a polymer coat layer is formed on the braiding tube surface which can ensure the effective porosity amount and interception effect of the hollow fiber tube.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

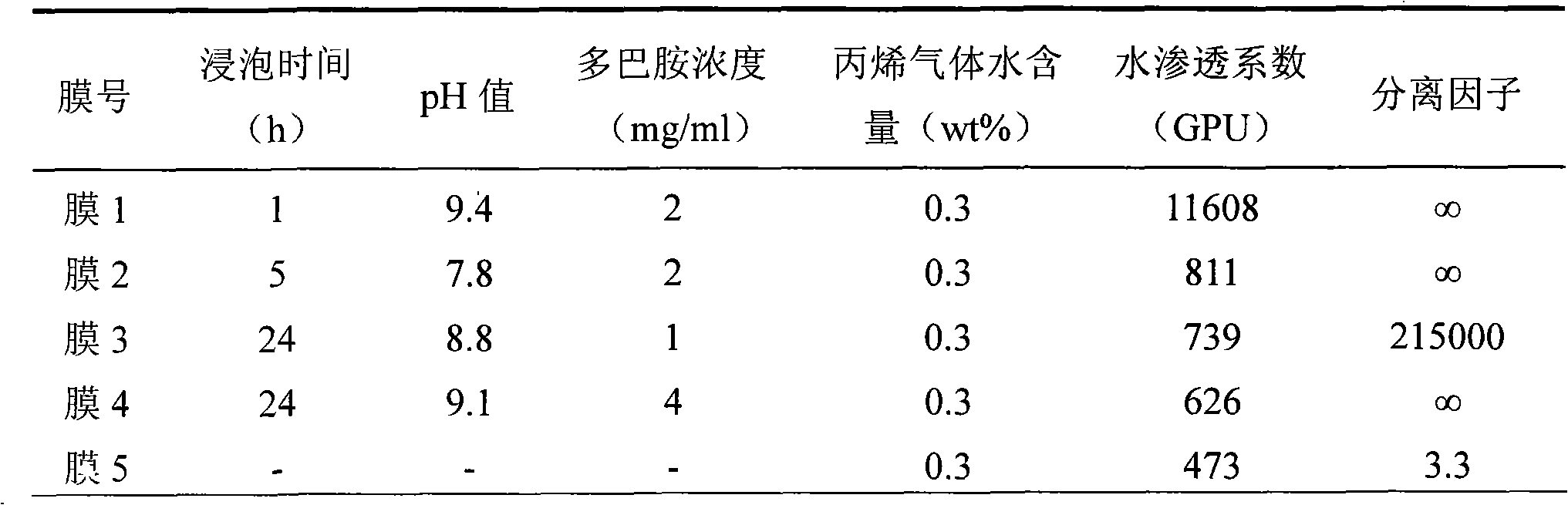

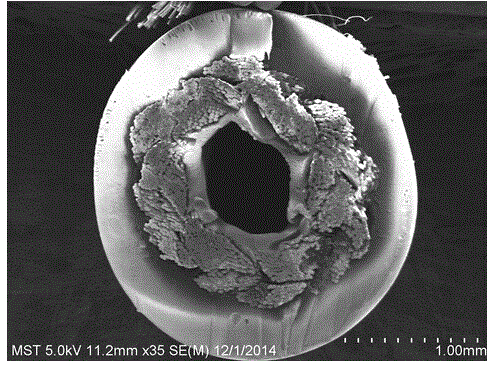

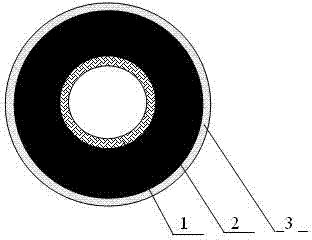

Hollow fiber compound film with ultra-thin active layer, preparation method and application thereof

InactiveCN101269303AThickness is easy to controlRich sourcesSemi-permeable membranesMembrane purification/separationProduct gasBuffer solution

The invention discloses a hollow fiber composite membrane of an ultrathin active layer. the preparation method and the application thereof, belonging to the technique of hollow fiber composite membrane. The supporting layer of the composite membrane is polysulfone hollow fiber membrane, the active layer is poly-dopamine, the thickness is 15 to 90 nm. The preparation process includes: pretreatment is performed for the polysulfone hollow fiber membrane; hydrochloric acid dopamine with certain mass is added into Tris-HCI buffer solution with certain concentration and certain pH value, and then the supporting layer of the polysulfone hollow fiber is immersed into the solution to obtain the poly-dopamine / polysulfone hollow fiber composite membrane. The hollow fiber composite membrane is used for gas dehumidification, is in particular suitable for dehydration of propylene gases. The hollow fiber composite membrane, the preparation method and the application thereof have the advantages that the ultra-thin, flawless active layer with adjustable thickness can be prepared on the supporting layer, the preparation process is simple with excellent dehumidification performance; the raw materials are abundant, the price is reasonable and the production cost of the membrane is low.

Owner:TIANJIN UNIV

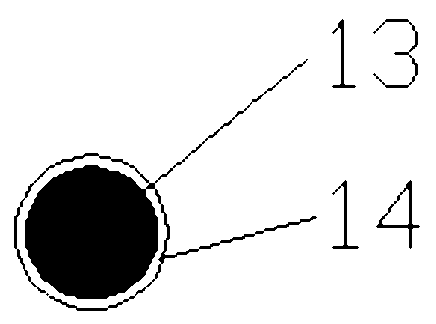

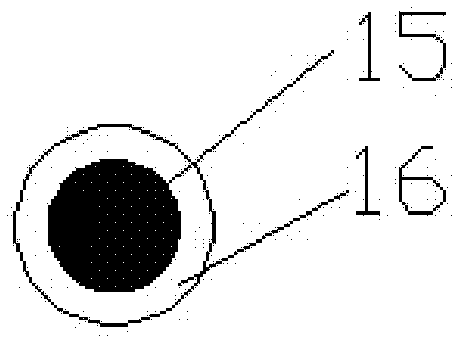

A braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film and a preparing method thereof

The invention discloses a preparing method of a braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film, and belongs to the field of polymer film product preparation. The preparing method includes firstly preparing a polyvinylidene fluoride solution A having a certain low concentration, dipping a braided tube with the solution A to allow the polyvinylidene fluoride solution to penetrate into the inside of the braided tube, coating the outside of the braided tube with a high-concentration polyvinylidene fluoride film casting solution B having a certain formula, and putting the braided tube coated with the solution A and the solution B into a coagulating bath to allow the polyvinylidene fluoride coated in the two times to be subjected to phase separation simultaneously. The polyvinylidene fluoride hollow fiber film prepared by the method is advantageous in that 1) the inner low-concentration polyvinylidene fluoride solution tightly surrounds fibers of the braided tube, is tightly connected to an outer film layer after phase transition, and is not liable to shed; 2) a high-aperture-ratio compact surface layer is formed from the outer high-concentration film casting solution and provides effects of filtration; and 3) the braided tube with high strength provides excellent film fiber longitudinal stretching strength.

Owner:安徽指南针科创园发展有限公司

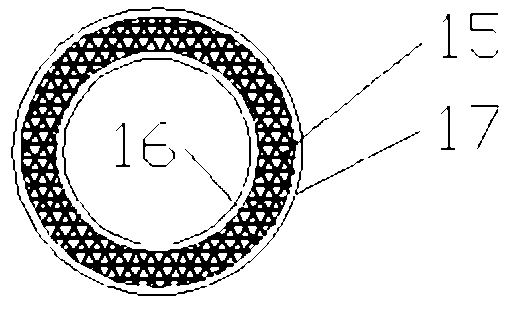

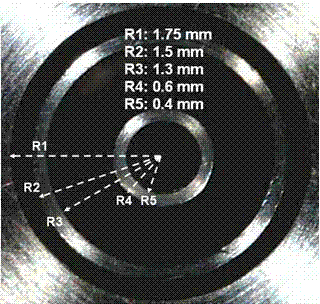

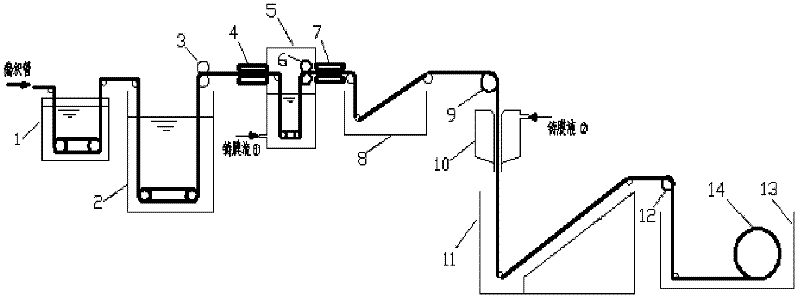

Hollow fiber ceramic oxygen permeation membrane with dual composite asymmetric structure and preparation method thereof

ActiveCN102895886AHigh oxygen transmission rateSimple preparation processSemi-permeable membranesHollow fibreSpinning

The invention belongs to the technical field of ceramic oxygen permeation membranes and particularly relates to a preparation method for a hollow fiber ceramic oxygen permeation membrane with a dual composite asymmetric structure. The preparation method comprises the following steps of: respectively preparing a membrane casting solution A and a membrane casting solution B which are different in oxygen permeation ceramic membrane material powder content, wherein the ceramic powder content of the membrane casting solution A is higher than that of the membrane casting solution B; spinning into a coagulation bath through a triple-concentric ring hole-contained spinning jet by taking the membrane casting solution A as an inner layer material and the membrane casting solution B as an outer layer material, solidifying, and then, forming; straightening and airing a solidified and formed hollow fiber membrane precursor; and sintering at high temperature to obtain the required hollow fiber oxygen permeation membrane. Compared with the ceramic oxygen permeation membranes prepared by a conventional method, the oxygen permeation rate of the hollow fiber ceramic oxygen permeation membrane with a dual composite asymmetric structure, which is prepared by the preparation method, is increased by 5.2-22 times, wherein the inner surface and outer surface of the hollow fiber ceramic oxygen permeation membrane are porous and the middle is compact. Moreover, one-time forming and one-time sintering are adopted. The process is simple, the operation is convenient, the membrane preparation cost is low, and industrial production can be conveniently implemented.

Owner:TIANJIN POLYTECHNIC UNIV +1

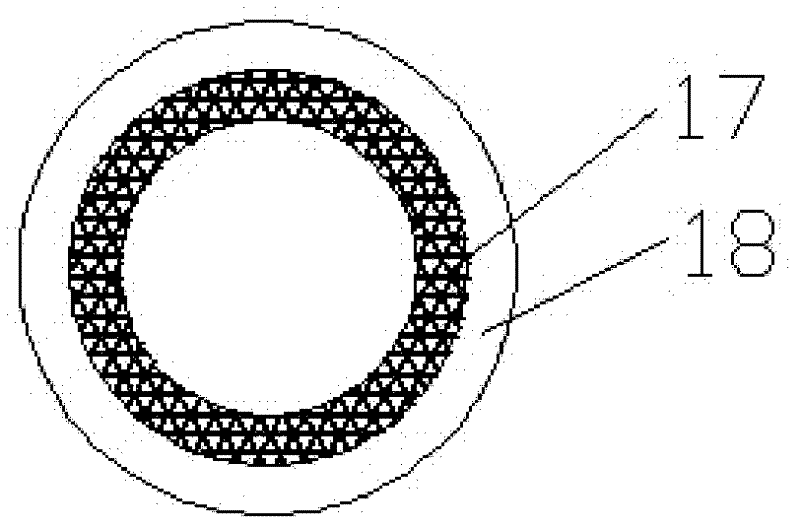

Method for preparing braided tube/polymer composite hollow fibrous membrane by thermal induced method

ActiveCN102553463AReduce binding resistanceExtended service lifeSemi-permeable membranesFiberHigh flux

The invention discloses a method for preparing braided tube / polymer composite hollow fibrous membrane by a thermal induced method. The method comprises the following steps of: preparing membrane-casting liquid 1 and membrane-casting liquid 2; dipping a polyethylene glycol terephthalate (PET) braided tube in a boiling NaOH solution with certain concentration to remove oil stains remained on the braided tube; modifying the braided tube of a supporting layer with a modifier; coating the high-molecular polymer membrane-casting liquid 1 onto the filament surface of the braided tube by a one-time dipping and one-time rolling method, thermoforming the round tube, and curing the tube in a gel bath; uniformly coating the membrane-casting liquid 2 on the outer surface of the membrane-laminated fibrous braided tube with spinning equipment, and curing composite filaments in cooling liquid; and displacing a diluent from a formed membrane with an extracting agent, and rinsing the membrane filamentsto obtain the braided tube / polymer composite hollow fibrous membrane. The braided tube / polymer composite hollow fibrous membrane prepared by the method has the characteristics of high flux, strength and interception and high-pressure backwash resistance; and moreover, the supporting layer and the coating layer are difficult to separate.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

