Method for preparing high-hydrophobicity microporous membrane

A microporous membrane and hydrophobic technology, which is applied in the field of highly hydrophobic microporous membrane and its preparation, can solve the problems of inapplicability and narrow scope of application of diffusion-induced phase separation, and achieve narrow pore size distribution range, excellent mechanical properties, and wide variety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of solid formwork:

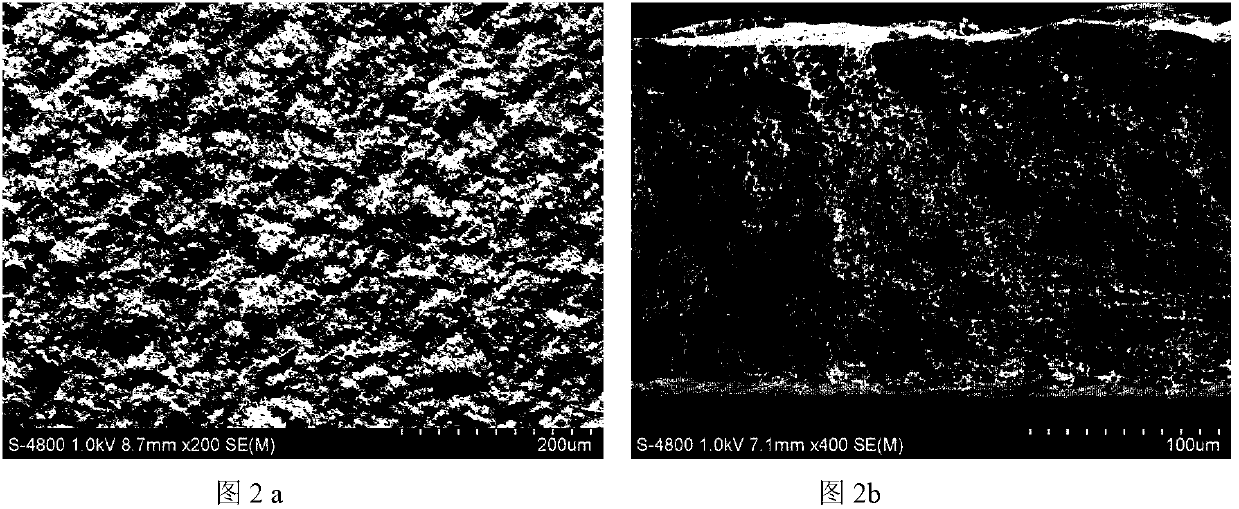

[0056] Compressed air with a gauge pressure of 0.5MPa carries 320 mesh quartz sand at high speed and sprays it on the surface of an aluminum plate with a geometric size of 300mm×200mm×4mm (thickness is 4mm). The treatment time is about 2min. Solid template. It is called a 320-mesh sandblasted aluminum plate, and its microstructure is randomly distributed crown-shaped pits, with a diameter of about 43 μm, a depth of about 8 μm, and a pit area fraction of about 0.57.

[0057] Membrane method:

[0058] 1) Take 30g of polypropylene resin with brand name T30S, and take 120g of mixed diluent (dibutyl phthalate (DBP) / dioctyl phthalate (DOP), where DBP accounts for 30wt% of the mixed diluent) , and put them into a 500ml three-necked bottle, under nitrogen protection and continuous stirring at 190°C for 2 hours, then keep it standing for 2 hours for defoaming to form a casting solution.

[0059] 2) At room temperature, coat the casting solutio...

Embodiment 2

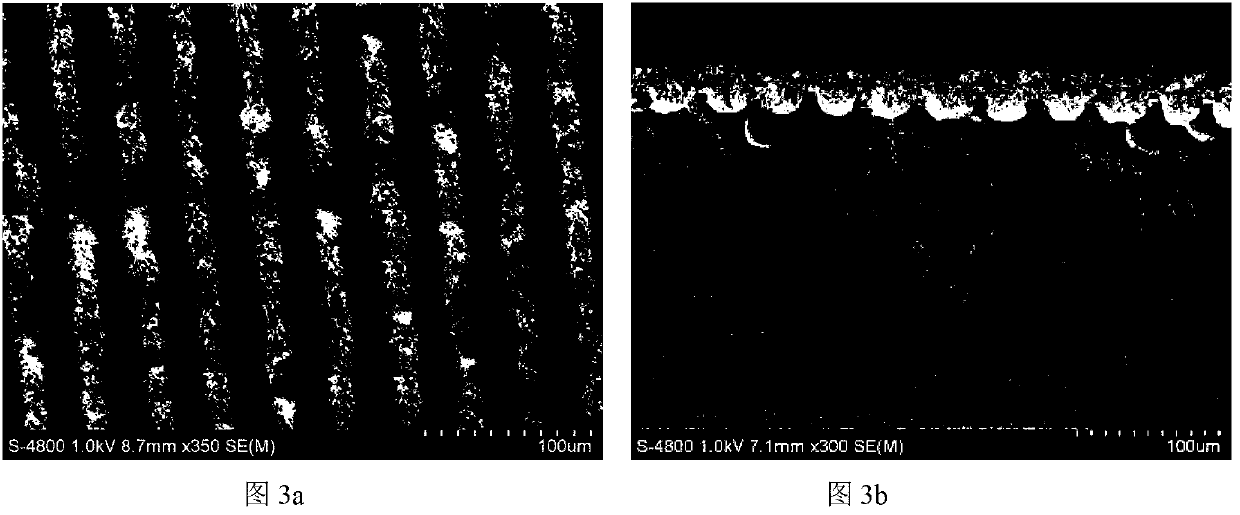

[0066] Preparation of solid formwork:

[0067] Using the HUST-UV multifunctional laser fine etching equipment, input the grating vector diagram with a grating constant of λ=46μm, etch an aluminum plate with a geometric size of 300mm×200mm×1.5mm, and obtain the grating constant λ=46μm and the peak height of the grating h= 20 μm solid template. It is called a 46μm grating aluminum plate, and the pit area fraction is about 0.50.

[0068] Membrane method:

[0069] 1) Take 30g of polypropylene resin with brand name T30S, and take 120g of mixed diluent (dibutyl phthalate (DBP) / dioctyl phthalate (DOP), where DBP accounts for 30wt% of the mixed diluent) , and put them into a 500ml three-necked bottle, under nitrogen protection and continuous stirring at 190°C for 2 hours, then keep it standing for 2 hours for defoaming to form a casting solution.

[0070] 2) At room temperature, coat the casting solution on a 46 μm grating aluminum plate at a constant temperature of 180°C. The thic...

Embodiment 3

[0077] 1) Take 30g of polypropylene resin with brand name T30S, and take 120g of mixed diluent (dibutyl phthalate (DBP) / dioctyl phthalate (DOP), where DBP accounts for 30wt% of the mixed diluent) , and put them into a 500ml three-necked bottle, under nitrogen protection and continuous stirring at 190°C for 2 hours, then keep it standing for 2 hours for defoaming to form a casting solution.

[0078] 2) At room temperature, coat the casting solution on a 46 μm grating aluminum plate at a constant temperature of 180°C. The thickness of the film solution is about 200 μm. After staying for 30 seconds, immerse the film solution and the aluminum plate in a tap water bath at 40°C to cool for 30 minutes. After liquid-liquid phase separation and polymer crystallization, the membrane liquid gel solidifies and transforms into a nascent membrane.

[0079] 3) The primary membrane was peeled off from the solid template. At room temperature, the prepared primary membrane was first soaked in e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com