Preparation method and application of persistently hydrophilic polyvinylidene fluoride membrane

A technology of polyvinylidene fluoride film and polyvinylidene fluoride, which is applied in the field of preparation of durable hydrophilic polyvinylidene fluoride film, can solve problems such as waste of raw materials, cumbersome preparation methods, and easy volatility of ethanol, and achieve high pollution resistance , Simple membrane making process, high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of persistent hydrophilic polyvinylidene fluoride flat sheet membrane:

[0037] (1) Preparation of casting solution: Add polyvinyl acetate, PVP-k30, and PEG-400 with mass content of 2%, 4%, and 7% respectively into N,N-dimethylethyl ether with mass content of 68%. In the amide, stir at 90°C until it is completely dissolved, then add polyvinylidene fluoride with a mass content of 19%, stir at 90°C until it is completely dissolved, and let the prepared mixture stand for defoaming to obtain the obtained Described casting solution (mass content in this step is the mass fraction that corresponding composition accounts for described casting solution);

[0038] (2) Preparation of durable hydrophilic polyvinylidene fluoride flat film: scrape the film on a clean glass plate with the prepared casting solution, then immerse in N,N-dimethylacetamide with a mass content of 15 % aqueous solution for 1 hour, and then placed in deionized water for phase inversion for 24 ho...

Embodiment 2

[0041] Preparation of persistent hydrophilic polyvinylidene fluoride flat sheet membrane:

[0042] (1) Preparation of film casting solution: polyvinyl acetate, PVP-k30, PEG-1000, potassium chloride, which are 1.5%, 5%, 4%, and 1% by mass content, are added to 70.5% N by mass content. , in N-dimethylformamide, stir at 90°C until it is completely dissolved, then add polyvinylidene fluoride with a mass content of 18%, stir at 90°C until it is completely dissolved, and let the prepared mixture stand Degassing to obtain the casting solution (the mass content in this step is the mass fraction of the corresponding components accounting for the casting solution);

[0043] (2) Preparation of durable hydrophilic polyvinylidene fluoride flat film: scrape the film on a clean glass plate with the prepared casting solution, and soak in N,N-dimethylacetamide with a mass fraction of 15% Take it out after 1 hour in the aqueous solution, and then place it in deionized water for phase inversion...

Embodiment 3

[0046] Preparation of durable hydrophilic polyvinylidene fluoride hollow fiber membranes:

[0047] (1) Preparation of casting solution: Add polyvinyl acetate, PVP-k30, and PEG-400 with a mass content of 1.5%, 5%, and 6% respectively into N,N-dimethylethyl ether with a mass content of 67.5%. In the amide, stir at 90°C until it is completely dissolved, then add polyvinylidene fluoride with a mass content of 20%, stir at 90°C until it is completely dissolved, and pressurize the prepared mixed solution to obtain the described Casting solution (the mass content in this step is the mass fraction of corresponding components accounting for the casting solution);

[0048] (2) Preparation of core liquid: add N,N-dimethylacetamide into deionized water, stir evenly to prepare a core liquid with a mass fraction of N,N-dimethylacetamide of 45%;

[0049] (3) Preparation of hydrophilic modified membrane: Extrude the prepared casting solution and core solution through a spinneret, and then im...

