Preparation method of polymeric micelle nanofiltration membrane and application thereof

A technology of polymer micelles and nanofiltration membranes, applied in the field of membrane separation, to achieve the effects of simple and easy methods, saving membrane production costs, and less polymer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

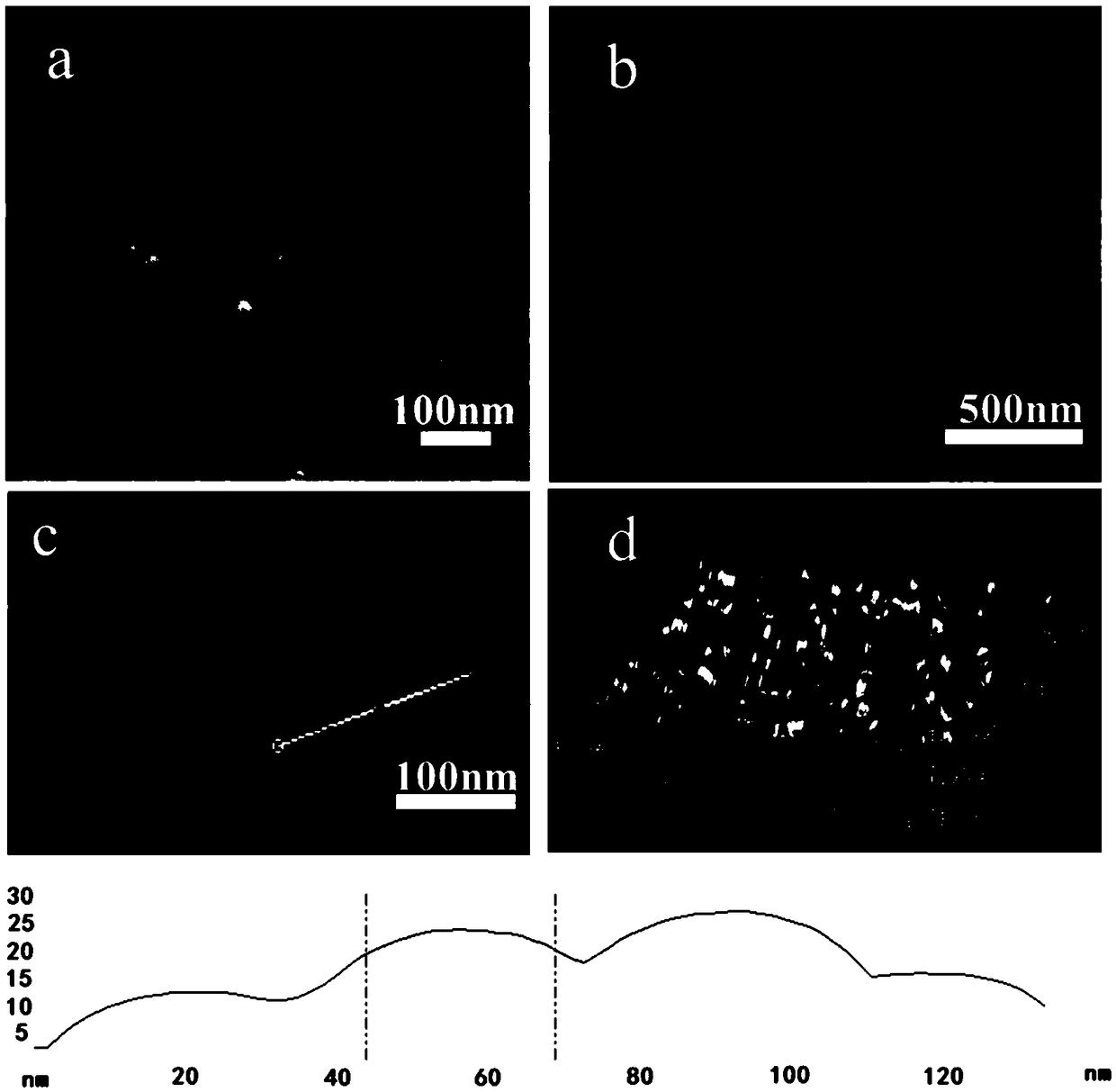

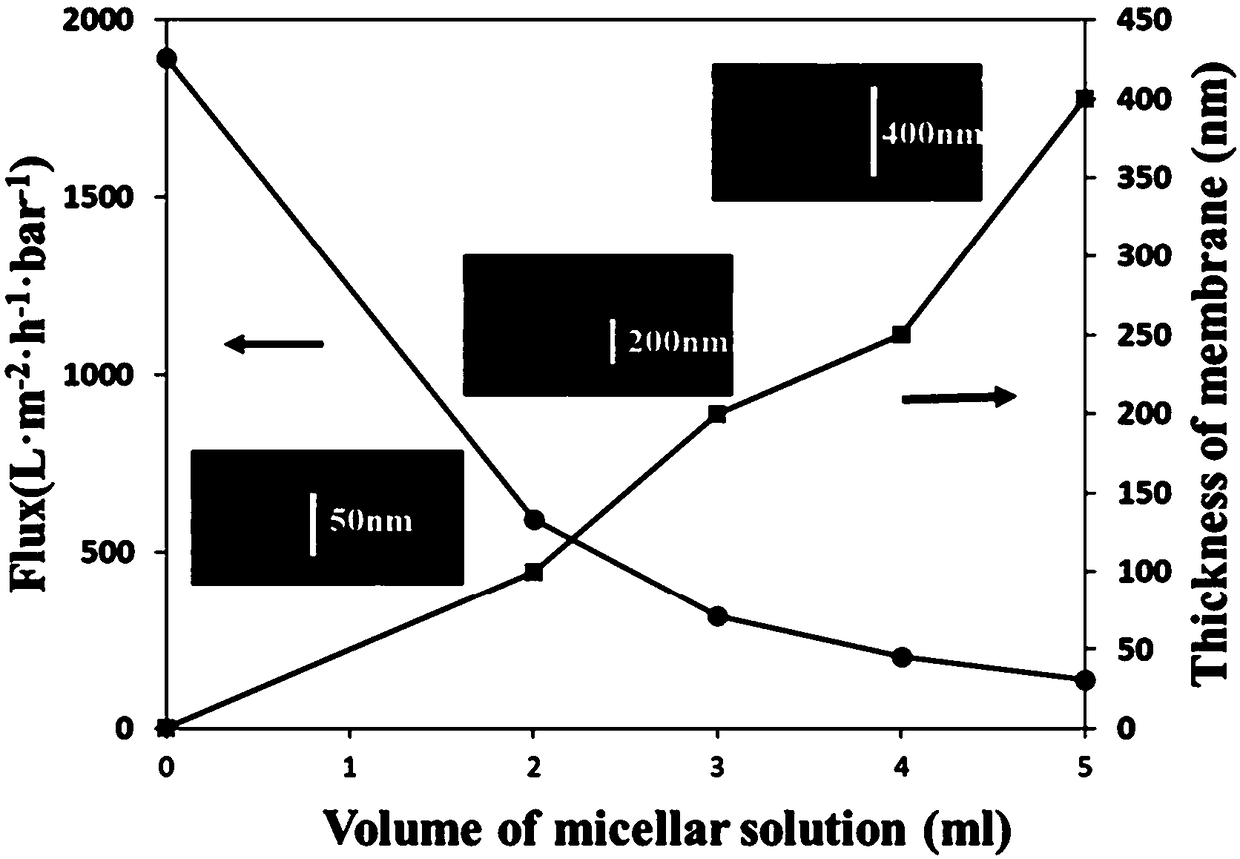

[0041](a) Weigh 10mg of polystyrene-block-polyacrylic acid (15000-b-1600g / mol), dissolve in 1ml of N,N-dimethylformamide solution, and / min stirring speed stirring for 12h, followed by adding methanol to dilute 4 times to obtain well-dispersed spherical micelles. Then, zinc acetate hexahydrate (2 mg / ml) prepared with methanol was added in an amount of 100 μl per 4 ml of solvent. Finally, through vacuum filtration, the micellar solution is spread on the macroporous substrate polycarbonate to obtain a complete spherical micellar film.

[0042] (b) Cut the spherical micellar membrane into discs of appropriate size (d=2.5cm), put them into a filter device, insert ultrapure water, give a certain pressure (1bar), and measure the unit area under this pressure. , the time required to flow out a unit volume of ultrapure water, from which the pure water flux is calculated according to the following formula. J=V / (A*Δt). Among them, V is the volume of the effluent, A is the effective a...