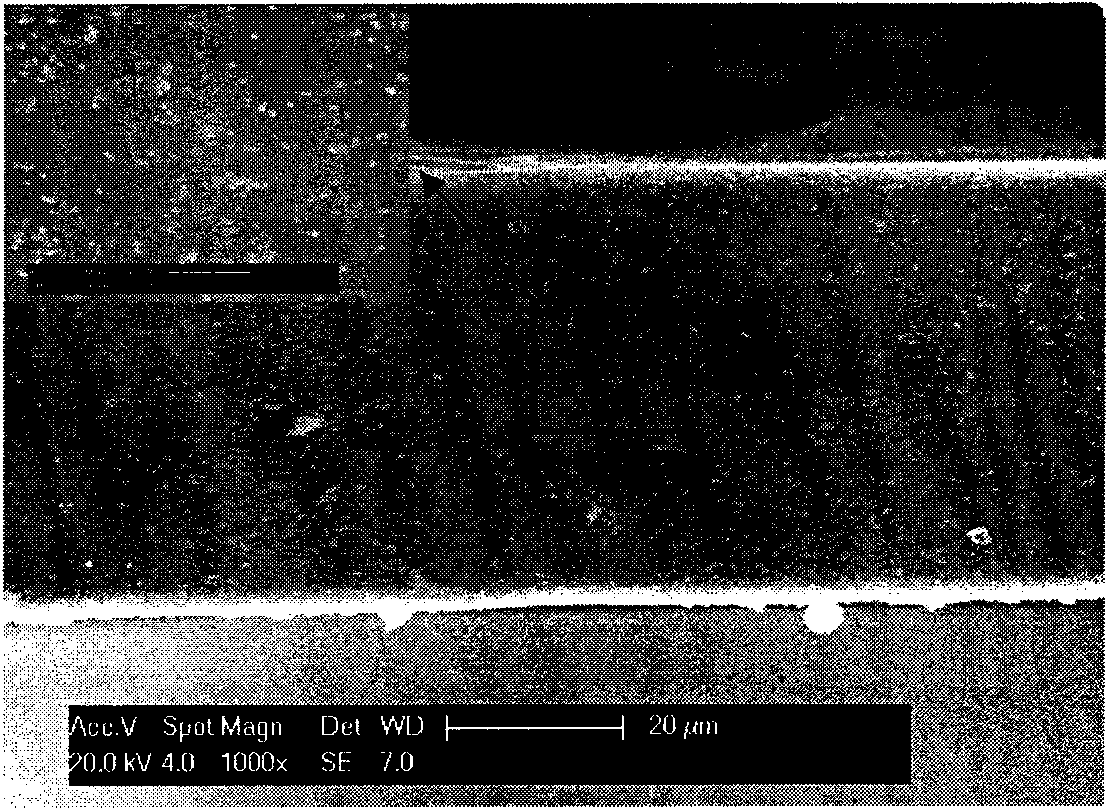

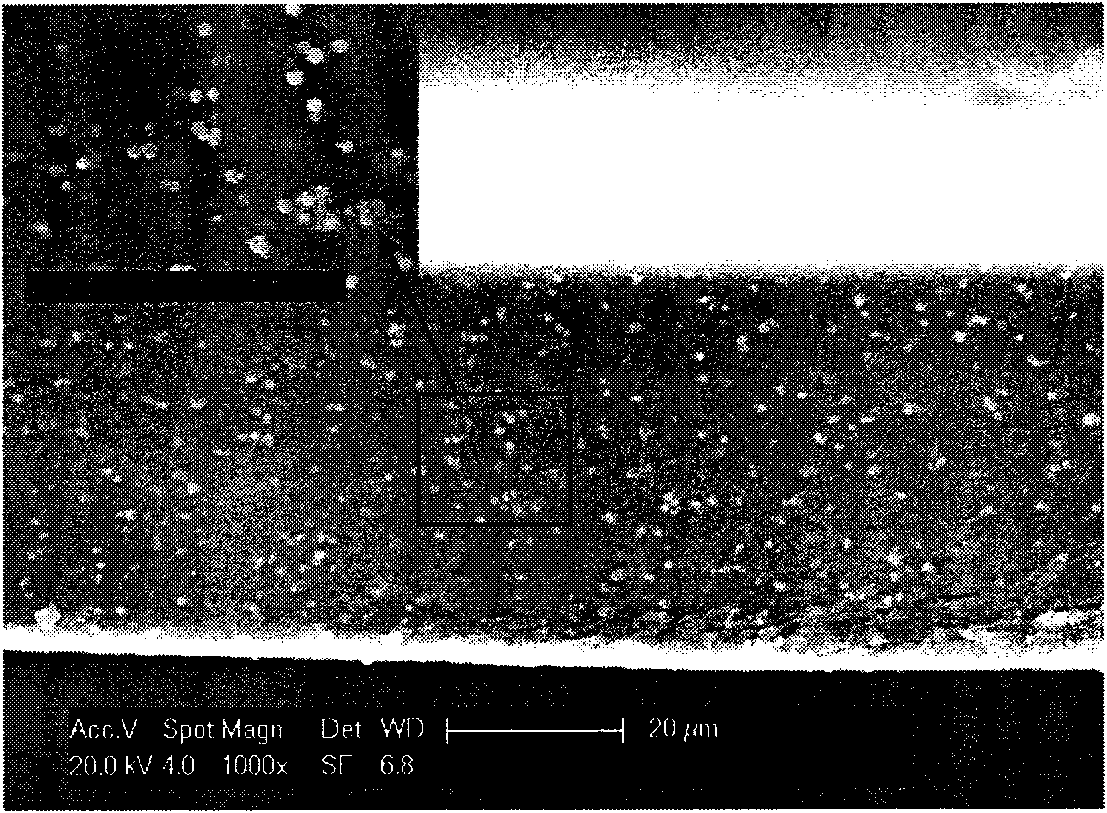

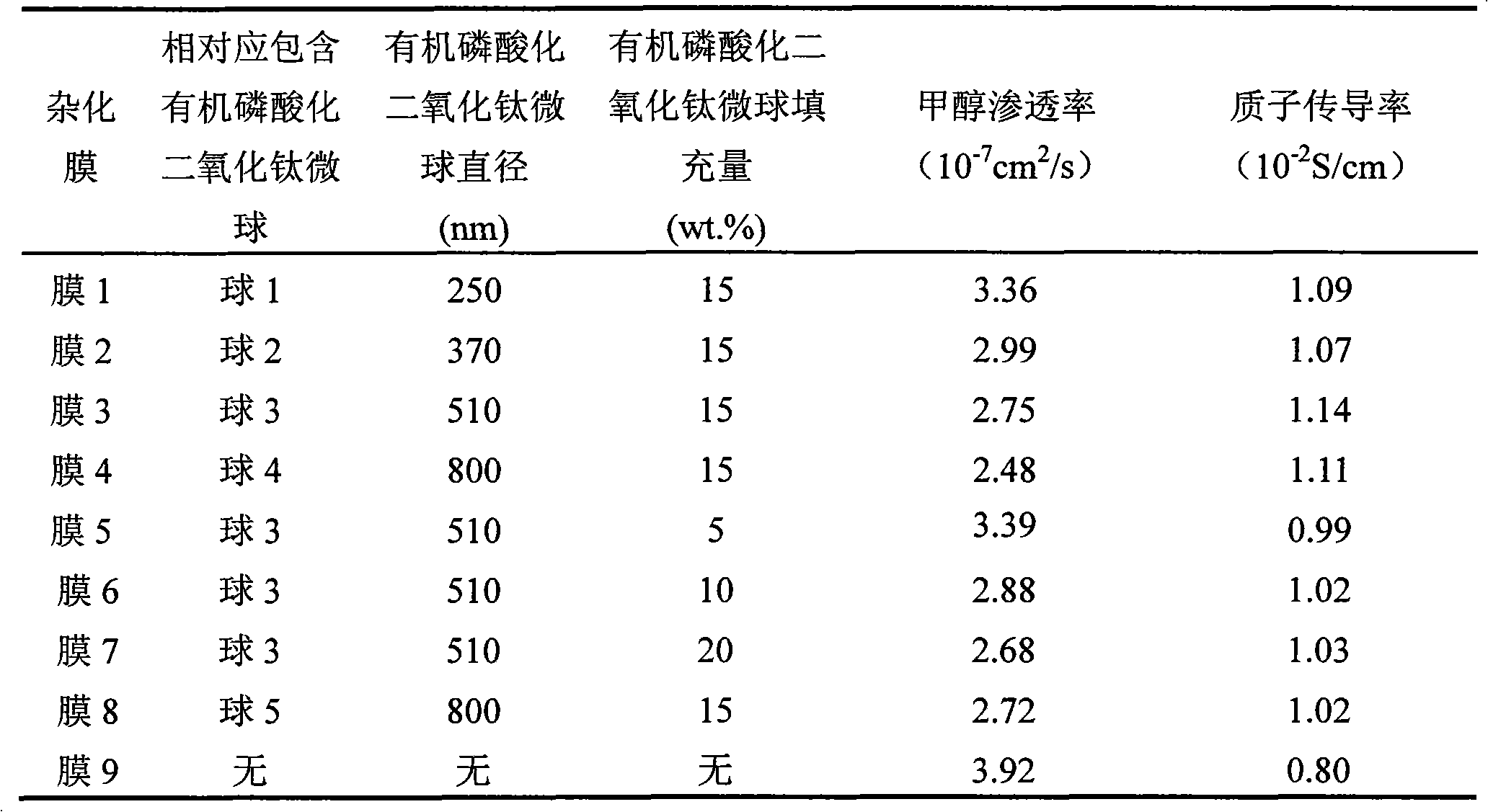

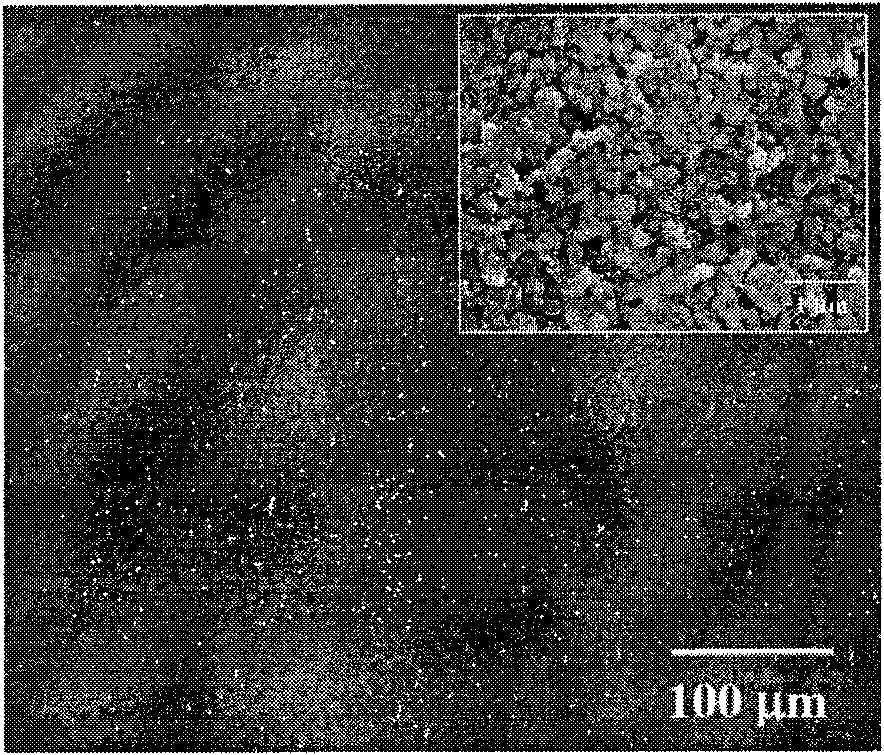

Organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as preparation and application

InactiveCN101624449AEasy to makeUniform and controllable particle sizeCell component detailsSolid electrolyte fuel cellsO-Phosphoric AcidAqueous acetone

The invention relates to an organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as a preparation and an application. The hybrid membrane is prepared by taking tetrabutyl titanate, glycol, organic phosphoric acid and chitosan as raw materials according to the following matching: the mole ratio of tetrabutyl titanate and glycol is 1:30-1:60 to prepare titanium dioxide micrballon, the mass volume ratio of titanium dioxide micrballon and organic phosphoric acid is 1:4-6, the mass ratio of titanium dioxide micrballon and chitosan is 0.05-0.2:1. The preparation method is as follows: the mixed solution of tetrabutyl titanate and glycol are precipitated in acetone water solution, washed and dried to obtain titanium dioxide micrballon which is put into organic phosphoric acid water solution for standing, the micrballon is put into glacial acetic acid water solution for ultrasound dispersion and is added with chitosan to obtain casting solution which subjects to casting on a substrate (glass plate) and is dried to form a membrane for crosslinking in sulphuric acid water solution, then washing and vacuum drying. The titanium dioxide micrballon and the membrane of the invention have rich source of raw materials, low cost and simple operation, and the prepared hybrid membrane has lower methanol permeability and higher proton conductivity, and can be used as direct methanol fuel cell membrane.

