Alloy high temperature oxidation resisting nanostructure conductive coating prepared with spinel powder reduction method

A technology of high temperature oxidation resistance and spinel structure, which is applied to conductive layers on insulating carriers, heating inorganic powder plating, circuits, etc. The method is simple, the film thickness is uniform and controllable, and the repeatability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

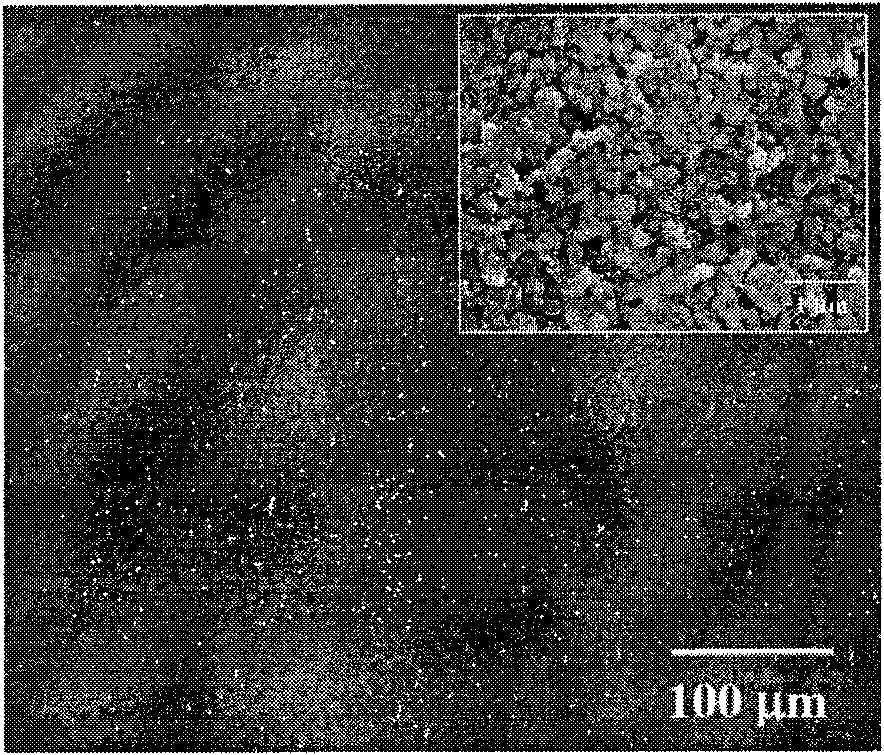

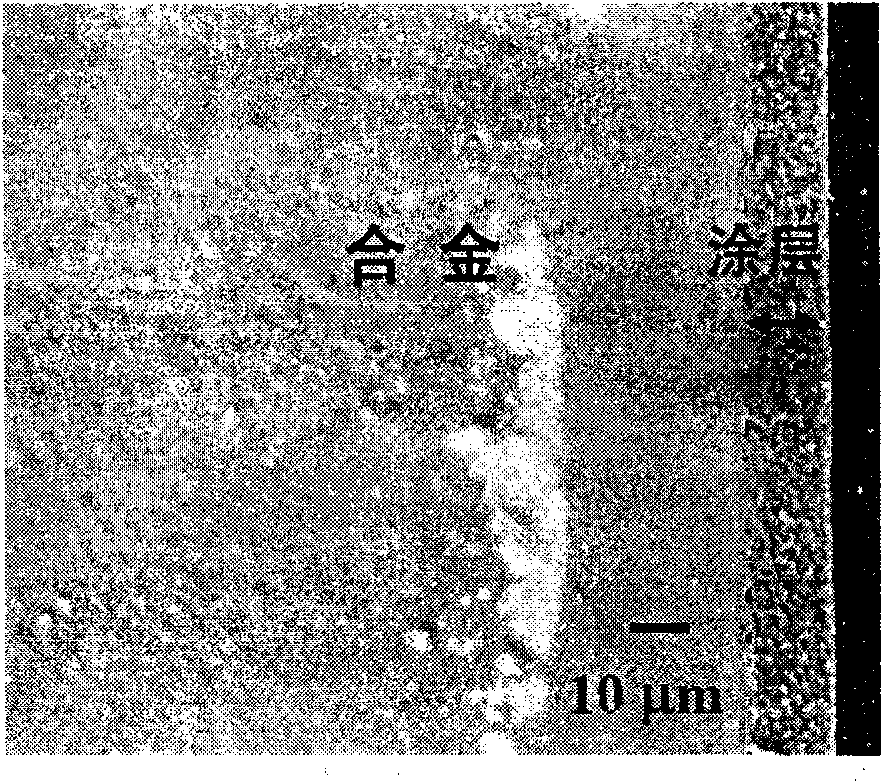

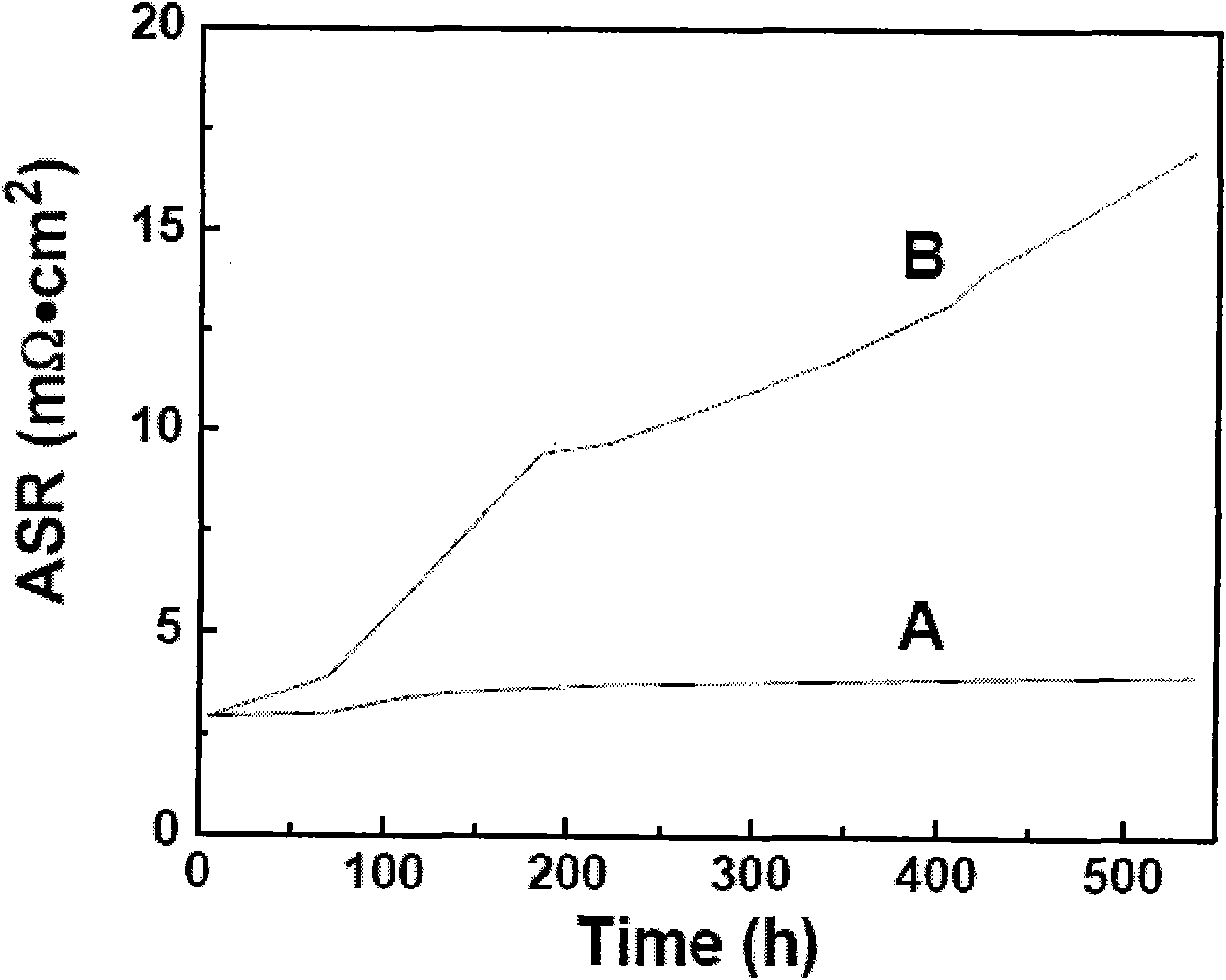

Image

Examples

Embodiment 1

[0034] Preparation and reduction treatment of spinel nanopowder materials: (i) prepared by citric acid gel (Pechini) method (Mn 0 / 9 Y 0.1 co 2 o 4 ) Spinel structure nanopowder material: the soluble salt of Y, Mn and Co is dissolved in deionized water at a ratio of 0.1:0.9:2 in the molar ratio of Y ions, Mn ions and Co ions, wherein Y ions, The total concentration of Mn ions and Co ions is 1 mol / L; add citric acid 3 times the total molar weight of Y ions, Mn ions and Co ions, mix and stir evenly, and heat and volatilize the solution at 80°C to form a sol. The sol was further dried in an oven at 