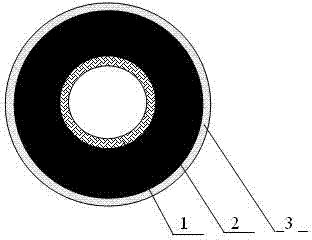

Hollow fiber ceramic oxygen permeation membrane with dual composite asymmetric structure and preparation method thereof

An asymmetric structure, double-composite technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of complex process, increase the production and application cost of hollow fiber ceramic oxygen permeable membrane, and achieve the goal of preparation The effect of simple process, low cost of film production and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

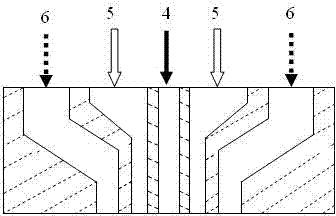

Method used

Image

Examples

Embodiment 1

[0022] La 0.6 Sr 0.4 co 0.2 Fe 0.8 O 3 / La 0.6 Sr 0.4 co 0.2 Fe 0.8 O 3 Preparation of Double Composite Asymmetric Structure Hollow Fiber Oxygen Permeable Membrane

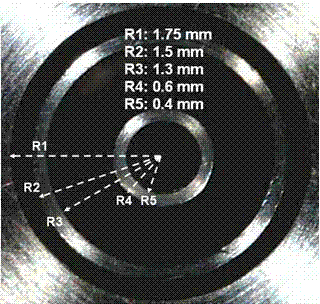

[0023] Use N-methylpyrrolidone solvent (NMP) as solvent, polyethersulfone (PESf) as polymer binder, polyvinylpyrrolidone (PVP) as dispersant, La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3(LSCF) powder is a ceramic oxygen-permeable membrane material, two casting solutions A and B are prepared, and the components of casting solution A are calculated by weight ratio, LSCF:PESf:NMP:PVP=60:3:30: 7. The composition of casting solution B is calculated by weight ratio, LSCF:PESf:NMP:PVP=40:12:45.5:2.5. Vacuum stirring and degassing the casting solutions A and B, then move them to two stainless steel injection tanks respectively, with the casting solution A as the inner material and the casting solution B as the outer material, and use a high-pressure injection pump to pass the casting...

Embodiment 2

[0026] La 0.6 Sr 0.4 co 0.2 Fe 0.8 O 3 / Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 O 3 Double composite asymmetric structure hollow fiber oxygen permeable membrane

[0027] Use NMP as solvent, PESf as polymer binder, PVP as additive, LSCF powder and Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3 (BSCF) The powder is a ceramic oxygen-permeable membrane material, and two casting solutions A and B are prepared, and the components of the casting solution A are calculated by weight ratio, LSCF: PESf: NMP: PVP = 68.4: 6: 25.1: 0.5, B casting solution components calculated by weight ratio, BSCF:PESf:NMP:PVP=50:10:38:2. After vacuum stirring and degassing the casting solution, use a high-pressure syringe pump to press it into the pure water coagulation bath through the spinneret with three concentric ring holes, and the discharge speeds of A casting solution and B casting solution are respectively controlled at 11 mL / min and 2.8 mL / min. The core fluid used was...

Embodiment 3

[0030] La 0.6 Sr 0.4 co 0.2 Fe 0.8 O 3 / SrCo 0.9 Nb 0.1 O 3 Double composite asymmetric structure hollow fiber oxygen permeable membrane

[0031] Using NMP as solvent, PESf as polymer binder, polyvinyl alcohol (PEG) as additive, LSCF powder and SrCo 0.9 Nb 0.1 o 3 (SCNb) The powder is a ceramic oxygen-permeable membrane material, and two casting solutions A and B are prepared, and the components of the casting solution A are calculated by weight ratio, LSCF:PESf:NMP:PEG=70:5.2:24.3: 0.5, B casting solution components calculated by weight ratio, SCNb:PESf:NMP:PEG=42.3:16:40:1.7. After vacuum stirring and degassing the casting solution, use a high-pressure syringe pump to press it into the pure water coagulation bath through the spinneret with three concentric ring holes, and the discharge speeds of A casting solution and B casting solution are respectively controlled at 10.5 mL / min and 2 mL / min. The core fluid used was a mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com