Owner:TIANJIN UNIV

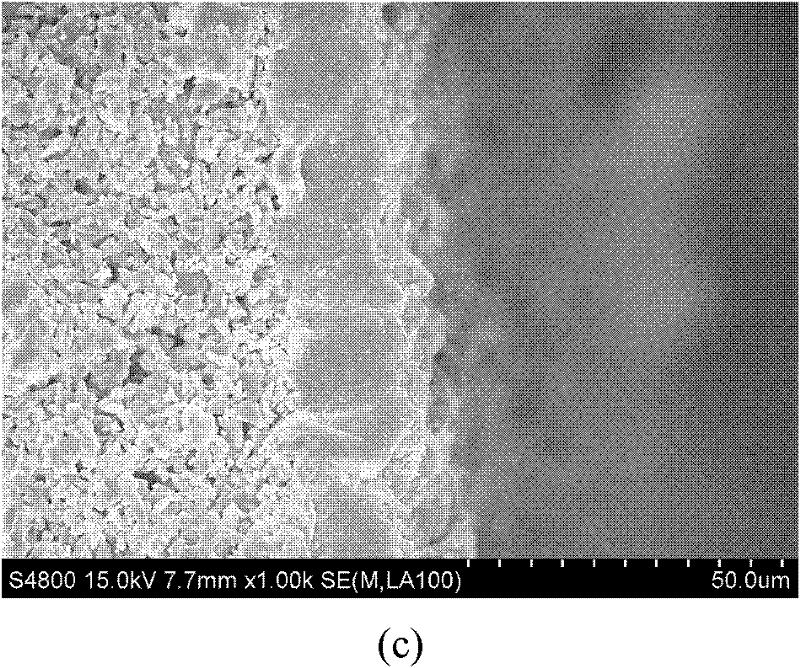

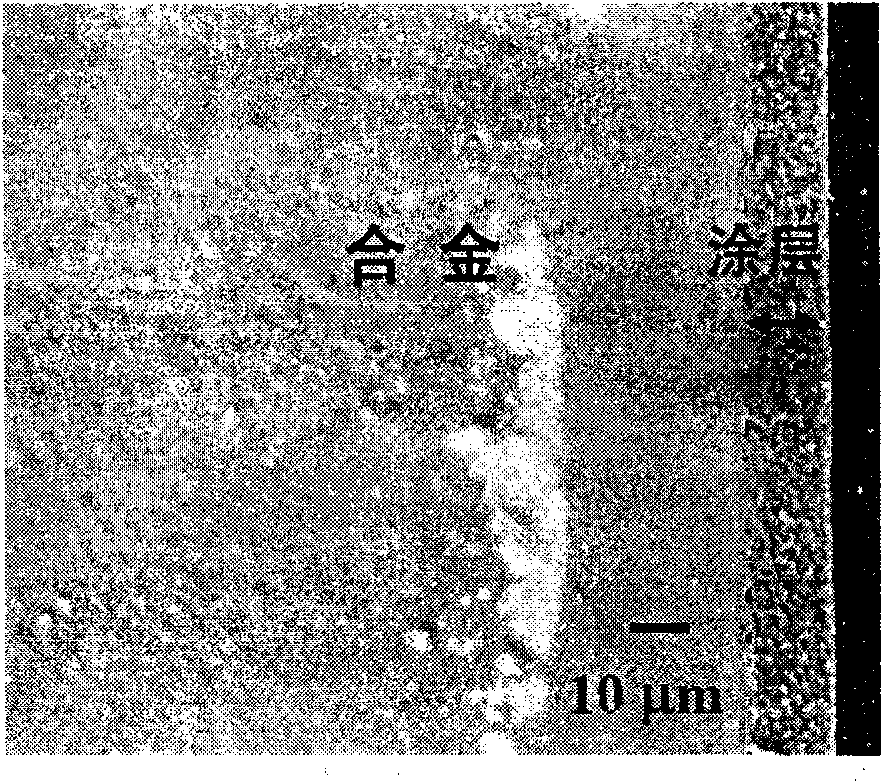

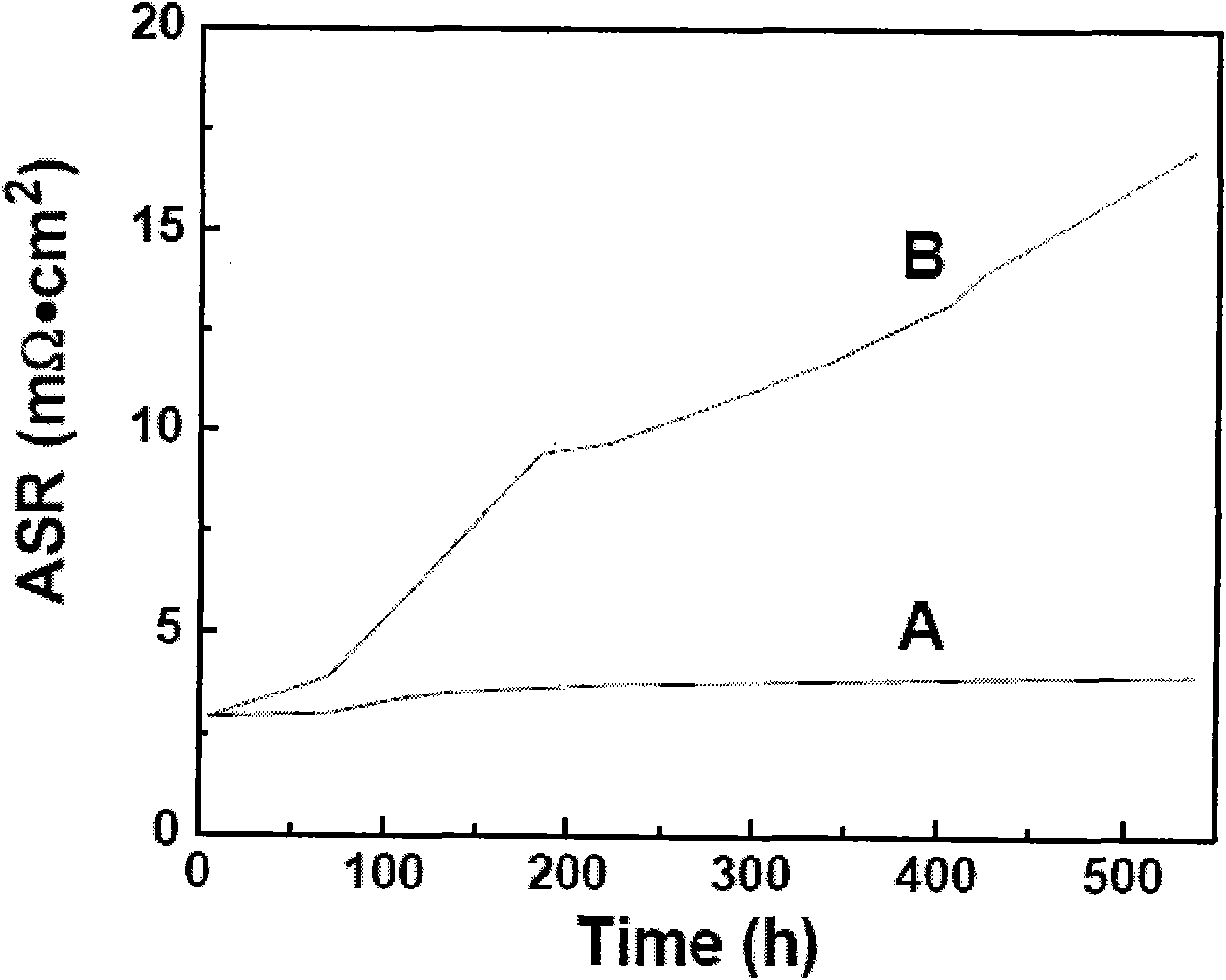

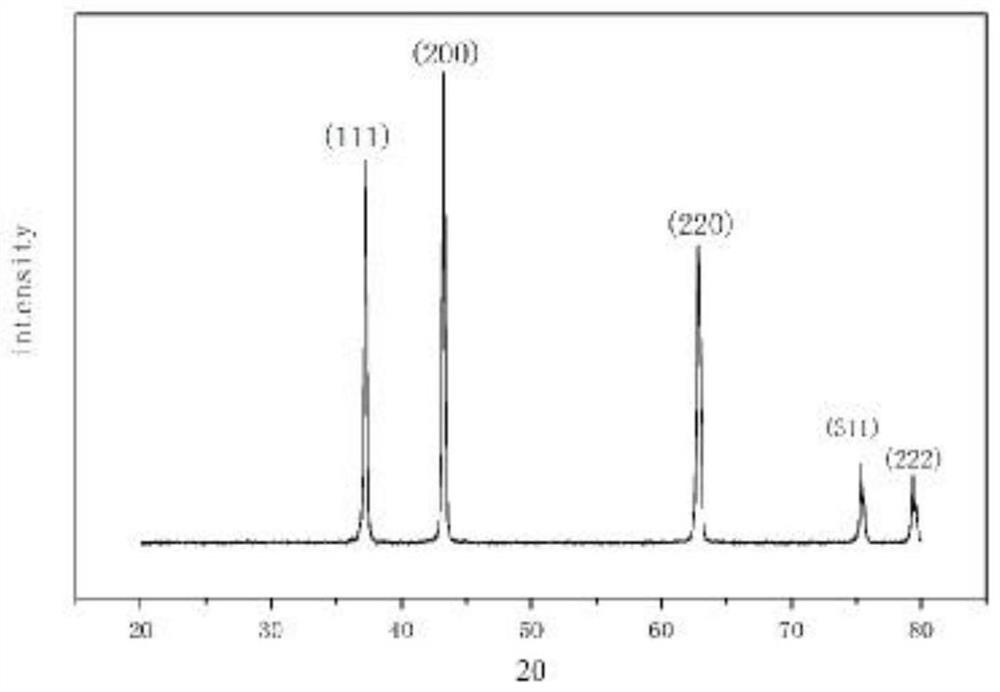

Alloy high temperature oxidation resisting nanostructure conductive coating prepared with spinel powder reduction method

InactiveCN101671829AImprove sinterabilityUniform and controllable thicknessConductive layers on insulating-supportsCable/conductor manufactureAlloy coatingNanostructure

The invention provides a preparing method of an alloy high temperature oxidation resisting nanostructure conductive coating, i.e. a spinel powder reduction coating method. On one hand, coating powdermaterial with favorable sintering performance is obtained by the regulation and control of the preparing process of coating powder material and effective reductive treatment; on the other hand, a nanometer microstructure film is prepared on the alloy surface by adopting silk screen assisted improved sizing agent coating technology. The film has controllable and even thickness and superior performance, and coating is tightly combined with the alloy; the coating alloy has lower area specific resistance (ASR) and higher long-time running stability under high temperature oxidation environment. Thespinel powder reduction coating method originated by the invention has simple film manufacturing method, low cost and strong repetitiveness, can be applied to coating preparation of alloy with different shapes or sizes, has superiority especially when preparing the large-area alloy coating in practical application, can greatly lower the preparing cost of the alloy coating and has strong applicability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

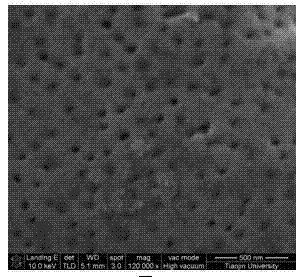

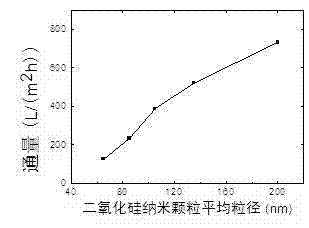

Solvent-free preparation method of aperture controllable porous film

InactiveCN102886211ALow costEasy to manufactureSemi-permeable membranesCross-link(Hydroxyethyl)methacrylate

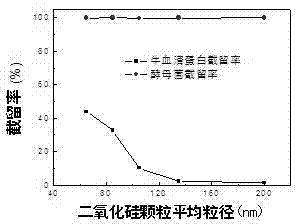

The invention discloses a solvent-free preparation method of an aperture controllable porous film. The process of the method comprises the following steps of: using 1-hydroxy-cyclohexyl phenyl ketone as an initiator, using hexanediol diacrylate as a cross-linking agent, and by ultraviolet light, initiating polymerization cross-linking curing film formation of a film forming monomer hydroxyethyl methacrylate and pore forming silicon dioxide nano particles between two glass sheets; and carrying out pore forming by removing a pore forming agent, i.e. the silicon dioxide particles. The method does not require an organic solvent in the preparation process, is green and has no pollution; and the solvent cost can be saved and a solvent recovery process is not required. The particle size of the prepared silicon dioxide nano particles can be regulated and controlled by the sol-gel process conditions; the aperture of the prepared porous film is consistent with the particle size of the pore forming agent, i.e. silicon dioxide nano particles; and the aperture of the film can be regulated and controlled by regulating the particle size of the silicon dioxide nano particles.

