Side-chain sulfonic acid type polyarylether, preparation method thereof and application of polyarylether in preparation of proton exchange membrane

A technology of polyarylether and chain sulfonic acid, which is applied in the field of polymer functional materials, can solve the problems of polymers losing mechanical properties, polymer swelling rate is serious, and polymer phase separation is not obvious enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

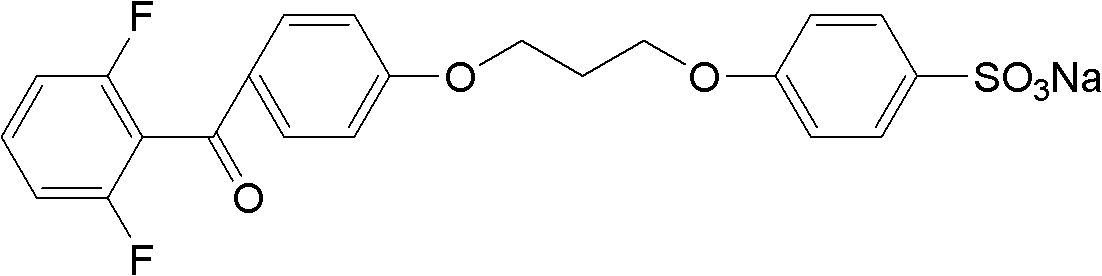

[0023] Example 1: Preparation of 4-(3-(4-(2,6-difluorobenzoyl)phenoxy)propoxy)sodium benzenesulfonate difluorosulfonated monomer

