Energy-saving type humidity-regulating vitrified plate for building and preparation method thereof

An energy-saving and humidity-regulating technology, which is applied to buildings, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

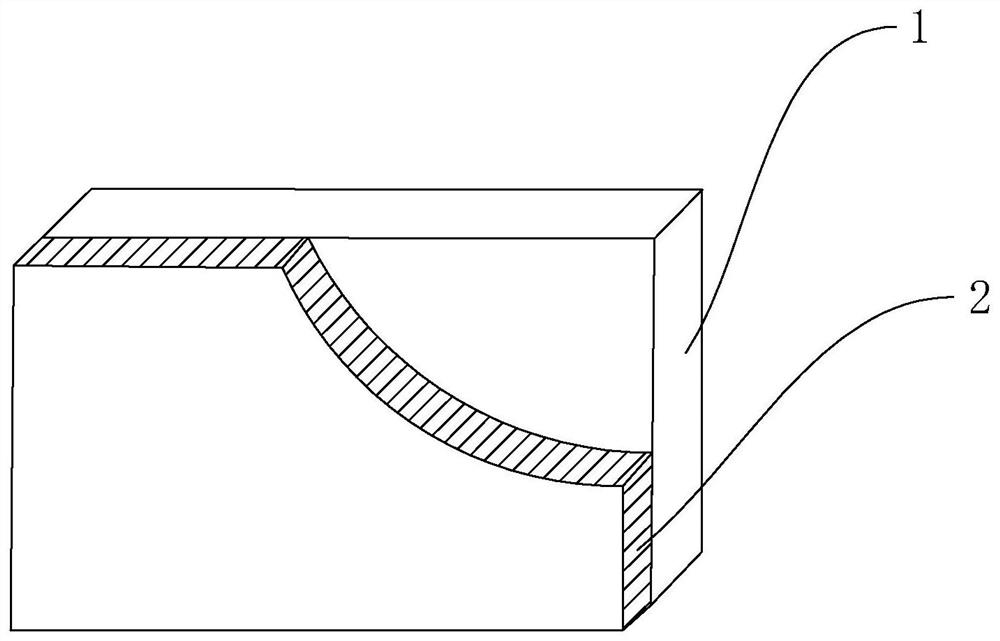

[0031] This embodiment provides building energy-saving humidity-regulating porcelain panels, combined with figure 1 As shown, it consists of a base material 1 and a humidity-regulating porcelain layer 2. The humidity-adjusting porcelain layer 2 is arranged on the upper surface of the base material 1. The base material 1 is a calcium silicate board or an inorganic honeycomb grouting board. 1. Any one of magnesium sulfate boards, the thickness of the humidity-adjusting vitrified layer 2 is 0.1mm. In this embodiment, the substrate 1 is an inorganic honeycomb grouting board.

[0032] Wherein, the humidity-adjusting porcelain layer 2 is composed of 30 parts of calcium carbonate, 25 parts of silicon dioxide, 8 parts of talcum powder, 3 parts of mica powder, 10 parts of attapulgite and 10 parts of humidity-regulating porcelain in parts by weight. layer additive composition. The particle size of the mineral powder is preferably 180 mesh.

[0033] On the basis of the breakthrough us...

Embodiment 2

[0040] This embodiment provides building energy-saving humidity-regulating porcelain panels, combined with figure 1 As shown, it consists of a base material 1 and a humidity-regulating porcelain layer 2. The humidity-adjusting porcelain layer 2 is arranged on the upper surface of the base material 1. The base material 1 is a calcium silicate board or an inorganic honeycomb grouting board. 1. Any one of the magnesium sulfate boards, the thickness of the humidity-adjusting vitrified layer 2 is 3mm. In this embodiment, the substrate 1 is a magnesium sulfate board.

[0041] Wherein, the humidity-adjusting porcelain layer 2 is composed of 45 parts of calcium carbonate, 35 parts of silicon dioxide, 15 parts of talcum powder, 10 parts of mica powder, 18 parts of attapulgite and 12 parts of humidity-regulating porcelain in parts by weight. layer additive composition.

[0042] Wherein, the low-temperature porcelain additive is compounded by 12 parts of dispersant, 15 parts of binder,...

Embodiment 3

[0044] This embodiment provides building energy-saving humidity-regulating porcelain panels, combined with figure 1As shown, it consists of a base material 1 and a humidity-regulating porcelain layer 2. The humidity-adjusting porcelain layer 2 is arranged on the upper surface of the base material 1. The base material 1 is a calcium silicate board or an inorganic honeycomb grouting board. 1. Any one of the magnesium sulfate boards, the thickness of the humidity-adjusting vitrified layer 2 is 2mm. In this embodiment, the substrate 1 is a calcium silicate board.

[0045] Wherein, the humidity-adjusting porcelain layer 2 is composed of 40 parts of calcium carbonate, 30 parts of silicon dioxide, 10 parts of talcum powder, 5 parts of mica powder, 15 parts of attapulgite and 10 parts of humidity-regulating porcelain in parts by weight. layer additive composition.

[0046] Wherein, the low-temperature vitrification additive is composed of 8 parts of dispersant, 10 parts of binder, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com