Owner:TIANJIN UNIV

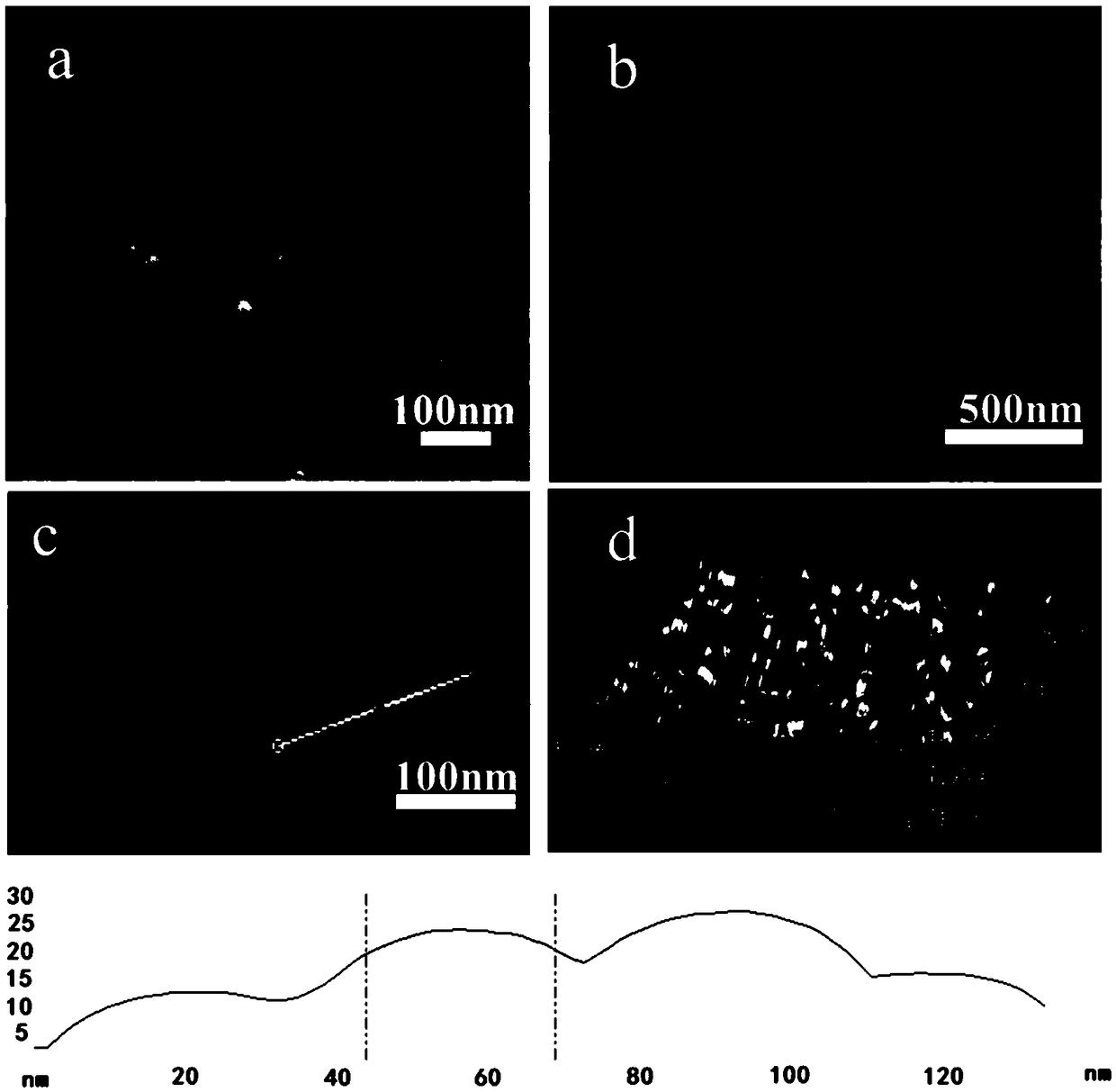

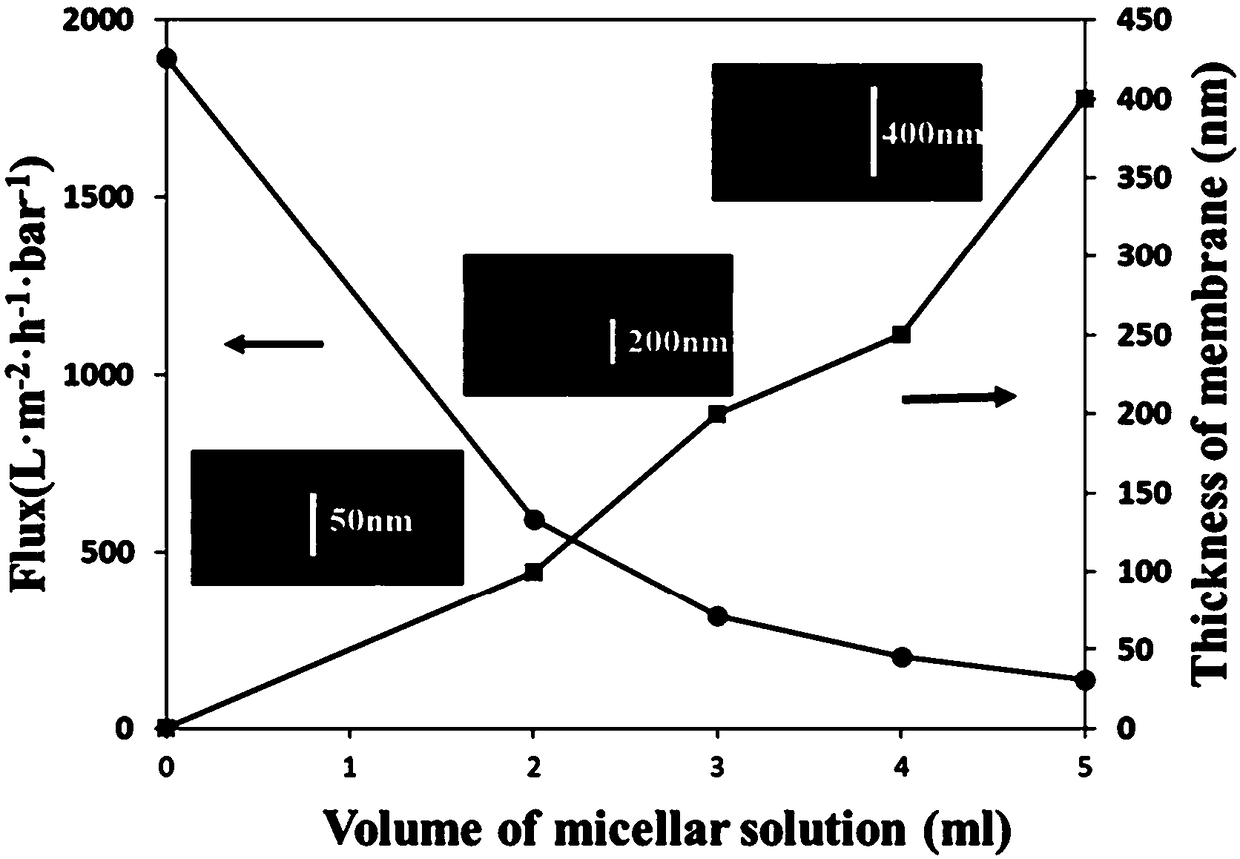

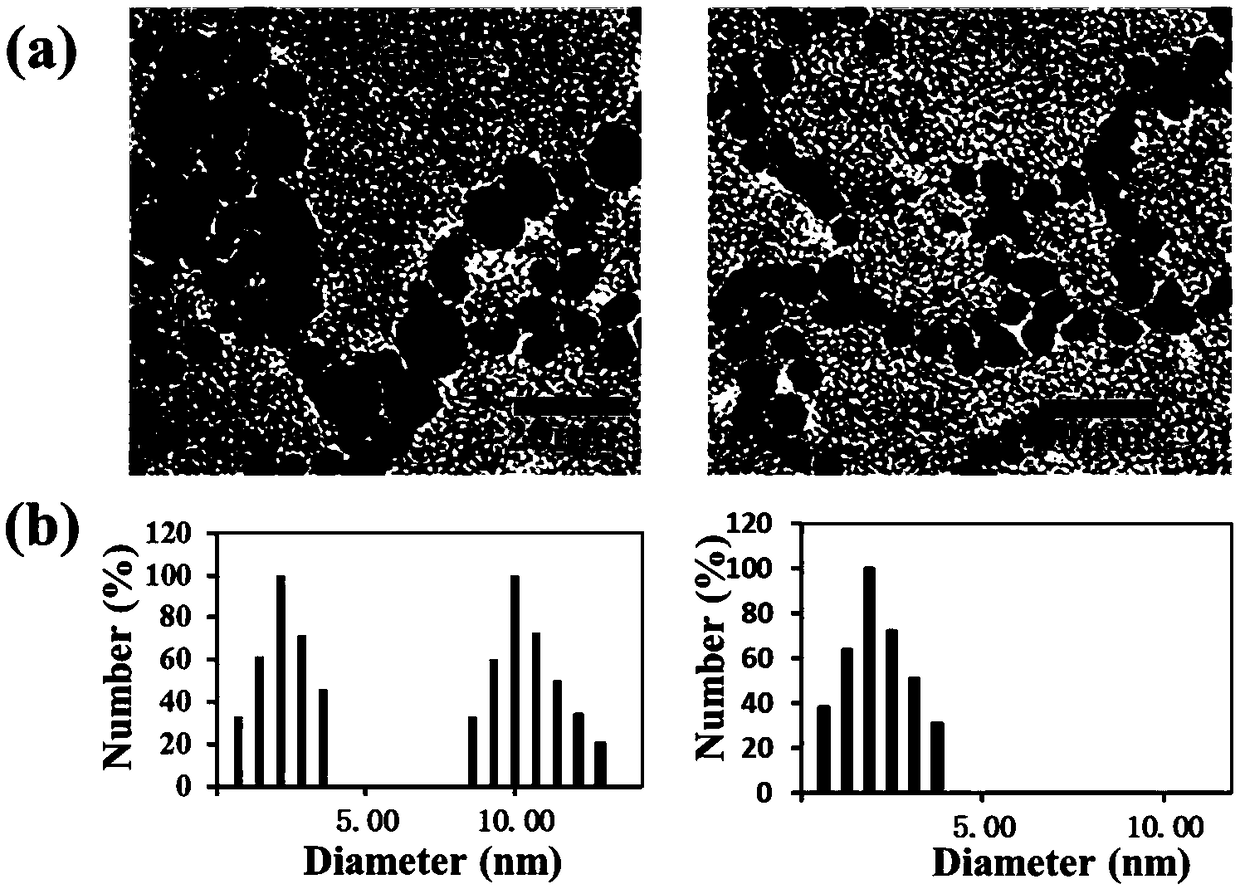

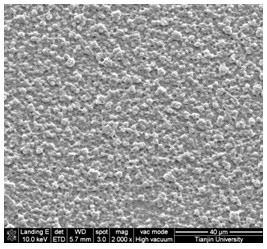

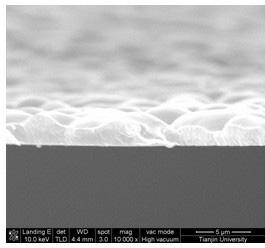

Preparation method of polymeric micelle nanofiltration membrane and application thereof

The invention discloses a preparation method of a polymeric micelle nanofiltration membrane and application thereof, which belongs to the field of porous material separation membranes. The polymer membrane is mainly attached to a macroporous substrate, and a polycarbonate membrane is chosen as the substrate layer. The preparation method of the micelle membrane comprises the following steps: a polymer with an appropriate block proportion and molecular weight is chosen to be dissolved in selective solvent, so that a micelle solution with a specific morphology is formed; the micelle solution is uniformly dispersed, spread onto the macroporous substrate by the vacuum filtration technology and naturally dried, and thereby the block copolymer separation membrane prepared by the dilute micelle solution is obtained. The voids formed between the piled micelles serve as part of membrane pores, thus playing the role of selective separation, while the macroporous substrate of the lower layer helpsincrease the separation efficiency of the membrane. Most of the current methods for preparing polymer membranes are complex and consume a great deal of energy. The membrane production method is universal and simple, the needed cost is low, and moreover, the produced membrane has high separation efficiency, and can be applied to the separation of different sizes of gold nanoparticles.

Owner:NANJING UNIV OF TECH

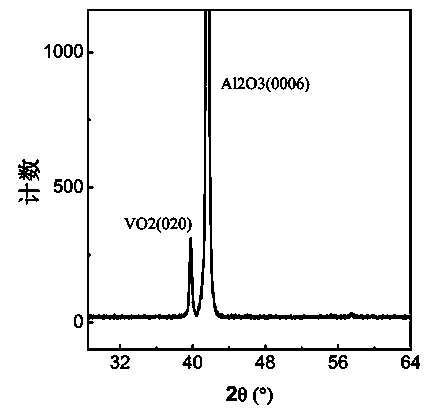

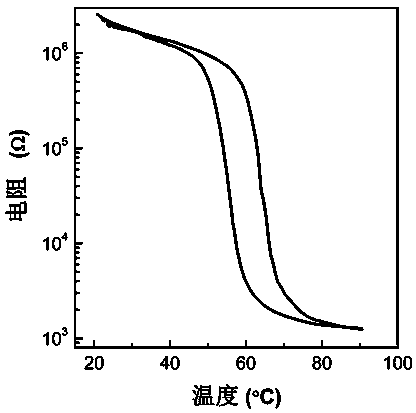

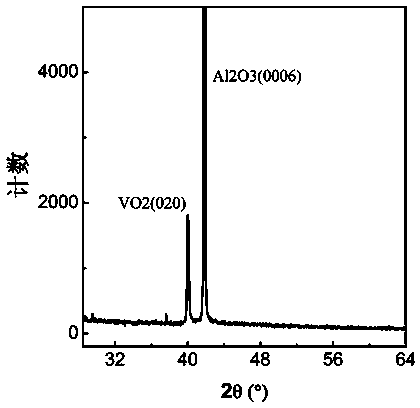

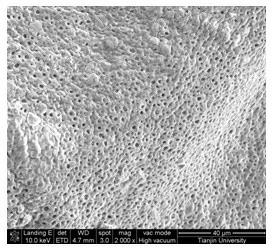

Liquid-phase preparation method of high-oriented vanadium dioxide film

ActiveCN104060241AAct as a reducing agentRestore evenlyLiquid/solution decomposition chemical coatingVanadium dioxidePhase change

The invention discloses a liquid-phase preparation method of a high-oriented vanadium dioxide film, belonging to the field of chemical function materials. The preparation method comprises the following steps: preparing precursor liquid by taking triisopropoxyvanadium oxide as solute, coating a sapphire substrate with the obtained precursor liquid to prepare a precursor film, and finally sintering the precursor film in a vacuum environment. According to the preparation method, the vanadium dioxide film is prepared by controlling vacuum sintering conditions on the basis of a liquid-phase method, the obtained film is good in growth orientation, the phase change temperature of the film is about 60 DEG C, and the change of electrical resistivity before and after the phase change is more than three orders of magnitude; in addition, the preparation process is simple and suitable for large-range popularization.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Method for preparing polymer porous membrane without solvent

InactiveCN102643449ALow costReduce the amount of adsorptionSemi-permeable membranesBenzoyl peroxidePolymer science

The invention discloses a method for preparing polymer porous membrane without solvent. The method includes steps of utilizing benzoyl peroxide as trigger and hexamethylene diacrylate as crosslinking agent, subjecting liquid-phase monomer methyl acrylic hydroxy ethyl ester to bulk polymerization between two glass sheets through thermal initiation, crosslinking and curing to forming a membrane; meanwhile, forming silica particles by porogen tetraethoxysilane through sol melting and gelling during membrane forming , and removing the silica particles to forming pores after membrane forming. The method for preparing polymer porous membrane has no needs of organic solvent and is environment-friendly, expense on solvent can be saved, solvent recycling process is omitted, and membrane forming cost is reduced. The surface of the membrane prepared by the method is high in hydrophilcity, low in protein adsorption and adjustable in thickness and expresses high flux, excellent separation effect and pollution-resistance performance when used for bioseparation.

Owner:TIANJIN UNIV

Composite membrane containing covalent organic framework material, and preparation method thereof

ActiveCN110787653AEasy to prepareHighly ordered pore structureSemi-permeable membranesMembranesPtru catalystAniline Compounds

The invention provides a composite membrane containing a covalent organic framework material, and a preparation method thereof, wherein the composite membrane comprises, by weight, 15-25 parts of an aniline compound, 15-26 parts of s-trisphenol benzenetrialdehyde, 8-10 parts of a catalyst, 25-35 parts of ethanol, 40-60 parts of PVDF and 15-25 parts of DMF. According to the invention, by compounding the covalent organic framework material and PVDF, the membrane preparation cost is reduced, and the covalent organic framework material can be uniformly dispersed in PVDF as the substrate, wherein PVDF can form micron-scale holes with a size of 1-1000 [mu]m, and comprises endpoint values, and the covalent organic framework has regular and uniform nano-scale holes with a size of 1-1000 nm and comprises endpoint values, so that the filtering and sterilization effects on different dyes are greatly enhanced through the micron-scale and nano-scale hierarchical holes.

Owner:孝感市思远新材料科技有限公司

Hollow fiber membrane and preparation method thereof

ActiveCN103920398AEasy to prepareSimple film making processSemi-permeable membranesHollow fibre membraneFiber

The invention discloses a hollow fiber membrane and a preparation method of the hollow fiber membrane. The hollow fiber membrane is characterized in that a mass percent formula of a membrane forming system comprises the following components in percentage by weight (the sum of the components is 100%): 12-30% of a polymer, 70-88% of an organic solvent and 0-10% of an additive, wherein the polymer is a general membrane forming polymer or a modified product; the organic solvent is a good solvent of the polymer and can be mutually dissolved with water; the additive is a substance capable of reacting with water or a water solution to generate gas. The preparation method is a simplified solution spinning method comprising the steps of: firstly preparing the polymer membrane forming system according to the formula, putting the polymer membrane forming system into an injection syringe or other conveniently-extruded containers, extruding polymer membrane forming liquid from a syringe needle or other pipelines under the pushing action of an injection pump or the other containers, soaking the extruded polymer membrane forming liquid into pure water or a water solution which can be an acid water solution or an alkali water solution according to different additives, solidifying and forming the membrane forming system by virtue of the water solution, meanwhile, reacting the additive with water, forming a cavity of the hollow fiber membrane due to the expansion of the generated gas, and finally obtaining the hollow fiber membrane.

Owner:无锡迈姆润环境科技有限公司

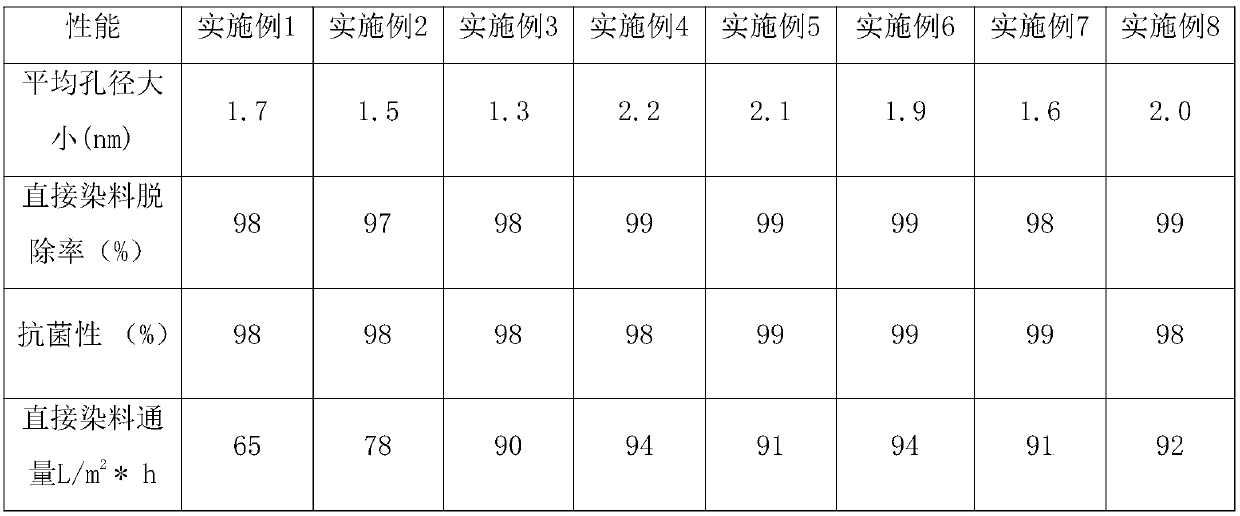

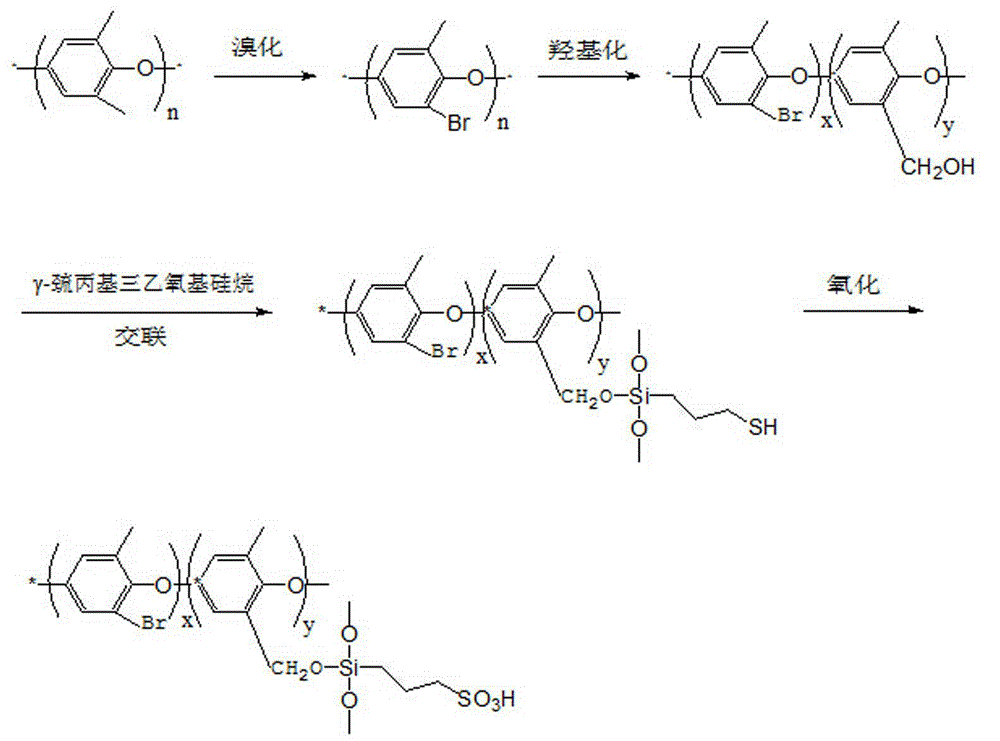

Preparation method of cross-linked polyphenyl ether composite proton exchange membrane

InactiveCN104130433AImprove proton conductivityImprove stabilityFinal product manufactureCell component detailsCross-linkGlass sheet

The invention relates to a preparation method of a proton exchange membrane used in fuel cells. The invention specifically relates to a preparation method of a cross-linked polyphenyl ether composite proton exchange membrane. According to the method, polyphenyl ether is dissolved in a chlorobenzene solution, such that a high-molecular solution is prepared; gamma-mercaptopropyl triethoxysilane or gamma-mercaptopropyl trimethoxysilane is added; the mixture is heated and stirred such that a solution is formed; the solution is cast on a glass plate and is dried and cross-linked, such that a membrane is formed; the cross-linked polyphenyl ether composite membrane is soaked and oxidized in a hydrogen peroxide solution under room temperature, such that the cross-linked polyphenyl ether composite proton exchange membrane is obtained. The composite proton exchange membrane provided by the invention has excellent proton conductivity, wherein the proton conduction rate is higher than that of a Nafion membrane. The membrane provided by the invention also has good stability. A swelling degree of the membrane provided by the invention is smaller than that of the Nafion membrane. The method provided by the invention also has the advantages of simple process and convenient operation. A membrane production cost is lower than that of the Nafion membrane. The method is suitable for industrialization.

