High-purity and high-activity nickel oxide-based powder, preparation method and application

A technology based on nickel oxide and nickel oxide powder, applied in the direction of nickel oxide/nickel hydroxide, etc., which can solve the problems of easy pollution of the environment, inability to further refine the powder, and inability to accurately control the particle size of the powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1: (adopt hot isostatic pressing method to prepare)

[0090] 1. Preparation of nickel oxide powder:

[0091] (a) Pass high-purity nickel vapor into oxygen at 1650°C to form high-nickel oxide;

[0092] (b) mixing high-nickel oxide and high-purity graphite reducing agent and roasting at 700°C to obtain a nickel oxide block;

[0093] (c) jet pulverization obtains nickel oxide coarse powder;

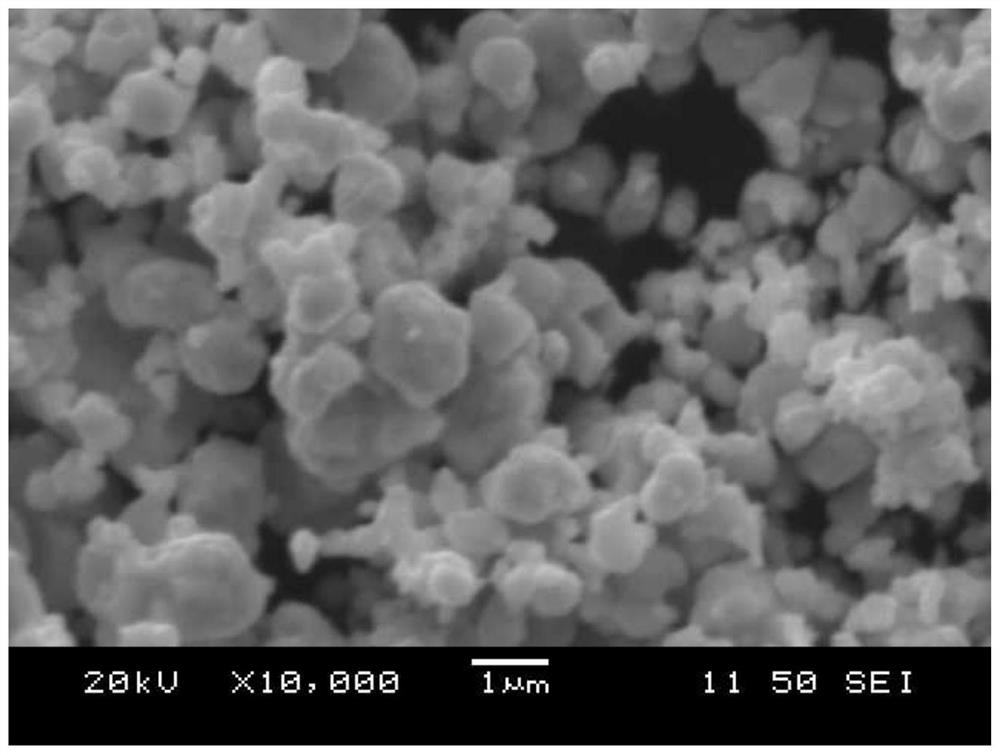

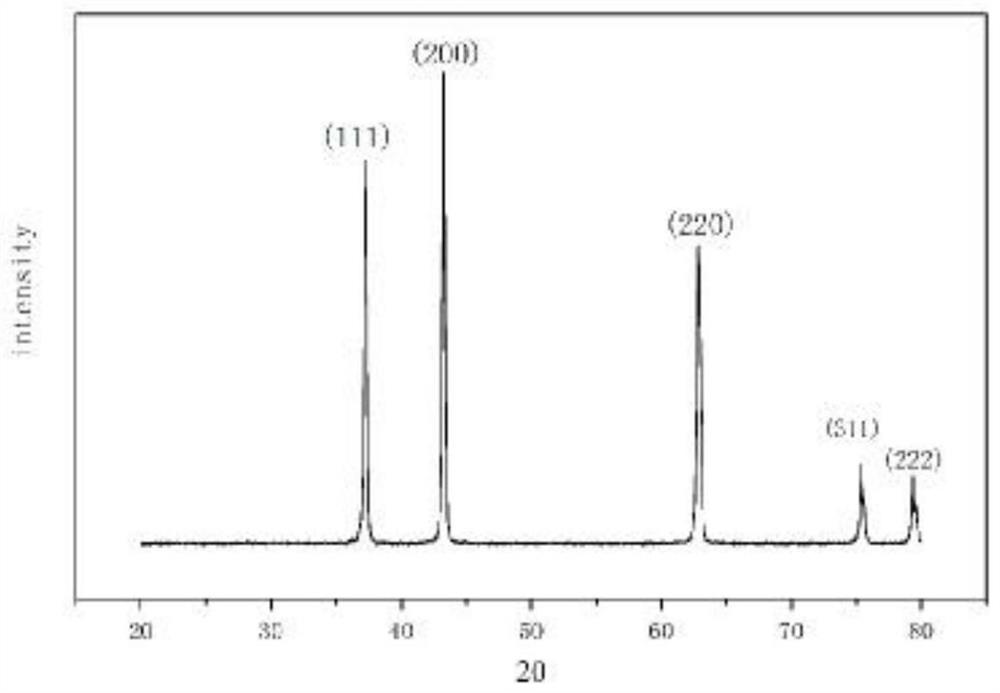

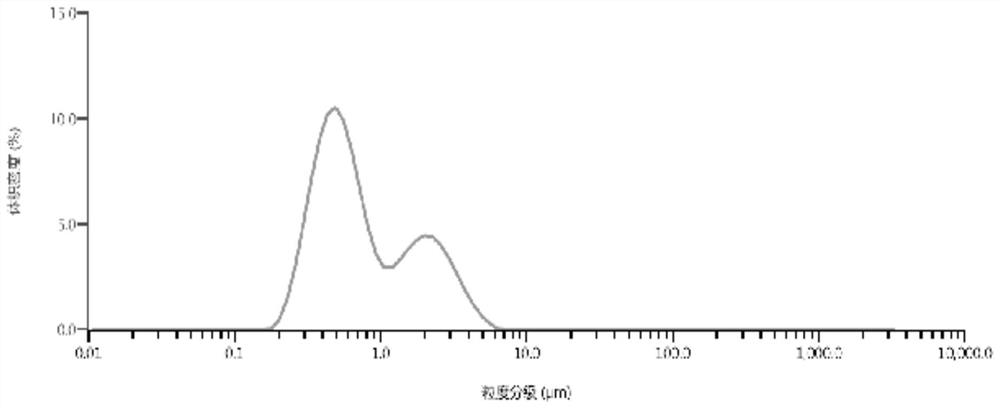

[0094] (d) The nickel oxide coarse powder is subjected to wet ball milling: the ball-to-material ratio is 3:1, the average diameter of the balls is 5 mm, the volume of the balls and the slurry accounts for 50% of the volume of the grinding chamber, and the ball mills for 15 hours to obtain the oxidized nickel oxide powder. Nickel powder; the purity of the obtained nickel oxide powder is 99.99%, and the micrograph of the nickel oxide powder is figure 1 , the XRD pattern of nickel oxide powder is figure 2 , the PSD picture of nickel oxide powder is image 3 , it can b...

