Water-treatment composite modified film and preparation method thereof

A composite modification and water treatment technology, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of underutilization and waste, save the cost of membrane production and reduce the dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1 A kind of composite modified membrane for water treatment

[0019] A composite modified membrane for water treatment, comprising a support material, a blank polymer cast film liquid layer and a polymer-modifier composite layer, the blank polymer cast film liquid layer is scraped on the surface of the support material, and the polymer-modifier The composite layer is scraped on the surface of the blank polymer cast film liquid layer. The composition of the polymer-modifier composite layer is as follows: the modifier is nano-TiO 2 , nano Ag, graphene oxide and its modified products, anionic surfactants, amphoteric surfactants or amphiphilic block polymers or a combination thereof.

[0020] In order to obtain better results, the composition of the blank polymer casting film liquid layer is: one or more of polyvinylidene fluoride, polytetrafluoroethylene, polysulfone, polyethersulfone, sulfonated polyethersulfone, and cellulose acetate The combination.

[0021] ...

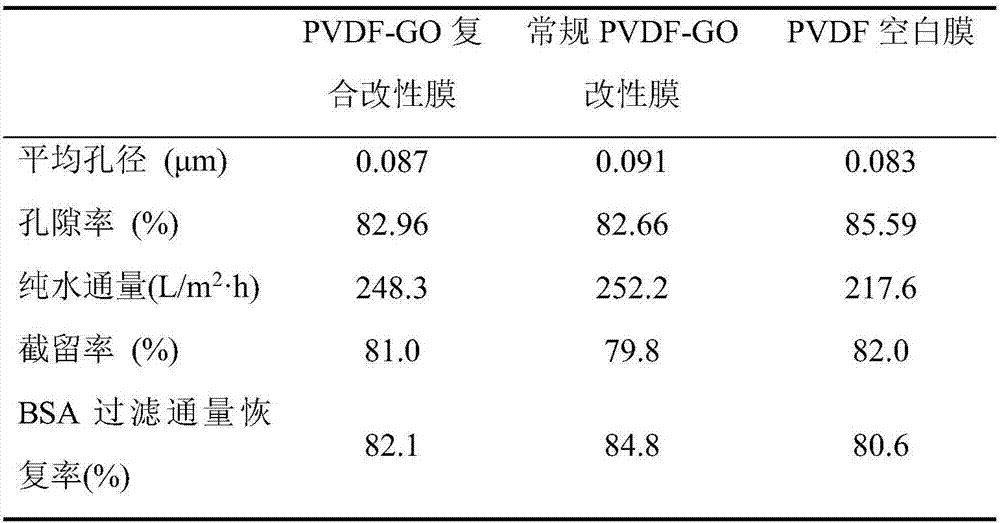

Embodiment 3

[0022] Embodiment 3 A kind of preparation method of composite modified membrane for water treatment

[0023] Add 0.1 g GO into a three-necked flask with 78 mL NMP, and use an ultrasonic cleaner to ultrasonicate the solution for 1 h until GO is completely dispersed. Then add 16g PVDF and 6g PEG, place in a 60o water bath and stir until PVDF and PEG are completely dissolved to form a uniform PVDF-GO composite casting solution. Another 16g of PVDF and 6g of PEG were added to a three-necked flask filled with 78mL of NMP, placed in a 60o water bath and stirred until PVDF and PEG were completely dissolved to form a uniform PVDF blank casting solution. The PVDF-GO modified film was scraped by layered scraping: firstly, the non-woven fabric was fixed on the surface of the CNC coating machine, the height of the scraper was adjusted to 150 μm, and the PVDF blank casting solution was poured in front of the scraper, and the scraping thickness was 150μm PVDF blank casting film liquid laye...

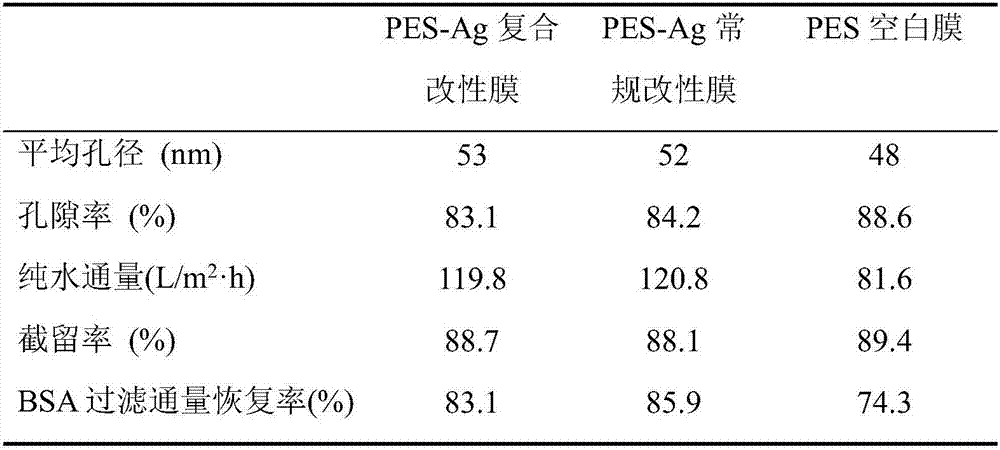

example 2

[0027] Example 2 A kind of preparation method of composite modified membrane for water treatment

[0028]Add 0.02g of Ag nanoparticles into a three-necked flask with 78mL of NMP, and use an ultrasonic cleaner to ultrasonicate the solution for 1h until Ag is completely dispersed. Then add 18g PES and 4g PVP, place in a 60o water bath and stir until the PES and PVP are completely dissolved to form a uniform PES-Ag composite casting solution. Another 18g of PES and 4g of PVP were added to a three-necked flask containing 78mL of NMP, placed in a 60o water bath and stirred until the PES and PVP were completely dissolved to form a uniform PES blank casting solution. Scrape the PES-Ag composite modified film by layered scraping: first, fix the non-woven fabric on the surface of the CNC coating machine, adjust the height of the scraper to 200 μm, pour the PES blank casting solution in front of the scraper, and scrape the thickness A 200 μm PES blank casting solution layer. Subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com