PUM

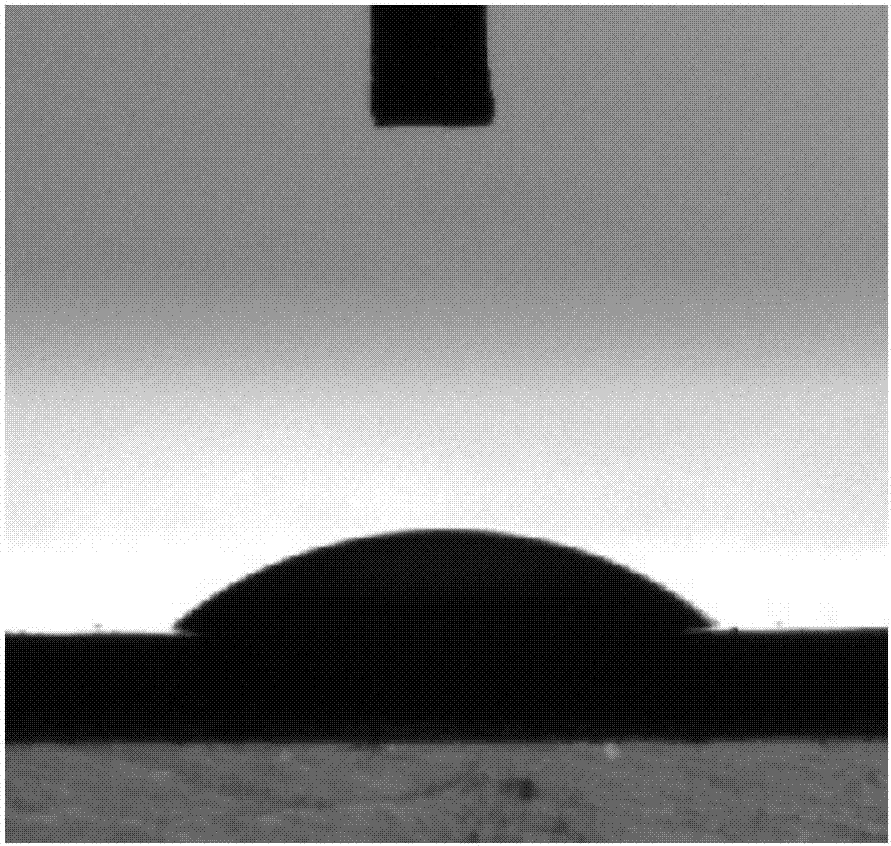

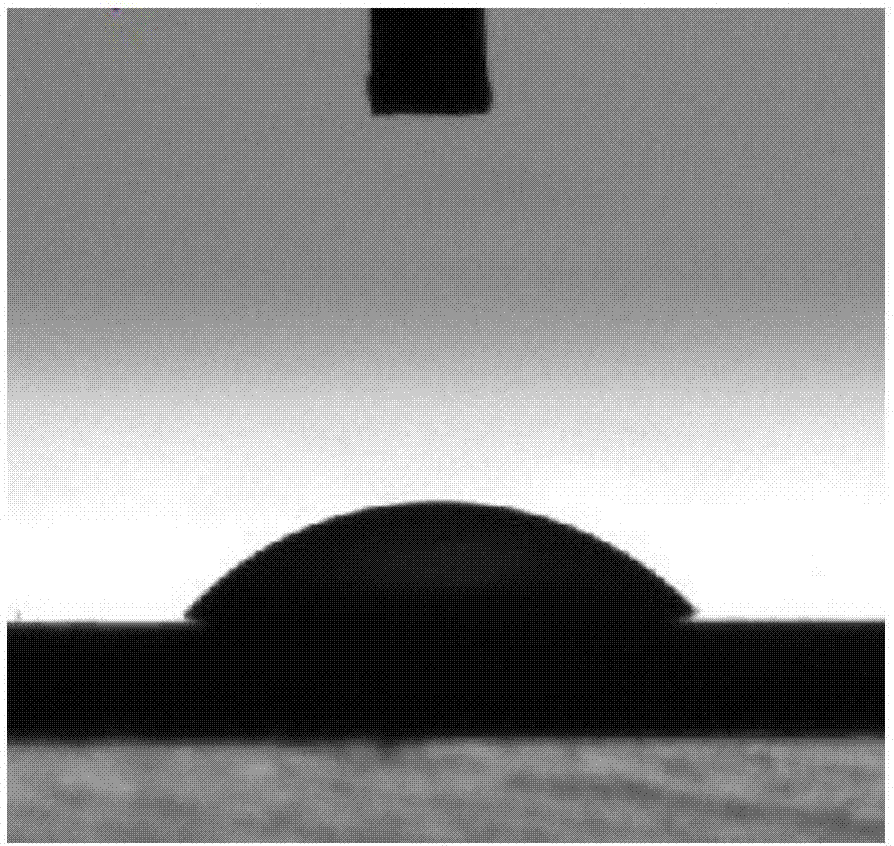

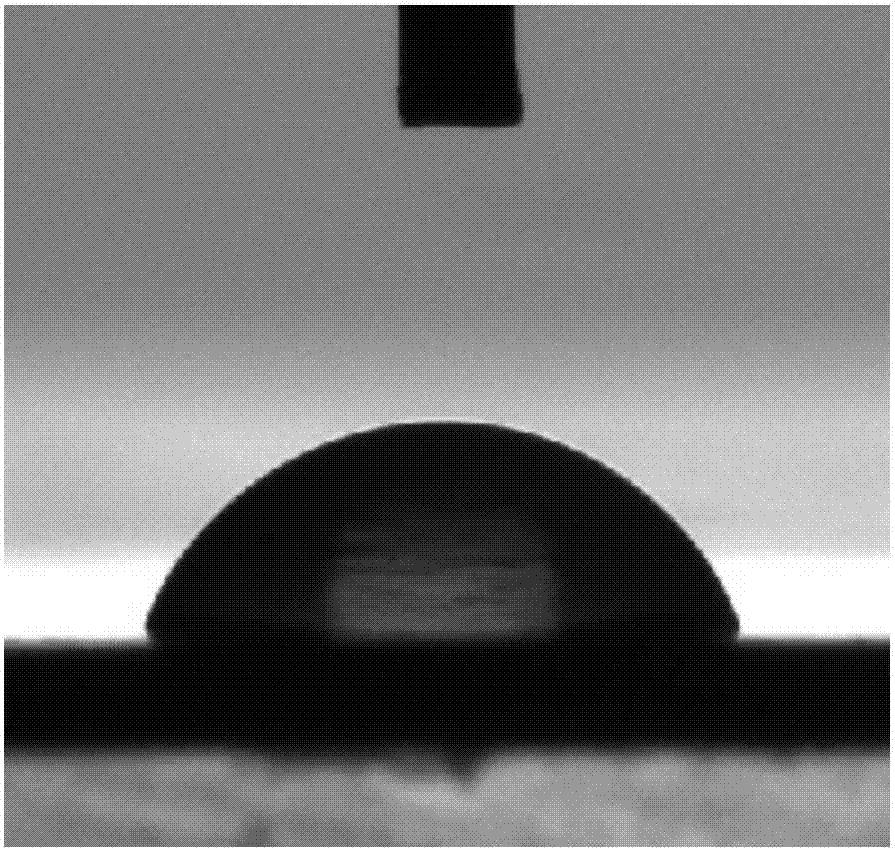

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com