Contact lens material and preparing method thereof

A contact lens and raw material technology, applied in the direction of instruments, optics, optical components, etc., can solve the problems affecting the wearing comfort of contact lenses, affecting the biocompatibility of contact lenses, and easily residual pectinase, etc., and achieve low production costs , high production efficiency, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

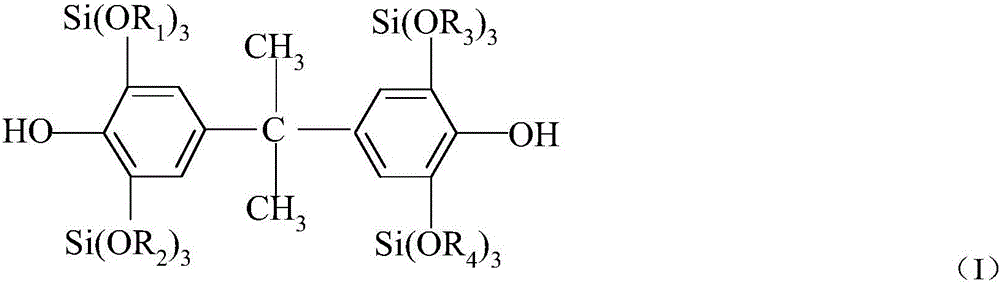

[0035] A contact lens material, the raw material for preparing said contact lens material includes 2,2'-bis(4-hydroxyl-3-trialkoxysilyl-5-trialkoxysilyl) represented by formula (I) - 30 parts of siloxane prepolymer of phenyl)propane, 30 parts of 2,4-toluene diisocyanate, 5 parts of acrylic acid, 5 parts of alkacrylic acid, 5 parts of alkoxyacrylic acid, 5 parts of acrylamide, dichloride 0.005 parts of zinc, 0.002 parts of azobisisobutyronitrile, 0.003 parts of azobisisoheptanonitrile, 0.001 parts of dibutyltin dilaurate;

[0036]

[0037] In (I), R1, R2, R3, R4 represent methyl (Me), ethyl (Et), n-propyl (n-Pr), n-butyl (n-Bu), phenyl (Ph) respectively.

Embodiment 2

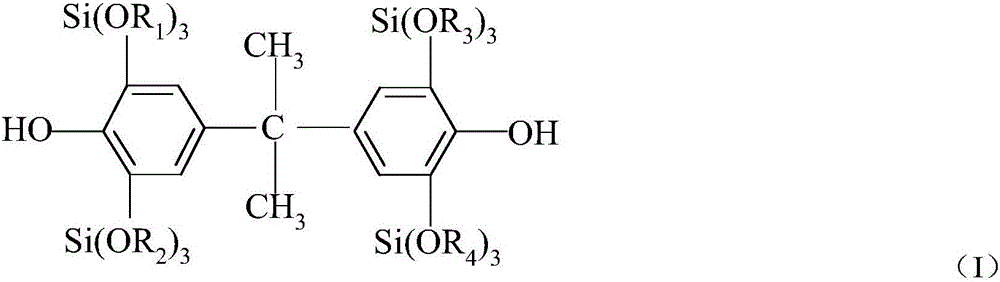

[0039] A contact lens material, the raw material for preparing said contact lens material includes 2,2'-bis(4-hydroxyl-3-trialkoxysilyl-5-trialkoxysilyl) represented by formula (I) -50 parts of siloxane prepolymer of -phenyl) propane, 60 parts of 2,6-toluene diisocyanate, 30 parts of hydroxyethyl ester, 30 parts of N-vinylpyrrolidone, 0.01 part of aluminum trichloride, isopropyl peroxide 0.005 parts of benzene, 0.005 parts of dibenzoyl peroxide, 0.005 parts of dibutyltin dilaurate;

[0040]

[0041] In (I), R1, R2, R3, R4 respectively represent a chloromethyl group, a chloroethyl group, a chloro-n-propyl group, a chloro-n-butyl group, a chlorophenyl group.

Embodiment 3

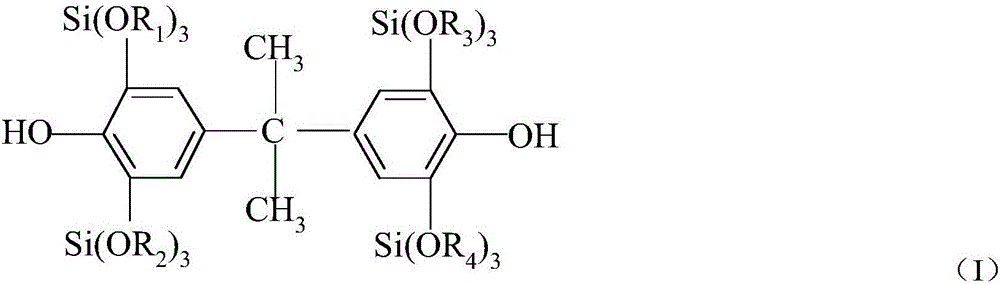

[0043] A contact lens material, the raw material for preparing said contact lens material includes 2,2'-bis(4-hydroxyl-3-trialkoxysilyl-5-trialkoxysilyl) represented by formula (I) - 35 parts of siloxane prepolymer of phenyl)propane, 40 parts of 2,4-toluene diisocyanate, 15 parts of alkylacrylamide, 15 parts of alkoxyacrylamide, 0.006 part of magnesium dichloride, p-menthane peroxide 0.003 parts, 0.003 parts of tert-butyl peroxide, 0.002 parts of dibutyltin dilaurate;

[0044]

[0045] In (I), R1, R2, R3, R4 respectively represent a chloromethyl group, ethyl group, n-propyl group, n-butyl group, phenyl group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com