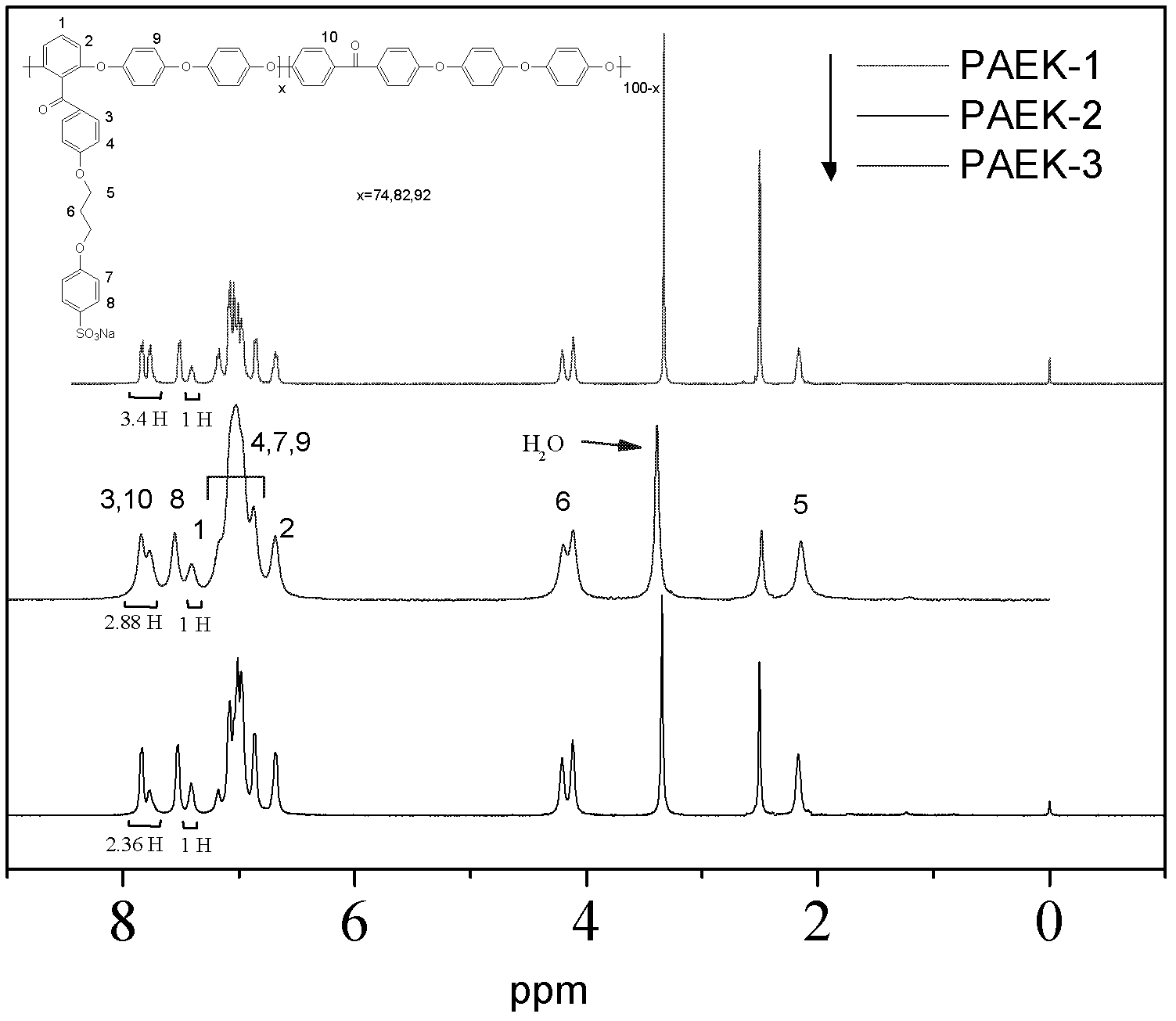

[0024] Put 4-(2,6'-difluorophenylcarbonyl) diphenylpropyl ether (10g) into 30mL concentrated sulfuric acid solution with a mass fraction of 95-98% at 50°C, stir for 4h; then discharge in 100ml neutralized with 1 mol / l sodium hydroxide solution to pH=7, and filtered to obtain a white solid. After recrystallization, sodium 4-(3-(4-(2,6-difluorobenzoyl)phenoxy)propoxy)benzenesulfonate difluorosulfonated monomer was obtained with a yield of 40%. FT-IR (KBr: 1 034cm -1 (-SO 3 Na), 1660cm -1 (C=O), 1257cm -1 (C-O-C). 1 H NMR (300MHz, DMSO) δ7.78(d, J=8.4Hz, 2H), 7.65(d, J=7.1Hz, 1H), 7.52(d, J=8.3Hz, 2H), 7.30(t, J =8.1Hz, 2H), 7.14(d, J=8.7Hz, 2H), 6.88(d, J=8.5Hz, 2H), 4.26(t, J=5.9Hz, 2H), 4.14(t, J=5.7 Hz, 2H), 2.41-1.98 (m, 2H).

