Method for preparing NaA molecular sieve membrane through induction of nanocrystal seeds

A technology of nano-crystal seeds and molecular sieves, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as failure to change the crystallization time, changing the size and surface structure properties of molecular sieve crystals, and complicated operations , to achieve the effects of reduced membrane production cost, high repeatability, and high permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of Nanoparticle Seed Crystals

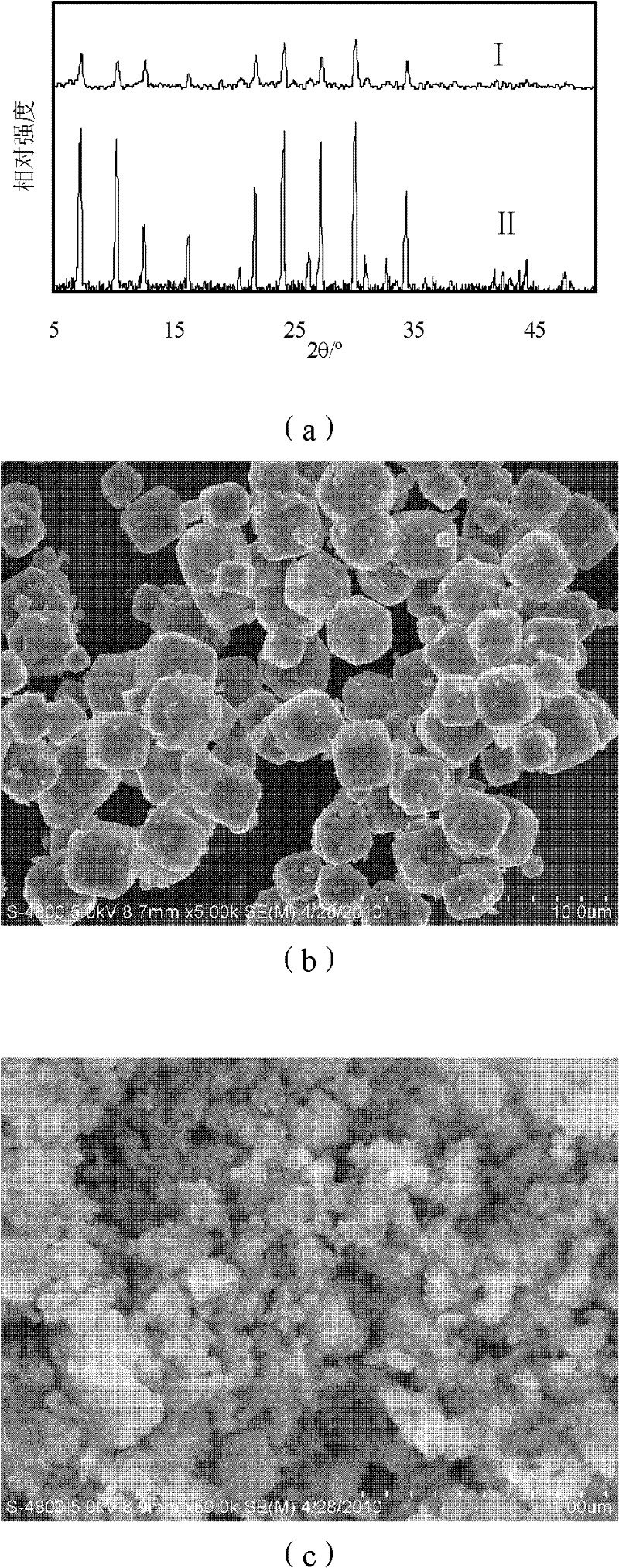

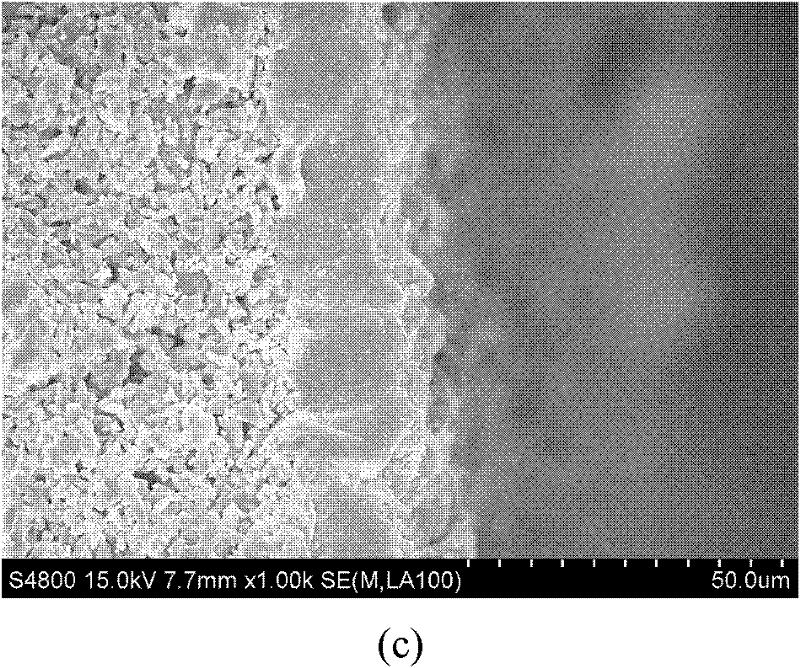

[0026] A high-energy ball mill was used to mill the seed crystals with an average particle size of 3.34 μm at a speed of 450 rpm, a treatment time of 3 h, and a ball-to-material mass ratio of 100:1. Obtaining the random morphology nanoparticle crystal seed that the average particle size is 300nm, its XRD diffraction pattern, SEM photo and TEM photo are shown in Fig. (1) (a), (c), (d) respectively, from the figure It can be seen that the seed crystals after ball milling have an irregular shape.

[0027] Step 2: Preparation of seed suspension

[0028] Weigh 0.1 g of nanoparticle seed crystals and place them in 50 ml of deionized water, stir, and ultrasonically disperse them evenly. The processed tubular alumina carrier is pre-coated with seed crystals by dipping and crystal coating method, and the carrier stays in the suspension for 5s.

[0029] Step 3: Preparation of NaA molecular sieve membrane

[0030] Add a certain...

Embodiment 2

[0032] Step 1: Preparation of Nanoparticle Seed Crystals

[0033] A high-energy ball mill was used to mill the seed crystals with an average particle size of 2.8 μm at a speed of 250 rpm, a treatment time of 2 h, and a ball-to-material ratio of 50:1. The random shape nanoparticle seed crystal with an average particle size of 500nm was obtained.

[0034] Then step 2, step 3 are the same as embodiment 1

Embodiment 3

[0036] Step 1: The preparation of nanoparticle seed crystals is the same as in Example 1

[0037] Step 2: Weigh 0.5 g of nanoparticle seed crystals and place them in 50 ml of deionized water, stir, and ultrasonically disperse them evenly. The treated carrier is pre-coated with seed crystals by dipping and crystal coating method, and the carrier stays in the suspension for 5s.

[0038] Step 3 is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com