Eco-friendly composite floor made by different material combinations

A composite floor, environmental protection technology, applied in the direction of building structure, floor, building, etc., to achieve the effect of good sound insulation, good stability, favorable protection and sustainable and rational development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

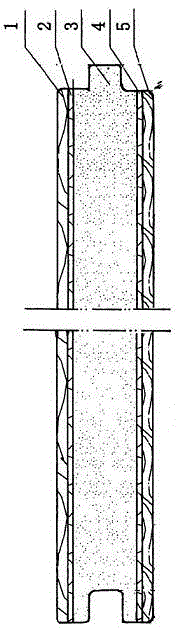

[0025] see figure 1 As shown, the present invention at least includes a surface layer 1 , a core layer 3 and a bottom layer 5 . The surface layer 1 is a solid wood veneer with a thickness of about 1.5-2.5 mm, beautiful texture and tough texture. The tough solid wood veneer is walnut veneer, redwood veneer, teak veneer, ant wood veneer, Wood veneer, oak veneer, beech veneer, sassafras veneer or pressed wood veneer. The core layer 3 is a formaldehyde-free wheat straw or rice straw homogeneous particle board, and its thickness is in the range of 12-15mm or more, depending on the requirements of the floor thickness. on both sides of the core layer 3 . The bottom layer 5 is a soft solid wood veneer, such as lauan, fir or cedar veneer, with a thickness of 1.5-2.5mm. The surface layer 1, the core layer 3 and the bottom layer 5 are respectively bonded together with formaldehyde-free isocyanic acid resin (so-called MDI glue) under pressure and heat. Usually the thickness of the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com