Embodiment 2

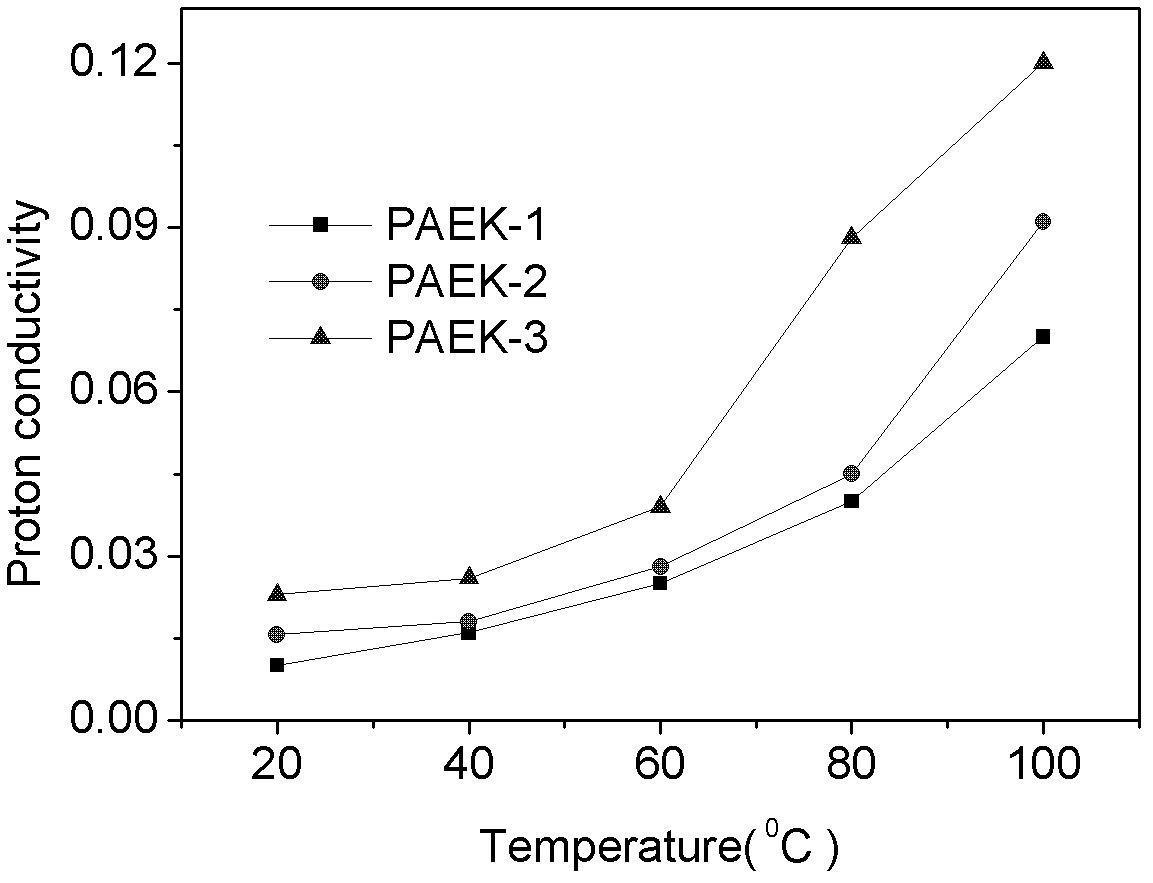

[0025] Embodiment 2: the preparation of polymer PAEK-1

[0026] In a three-neck flask equipped with a stirrer, a water dispenser and a nitrogen port, add 10 mmol of 4,4'-dihydroxydiphenyl ether, 7.36 mmol of 4-(3-(4-(2,6-difluoro Benzoyl)phenoxy)propoxy)sodium benzenesulfonate, 2.64mmol of 4,4'-difluorobenzophenone, 11mmol of anhydrous potassium carbonate, 40ml of sulfolane and 8ml of toluene were put into the three-necked flask In the process, nitrogen gas was passed, and the temperature was raised to 120°C. Reflux with water for 2 hours, steam the dehydrating agent, raise the temperature to 175°C and react for 6 hours, then pour the reaction mixture into water to obtain a polymer, then crush it into particles of about 10 mesh with a pulverizer, and then filter it with a Buchner funnel for more After washing with deionized water and ethanol, vacuum drying at 100° C. for 12 hours yielded polymer PAEK-1 with a yield of over 90%. Its sulfonation degree is 0.74 and its glass tr...

Embodiment 3

[0027] Embodiment 3: the preparation of the PAEK-2 of polymer

[0028]In a three-neck flask equipped with a stirrer, a water vessel and a nitrogen port, add 10 mmol of 4,4'-dihydroxydiphenyl ether, 8.1 mmol of 4-(3-(4-(2,6-difluoro Benzoyl)phenoxy)propoxy)sodium benzenesulfonate, 1.9mmol of 4,4'-difluorobenzophenone, 11mmol of anhydrous potassium carbonate, 45ml of sulfolane and 9ml of toluene were put into the three-necked flask In the process, nitrogen gas was passed, and the temperature was raised to 120°C. Reflux with water for 2 hours, steam the dehydrating agent, raise the temperature to 175°C and react for 6 hours, then pour the reaction mixture into water to obtain a polymer, then crush it into particles of about 10 mesh with a pulverizer, and then filter it with a Buchner funnel for more After washing with deionized water and ethanol, vacuum drying at 100° C. for 12 hours yielded polymer PAEK-2 with a yield of over 90%. Its degree of sulfonation is 0.81, and its gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com