Combined treatment method of phenol-containing coal gas wastewater

A treatment method, coal-to-gas technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the difficulties of large-scale use of treatment technology, COD is difficult to meet standards, and operating costs Advanced problems, to achieve the effect of improving the reaction rate of catalytic oxidation, stabilizing the quality of effluent water, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

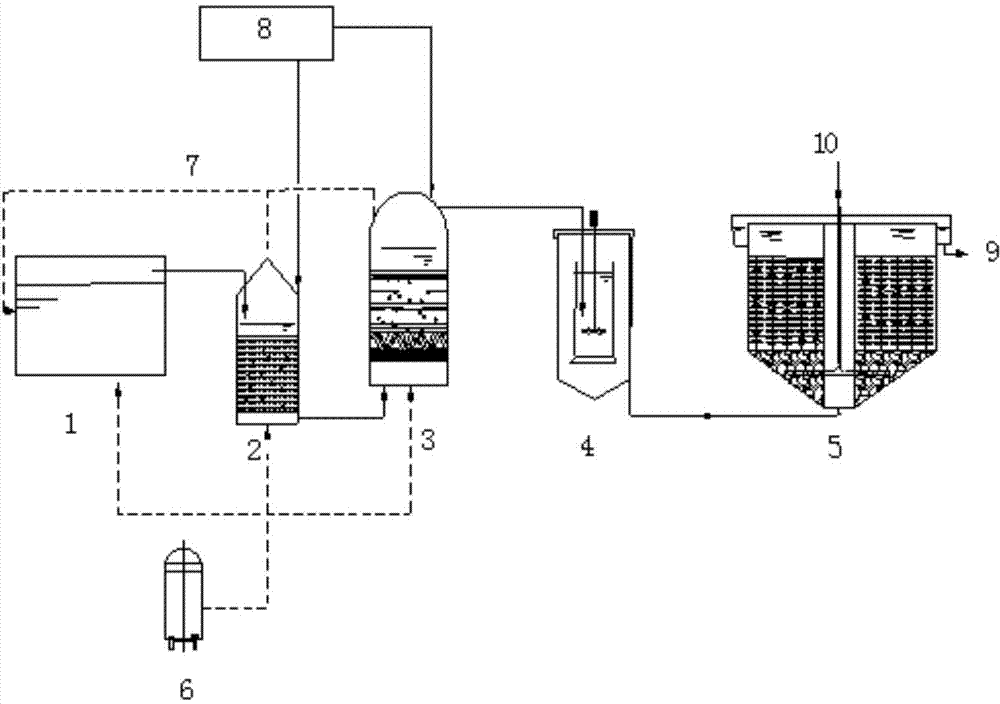

Method used

Image

Examples

Embodiment 1

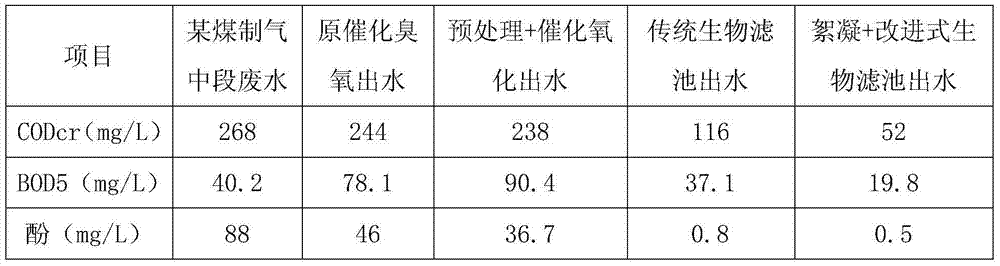

[0039] According to the process described in the present invention, a certain phenol-containing coal gas production wastewater is treated, and the reaction conditions are as follows: first, the wastewater enters the premixing device, the ozone dosage is 69mg / L, and the residence time is 8 minutes; the premixed water enters the ozone catalytic oxidation treatment system , the dosage of ozone is 165mg / L, pH9, and the residence time is 16 minutes; the effluent is separated by gyromagnetic dosing, and the aluminum-containing composite agent is polyaluminum ferric sulfate, and the main component of the polymer flocculant is polyacrylamide; The dosage is 1.8%, 0.008%, pH8, and the residence time is 40 minutes; the effluent treated with the drug enters the biological treatment system, the gas-water ratio is 16:1, and the residence time is 20hr. After treatment, indicators such as COD meet the requirements for discharge or reuse, see Table 1:

[0040]

Embodiment 2

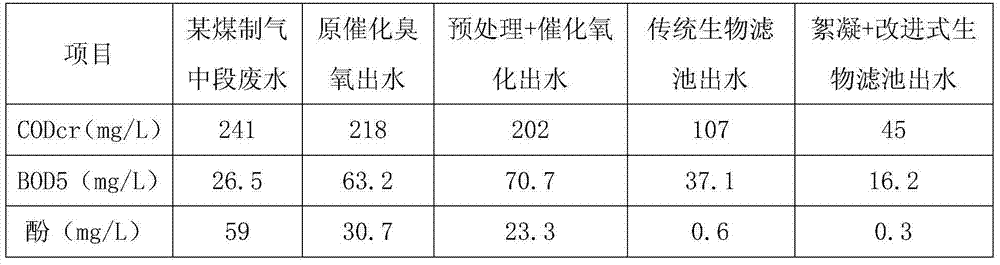

[0042] According to the process of the present invention, a certain phenol-containing coal gas production wastewater is treated, and the reaction conditions are as follows: first, the wastewater enters the premixing device, the ozone dosage is 50 mg / L, and the premixing reaction time is 8 minutes; the premixed water enters the ozone catalytic oxidation Treatment system, the dosage of ozone is 100mg / L, and the reaction time is 15 minutes; the effluent is separated by gyromagnetic dosing, adding 2.0% of aluminum-containing compound agent, 0.01% of polymer flocculant, etc., and the residence time is 30 minutes; dosing treatment The effluent enters the biological treatment system with a gas-water ratio of 20:1 and a residence time of 26hr. After treatment, indicators such as COD meet the requirements for discharge or reuse, see Table 2:

[0043]

Embodiment 3

[0045] According to the process described in the present invention, a certain phenol-containing coal gasification wastewater is treated, and the reaction conditions are as follows: first, the wastewater enters the premixing device, the dosage of ozone is 80mg / L, and the reaction time is 10 minutes; the premixed water enters the ozone catalytic oxidation treatment system , the dosage of ozone is 180mg / L, and the reaction time is 12 minutes; the effluent is separated by gyromagnetic dosing, adding 1.2% of aluminum-containing compound agent, 0.002% of polymer flocculant, etc., and the residence time is 60 minutes; Biological treatment system, the gas-water ratio is 25:1, and the residence time is 18hr. After treatment, indicators such as COD meet the requirements for discharge or reuse, see Table 3:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com