Owner:TAIYUAN UNIV OF TECH

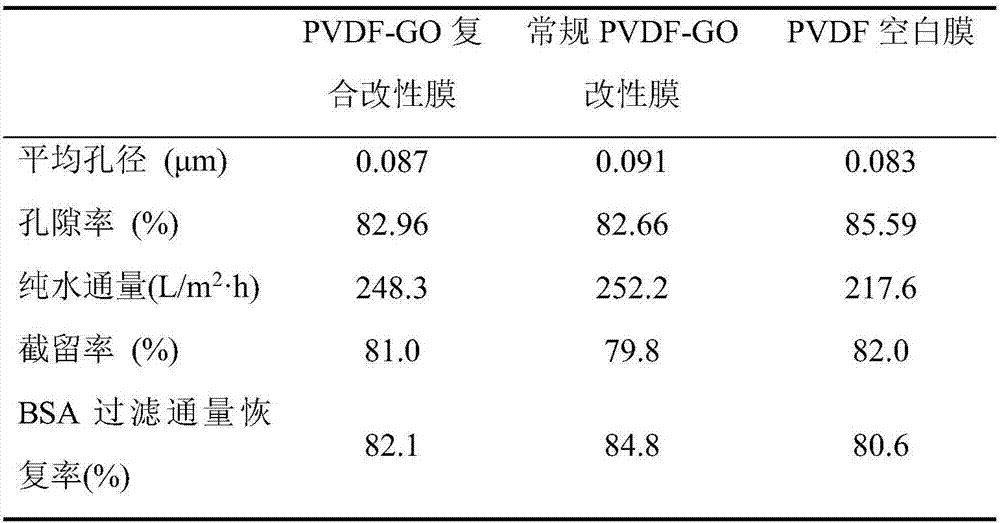

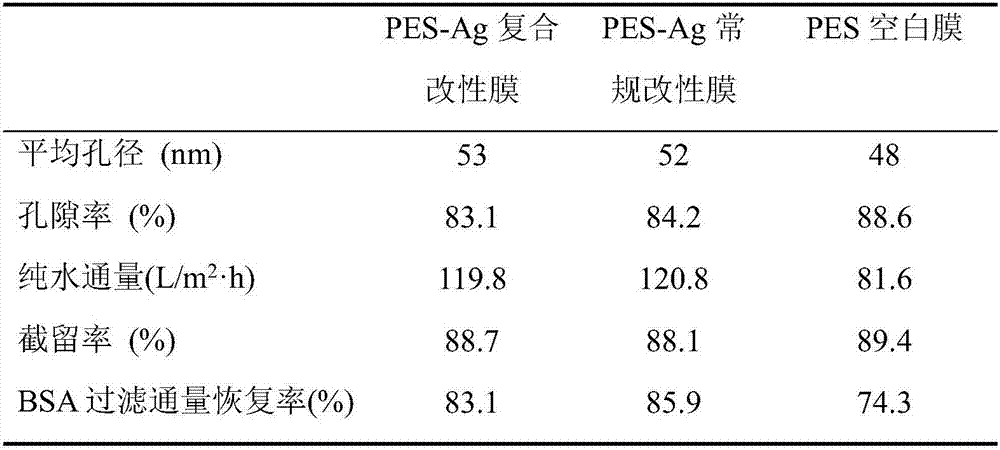

Water-treatment composite modified film and preparation method thereof

InactiveCN107983164AReduce dosageReduce film production costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLiquid layerPolymer science

The invention discloses a water-treatment composite modified film and a preparation method thereof. The water-treatment composite modified film comprises a support material, a blank polymer casting film liquid layer and a polymer-modifying agent composite layer, wherein the blank polymer casting film liquid layer is arranged on the surface of the support material in a scraping manner, and the polymer-modifying agent composite layer is arranged on the surface of the blank polymer casting film liquid layer in a scraping manner; and the constitution of the polymer-modifying agent composite layeris as follows: a modifying agent contains one or combination of nano-TiO2, nano-Ag, graphene oxide, a modified substance of graphene oxide, an anionic surfactant, an ampholytic surfactant or an amphiphilic block polymer. A layering film scraping method provided by the invention has the beneficial effects that on the basis that the filtration and anti-pollution performance of the modified film aresimilar to the filtration and anti-pollution performances of a conventional modified film, the use amount of the modifying agent can be greatly reduced, and the film preparation cost can be saved.

Owner:JIANGNAN UNIV

Pervaporation membrane for esterification reaction and method for producing the same

InactiveCN101219347AEasy to makeImprove controllabilityOrganic compound preparationCarboxylic acid esters preparationWater bathsEthyl fumarate

The invention relates to a permeable pervaporation membrane used in esterification and a preparation method thereof. The permeable pervaporation membrane employs chitosan and ethyl orthosilicate as raw materials which are matched according to the weight ratio between the chitosan and the ethyl orthosilicate is 10: 0.5-50:1. The preparation method is that the chitosan (CS) is dissolved into acetic acid hydrosolution and then is stirred in water bath of 80 DEG C, thus obtaining chitosan solution; the chitosan solution is filtered before the ethyl orthosilicate is added for stirring for 2 hours under room temperature, thus obtaining casting solution through stewing and deaerating; the casting film solution is ventilated and dried for 48 hours under 20-30 DEG C and is heat treated for 2 hours under 120 DEG C, thus obtaining CS-TEOS hybrid membranes. The invention has simple preparation, abundant raw materials and low cost; the CS-TEOS hybrid membranes being prepared can be used in the esterification for permeating and evaporating dehydration in coupling process to improve the yield of ethyl lactate, water permeable flux reaches 97.5g m<-2>h<-1> and the yield of the ethyl lactate is improved from 66.4 percent to 80.0 percent.

Owner:TIANJIN UNIV

Method for preparation of polyvinylidene fluoride membrane by complex thermally induced phase separation

InactiveCN103252172AReduce manufacturing costImprove throughputSemi-permeable membranesNitrogenFree cooling

The invention relates to a method for preparation of a polyvinylidene fluoride (PVDF) membrane by complex thermally induced phase separation. The method comprises the steps of: 1) preparation of a membrane casting solution: weighing 65%-85% of caprolactam and 15%-35% of polyvinylidene fluoride, mixing them uniformly, heating the mixture in oil bath to 115DEG C-170DEG C for 0.5h-2h under nitrogen protection to make the caprolactam and polyvinylidene fluoride dissolved, then performing constant temperature stirring for 0.5h-1.5h, and conducting standing to obtain a standard membrane casting solution, leaving the membrane casting solution to natural cooling so as to obtain a solid mixture; 2) membrane formation: placing the solid mixture into a vacuum oven and heating it to 115DEG C-170DEG C to remelt it, then carrying out membrane scraping by a membrane scraper; and 3) gel membrane formation: placing the scraped nascent state membrane into water or ethanol quickly, and conducting extraction to obtain the polyvinylidene fluoride membrane. The method provided in the invention takes caprolactam as a solvent to prepare the membrane by complex thermally induced phase separation, and has the characteristics of simple process and no pollution. The prepared PVDF membrane has chemical stability and high strength, and can provide high performance membrane products for an MBR process.

Owner:NINGBO UNIV

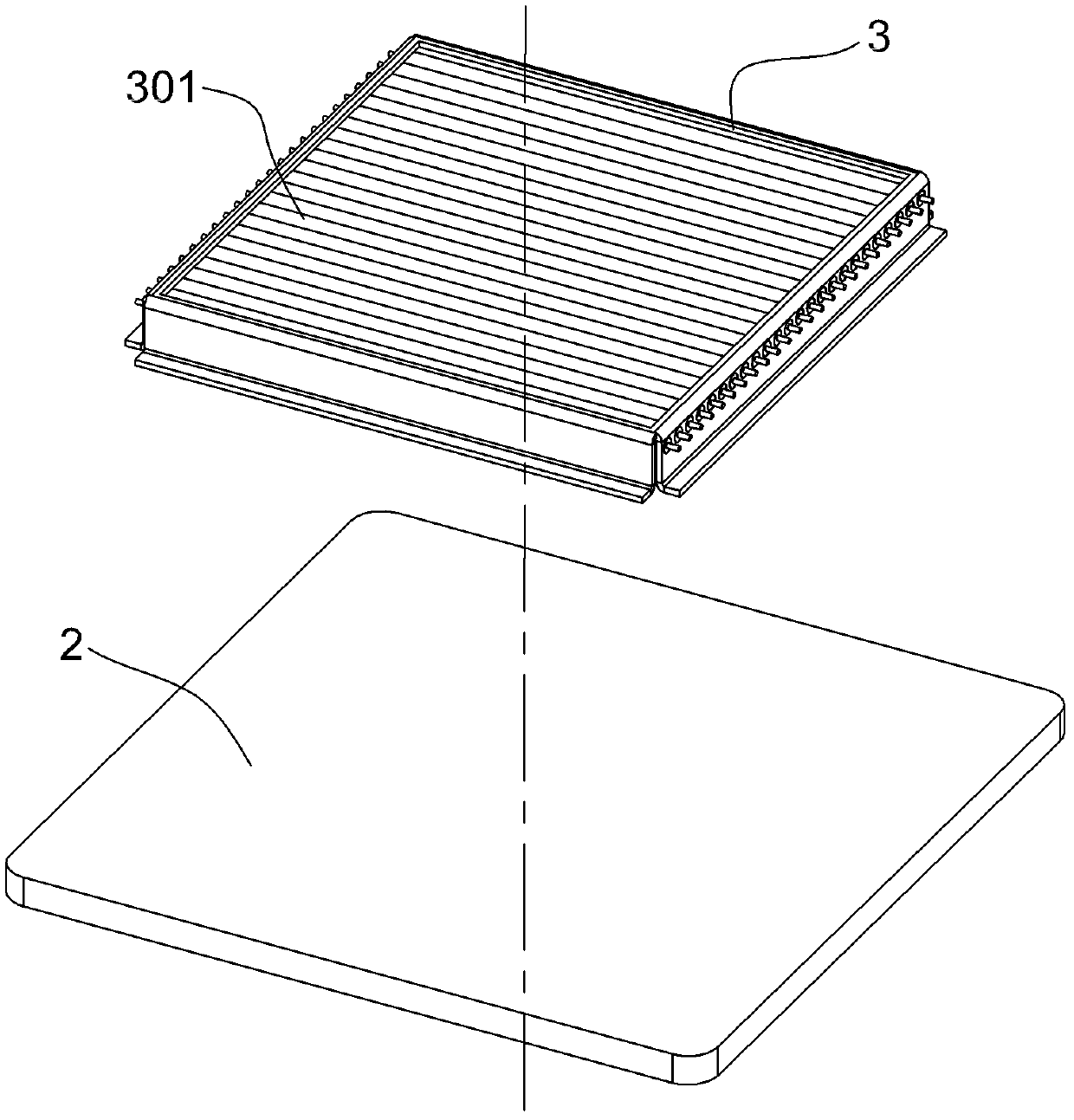

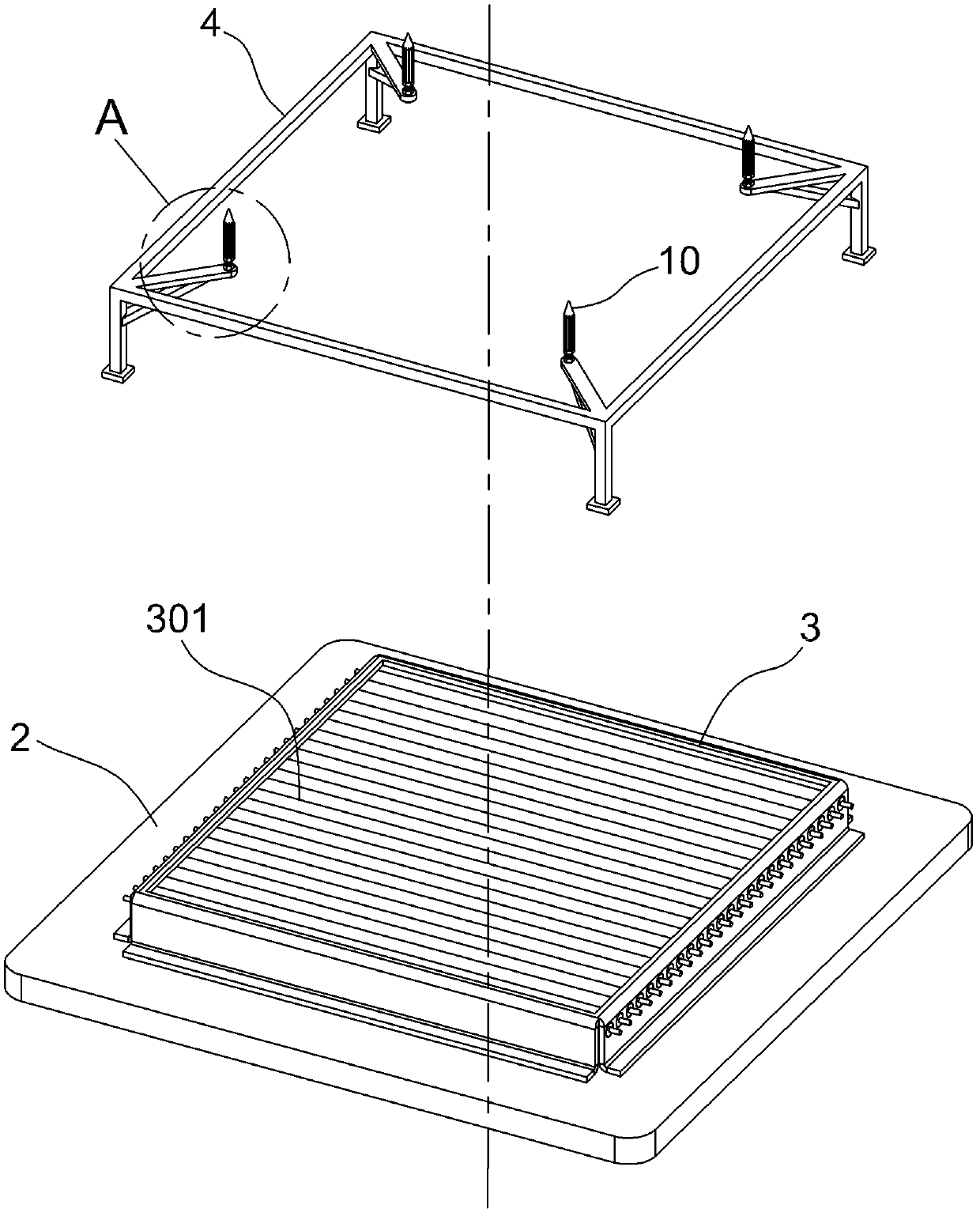

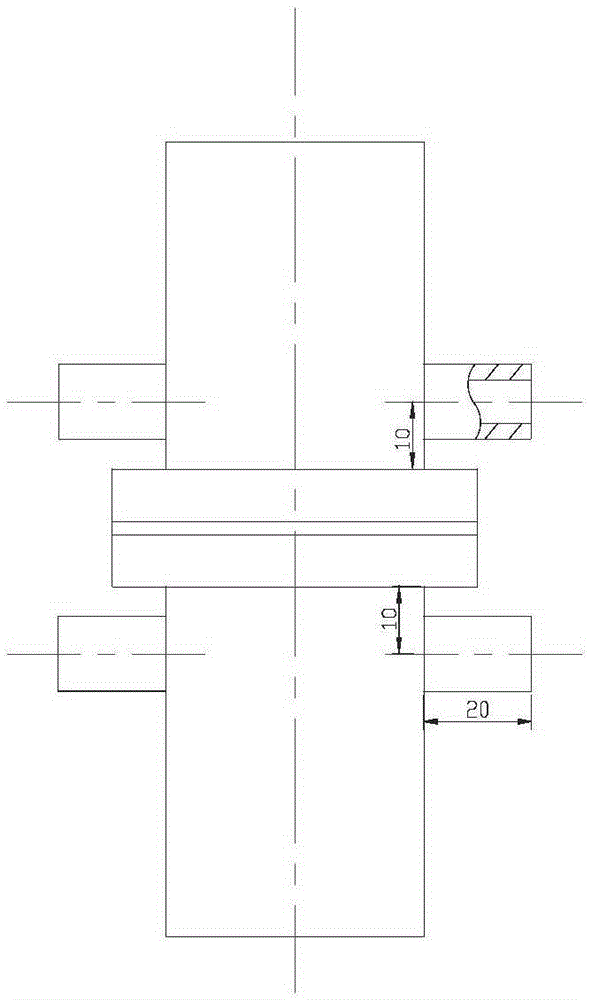

Solution casting method

A solution casting method comprises the following steps of: dissolving a solute in a solvent to prepare a casting solution; preparing a casting plate by float glass; arranging a heating device on an insulation base plate; arranging a rack on the periphery of the heating device and putting the casting plate on the rack; arranging a cooling water jacket on the insulation base plate, and letting the cooling water jacket encircle the heating device, the rack and the casting plate; arranging a condensed solvent collecting tank at the bottom of the cooling water jacket; pouring the casting solution into the casting plate; arranging an insulation top cover over the cooling water jacket, and sealing the internal space encircled by the cooling water jacket and the insulation base plate; starting the heating device to heat the casting solution so as to completely evaporate the solvent in the casting solution; continuously heating to further raise crystallization degree of a film; stopping heating, and peeling the film off from the casting plate; detecting the film thickness, adjusting the heating field, and raising thickness uniformity of the finished product film. The method provided by the invention has advantages of simple technology, cheap equipment and low film preparation cost. the finished product film has advantages of high degree of crystallization, isotropy, uniform thickness, few impurities, good appearance, high yield and the like.