Embodiment 2

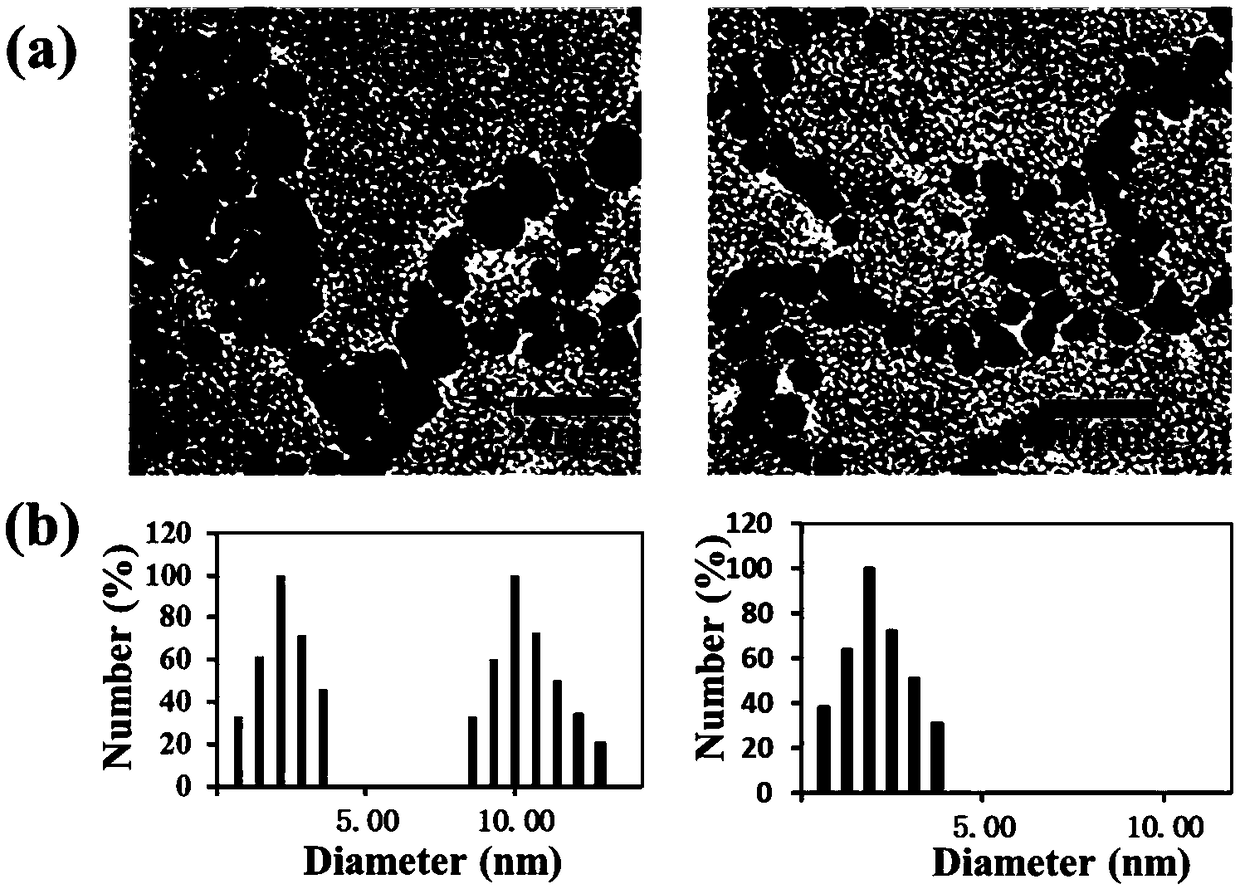

[0050] (a) Weigh 10mg of polymer poly-4-vinylpyridine-block-polystyrene-block-poly-4-vinylpyridine (4500-b-27000-b-4500g / mol), dissolve it in 0.2ml In toluene and 0.8ml methanol, stir at room temperature (18-20°C) at a stirring speed of 500r / min for 12 hours, then add methanol to dilute 5 times to obtain well-dispersed columnar micelles. Finally, the micellar solution was spread on the macroporous substrate polycarbonate by vacuum filtration technology to obtain a complete columnar micellar film.

[0051] (b) Cut the columnar micellar membrane into discs of appropriate size (d=2.5cm), put them into the filter device, add 10nm gold particles to it, give a certain pressure (1bar), and analyze the membrane by ultraviolet spectrum and transmission electron microscope Measure the effluent and stock solution.

[0052] Depend on Figure 5 It can be seen that the surface of the membrane produced in Example 2(a) is composed of many columnar fibers, which are covered interlacedly to f...

Embodiment 3

[0055] (a) Weigh 5mg of the polymer polystyrene-block-polyacrylic acid (15000-b-1600g / mol), dissolve it in 0.5ml of toluene and 0.7ml of methanol, at room temperature (18-20°C) at 500r / min Stir at the stirring speed for 12 hours, and then add methanol to dilute 2 times to obtain well-dispersed lamellar micelles.

[0056] Depend on Figure 7 It can be seen that the surface of the membrane prepared in Example 3(a) is composed of sheets with uniform size, and the morphology is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com