Solvent-free preparation method of aperture controllable porous film

A porous membrane, solvent-free technology, applied in the field of membrane separation, can solve the problems of poor recovery economy, high cost of organic solvent, low concentration of organic solvent, etc. The effect of membrane cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

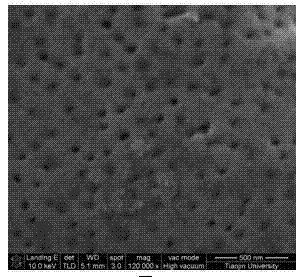

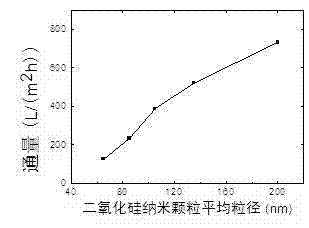

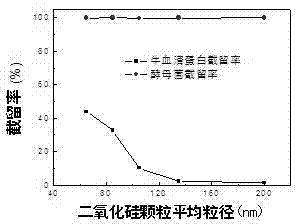

Image

Examples

Embodiment 1

[0016] Measure 300mL of ethanol, 20mL of deionized water and 3.5mL of ammonia water into a clean and dry round-bottomed flask in turn, stir magnetically for 5min, ultrasonically treat for 5min, stir at a constant temperature of 30°C for 10min, add 5mL of ethyl orthosilicate, and react for 24h. Then add 1mL of 3-(methacryloyloxy)propyltrimethoxysilane, react for 24h, centrifuge for 10min, and rotate at 10000rpm, collect the powder and put it in an oven at 90°C for 48h, and grind to obtain silica nanoparticles .

[0017] Weigh 1.0 g of monomer hydroxyethyl methacrylate, 320 mg of the above silica nanoparticles, 80 mg of crosslinking agent 1,6-hexanediol diacrylate and 10 mg of initiator 1-hydroxycyclohexyl phenyl ketone, and mix The casting solution was prepared, and the casting solution was ultrasonically treated for 5 minutes under the protection of nitrogen. Measure the casting solution with a volume of 50 μL and drop it on one end of the first glass piece (75mm*25mm), cover...

Embodiment 2

[0020] Measure 200mL of ethanol, 20mL of deionized water and 5mL of ammonia water into a clean and dry round-bottomed flask in sequence, stir magnetically for 5min, ultrasonically treat for 5min, stir at a constant temperature of 40°C for 10min, add 5mL of ethyl orthosilicate, react for 24h, and then Add 1mL of 3-(methacryloyloxy)propyltrimethoxysilane, react for 24h, centrifuge for 10min at 10,000rpm, collect the powder and put it in an oven at 90°C for 48h, and grind to obtain silica nanoparticles.

[0021] Weigh 1.0 g of monomer hydroxyethyl methacrylate, 320 mg of the above silica nanoparticles, 80 mg of crosslinking agent 1,6-hexanediol diacrylate and 10 mg of initiator 1-hydroxycyclohexyl phenyl ketone, and mix The casting solution was prepared, and the casting solution was ultrasonically treated for 5 minutes under the protection of nitrogen. Measure the casting solution with a volume of 50 μL and drop it on one end of the first glass piece (75mm*25mm), cover the castin...

Embodiment 3

[0024] Measure 200mL of ethanol, 20mL of deionized water and 5mL of ammonia water into a clean and dry round-bottomed flask in turn, stir magnetically for 5min, ultrasonically treat for 5min, stir at a constant temperature of 40°C for 10min, add 2.5mL of ethyl orthosilicate, and react for 24h. Then add 1mL of 3-(methacryloxy)propyltrimethoxysilane, react for 24h, centrifuge for 10min at 10,000rpm, collect the powder and put it in an oven at 90°C for 48h, and grind to obtain silica nanoparticles .

[0025] Weigh 1.0 g of monomer hydroxyethyl methacrylate, 320 mg of the above silica nanoparticles, 80 mg of crosslinking agent 1,6-hexanediol diacrylate and 10 mg of initiator 1-hydroxycyclohexyl phenyl ketone, mix The casting solution was prepared, and the casting solution was ultrasonically treated for 5 minutes under the protection of nitrogen. Measure the casting solution with a volume of 50 μL and drop it on one end of the first glass piece (75mm*25mm), cover the casting solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com