A braided tube homogeneously-enhanced type polyvinylidene fluoride hollow fiber film and a preparing method thereof

A technology of polyvinylidene fluoride and polyvinylidene fluoride resin, which is applied in the field of polymer hollow fiber membrane preparation, and can solve the problem of easy peeling off of the cortex and poor bonding force between the braided tube reinforced hollow fiber membrane polyvinylidene fluoride resin and the braided tube and other issues, to achieve the effect of reducing membrane production cost, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

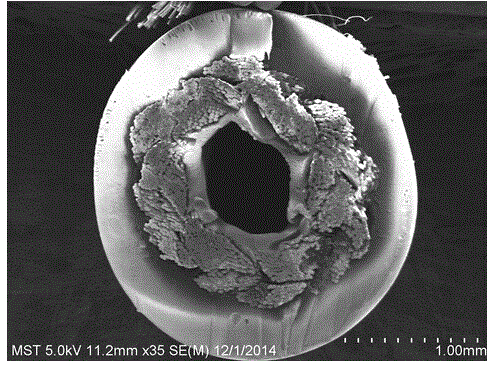

Image

Examples

Embodiment 1

[0077] (1) Configuration of braided tube soaking solution A: by mass percentage, first weigh 6% polyvinylidene fluoride resin and place it in a jar, then add 88% solvent and 6% hydrophilic agent to it, and stir to accelerate Dissolution of polyvinylidene fluoride and hydrophilic agent, and finally let it stand for defoaming.

[0078] In this process step, the braided tube is braided by polyester fiber and polyamide fiber, the inner diameter of the braided tube is 0.7mm, and the outer diameter is 1.9mm; the polyvinylidene fluoride PVDF resin is Solef 6010, purchased from Shanghai Solvay Co., Ltd.; The solvent is N,N-dimethylacetamide (DMAC); the hydrophilic agent is a mixture of glycerol and polyethylene glycol 400 at a ratio of 2:1.

[0079] (2) The configuration of coating casting solution B on the outside of the braided tube: in terms of mass percentage, first weigh 15% polyvinylidene fluoride resin and place it in a jar, then add 8% polymer to the jar to form holes agent, ...

Embodiment 2

[0086] (1) Configuration of braided tube soaking solution A: First weigh 2% polyvinylidene fluoride resin and place it in a jar, then add 88% solvent and 10% hydrophilic agent to it, and stir to accelerate Dissolution of polyvinylidene fluoride and hydrophilic agent, and finally let it stand for defoaming.

[0087] In this process step, the braided tube is braided by polyester fiber and polyamide fiber, the inner diameter of the braided tube is 0.7mm, and the outer diameter is 1.0mm; the polyvinylidene fluoride PVDF resin is 6010, purchased from Shanghai Solvay Co., Ltd.; the solvent It is N,N-dimethylformamide (DMF); the hydrophilic agent is made by mixing isopropanol and n-butanol at a ratio of 3:1.

[0088] (2) The configuration of coating casting solution B on the outside of the braided tube: in terms of mass percentage, first weigh 14% polyvinylidene fluoride resin and place it in a jar, then add 7% polymer to the jar to form holes agent, 75% solvent and 4% hydrophilic a...

Embodiment 3

[0094] (1) Configuration of braided tube soaking solution A: by mass percentage, first weigh 10% polyvinylidene fluoride resin and place it in a jar, then add 87% solvent and 3% hydrophilic agent to it, and stir to accelerate Dissolution of polyvinylidene fluoride and hydrophilic agent, and finally let it stand for defoaming.

[0095] In this process step, the braided tube is braided by polyester fiber and polyamide fiber, the inner diameter of the braided tube is 0.7mm, and the outer diameter is 1.5mm; the polyvinylidene fluoride PVDF resin is 6010, purchased from Shanghai Solvay Co., Ltd.; the solvent It is N,N-dimethylacetamide (DMAC); the hydrophilic agent is made by mixing ethanol and ethylene glycol at a ratio of 2:1.

[0096] (2) The configuration of coating casting solution B on the outside of the braided tube: in terms of mass percentage, first weigh 18% polyvinylidene fluoride resin and place it in a jar, then add 10% polymer to the jar to form holes agent, 64% solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com