Alumina doped mixed conductive dense oxygen penetrating membrane material

A kind of technology of alumina and oxygen permeable membrane, which is applied in the direction of semipermeable membrane separation, membrane technology, oxygen production, etc., can solve the problems of insufficient membrane material structure and chemical stability, high membrane cost, etc., and achieve good chemical and structural stability , Improve mechanical strength and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

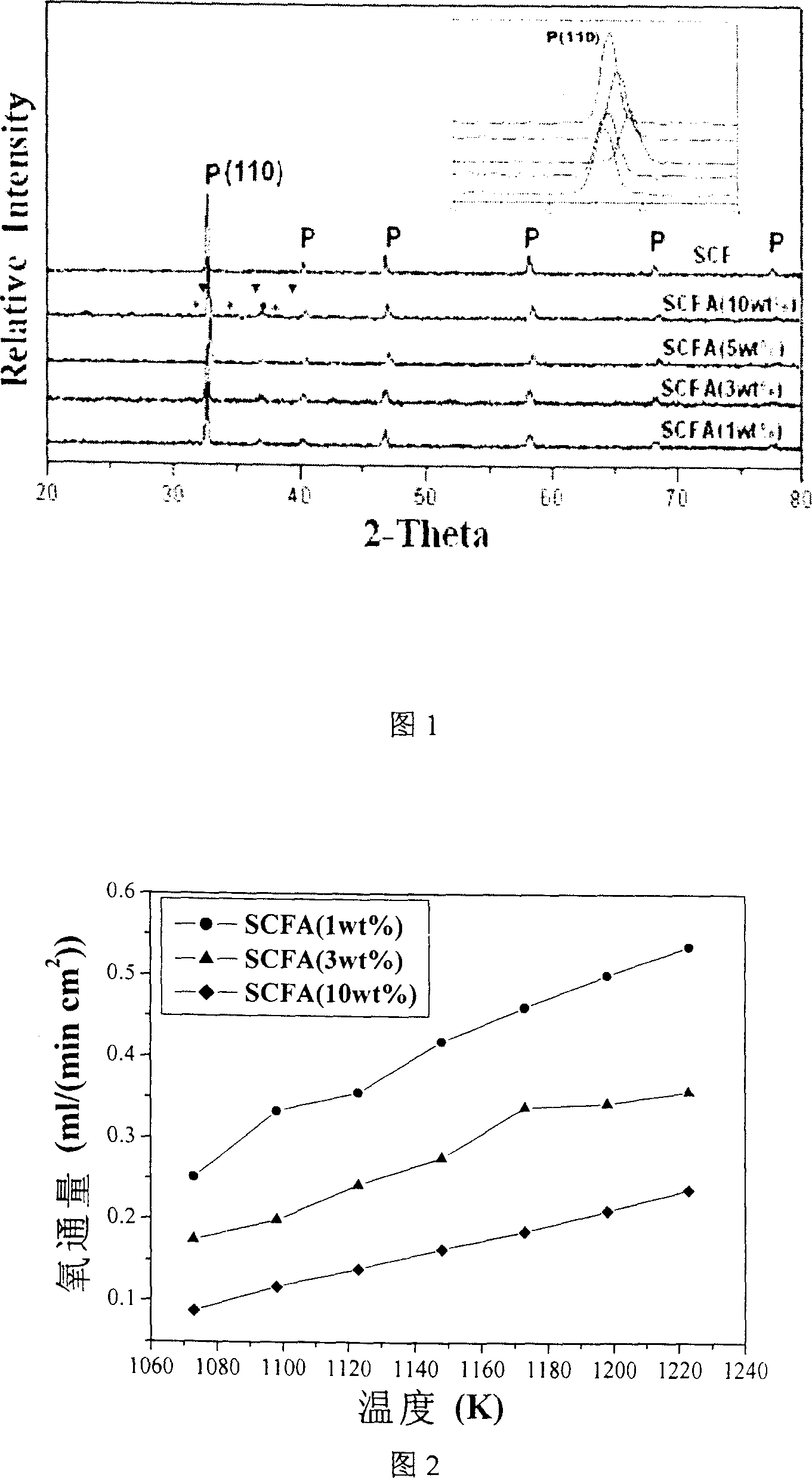

[0018] The existing perovskite material SrCo 0.8 Fe 0.2 o 3-δ and Al 2 o 3 The materials of the present invention with doping amounts of 1, 3, 5 and 10% were respectively calcined at 950° C. in an air atmosphere for 5 hours, and then subjected to X-ray diffraction test. The results are shown in FIG. 1 .

[0019] It can be seen from Figure 1 that Al 2 o 3 There is no impurity peak in the material with a doping amount of 1-5% by weight, indicating that a complete perovskite structure has been formed; Al 2 o 3 The doping amount is 10%, such as Al 2 o 3 、CoAl 2 o 4 and SrFe 7 al 5 o 19 and other miscellaneous phases. with SrCo 0.8 Fe 0.2 o 3-δ material compared to doped 10% Al 2 o 3 The diffraction peak of the material around 32° has a certain shift, indicating that the microstructure of the material has changed.

