Preparation method of cross-linked polyphenyl ether composite proton exchange membrane

The technology of proton exchange membrane and polyphenylene ether is applied in the field of preparation of cross-linked polyphenylene ether composite proton exchange membrane, which can solve the problems of low stability and high cost of proton exchange membrane, and achieve good stability and low cost of membrane production. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

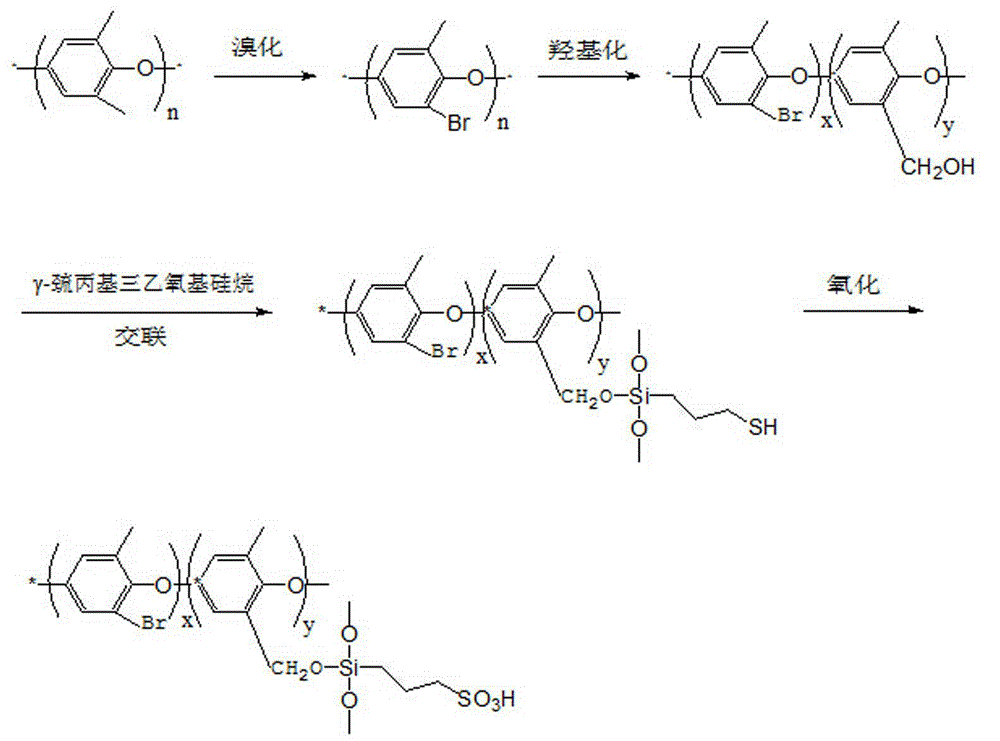

[0021] A preparation method for a cross-linked polyphenylene ether composite proton exchange membrane, comprising the following steps:

[0022] A polyphenylene ether solution with a mass of 5 grams was dissolved in a chlorobenzene solution with a mass of 10 grams to obtain a polyphenylene ether solution;

[0023] Heat the polyphenylene ether solution to 90°C and stir for 1 hour;

[0024] Then add 0.5 g of brominating reagent to the above polyphenylene ether solution, and stir for 10 hours, then cool to room temperature and filter to obtain the filtrate, wash and dry the filtrate to obtain brominated polyphenylene ether. The bromination reagent is elemental bromine;

[0025] Soak brominated polyphenylene ether in a sodium hydroxide solution with a temperature of 80°C and a concentration of 2 mol / L for 20 hours to obtain hydroxylated brominated polyphenylene ether;

[0026] The hydroxylated brominated polyphenylene ether was dissolved in the chlorobenzene solution to obtain th...

Embodiment 2

[0032] A preparation method for a cross-linked polyphenylene ether composite proton exchange membrane, comprising the following steps:

[0033] A polyphenylene ether solution with a quality of 6 grams was dissolved in a chlorobenzene solution with a quality of 60 grams to obtain a polyphenylene ether solution;

[0034] Heat the polyphenylene ether solution to 110°C and stir for 3 hours;

[0035] Then add 1.5 grams of brominating reagent to the above polyphenylene ether solution, stir for 13 hours, then cool to room temperature and filter to obtain the filtrate, wash and dry the filtrate to obtain brominated polyphenylene ether. The bromination reagent is N-bromosuccinimide;

[0036] Soak brominated polyphenylene ether in a sodium hydroxide solution with a temperature of 82°C and a concentration of 2.4mol / L for 30 hours to obtain hydroxylated brominated polyphenylene ether;

[0037] The hydroxylated brominated polyphenylene ether is dissolved in the chlorobenzene solution to ...

Embodiment 3

[0043] A preparation method for a cross-linked polyphenylene ether composite proton exchange membrane, comprising the following steps:

[0044] A polyphenylene ether solution with a mass of 7 grams was dissolved in a chlorobenzene solution with a mass of 120 grams to obtain a polyphenylene ether solution;

[0045] Heat the polyphenylene ether solution to 130°C and stir for 5 hours;

[0046]Then add 2.5 grams of brominating reagent to the above polyphenylene ether solution, and stir for 16 hours, then cool to room temperature and filter to obtain the filtrate, wash and dry the filtrate to obtain brominated polyphenylene ether. The bromination reagent is elemental bromine;

[0047] Soak brominated polyphenylene ether in a sodium hydroxide solution with a temperature of 84°C and a concentration of 2.8 mol / L for 40 hours to obtain hydroxylated brominated polyphenylene ether;

[0048] The hydroxylated brominated polyphenylene ether is dissolved in the chlorobenzene solution to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com