160°C, expanded and solidified into a xerogel, heated and burned in a high-temperature furnace at 400°C to remove organic matter as much as possible, and then calcined at 700°C to burn off residual organic matter and form a phase. After that, it was further ball-milled in absolute ethanol and dried to obtain Y-doped Mn-Co(Mn 0.9 Y 0.1 co 2 o 4 ) spinel nano powder material. (ii)...

Embodiment 2

[0040] Preparation and reduction treatment of spinel nanopowder materials: (i) prepared by combustion method (MnCo 1.8 Fe 0.2 o 4 ) Spinel structure nanopowder material: the soluble salt of Mn, Co and Fe is dissolved in deionized water at the ratio of 1:1.8:0.2 in the molar ratio of Mn ion, Co ion and Fe ion, wherein the total amount of cations is The concentration is 1mol / L; add glycine 3 times the total molar amount of cations, mix and stir evenly, heat and dry the liquid on an electric furnace and then burn it, and the burned powder is heated in a high-temperature furnace at 700°C to remove residual organic matter and form a phase . Then further ball milling in absolute ethanol and drying to obtain Mn-Co-Fe nano powder material. (ii) The nano-powder was further reduced at 700° C. under a hydrogen reducing atmosphere for 1 hour, and the temperature was lowered to obtain an intermediate powder for coating.

[0041] Preparation of the coating film: (i) mix the powder after...

Embodiment 3

[0043] Preparation and reduction treatment of spinel nanopowder materials: (i) prepared by citric acid gel (Pechini) method (Mn 1.5 co 1.5 o 4 ) Spinel structure nanopowder material: the soluble salt of Mn and Co is dissolved in deionized water at a ratio of 1:1 by the molar ratio of Mn ions and Co ions, wherein the concentration of the sum of Mn ions and Co ions is 2mol / L; Mn in other preparation steps and embodiment 1 0.9 Y 0.1 co 2 o 4 Nano powder preparation and sintering conditions are the same. (ii) Mn to be prepared 1.5 co 1.5 o 4 The nano-powder was further reduced at 700° C. for 2 hours in a hydrogen reducing atmosphere, and the temperature was lowered to obtain an intermediate powder for coating.

[0044] Preparation of the coating film: (i) mix the powder after the above-mentioned reduction treatment with terpineol and ethyl cellulose, etc., and carry out ball milling for 15 hours to obtain a powder slurry for the coating film, wherein the organic slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com