Embodiment 2

[0110] Embodiment 2: (adopt hot isostatic pressing method to prepare)

[0111] The difference between this example and Example 1 is that the dopant source components in the raw material preparation step of A are Li:Na:Zn:W=1:0.5:0.8:1.2 in terms of molar ratio;

[0112] The obtained ceramic target has an average grain size of 4 μm, a doped phase size of 200 nm, a bulk electrical conductivity of 25 S / cm, and a relative density of 99.1% measured by the drainage method.

Embodiment 3

[0113] Embodiment 3: (adopt hot isostatic pressing method to prepare)

[0114] 1. Preparation of nickel oxide powder:

[0115] (a) Pass high-purity nickel vapor into oxygen at 1600°C to form high-nickel oxide;

[0116] (b) roasting high nickel oxide in a hydrogen atmosphere at 1000°C to obtain a nickel oxide block;

[0117] (c) jet pulverization obtains nickel oxide coarse powder;

[0118] (d) The nickel oxide coarse powder is subjected to wet ball milling: the ball-to-material ratio is 2:1, the average diameter of the balls is 0.3mm, the volume of the balls and the slurry accounts for 2 / 3 of the volume of the grinding chamber, and the ball mills for 20 hours to obtain the Described nickel oxide powder; The purity of the nickel oxide powder that obtains is 99.995%, and the micrograph of the nickel oxide powder that present embodiment prepares is Figure 5 , the PSD picture is Image 6 , the average particle size of the nickel oxide powder prepared in this example is 500n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com