Owner:山西金能世纪科技有限公司

Microwave hydrothermal preparation method of NiTiO3 nano film

InactiveCN101775656AHigh purityImprove uniformityPolycrystalline material growthFrom normal temperature solutionsProcess equipmentTemperature control mode

The invention discloses a microwave hydrothermal preparation method of a NiTiO3 nano film, comprising the following steps: adding analytically pure nickel nitrate hexahydrate in ethanol to obtain a solution A; adding analytically pure tetrabutyl titanate, citric acid, water and acetylacetone in the solution A to obtain a solution B; placing a silicon substrate in hydrogen peroxide for ultrasonic oscillation and drying; pouring the solution B in a hydro-thermal reaction kettle, placing the silicon substrate in the hydro-thermal reaction kettle and immersing in film-coating liquid; sealing the hydro-thermal reaction kettle and placing in an MDS-8 type warm-pressing double control microwave hydro-thermal reactor; selecting a temperature controlling mode or a pressure controlling mode to react, and cooling naturally to the room temperature after reaction; and opening the hydro-thermal reaction kettle, taking the silicon substrate, respectively washing with deionized water, absolute ethyl alcohol or isopropanol, and drying to obtain the final product NiTiO3 nano film. The reaction can be finished in liquid phase in one time, post-treatment is avoided, the process equipment is simple, and the obtained film has high purity and favorable uniformity.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of persistently hydrophilic polyvinylidene fluoride membrane

ActiveCN107362698AHigh retention rateIncrease water flowSemi-permeable membranesMembranesLithium chloridePolyethylene glycol

The invention discloses a preparation method of a persistently hydrophilic polyvinylidene fluoride membrane. The preparation method includes the steps: (1) casting membrane solution preparation: dissolving polyvinyl acetate and additives into solvents, adding polyvinylidene fluoride and then dissolving the polyvinylidene fluoride in the solvents to obtain casting membrane solution; (2) persistent hydrophilic polyvinylidene fluoride membrane preparation: preparing the persistent hydrophilic polyvinylidene fluoride membrane from the casting membrane solution prepared in the step (1) by a phase inversion method. The additives are compositions of one or more of polyvinylpyrrolidone, polyethylene glycol, polyvinyl alcohol, polymethyl methacrylate, lithium chloride, potassium chloride, titanium dioxide, silicon dioxide and oxidized graphene. The polyvinylidene fluoride membrane has the advantages of good and persistent hydrophily, high discharge capacity and interception rate, strong anti-pollution performance and simple preparation method.

Owner:SUZHOU SUJING NEW MATERIALS IN ENVIRONMENTAL PROTECTION

Method for preparing compound nanofiltration membrane

The invention discloses a method for preparing a compound nanofiltration membrane, which comprises the following steps: firstly adopting an electron beam irradiation basement membrane under nitrogen protection, wherein the irradiation dose is 10 to 300kGy, and the irradiation time is 1 to 3 minutes; then soaking the basement membrane into a monomer aqueous solution or hanging the basement membrane in monomer steam in a sealed container, processing for 2 to 12 hours, enabling a free radical on the surface of the basement membrane to initiate a liquid monomer or a gaseous monomer to generate cross linking and graft reactions, and forming a polyacrylic functional layer on the surface of the basement membrane to prepare the compound nanofiltration membrane, wherein the basement membrane is a polysulphone membrane, a polyvinylidene fluoride membrane, a polyether sulfone membrane, a polypropylene membrane or a cellulose acetate membrane; the form of the basement membrane is a flat sheet membrane, a tubular membrane or a hollow-fiber membrane; and the monomer is crylic acid, and the mass concentration of the monomer aqueous solution is 0.1 to 10g / L.

Owner:TIANJIN POLYTECHNIC UNIV

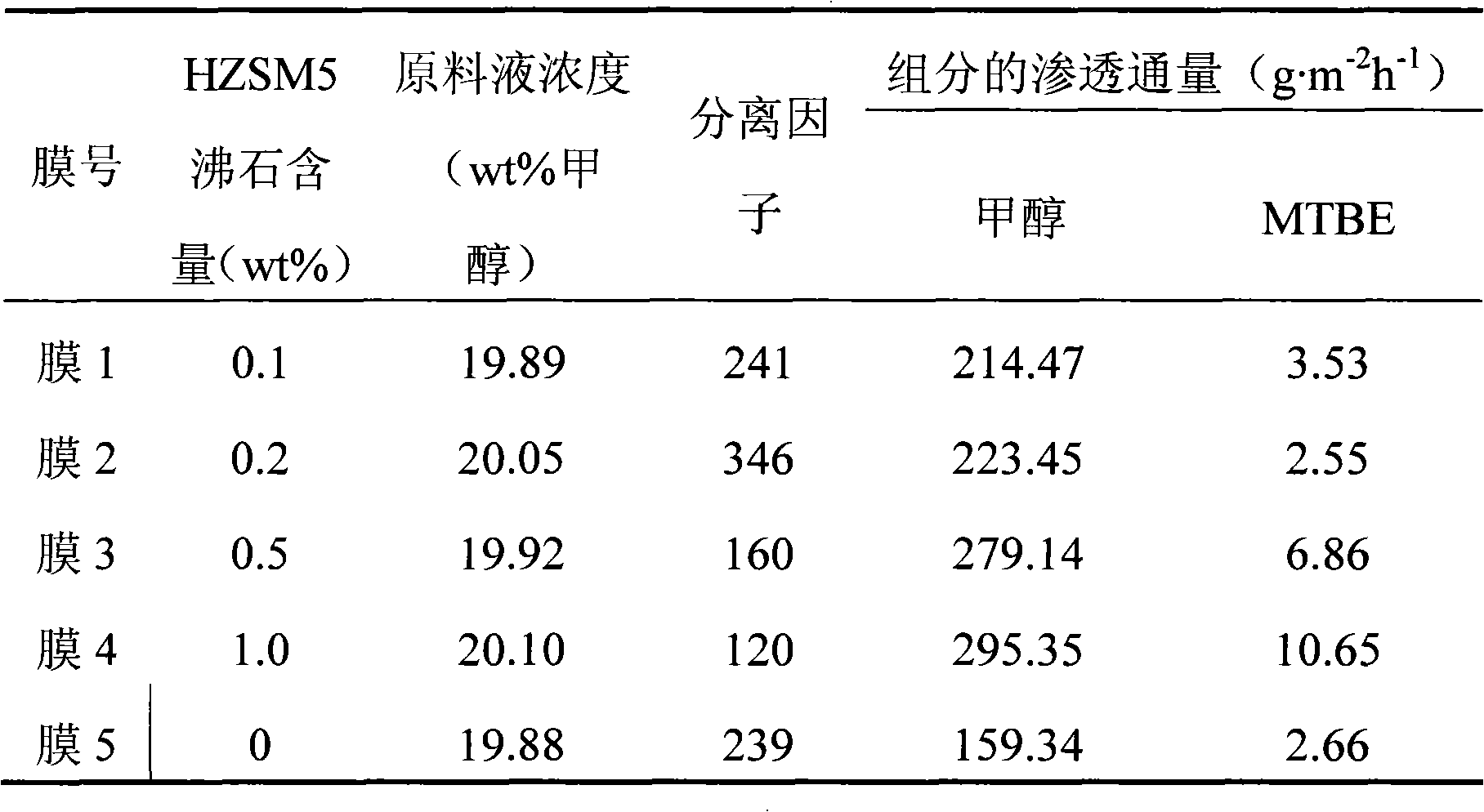

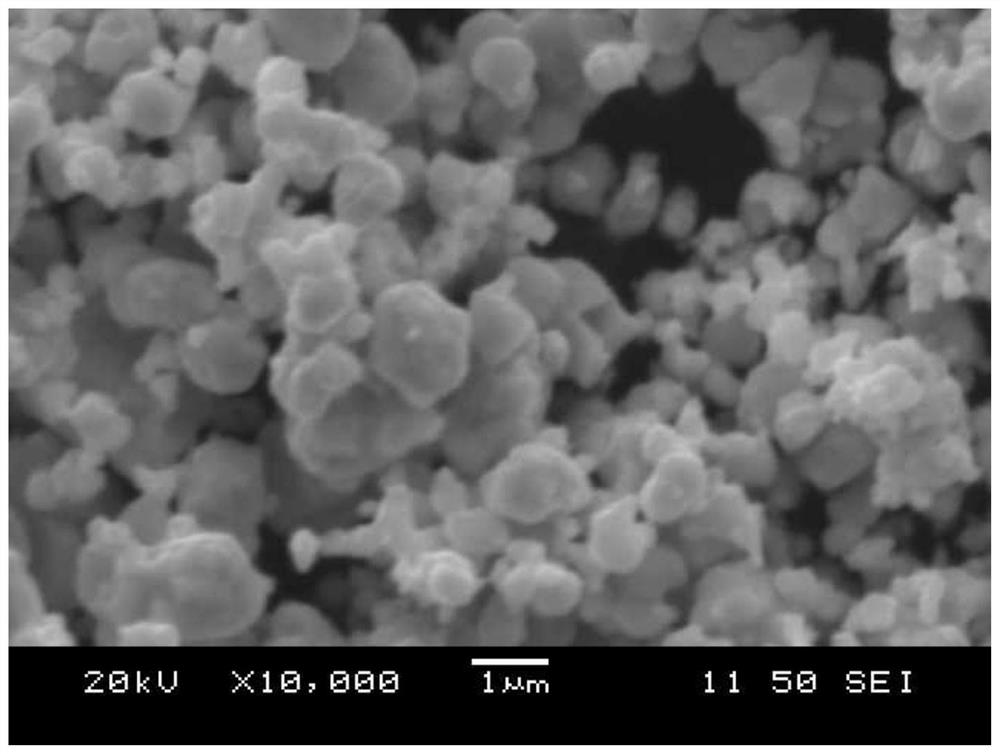

Preparation method and application of hybrid pervaporation membrane

InactiveCN101574627AEasy to makeImprove controllabilitySemi-permeable membranesSeparation factorAcetic acid

The invention relates to a preparation method and application of hybrid pervaporation membrane. The method comprises the following steps: adding Cellulose acetate in which combined acetic acid accounts for 54.5 to 56.0 percent by weight and HZSM5 zeolite of which the average particle size is 0.5 mu m into N,N-dimethylformamide according to the mass ratio of 99.5:0.5-98:2 to prepare 5 mass percent solution; stirring the solution for 1 to 2 hours at a temperature of between 20 and 30 DEG C till the cellulose acetate is completely dissolved; ultrasonically stirring the solution for 1 to 2 hours, standing and defoaming to obtain casting solution; pouring the casting solution on a clean glass plate, scraping by use of a scraper, ventilating and drying for 24 to 30 hours at a temperature of between 20 and 30 DEG C; and obtaining HZSM5 filled cellulose acetate membrane. The obtained HZSM5 zeolite filled cellulose acetate membrane is used for the pervaporation and separation of methanol / MTBE mixture, wherein the permeation flux is up to 227g*mh, and the separation factor is 806. The method has the advantages of simple preparation process, abundant raw materials and low price.

Owner:PETROCHINA CO LTD +1

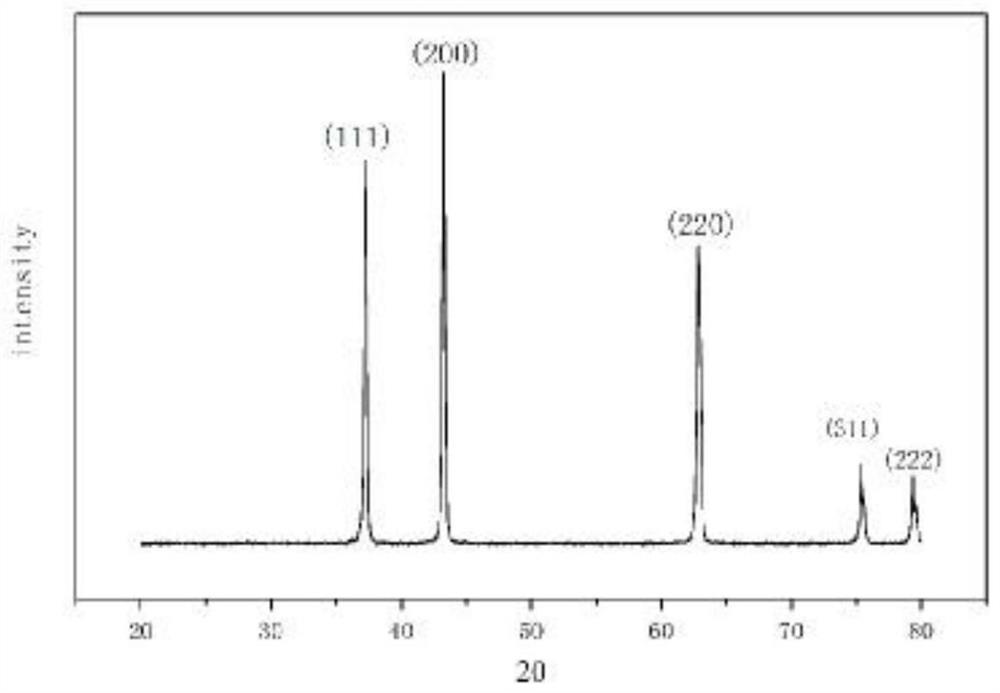

Cold isostatic pressing forming preparation method of nickel oxide-based ceramic target material

InactiveCN112456971AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedMass fraction

The invention relates to a cold isostatic pressing forming preparation method of a nickel oxide-based ceramic target material, wherein the method comprises the following steps: A, preparing raw materials: preparing mixed powder of nickel oxide powder and doped source powder, wherein the total mass fraction of doped source elements in the mixed powder is not more than 10%, wherein the doping sourceelement is selected from one or more of 0-6% of Li, 0-0.3% of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% ofV, 0-10% of W and 0-2.5% of Ti; B, carrying out spray drying; C, compacting by vibration; D, feeding a mold into a cold isostatic pressing chamber for pressing; E, degumming a biscuit; F, sintering;G, cooling after heat preservation is finished; and H, machining or not machining according to needs. The preparation method can be used for preparing the nickel oxide-based ceramic which is good in conductivity, relatively high in purity and fine in grain size.

