Polyvinyl alcohol hybrid membrane pervaporation device for laboratories and permeation separation technology thereof

A polyvinyl alcohol and pervaporation technology, applied in semi-permeable membrane separation, pervaporation, membrane technology and other directions, can solve the problems of high energy consumption and low separation efficiency, and achieve improved separation efficiency, simple separation process, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the examples, but the implementation of the present invention is not limited thereto.

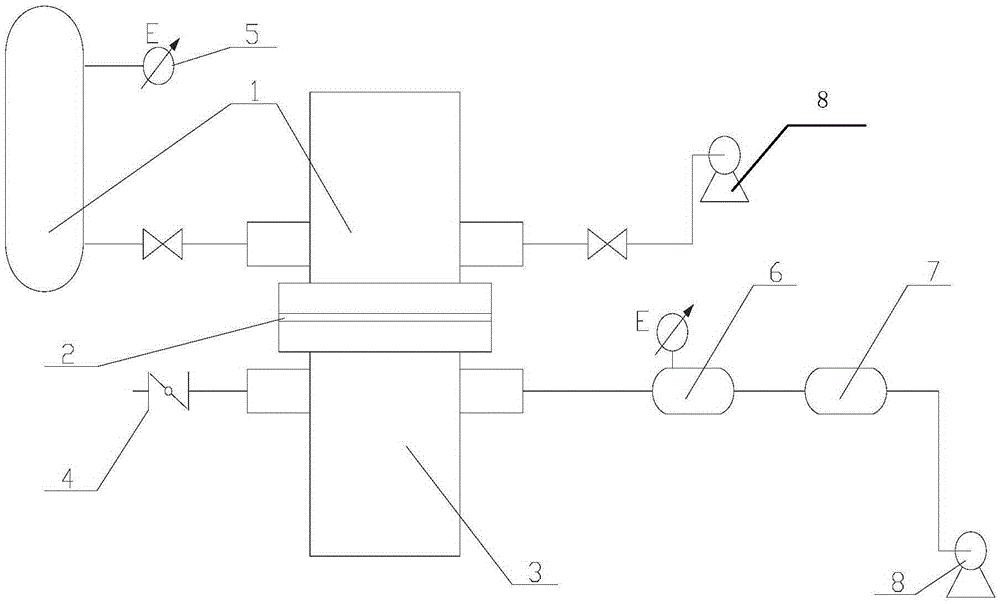

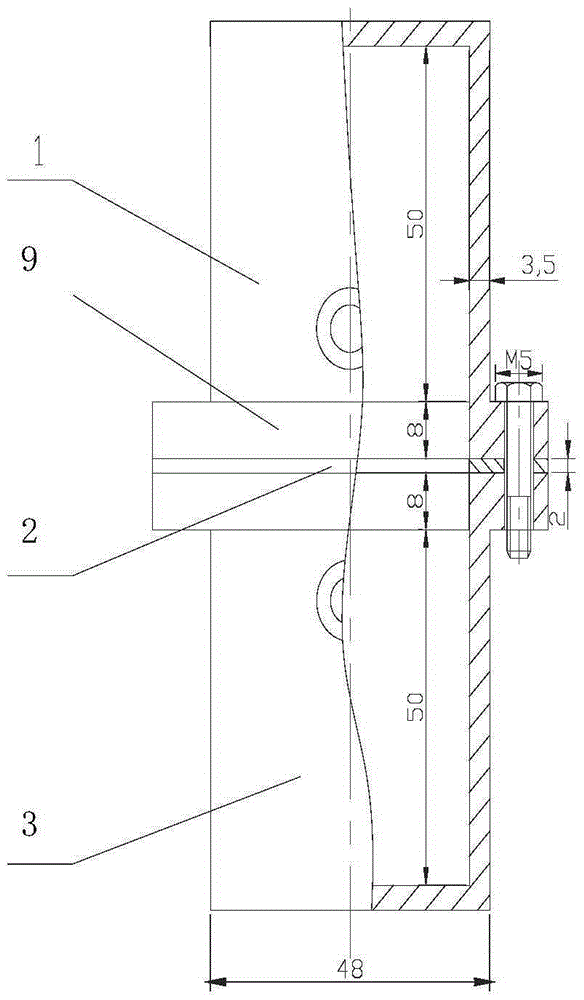

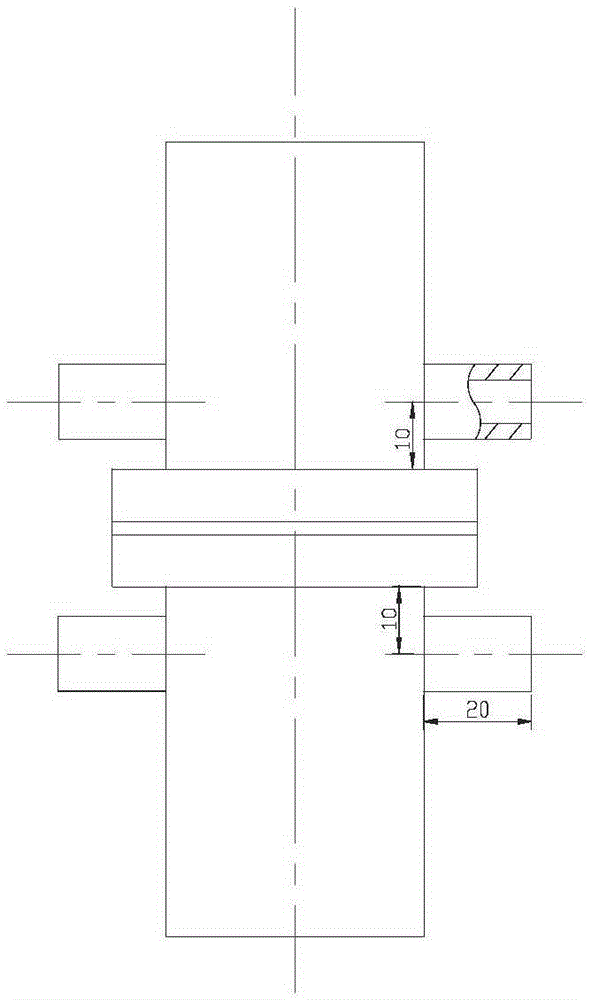

[0036] Such as figure 1 As shown, a polyvinyl alcohol hybrid membrane pervaporation device for laboratory use includes a raw material chamber 1, a permeation membrane 2, a permeation side chamber 3, a pervaporation pressure regulator 4, a heat exchange device 5, and a permeate condensation Device 6, permeation tank 7 and permeation side vacuum pump device 8; pervaporation membrane 2 is located between raw material cavity 1 and permeation side cavity 3, fixed by flange 9, with stainless steel mesh to protect pervaporation membrane 2, The permeation evaporation pressure regulator 4 is connected to the permeate side cavity 3, the permeate side cavity 3 is connected to the permeate condensation device 6, the seepage tank 7 is connected to the permeate condensation device 6, and the permeation side vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com