Preparation method and application of hybrid pervaporation membrane

A pervaporation membrane and pervaporation technology, which is applied in the preparation and application of hybrid pervaporation membranes, achieves the effects of strong controllability, abundant raw material sources, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

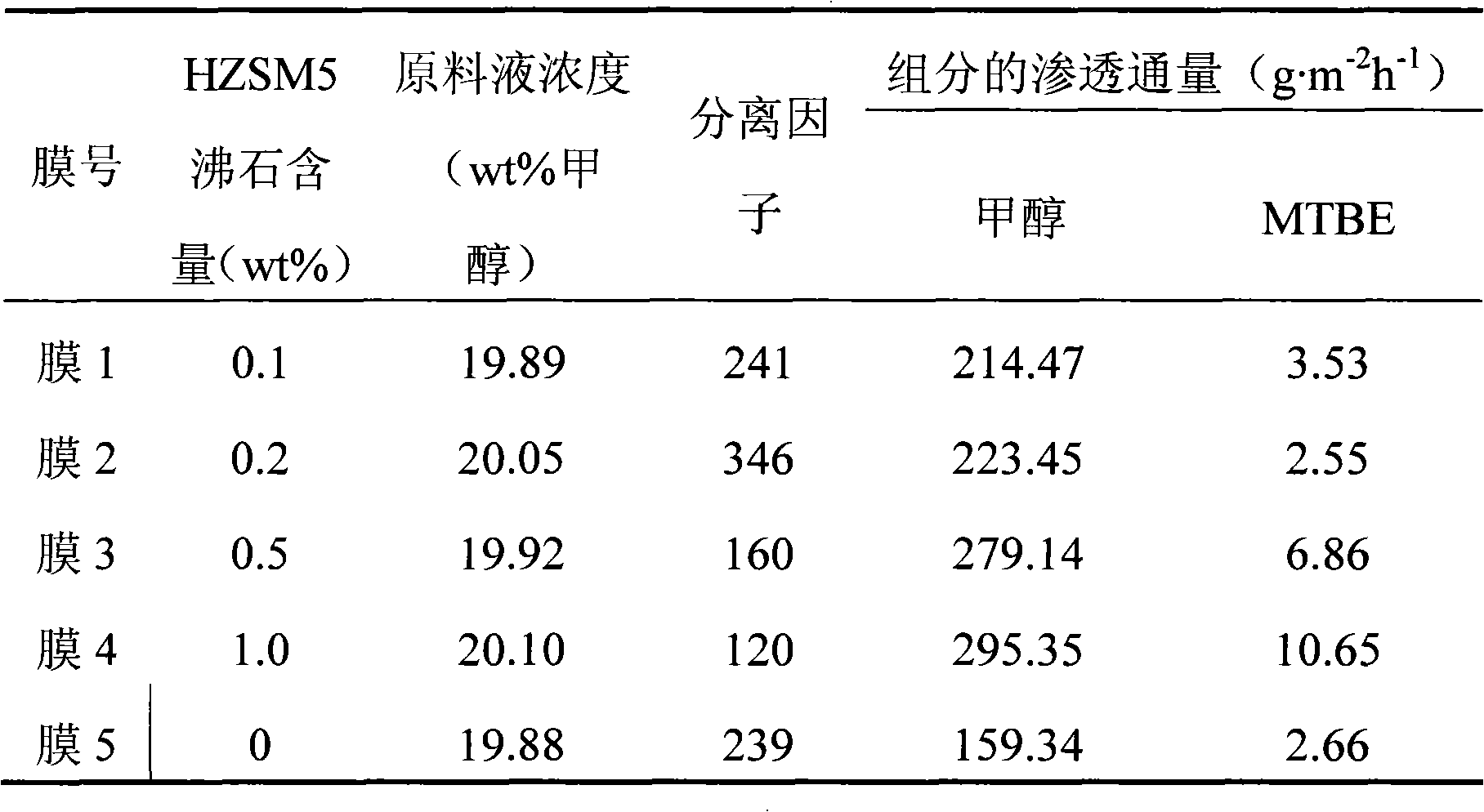

Embodiment 1

[0013]0.75g of cellulose acetate bound to 54.5-56.0wt% acetic acid and 0.0038g of ground HZSM5 zeolite with an average particle size of 0.5 μm were dissolved in 14.25g of N, N-dimethylformamide, and the After stirring at a rotating speed for 1 h to dissolve the cellulose acetate, continue to combine stirring at a rotating speed of 500 r / min and an ultrasonic power of 160 w for 1 h to obtain 15,0038 g of a uniformly dispersed casting solution containing 0.50 wt % zeolite. Let it stand for 10 minutes for defoaming to obtain a uniform and foam-free casting solution. Pour the foam-free casting solution on a clean glass plate, scrape the film with a 600 μm thick scraper, and dry it at 20°C for 26 hours to form a film (film 1). The average thickness of the film is 12 μm.

Embodiment 2

[0015] Dissolve 0.75g of cellulose acetate bound to 54.5-56.0wt% acetic acid and 0.0075g of ground HZSM5 zeolite with an average particle size of 0.5 μm in 14.25g of N,N-dimethylformamide at a speed of 500r / min After stirring for 1 hour to dissolve the cellulose acetate, continue to combine stirring at a speed of 500 r / min and an ultrasonic power of 160 W for 1 hour to obtain 15.0075 g of uniformly dispersed zeolite content of 1 wt % casting solution. Let it stand for 10 minutes for defoaming to obtain a uniform and foam-free casting solution. Pour the foam-free casting solution on a clean glass plate, scrape the film with a 600 μm thick scraper, and dry it at 20°C for 26 hours to form a film (film 2). The average thickness of the film is 12 μm.

Embodiment 3

[0017] Dissolve 0.75g of cellulose acetate bound to 54.5-56.0wt% acetic acid and 0.0114g of ground HZSM5 zeolite with an average particle size of 0.5 μm in 14.25g of N,N-dimethylformamide at a speed of 500r / min After stirring for 1 h to dissolve the cellulose acetate, continue to combine stirring at a speed of 500 r / min and a power of 160 w for 1 h to obtain 15.0114 g of a uniformly dispersed casting solution with a zeolite content of 1.5 wt%. Let it stand for 10 minutes for defoaming to obtain a uniform and foam-free casting solution. Pour the foam-free casting solution on a clean glass plate, scrape the film with a 600 μm thick scraper, and dry it at 20°C for 26 hours to form a film (film 3). The average thickness of the film is 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com