Owner:北京航大微纳科技有限公司

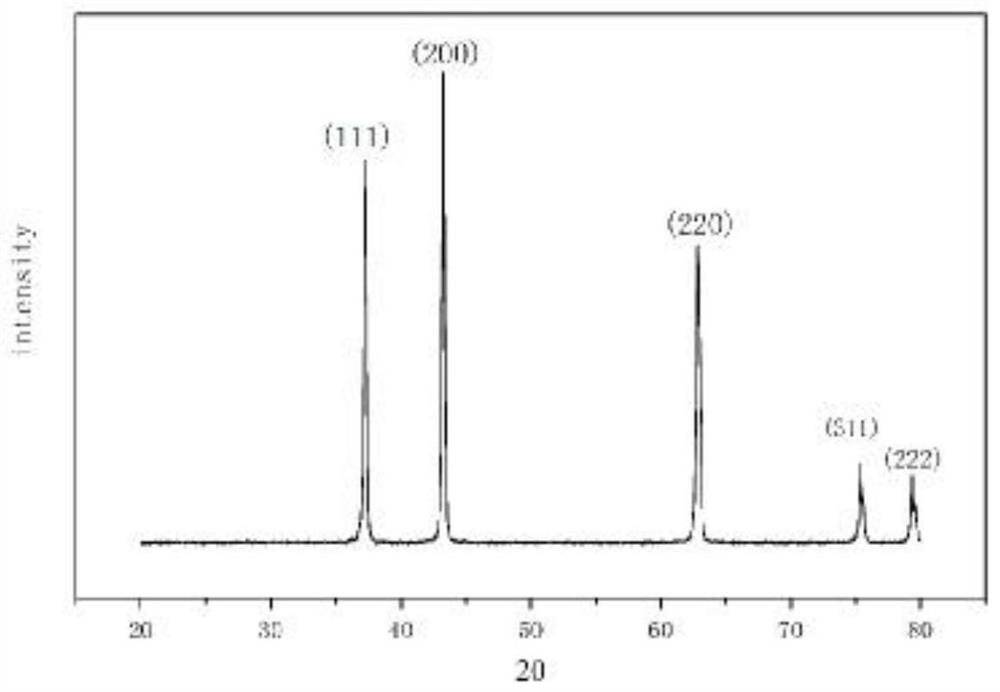

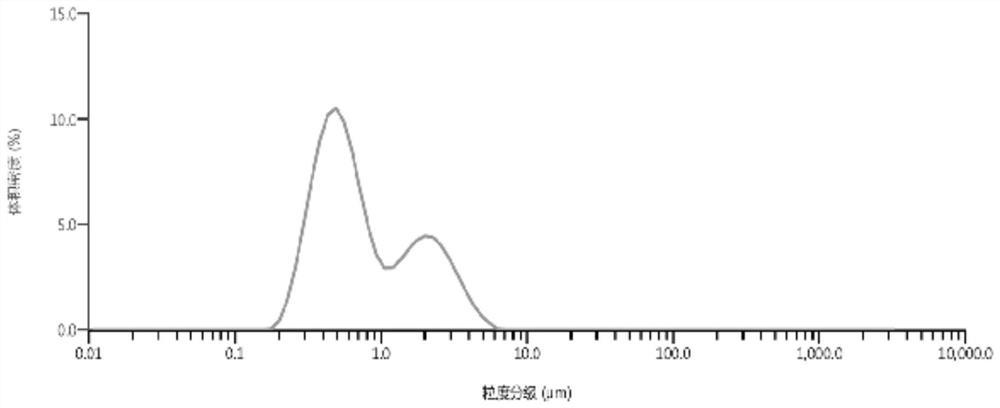

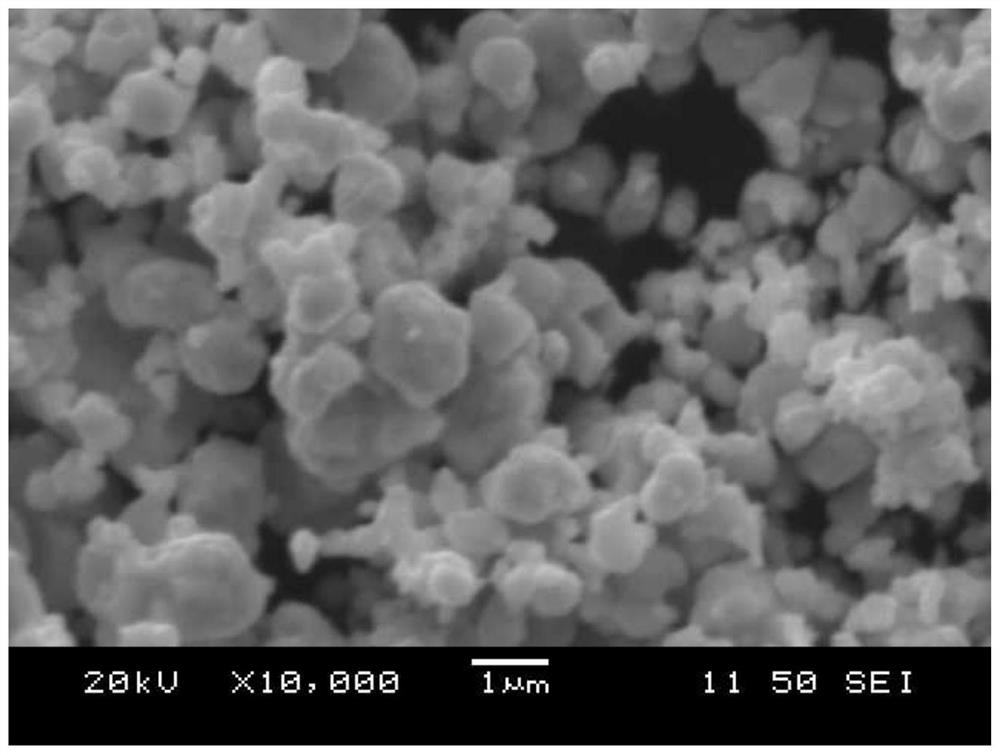

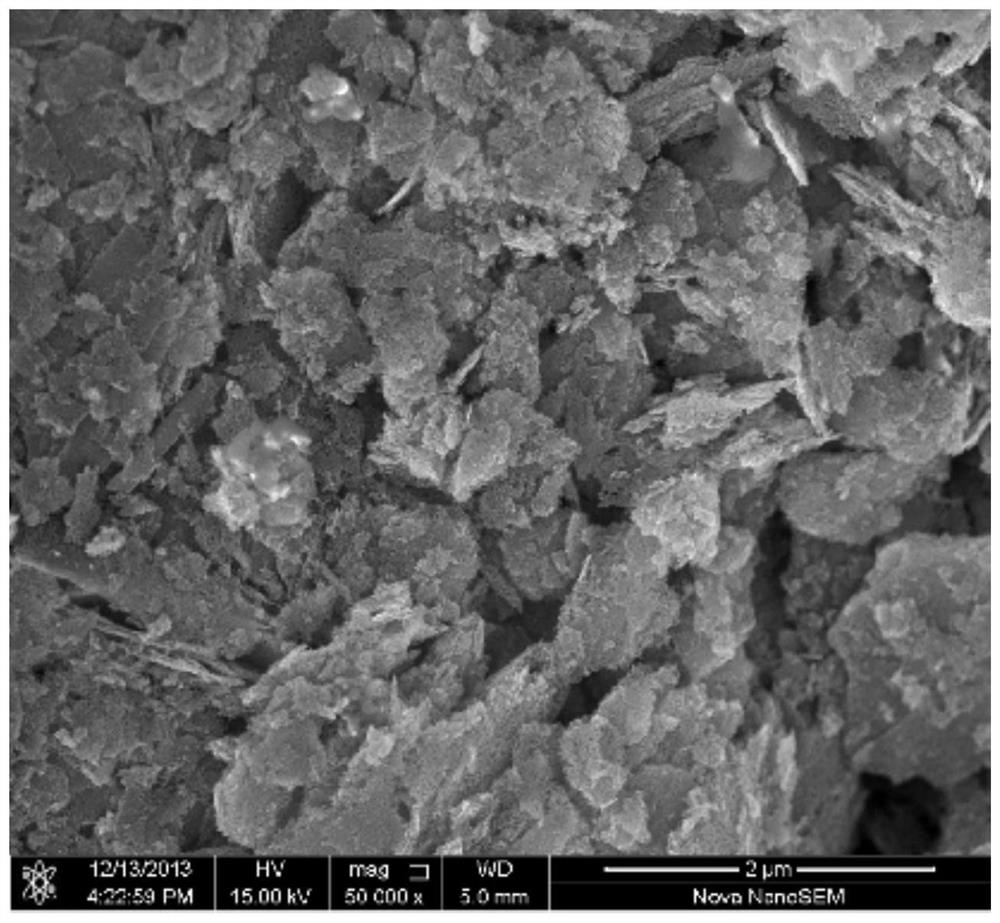

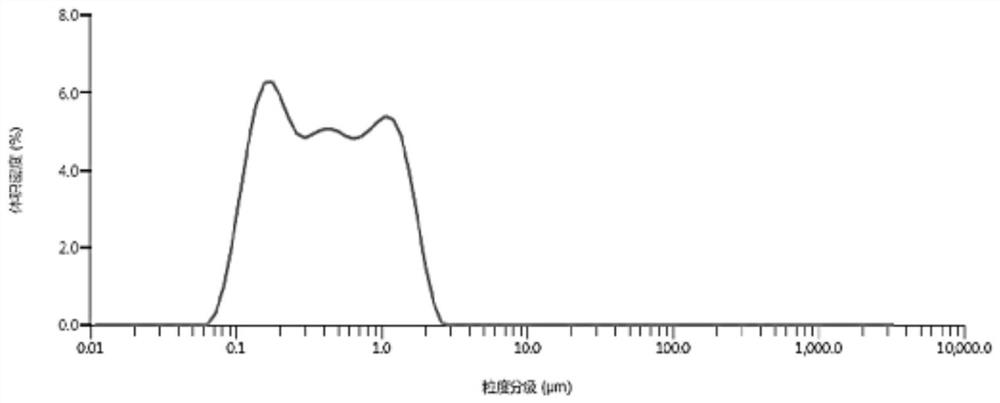

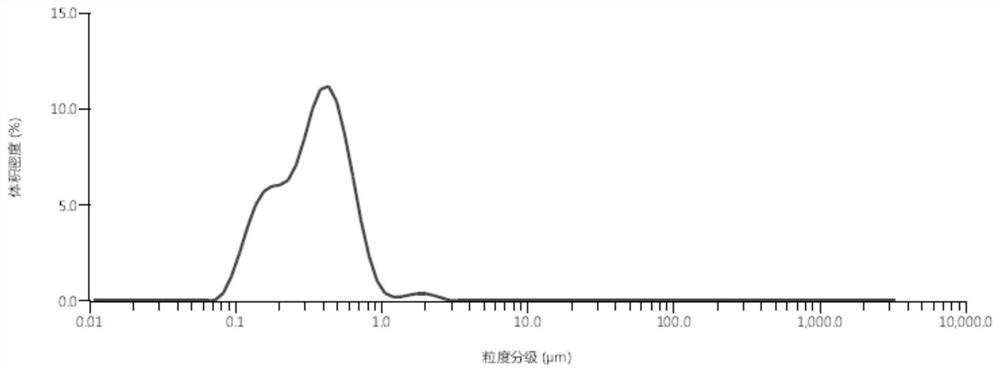

High-purity and high-activity nickel oxide-based powder, preparation method and application

PendingCN112374554AImprove conductivityHigh densityNickel oxides/hydroxidesMetallurgyPhysical chemistry

The invention relates to high-purity and high-activity nickel oxide-based powder, a preparation method and application. The nickel oxide-based powder is mixed powder containing nickel oxide powder anddoping source powder, wherein the total mass fraction of doping source element in the mixed powder is not higher than 10%, the doping source element is selected from one or more of 0-6% of Li, 0-0.3%of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% of V, 0-10% of W and 0-2.5% of Ti, the purity of the nickel oxide powder and the doping source powder is higher than 99.99%, the average particle size is 500 nm-2 [mu]m, and the D50 particle size is 50-800 nm. According to the invention, the powder is high in purity, and the particle size reaches the nanoscale, so that the activity of the powder is improved, and the conductivity of ceramic prepared from the powder is improved.

Owner:BEIJING ORIENT

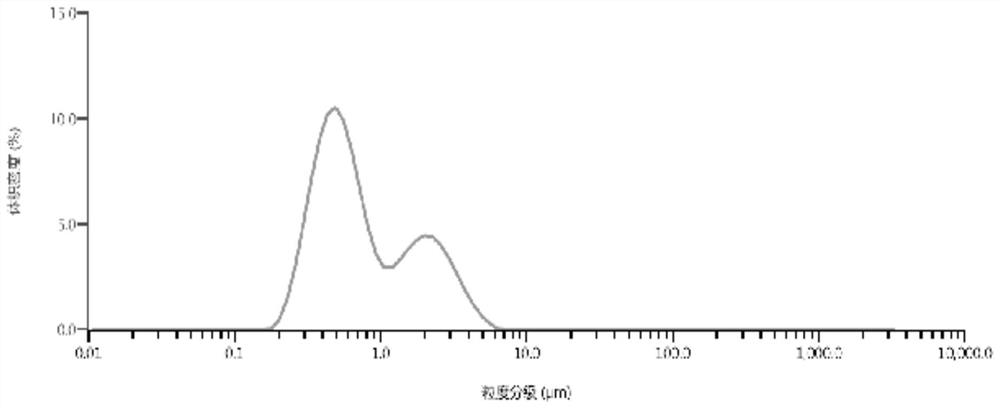

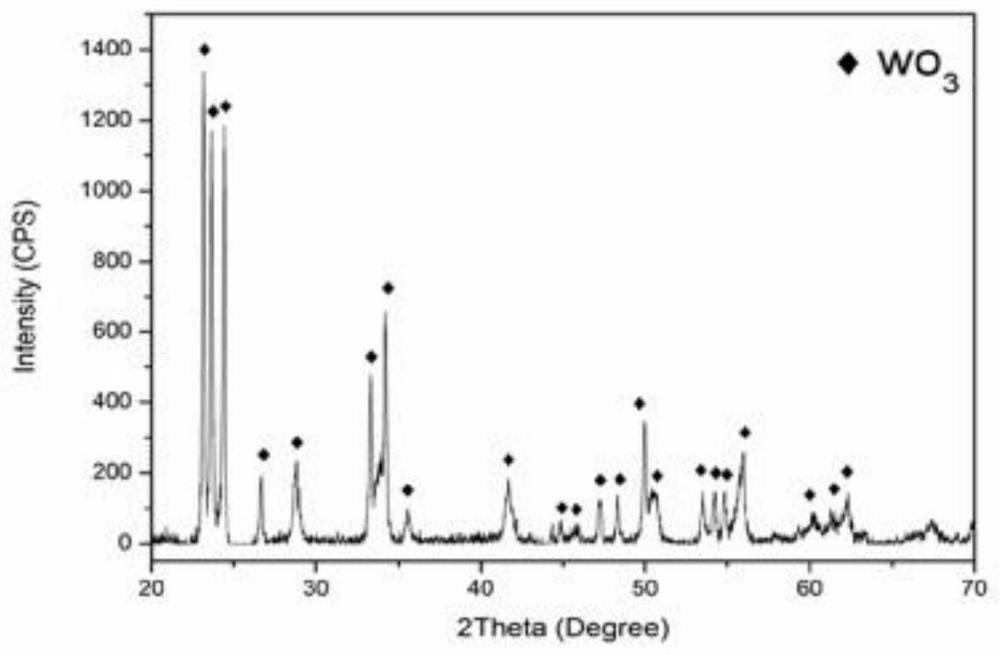

Cold isostatic pressing forming preparation method of tungsten oxide-based ceramic target material

InactiveCN112479707AWide particle size distributionHigh bulk densityVacuum evaporation coatingSputtering coatingHigh densityMetallurgy

The invention relates to a cold isostatic pressing forming preparation method of a tungsten oxide-based ceramic target material, which comprises the following steps of raw material preparation: takingprimary mixed powder containing high-purity tungsten oxide and doping source powder, enabling the doping source to be selected from at least three of Ti, Mo, V, Al, Li and Zr, enabling the purity ofthe mixed powder to be greater than 99.95%, enabling the average particle size to be 500nm to 1800nm, and enabling the D50 particle size to be 200-750nm, wherein the quantitative relation of M1, M2, M3, M4 and M5 conforms to the formula as described in the specification, conducting spray drying, powder filling and compaction, pressing, biscuit degumming and sintering, taking out the sintered blankafter heat preservation, and conducting or not conducting machining according to needs. The cold isostatic pressing forming preparation method can be used for preparing the tungsten oxide-based ceramic target material with good conductivity, higher purity, fine grain size and high density.