Embodiment 2

[0021] Will Al 2 o 3 Doping amount is 1, 3 and 10% under the pure oxygen permeability condition of the material of the present invention, respectively with oxygen partial pressure gradient being 0.21 / 1×10 -3 atm for oxygen transmission rate test, the results shown in Figure 2.

[0022] It can be seen from Figure 2 that the oxygen permeability decreases with the decrease of temperature, and with the increase of Al 2 o 3 decreased with increasing doping levels.

Embodiment 3

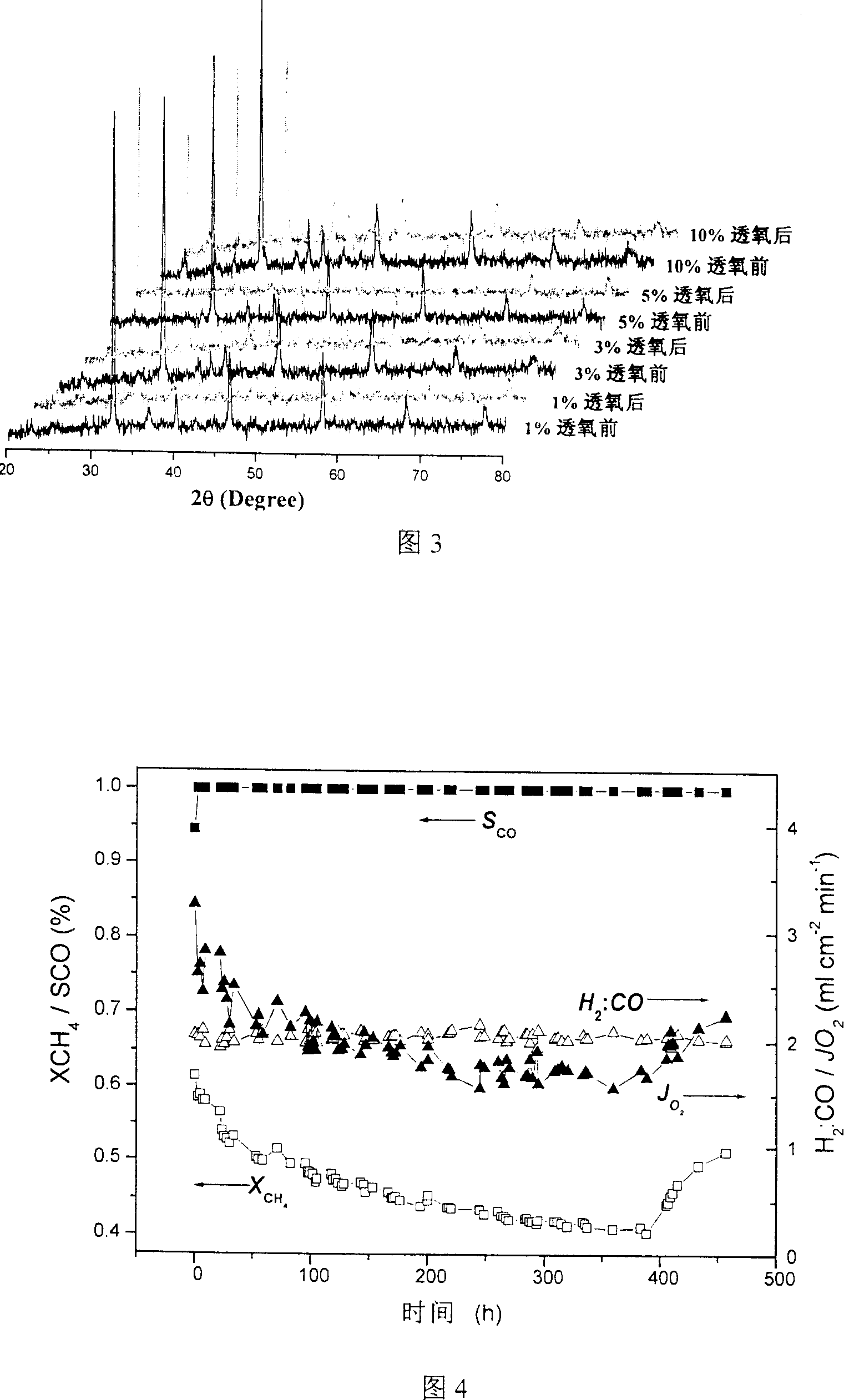

[0024] to Al 2 o 3 The materials of the present invention with doping amounts of 1, 3, 5 and 10% were subjected to X-ray diffraction tests before and after oxygen permeability, and the results are shown in FIG. 3 .

[0025] As can be seen from the results in Figure 3, 1-5% Al 2 o 3 Doped SrCo 0.8 Fe 0.2 o 3-δ The structure remained almost the same before and after the oxygen permeability test, while 10% Al 2 o 3 Doped SrCo 0.8 Fe 0.2 o 3-δ Subtle changes have taken place in the material of the film, indicating that the microstructure of the latter material changes more than that of Al during the membrane catalytic reaction. 2 o 3 Materials with lower doping levels will be more pronounced. Therefore the Al in the material of the present invention 2 o 3 Doping amount does not exceed 20%, Al 2 o 3 The optimal range of the doping amount is 1-10%, and the material within this range of doping amount is relatively stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com