Owner:北京航大微纳科技有限公司

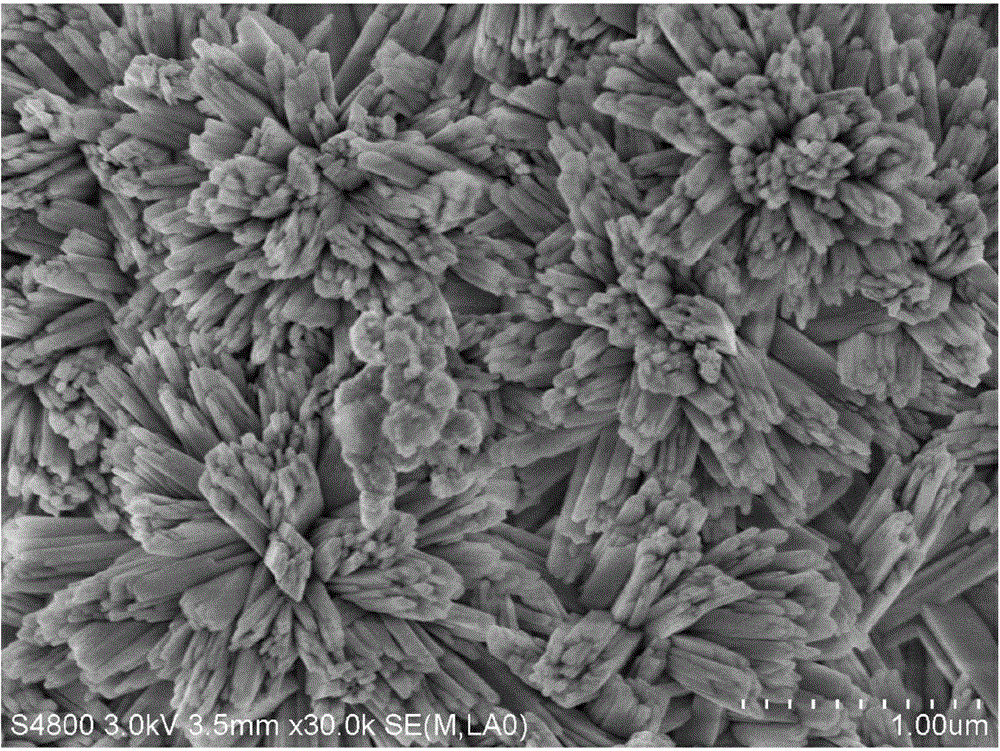

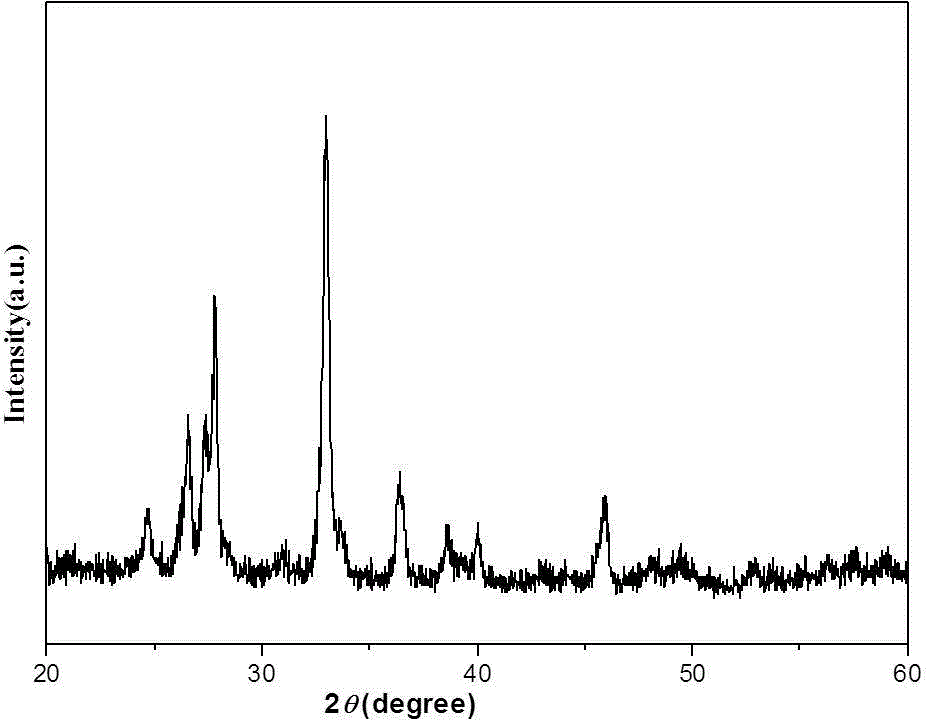

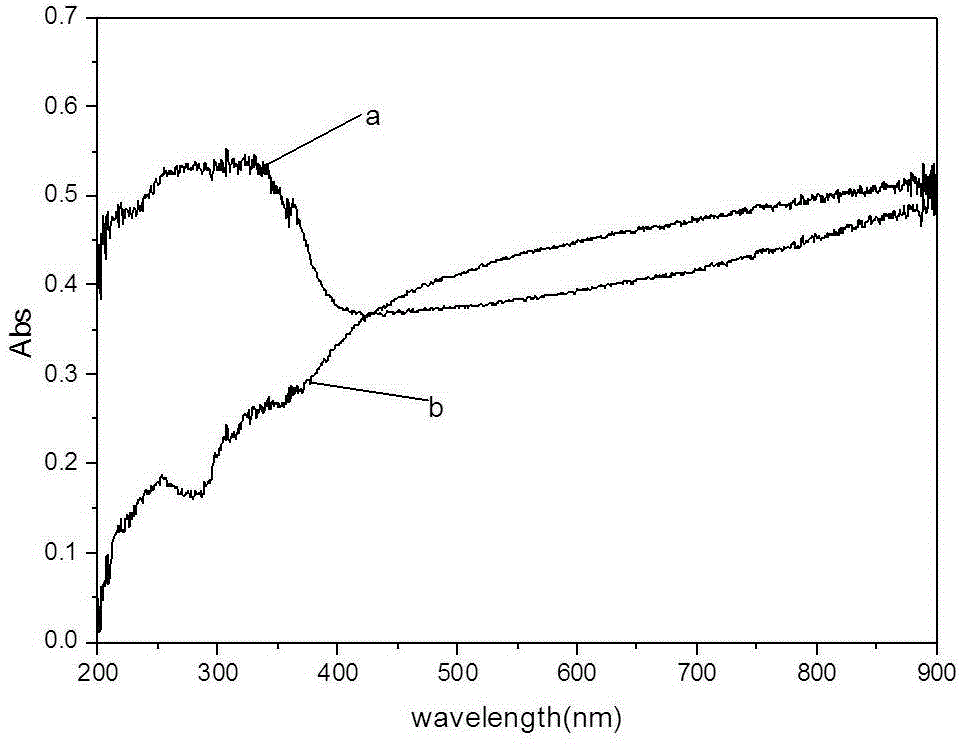

Solvothermal preparation method of silicon-surface vertically-assembled CeO2 nanorod film

InactiveCN104628025AReduce film production costHigh visible light transparencyRare earth metal compoundsSilicon matrixSilicon solar cell

The invention relates to a solvothermal preparation method of a silicon-surface vertically-assembled CeO2 nanorod film, which comprises the following steps: preparing a precursor solution by using ethanol as a solvent, and reacting the raw materials CeCl3 and CO(NH2)2 under the solvothermal conditions of 160-200 DEG C by using a clean silicon chip as a base to prepare the film formed by vertically assembling CeO2 nanorods on the silicon chip surface. The method has the advantages of simple equipment and low film-preparation cost, and does not need to perform high-temperature treatment on the silicon base and film. The prepared film is vertically assembled from the CeO2 nanorods, is thin and uniform, has the advantages of high visible light transparency, favorable adhesiveness and high ultraviolet resistance, has very strong emission peak at 380-390nm, and has wide application prospects in the aspect of crystalline silicon solar cell ultraviolet resistance.

Owner:BOHAI UNIV

Hot press molding preparation method of nickel oxide-based ceramic target material

PendingCN112481592AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedFine grain

The invention relates to a hot press molding preparation method of a nickel oxide-based ceramic target material. The method is characterized by comprising the following steps that A, raw materials areprepared; B, spray drying is carried out; C, a mixed powder body prepared in the step B is put into a hot pressing mold; D, pre-pressurizing and degassing are carried out on the mold; E, hot pressingsintering is carried out, specifically, the pressure intensity is 5-100 MPa, the vacuum degree is 0.1-10 Pa, the sintering temperature is 600-950 DEG C, the heat preservation time is 2-5 h, and the temperature rising speed is 0.5-3 DEG C / min; D, after heat preservation is finished, pressure is relieved, and sintered blanks are taken out; and E, machining is carried out or not carried out according to needs. Through the method the nickel oxide-based ceramic target material with good conductivity, higher purity and fine grain size can be prepared, and the method can realize net size forming andis high in efficiency.

Owner:北京航大微纳科技有限公司

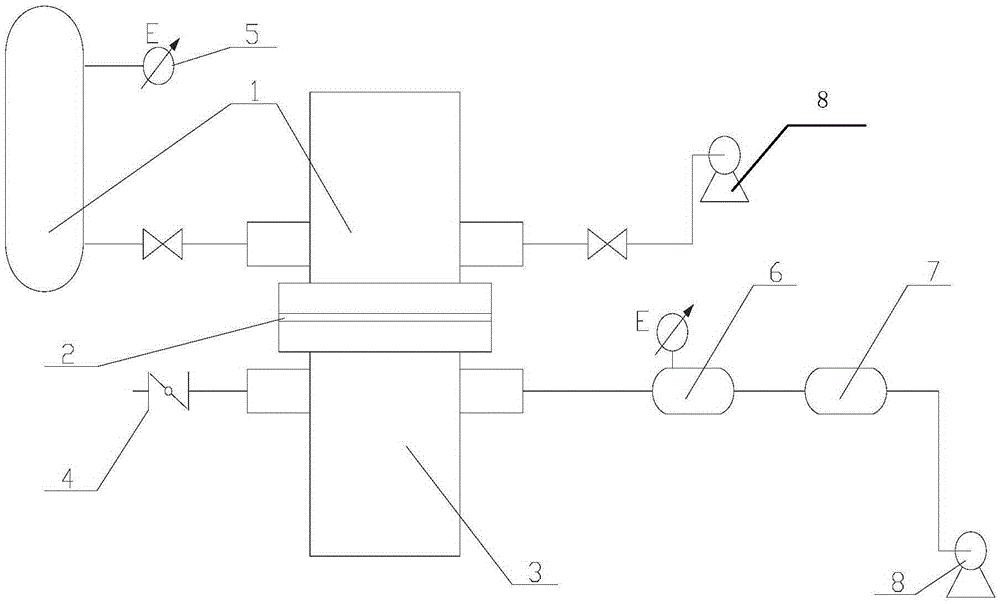

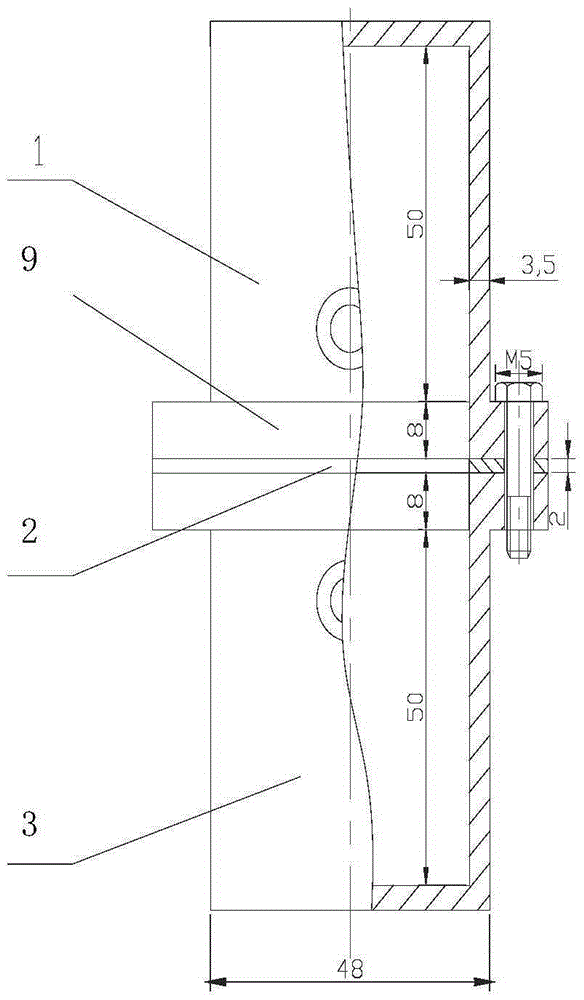

Polyvinyl alcohol hybrid membrane pervaporation device for laboratories and permeation separation technology thereof

InactiveCN105413467AImprove efficiencyEasy to makeDistillationPolyvinyl alcoholSeparation technology

The invention discloses a polyvinyl alcohol hybridized membrane pervaporation device for laboratories and a permeation separation technology thereof. The device comprises a raw material cavity, a pervaporation membrane, a permeation side cavity, a pervaporation pressure adjusting device, a heat exchange device, a penetrating fluid condensing device, a seeping tank and a permeation side vacuum pump device, wherein a polyvinyl alcohol (PVA) and tetraethyl orthosilicate (TEOS) hybrid membrane is taken as the pervaporation membrane. By adopting the device, the problems that a traditional separation technology in the prior art is high in energy consumption and low in separation efficiency can be effectively solved. Due to the fact that a polyvinyl alcohol hybrid membrane for pervaporation is added with tetraethyl orthosilicate, the mechanical performances, such as swelling property and fragility, of the polyvinyl alcohol membrane are improved; the compactness of the polyvinyl alcohol membrane is improved; the permeation flux of the membrane is reduced; the selectivity of the membrane is improved; an esterification reaction is facilitated; and the conversion rate of the esterification reaction is improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com